Permeability measurement device and measurement method in rock rheological process

A technology of measuring device and rock, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

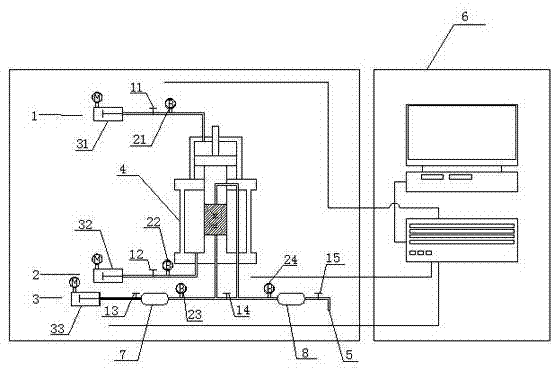

Method used

Image

Examples

Embodiment 1

[0041] 1) This example is to measure the permeability coefficient in the rheological process of sandstone. First, a test rock sample with a diameter of 50 mm and a height of 100 mm is made according to the standard, and the rock sample is saturated with a vacuum saturation device and loaded into a triaxial pressure chamber;

[0042]2) Apply the confining pressure to the predetermined value of 2MPa, and keep the confining pressure unchanged;

[0043] 3) After the confining pressure is stable, apply the water inlet pressure to 1MPa, the water outlet is in contact with the atmosphere, and keep the water inlet pressure unchanged;

[0044] 4) After stable seepage flows out of the water outlet, apply the deviatoric stress value, and conduct the rheological experiment under the action of the first-level deviatoric stress, and the predetermined rheological time is 48 hours.

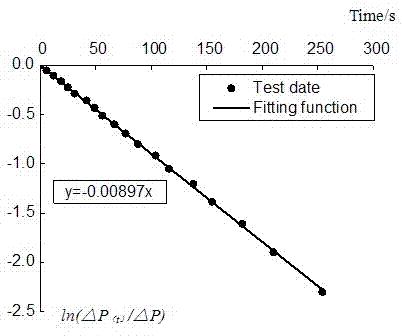

[0045] 5) Close the water outlet valve, load the water inlet pressure to 1.5MPa instantaneously, close the wat...

Embodiment 2

[0049] 1) This example is to measure the permeability coefficient in the rheological process of granite. First, a test rock sample with a diameter of 50 mm and a height of 100 mm is made according to the standard, and the rock sample is saturated by a vacuum saturation device and loaded into a triaxial pressure chamber;

[0050] 2) Apply the confining pressure to the predetermined value of 2MPa, and keep the confining pressure unchanged;

[0051] 3) After the confining pressure is stable, apply the water inlet pressure to 1MPa, the water outlet is in contact with the atmosphere, and keep the water inlet pressure unchanged;

[0052] 4) After stable seepage flows out of the water outlet, apply the deviatoric stress value, and conduct the rheological experiment under the action of the first-level deviatoric stress, and the predetermined rheological time is 48 hours.

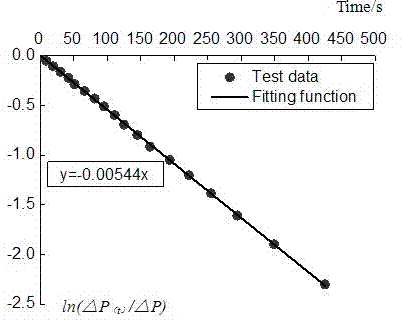

[0053] 5) Close the water outlet valve, load the water inlet pressure to 1.5MPa instantaneously, close the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com