Defrosting detector and defrosting control method based on frost layer thickness

A detector and frost layer technology, which is applied in the field of air source heat pump control, can solve the problems of sensitive components being easily affected by the outdoor environment, inaccurate defrosting judgment, and difficulties in practical application, and achieve simple structure, high reliability, and cheap materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

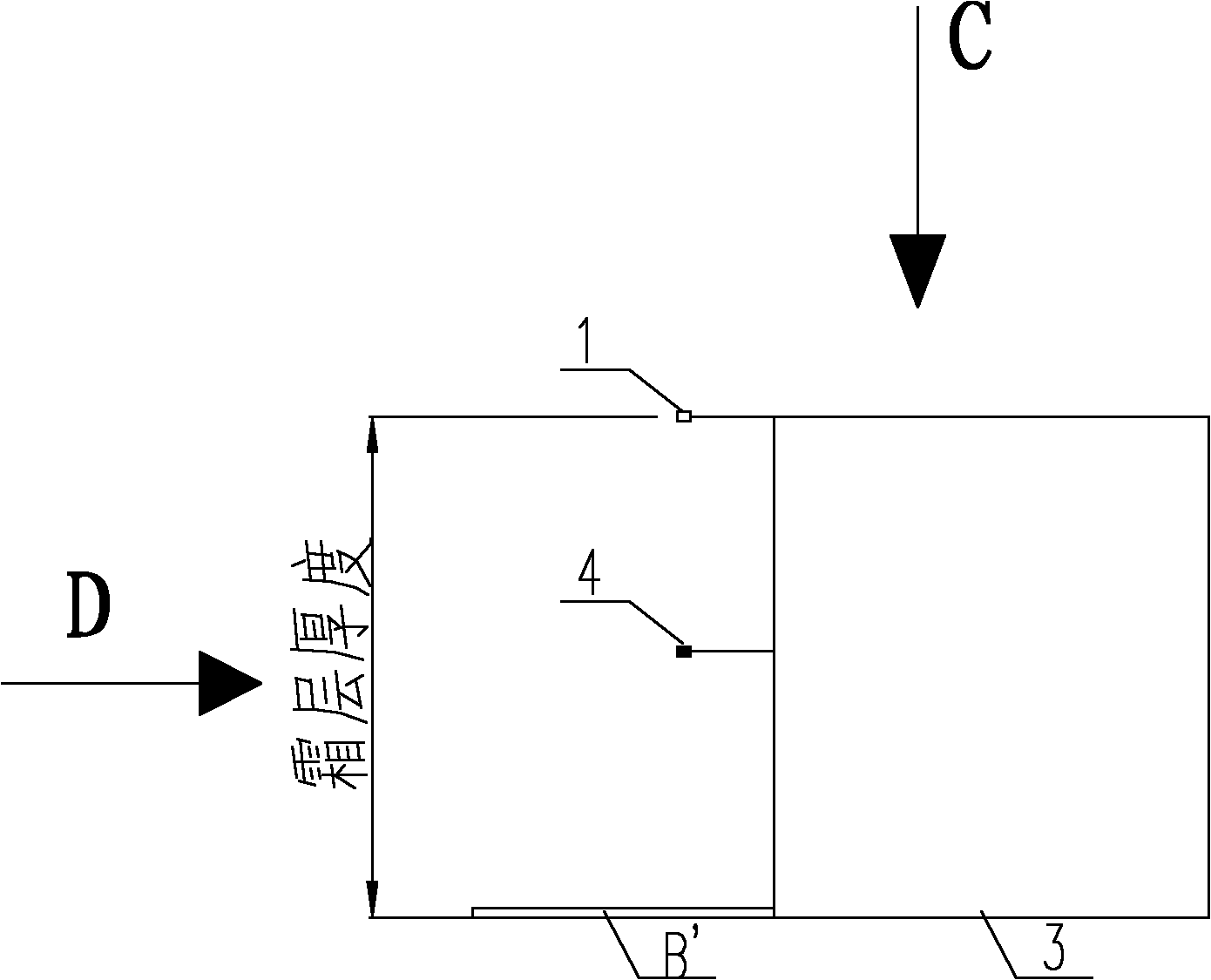

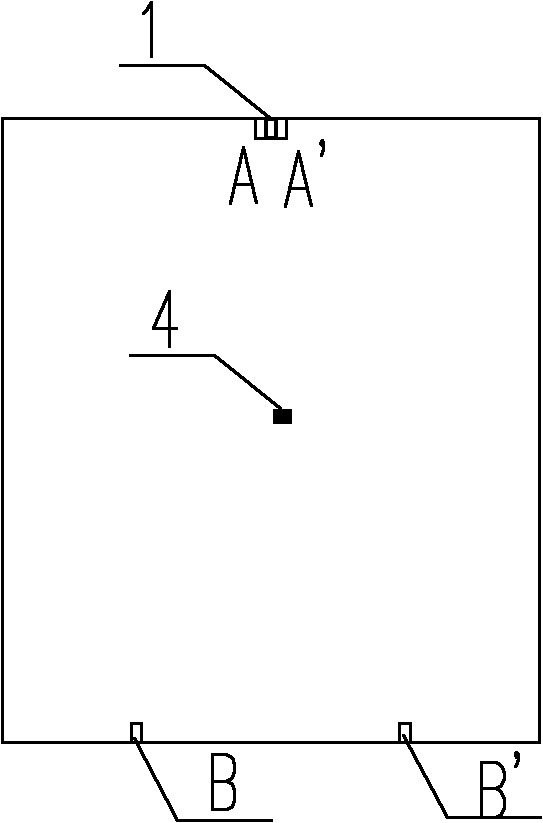

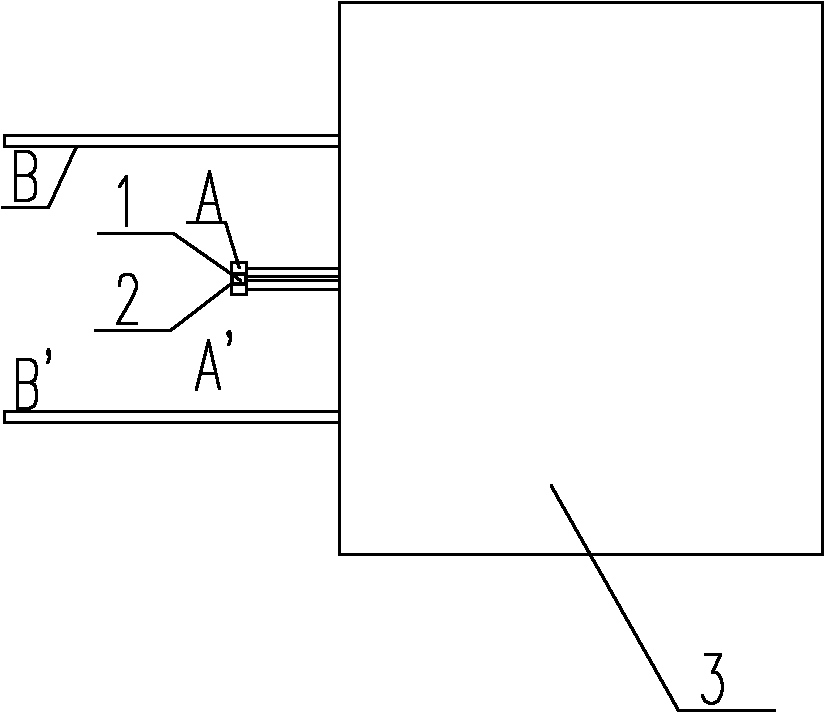

[0039] Specific implementation mode one: the following combination Figure 1 to Figure 6 Describe this embodiment, a defrosting detector based on the thickness of the frost layer described in this embodiment, which includes a heating resistor 1, a heat-insulating plastic body 3, a temperature sensor 4, a first electrode pair A-A', a second electrode For BB', power supply, defrost detector start switch K1, defrost start switch K2, intermittent switch K3, defrost start resistor R1 and defrost judgment completion resistor R2, the outer surface of heating resistor 1 is coated with insulating layer 2 , the first electrode pair A-A' is respectively arranged on the left and right end faces of the heating resistor 1, the heating resistor 1 and the second electrode pair BB' are located outside one side of the heat-insulating plastic body 3, and are mechanically connected to it, the heating resistor 1 is arranged on the top of the side, and the second electrode pair BB' is arranged on t...

specific Embodiment approach 2

[0056] Specific embodiment two: This embodiment is based on the defrosting control method of the defrosting detector based on the thickness of the frost layer described in the first embodiment, the method is:

[0057] The defrost detector does not work: when the air source heat pump is in cooling operation, the defrost detector does not work, and the defrost detector start switch K1, defrost start switch K2, and intermittent switch K3 are disconnected;

[0058] Defrost detector activation state: when the temperature detected by the temperature sensor 4 is between -12°C and 1°C, the defrost detector start switch K1 is closed, the intermittent switch K3 is intermittently closed, and the defrost detector is started;

[0059] The defrosting start state of the air source heat pump: when the intermittent switch K3 is closed, the heating resistor 1 is in a closed loop, and the heat generated by the heating resistor 1 will melt the frost on the surface of the insulating layer 2 outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com