Composite polypropylene microporous membrane, and preparation method and application thereof

A technology of compounding polypropylene and microporous film, applied in the field of microporous film, can solve the problems of poor fit, poor wettability, low surface energy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

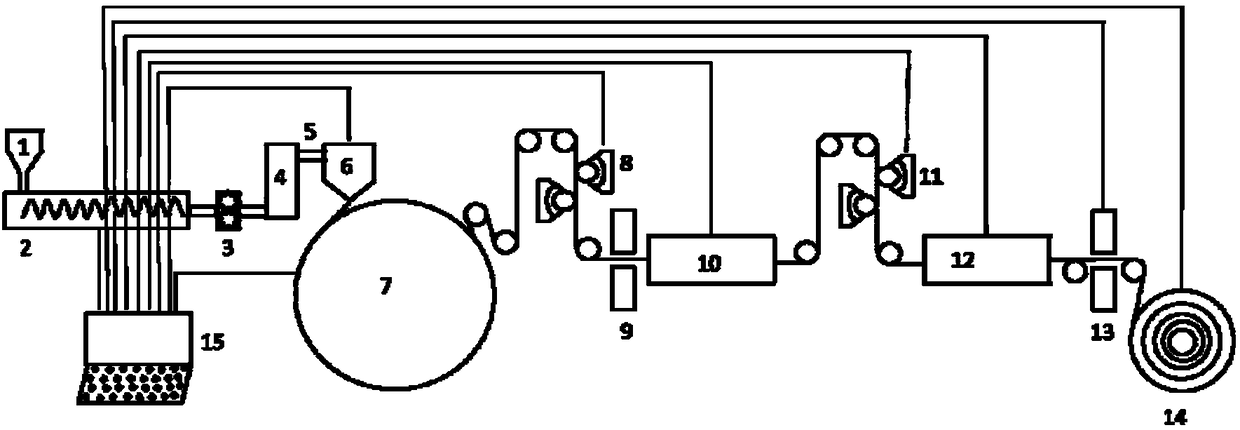

[0124] The homopolypropylene resin whose melt index is 2.5g / 10min is mixed with the polypropylene beta crystal nucleating agent N,N-dicyclohexyl-2,6 naphthalene diamide accounting for 0.03wt% of the homopolypropylene resin, and passed The feeder 1 is fed into the single-screw extruder 2. After melting at a temperature of 160-230°C, it is metered by the metering pump 3. After passing through the filter 4, it enters the T-shaped die head 6 through the second melt pipeline 5. out, and cooled on the casting roll 7 to obtain a polypropylene film containing a β-crystal nucleating agent. The thickness of the polypropylene membrane containing β-crystal nucleating agent is 140 microns.

[0125] The film passes through the film thickness gauge 9 and enters the longitudinal stretching system 10, and is subjected to 4.5 times longitudinal stretching at 100° C. to obtain a longitudinal stretched film.

[0126] The longitudinally stretched film is coated on both sides with an aqueous polym...

Embodiment 2

[0130] Embodiment 2 is the same as Embodiment 1, and the only difference is that the longitudinal stretch film is coated with Nafion solution (purchased from DuPont) on one side surface through the coating system (II), and the thickness of the coating after drying is 3 microns. Stretching to obtain a single-sided coated composite polypropylene microporous membrane of Nafion with a non-porous compact structure on one side surface.

[0131] The thickness of the coating layer is 1.0 micron; the thickness of the composite polypropylene microporous membrane is 19 micron.

[0132] When the composite polypropylene microporous membrane prepared above is used as a lithium-sulfur battery separator, since the Nafion layer on the surface has a non-porous and compact structure, polysulfides dissolved in the electrolyte cannot be transported through the separator, while lithium ions can Combined with the sulfonate in Nafion for transport, the composite polypropylene microporous membrane can...

Embodiment 3

[0134] Embodiment 3 is the same as Embodiment 1, the difference is only that the xylene solution of polydimethylsiloxane is coated on one side of the longitudinally stretched film through the second coating system, and the thickness of the coating after drying is 6 microns. A composite polypropylene microporous membrane coated on one side of polydimethylsiloxane with non-porous compact structure is obtained through transverse stretching.

[0135] The thickness of the coating layer is 2 microns; the thickness of the composite polypropylene microporous membrane is 20 microns.

[0136] The composite polypropylene microporous membrane prepared above is used as a gas separation membrane to separate ethanol / water solution by pervaporation, and a good separation effect is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com