Rotating biological-cathode microbiological fuel cell and sewage treatment method thereof

A sewage treatment method and fuel cell technology, applied in the field of environmental engineering, can solve problems such as non-compliance, secondary pollution, and reduced catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

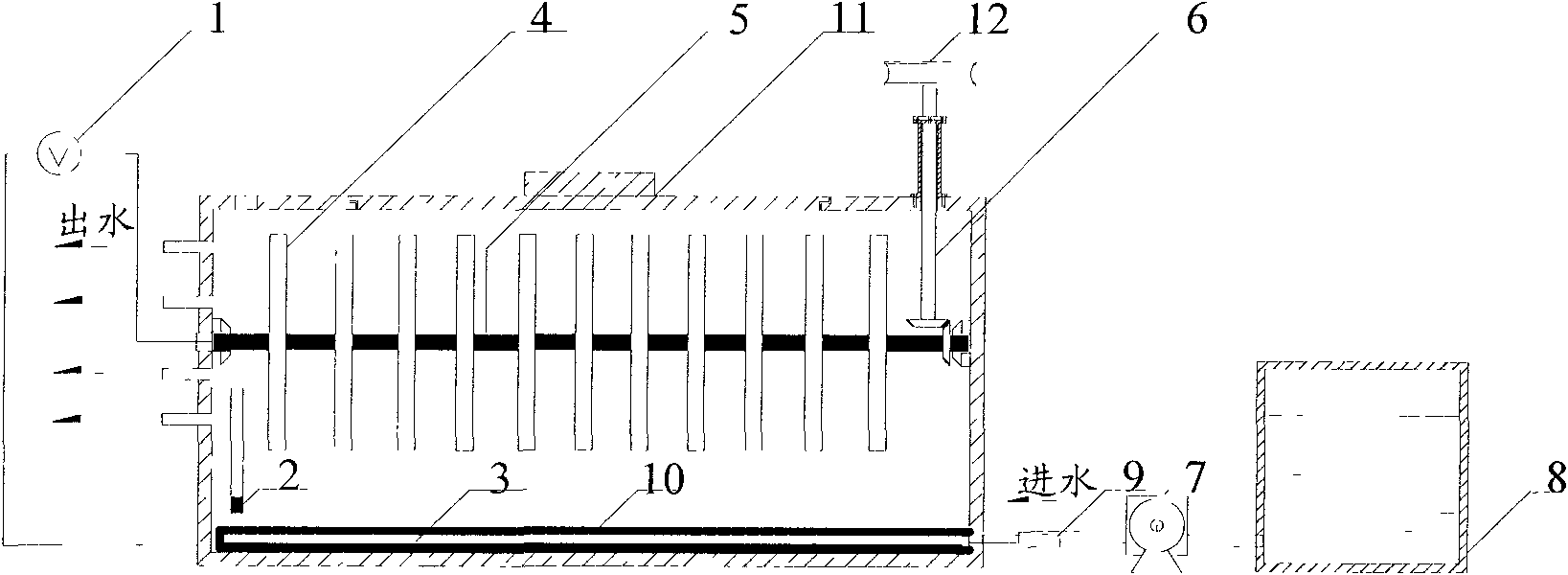

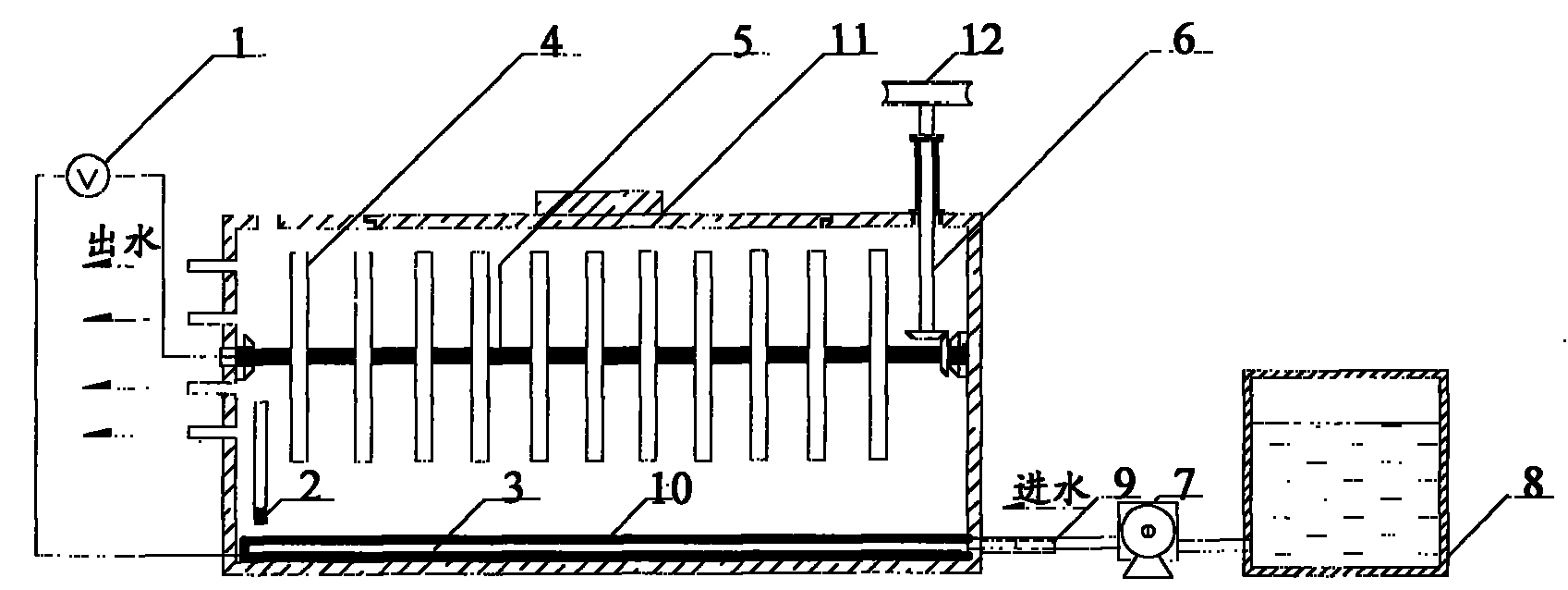

[0015] The amount of domestic sewage treated is 40m 3 / d meter, COD concentration is 200mg / L, TN concentration is 50mg / L. The HRT of the rotary biocathode microbial fuel cell is designed to be 8h, and the reactor volume is 16m 3 . The specific dimensions are: length 4m, width 1m, effective water depth 3.5m, super height 0.5m, total height 4m. The diameter of the cathode ring is 0.9m, and a carbon filament cathode ring is set every 0.3m on the rotating shaft; the anode carbon fiber is 4×1m 2 . The maximum distance between the ring and the bottom of the pool is 2.6m, the minimum distance is 0m, and the rotation speed of the cathode ring is less than 10rpm.

[0016] Domestication and film formation: the reactor is inoculated with anaerobic sludge. During the period, the reaction tank is covered with a lid 11, and N2 is exposed to make the entire reactor in an anaerobic state. The production capacity is used as the domestication maturity indicator, and the voltmeter 1 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com