Pressure alternate gas exhausting method by slotting and fracturing coal seams

A technology for gas extraction and slitting, which is applied in the directions of gas discharge, mining fluid, mining equipment, etc., can solve problems such as affecting the application of gas extraction, reducing the concentration of gas extraction, and reducing the permeability of coal seams, and achieves good on-site application value. and social benefits, the effect of increasing the amount of gas drainage and increasing the concentration of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

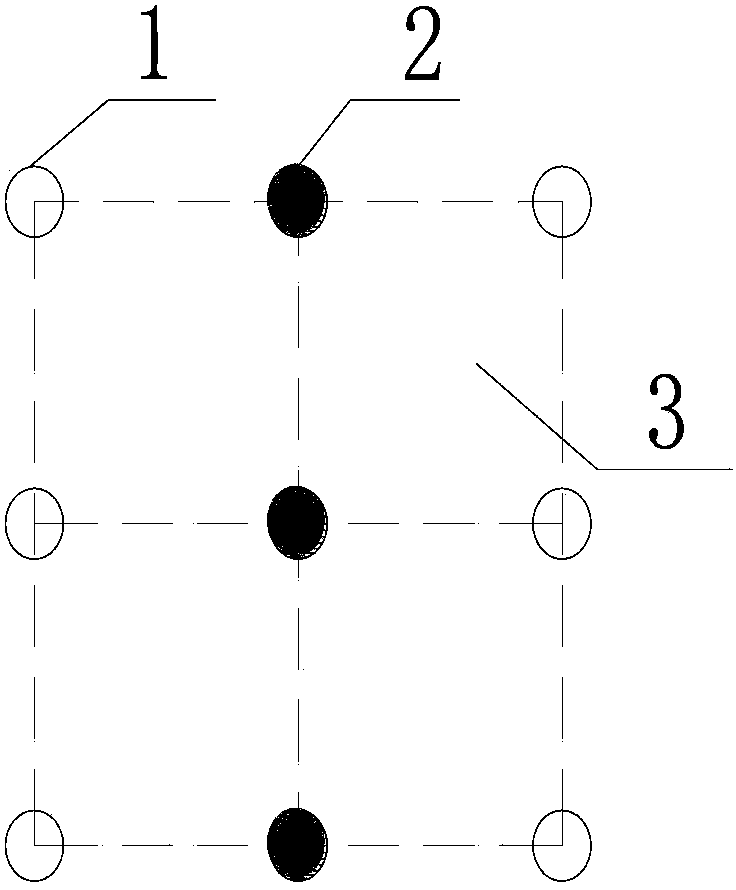

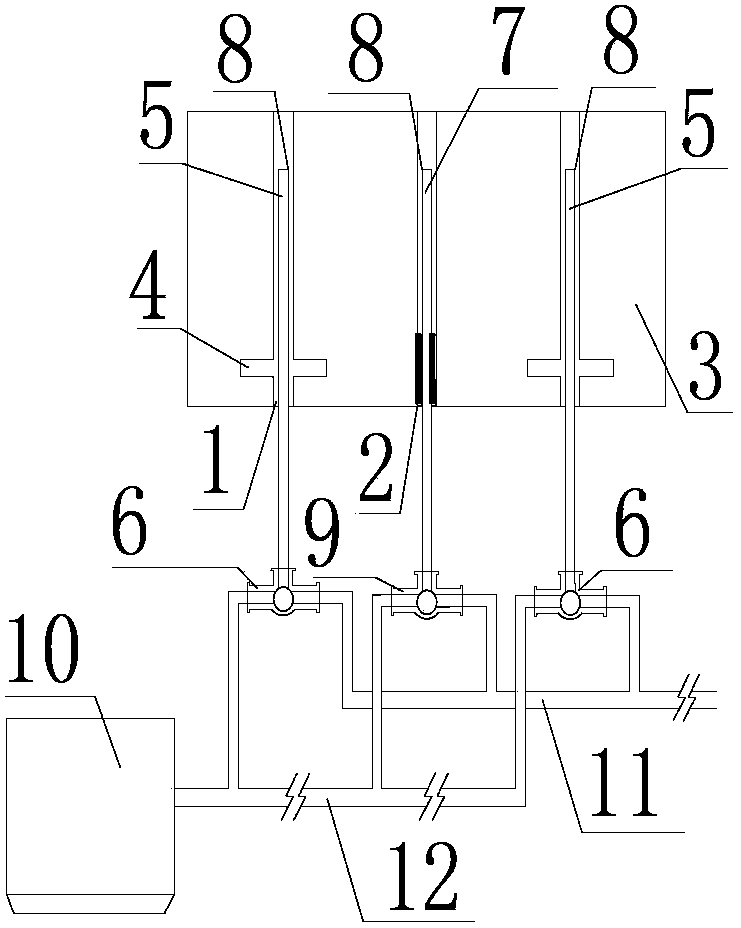

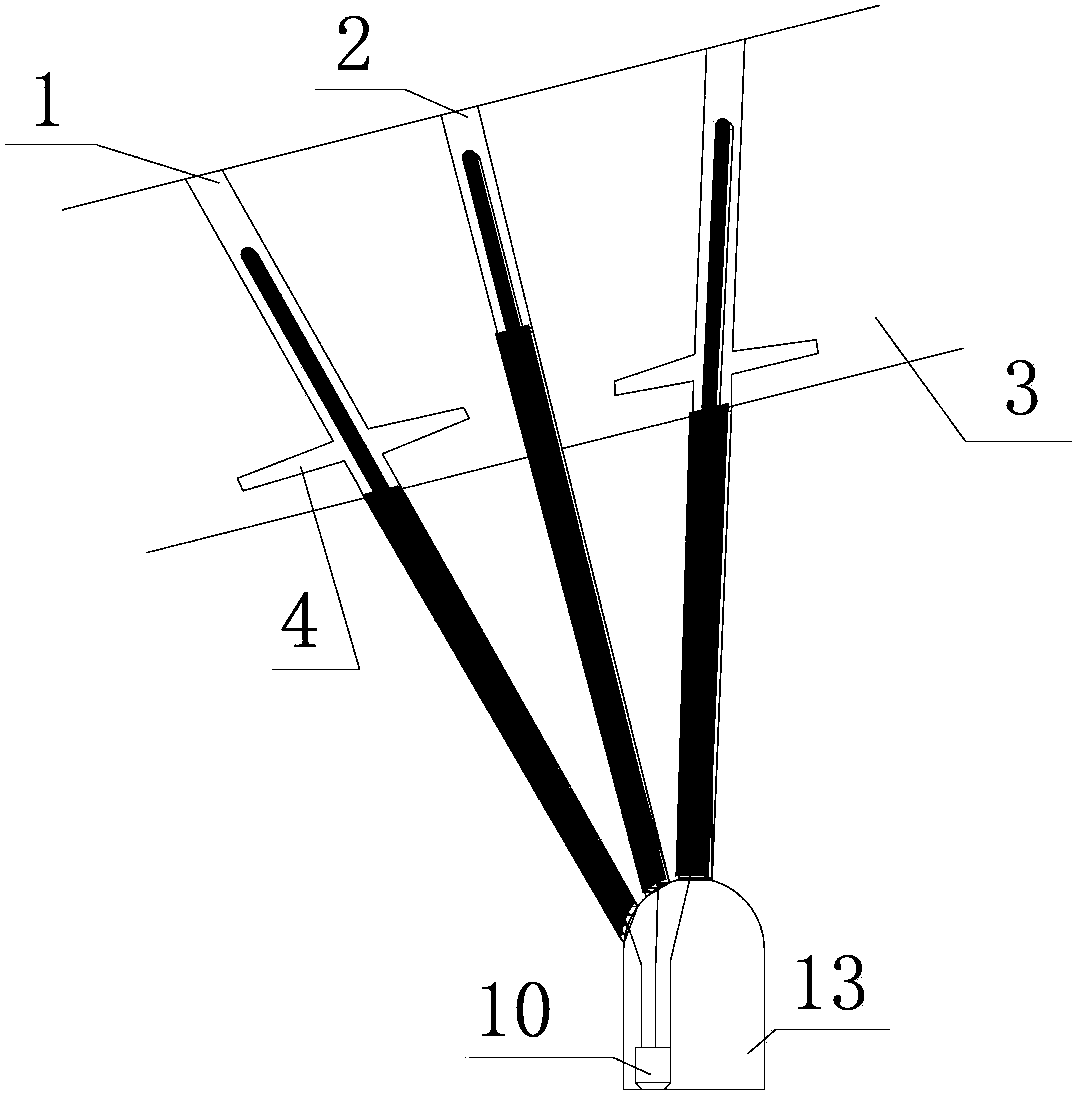

[0030] Embodiment 1, according to the parameter design borehole parameter of protection coal seam in the bottom pumping roadway measure, setting adjacent borehole sees coal point distance is 4.0-7.0m, with reference to figure 1 The layout of slotted borehole 1 and fracturing borehole 2 is used to construct boreholes in coal body 3, refer to figure 2 image 3, first perform high-pressure water jet slits in the slit borehole 1 to form an annular slit 4, insert the steel pipe 5 into the slit borehole 1, the end of the steel pipe 8 is 1.0-1.5m away from the coal seam roof, and then seal the hole and inject Slurry to the coal seam floor, adjust the steel pipe three-way ball valve 6 outside the steel pipe 5, close the high-pressure water pipe 12, make the steel pipe 5 communicate with the main gas extraction pipeline 11, carry out slotted drilling 1 gas extraction, and follow the above method to sequentially clean the other cutting pipes. seam drilling 1 construction;

[0031] Wh...

Embodiment 2

[0033] Embodiment 2, with reference to Figure 4 For the arrangement of slotted borehole 1 and fracturing borehole 2, the number and parameters of slotted borehole 1 and fracturing borehole 2 are designed in combination with the actual situation on site, and the operation is carried out according to the operation steps of Example 1.

Embodiment 3

[0034] Embodiment 3, with reference to Figure 5 For the arrangement of slotted borehole 1 and fracturing borehole 2, the number and parameters of slotted borehole 1 and fracturing borehole 2 are designed in combination with the actual situation on site, and the operation is carried out according to the operation steps of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com