Paper sheet thickness detection device

A technology for thickness detection and paper, applied in the field of thickness measurement devices, can solve problems such as inability to distinguish response signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

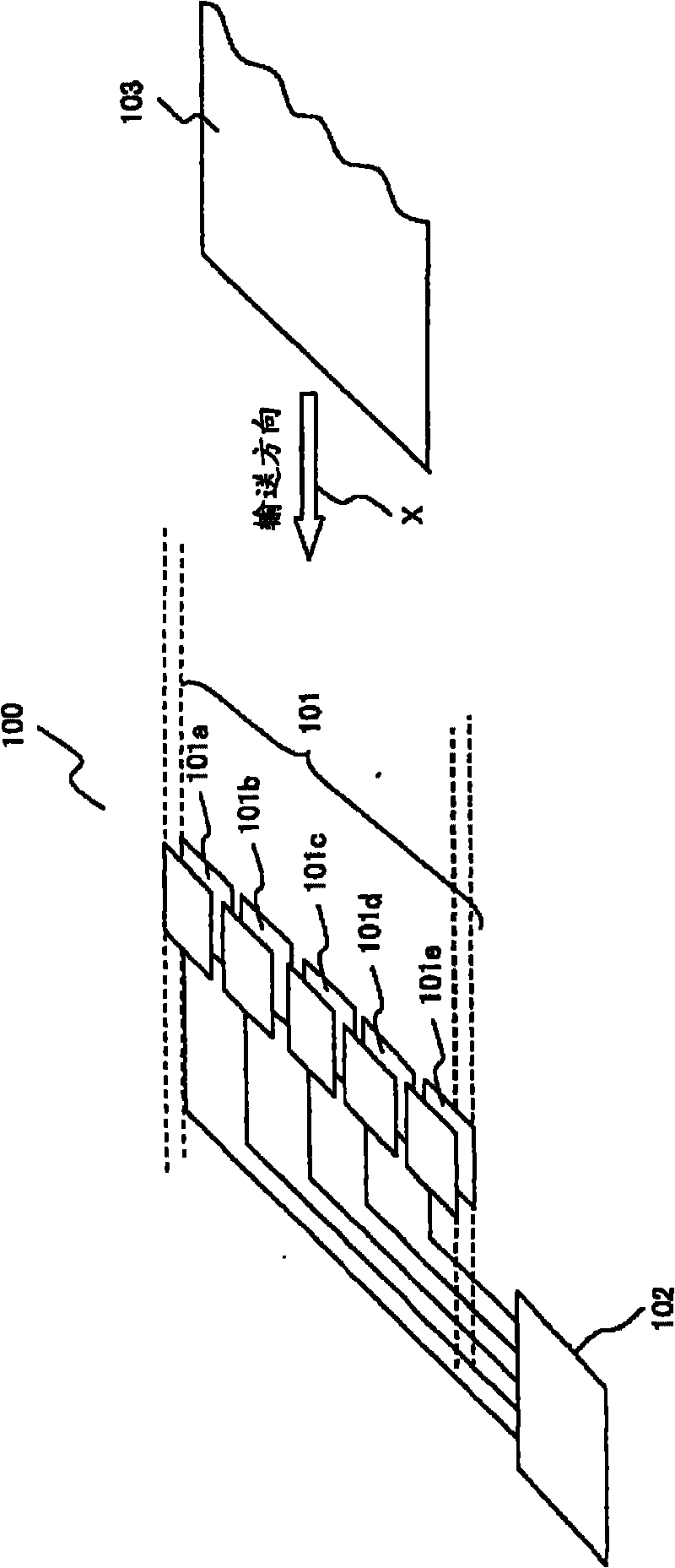

[0041] Below, according to Figure 3 ~ Figure 11 Embodiments of the present invention will be described.

[0042] image 3 It is a figure explaining the operating principle of the paper thickness detecting device of the embodiment of the present invention.

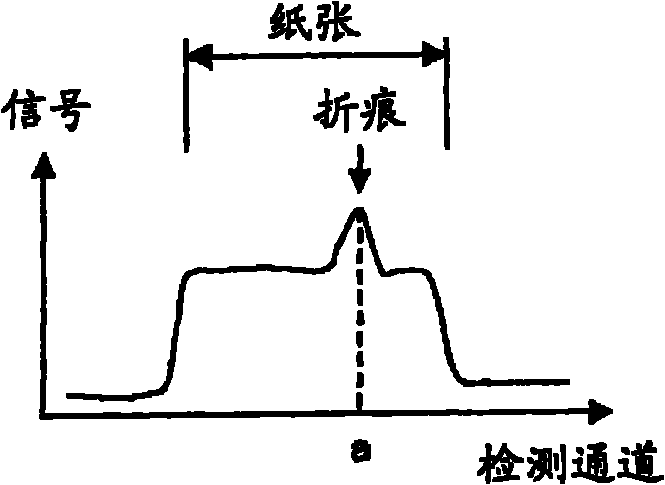

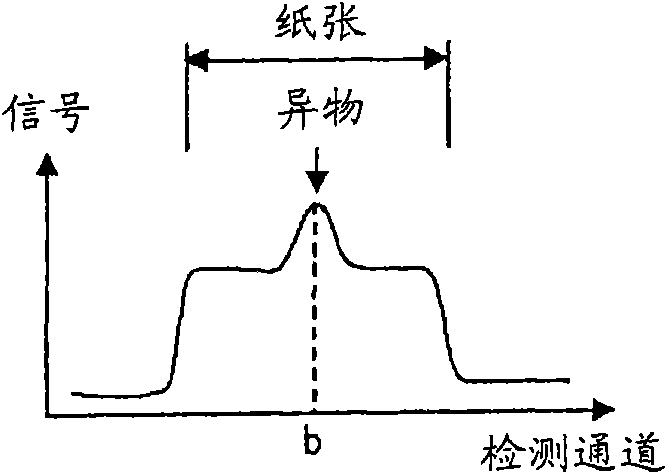

[0043] image 3 The shown paper thickness detecting device 300 has: when a paper 304 such as a banknote or copy paper is inserted, a first sensor 301 and a second sensor 302 whose capacitance changes; signal (eg Figure 8A and Figure 8B signal shown. Hereinafter referred to as “response signal”), the thickness detection unit 303 detects the thickness of the paper 304 .

[0044] The first sensor 301 is composed of a plurality of capacitance sensors (hereinafter, the capacitance sensors are simply referred to as “sensors”) including a first application electrode and a first detection electrode. In addition, the first application electrode may be constituted by one common electrode.

[0045] In addition, each sensor of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com