Self-circulation smashing and grinding device for rice processing

A rice processing and grinding device technology, which is applied in application, cocoa, grain processing, etc., can solve the problems of poor grinding effect and incomplete grinding, achieve the effect of improving the grinding effect, solving the problem of incomplete grinding, and improving the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

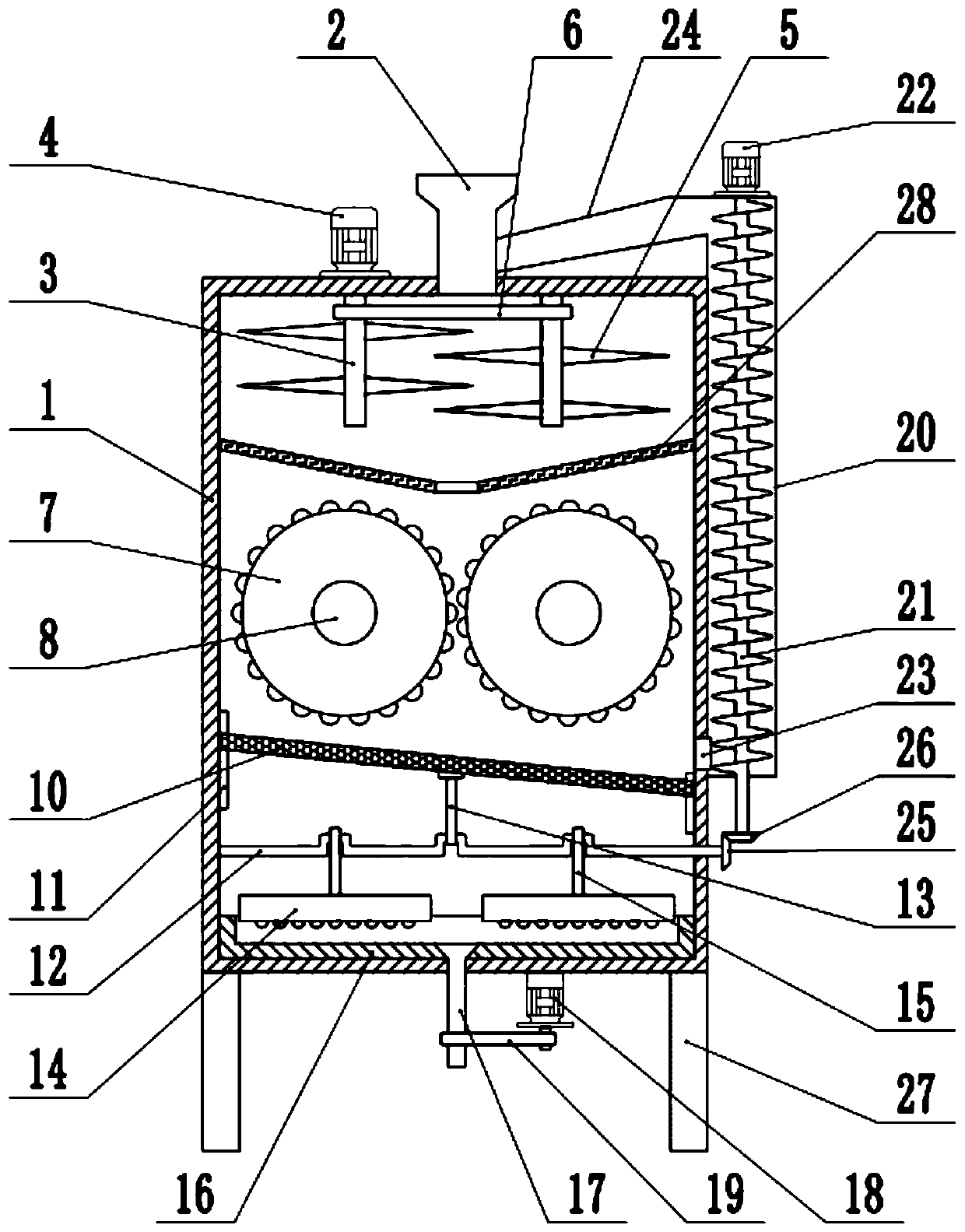

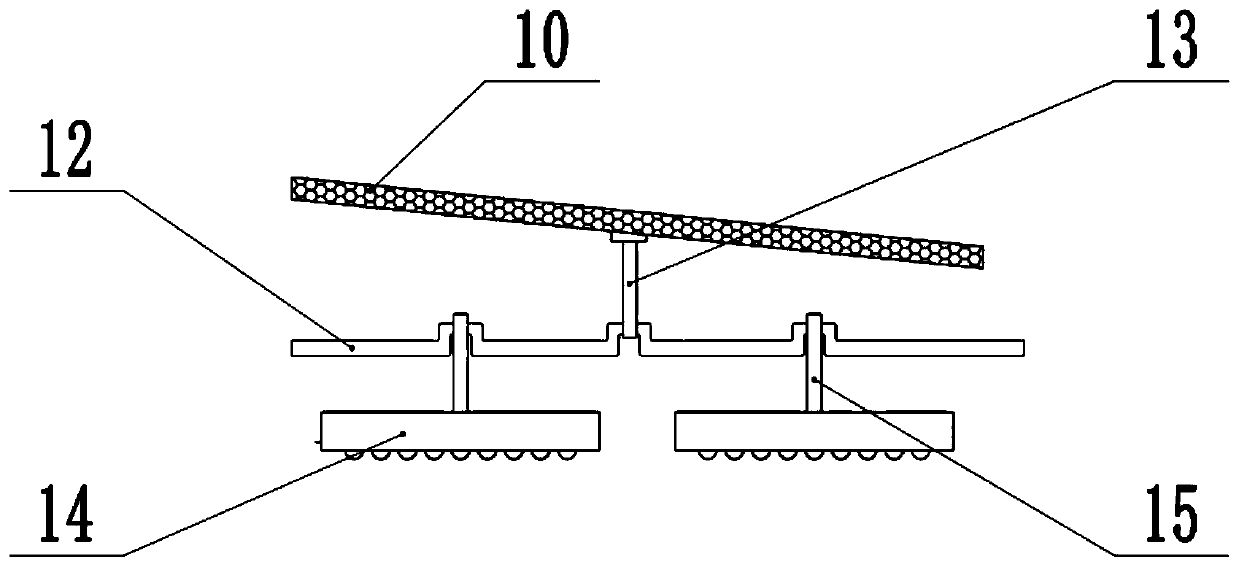

[0023] see Figure 1-4 , in the embodiment of the present invention, a self-circulating crushing and grinding device for rice processing includes a casing 1, a crushing shaft 3, a crushing blade 5, a first transmission belt 6 and a grinding disc 16, and the top of the casing 1 is equipped with a feeding port 2 , the feeding port 2 communicates with the casing 1, and the rice is poured into the casing 1 through the feeding port 2, and a crushing mechanism is installed inside the casing 1, and the crushing mechanism includes a crushing shaft 3, a crushing motor 4, a crushing blade 5 and a first transmission belt 6, and the casing 1 is equipped with a crushing shaft 3, the crushing shaft 3 is connected to the top of the shell 1 in rotation, there are two crushing shafts 3, arranged symmetrically on the left and right, the two crushing shafts 3 are connected by the first transmission belt 6, and the top of the shell 1 A crushing motor 4 is fixedly connected, and the shaft extensio...

