A testing system and testing method for gearbox mechanical efficiency on a complete vehicle

A technology of mechanical efficiency and testing system, which is applied in the field of gearbox testing, can solve problems such as inaccurate representation of gearbox mechanical efficiency testing technology, unreliable test results, etc., to improve reliability and credibility, reliable testing, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

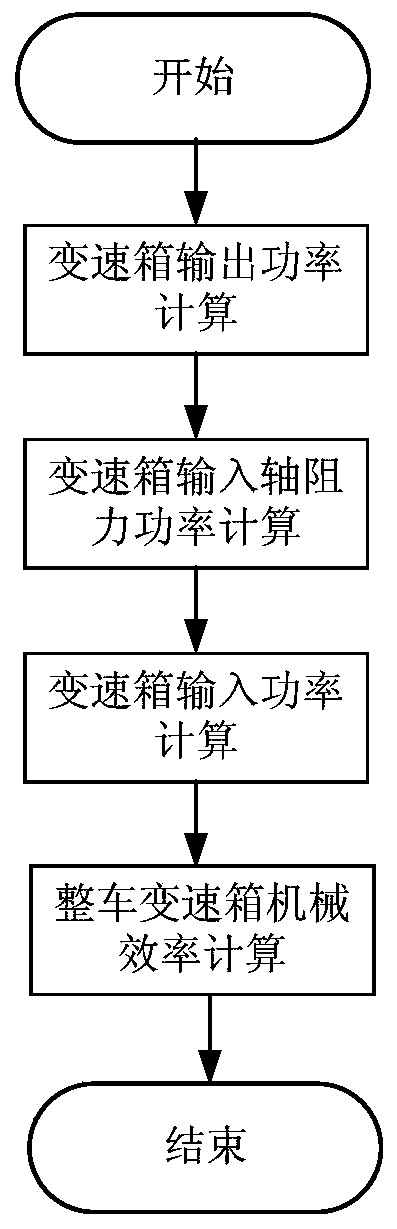

[0044] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

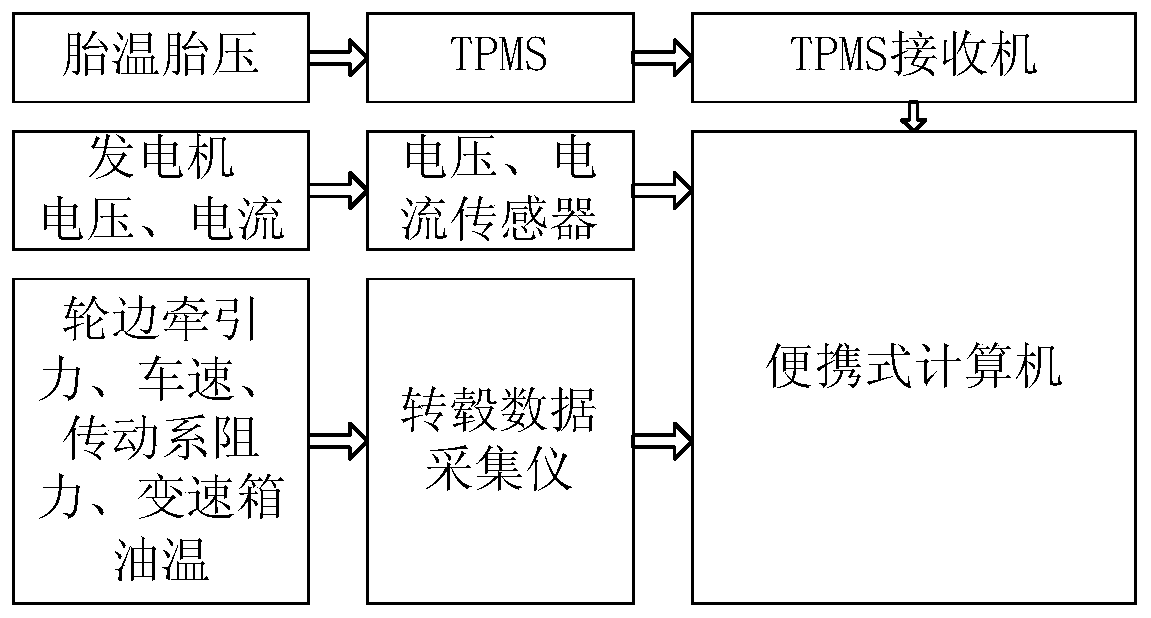

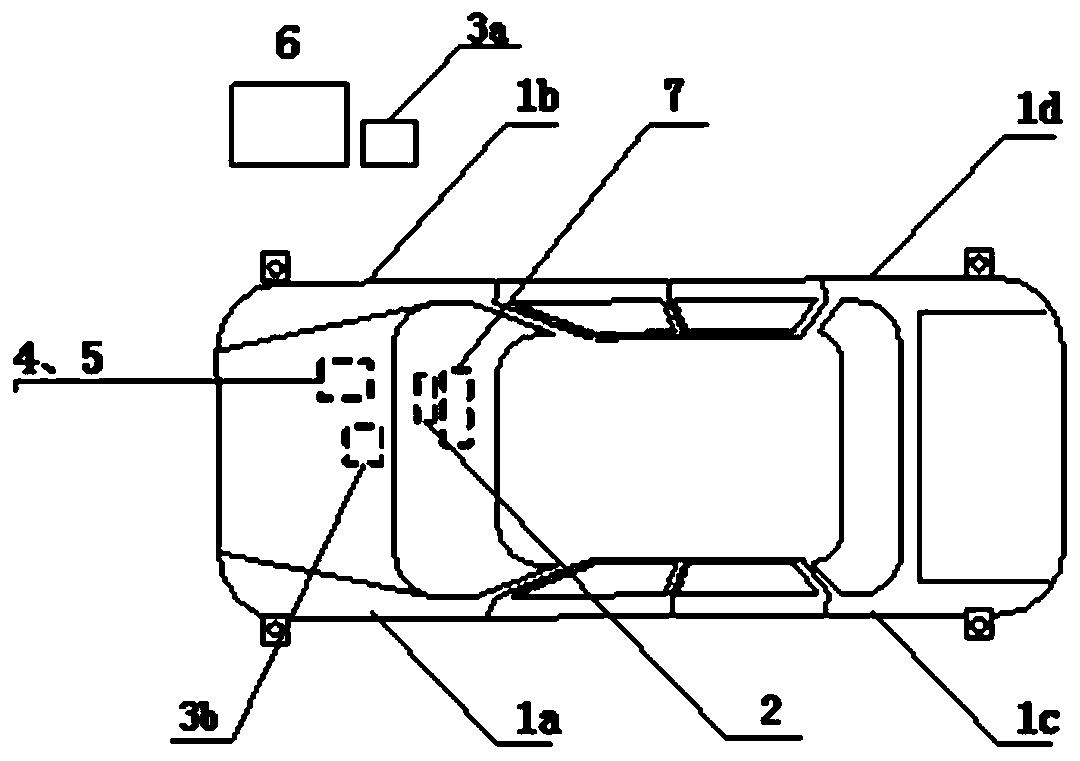

[0045] The present application provides a transmission mechanical efficiency test system on a complete vehicle, including a first TPMS1a, a second TPMS1b, a third TPMS1c, and a fourth TPMS1d, which are respectively set at the four wheels of the test vehicle, and are set at each At the valve core of the wheel.

[0046] These four TPMSs are all connected to the TPMS receiver 2 by electric signals or by hard wires.

[0047] Including the first K-type thermocouple 3a and the second K-type thermocouple 3b; wherein the first K-type thermocouple is connected with the AVL hub data acquisition instrument 6; the second K-type thermocouple is thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com