Horizontal directional carbon nanotube array and preparation method thereof

A carbon nanotube array, horizontally oriented technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems that cannot be used to prepare single-wall carbon nanotube arrays, etc., and achieves fast and efficient preparation process and simple conditions. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 11: growing a self-supporting single-walled carbon nanotube film with a thickness of about 200 nm by using a floating catalytic chemical vapor deposition method. The carbon nanotube film may have an orientation direction, and most of the carbon nanotubes therein generally extend along the orientation direction.

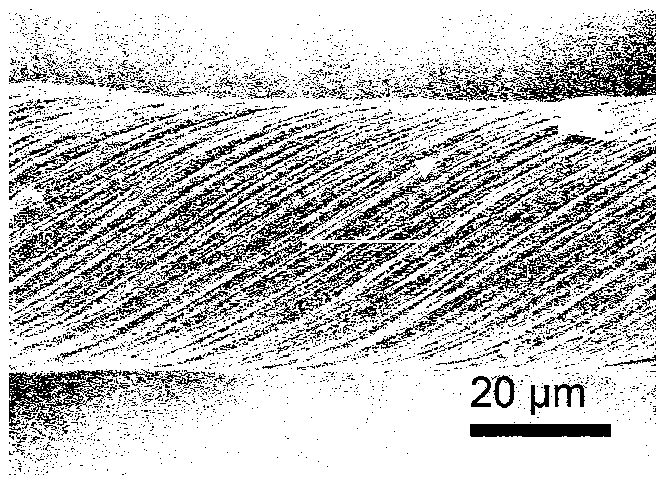

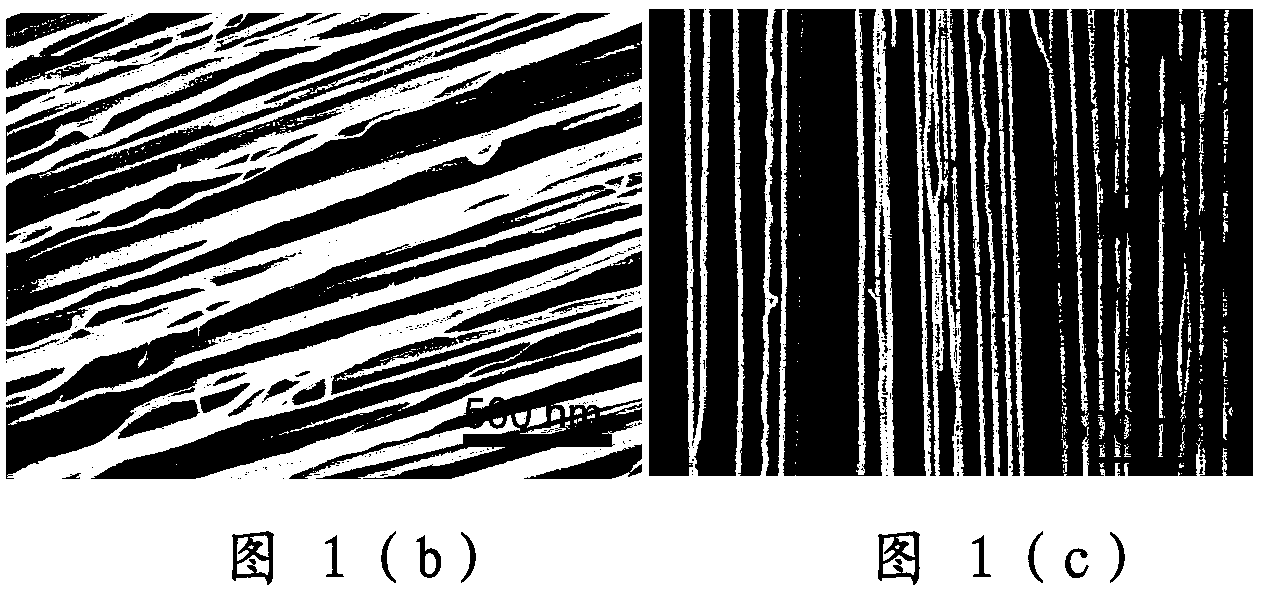

[0033] Step 12: Hold both ends of the carbon nanotube film with tweezers, and twist / twist it evenly along the orientation direction of the film to form a carbon nanotube rope with a length direction. As shown in Figure 1(a), a carbon nanotube rope has a length of about 2 cm and a diameter of about 40 μm.

[0034]The direction of the arrow in Figure 1(a) indicates the twisting direction of the carbon nanotube rope, that is, the orientation of the carbon nanotube bundle on the surface of the carbon nanotube rope. The angle between the orientation and the axial direction or length direction of the rope can indicate the degree of twisting and the magnitude of...

Embodiment 2

[0043] Step 21: growing a self-supporting single-walled carbon nanotube film with a thickness of about 100 nm by using a floating catalytic chemical vapor deposition method. Similar to Embodiment 1, the carbon nanotube film can also have an orientation direction.

[0044] Step 22: soaking the carbon nanotube film in ethanol solvent to remove the high self-adsorption of the carbon nanotube film. The ethanol liquid level can be equal to the surface of the carbon nanotube film or less than 0.5mm higher than the surface of the film.

[0045] In other embodiments, other volatile organic solvents such as water or acetone may also be used instead of ethanol.

[0046] Step 23: Clamp one end of the carbon nanotube film, and slowly "pull" the carbon nanotube film out of the ethanol. Due to the effect of gravity and surface tension, the carbon nanotube film will shrink into a strip. Nevertheless, the overall shape of the strip is still film-like. In the actual operation process, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com