Shock absorption loop for automotive transmission and manufacturing process thereof

A transmission system and damping ring technology, which is applied to springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve the problem of uneven rotation of inner universal joints and differential gears, harsh screams Sound, vehicle wave coupling noise and other problems, to achieve the effect of good elasticity, stable natural frequency, and improved comfort performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Natural Rubber NR: 80 Carbon Black N770: 35

[0029] High aromatic oil: 5 Anti-aging agent: 3.5

[0030] Stearic acid: 1 Indirect zinc oxide: 4

[0031] Sulfur: 2.0 Accelerator: 1.2

[0032] Anti-scorch agent: 0.2

Embodiment 2

[0034] Natural rubber NR: 100 Carbon black N770: 40

[0035] High aromatic oil: 8 Anti-aging agent: 4.5

[0036] Stearic acid: 1 Indirect zinc oxide: 5

[0037] Sulfur: 2.5 Accelerator: 1.5

[0038] Anti-scorch agent: 0.3

Embodiment 3

[0040] Natural rubber NR: 120 Carbon black N770: 55

[0041] High aromatic oil: 10 Anti-aging agent: 5.5

[0042] Stearic acid: 2 Indirect zinc oxide: 6

[0043] Sulfur: 2.5 Accelerator: 1.8

[0044] Anti-scorch agent: 0.3

[0045] Among them, the anti-aging agent is anti-aging agent RD and anti-aging agent 4010NA, the accelerator is CZ, and the anti-scorch agent is CTP;

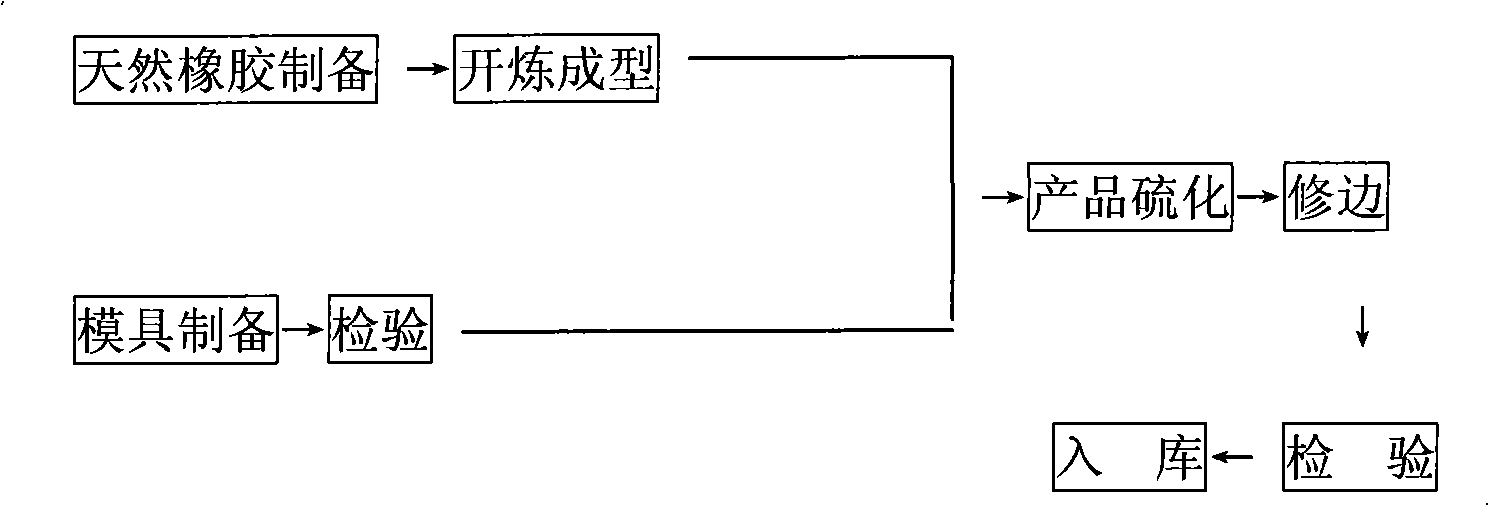

[0046] The manufacturing process of the damping ring includes the following examples:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com