Embodiment 2

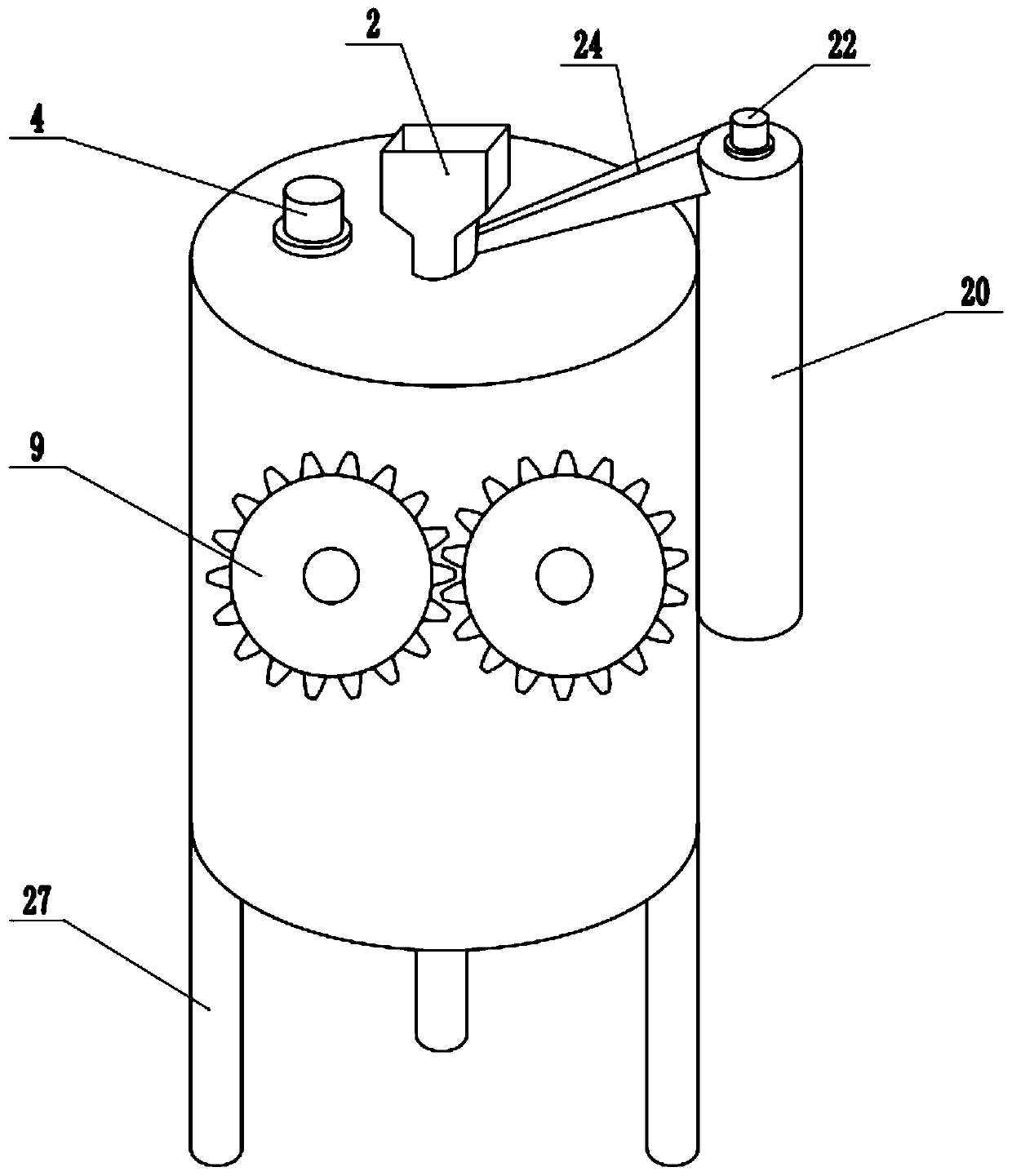

[0027] On the basis of Embodiment 1, the rice milling mechanism includes a rolling roller 7, a rolling shaft 8, and a gear set 9. There are two rolling shafts 8, which are arranged symmetrically. The wall is connected by rotation, and the rolling roller 7 is sleeved on the rolling shaft 8. The ends of the two rolling shafts 8 pass through the side wall of the casing 1 and extend to the outside of the casing 1, and the ends of the two rolling shafts 8 pass through The gear sets 9 are connected, and the outer wall of the housing 1 is also equipped with a driving motor. The shaft end of the driving motor is connected with the end of one of the rolling shafts 8, and the crushed rice falls into the two rolling rollers 7. During this time, the driving motor is used to drive the rolling shaft 8 to rotate, thereby driving the rolling roller 7 to rotate, and the rice is crushed by the rolling roller 7 to carry out the rice milling operation.

Embodiment 1、 Embodiment 2

[0028]In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: put rice into the casing 1 through the feeding port 2, start the crushing motor 4, drive the crushing shaft 3 to rotate, and use the crushing blade 5 to carry out preliminary crushing of the rice. The crushed rice falls on the material guide plate 28, and then falls between the two rolling shafts 8 through the feeding hole on the material guiding plate 28, and the rolling roller 7 is driven by the driving motor to rotate, thereby driving the rolling shaft 8 Rotate, use the rolling shaft 8 to crush the rice, and carry out the rice milling operation. The crushed rice falls on the sieve plate 10, and the rice is screened by the sieve plate 10, and the incompletely crushed rice enters through the circular feeding port 23. In the circulation cylinder 20, the rice is conveyed upwards by the screw 21, and put into the feeding port 2 again, and the rice is crushed in a circular m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com