Device and method for simultaneously measuring permeability coefficient, compressibility coefficient and porosity of rock

A technology of permeability coefficient and compressibility coefficient, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., which can solve the problem of single permeability parameter, single function, and inability to realize simultaneous measurement of multiple parameters of rock seepage characteristics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

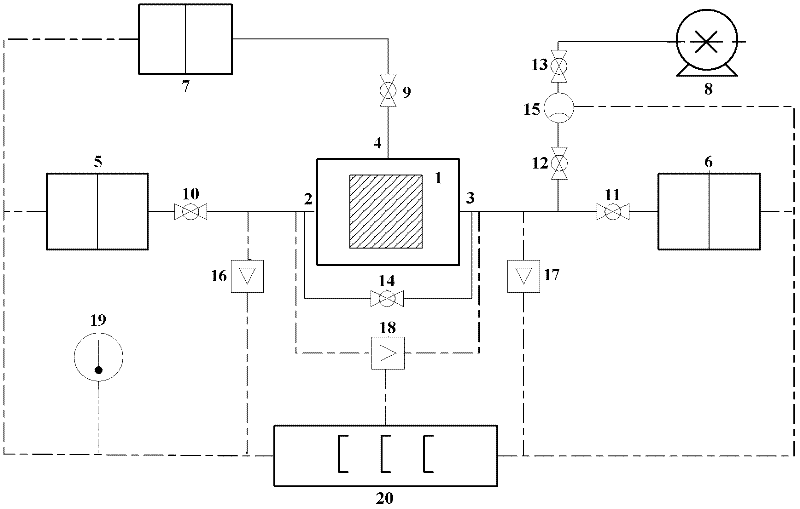

[0049] Further illustrate the present invention below in conjunction with accompanying drawing.

[0050] see figure 1 , the device for simultaneously measuring rock permeability coefficient, compressibility coefficient and porosity, consists of pressure chamber 1, upstream inlet 2, downstream inlet 3, confining pressure inlet 4, upstream pump 5, downstream pump 6, confining pressure pump 7, vacuum pump 8, confining pressure Pressure valve 9, upstream needle valve 10, downstream needle valve 11, vacuum needle valve 12, vacuum valve 13, separation valve 14, vacuum gauge 15, upstream pressure gauge 16, downstream pressure gauge 17, differential pressure gauge 18, thermometer 19, control The platform 20 is composed of a rock core, the pressure chamber 1 has a rock core, the confining pressure inlet 4 is sequentially connected to the confining pressure valve 9 and the confining pressure pump 7; the upstream inlet 2 is respectively connected to the upstream pressure gauge 16 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com