Heteroatom-doped porous graphite electro-catalyst and preparation and application thereof as well as device

A technology of porous graphene and electrocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical/physicochemical processes of energy application, etc. Long reaction time and other problems, to achieve the effect of reducing van der Waals interaction, improving electrocatalytic performance, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

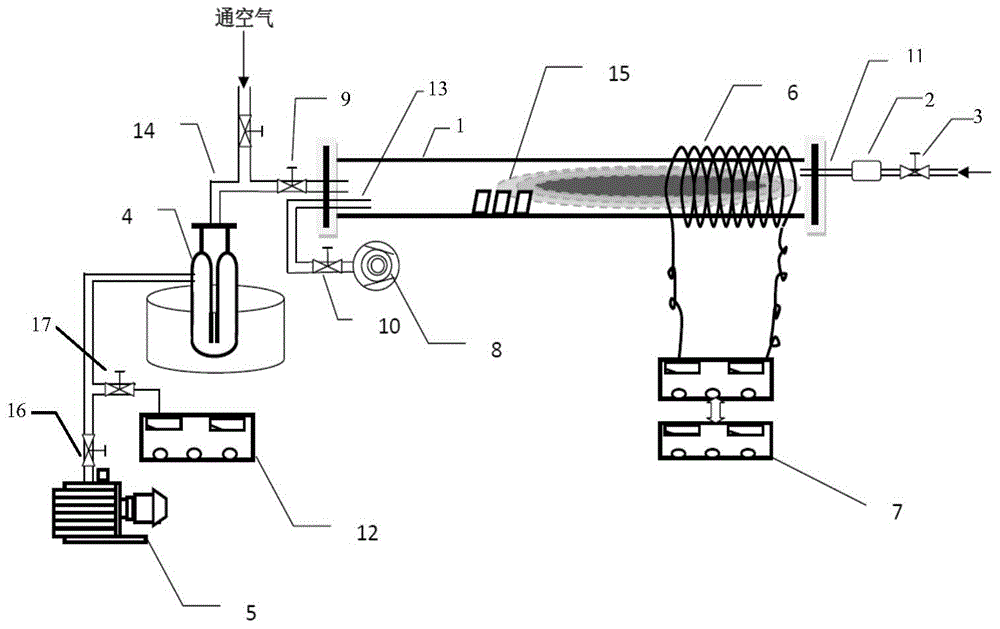

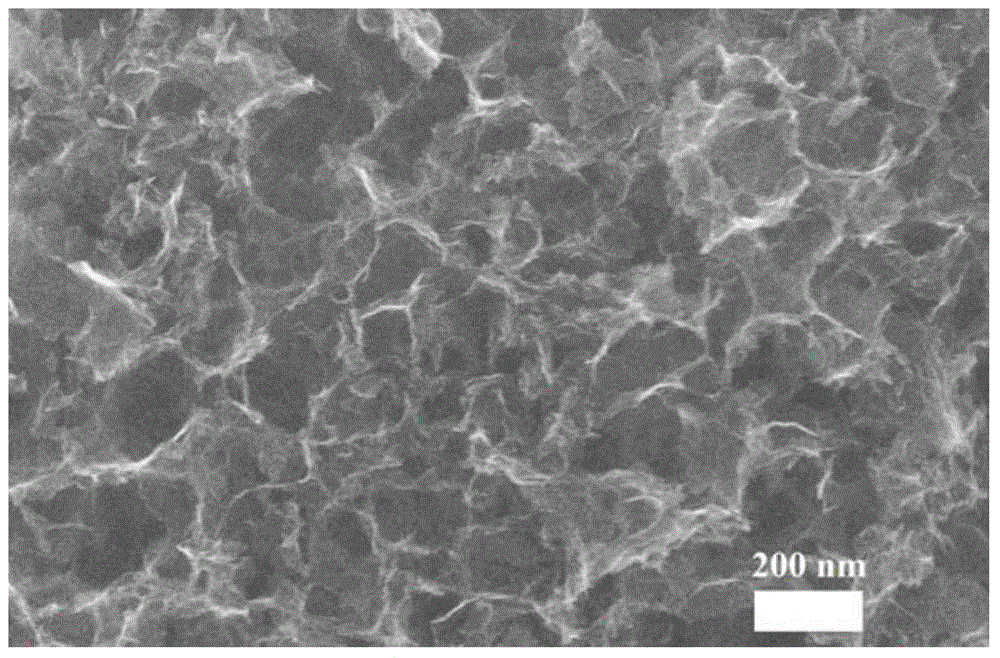

[0053] A preparation method of heteroatom-doped porous graphene electrocatalyst, specifically comprising the following steps:

[0054] (1) Synthesis of graphene oxide

[0055] Adopt improved Hummers method to prepare graphene oxide, its technological process is as follows:

[0056] (1-1) Assemble the reaction flask in an ice-water bath, add a solid mixture of 1g of expanded graphite powder and 2.5g of sodium nitrate to the reaction flask under stirring (the stirring speed is 500r / min), and then add 150mL of mass percentage 95% concentrated sulfuric acid, reacted in an ice-water bath for 30 minutes; then, added 15 g of potassium permanganate 60 times (1 min each time), controlled the reaction temperature at 0 ° C, and continued to react for 12 h; then added 150 mL of deionized water to dilute After stirring and reacting for 30 minutes (the rotating speed of stirring is 500r / min), the temperature was raised to 98° C. at a heating rate of 10° C. / min, and the heat preservation re...

Embodiment 2

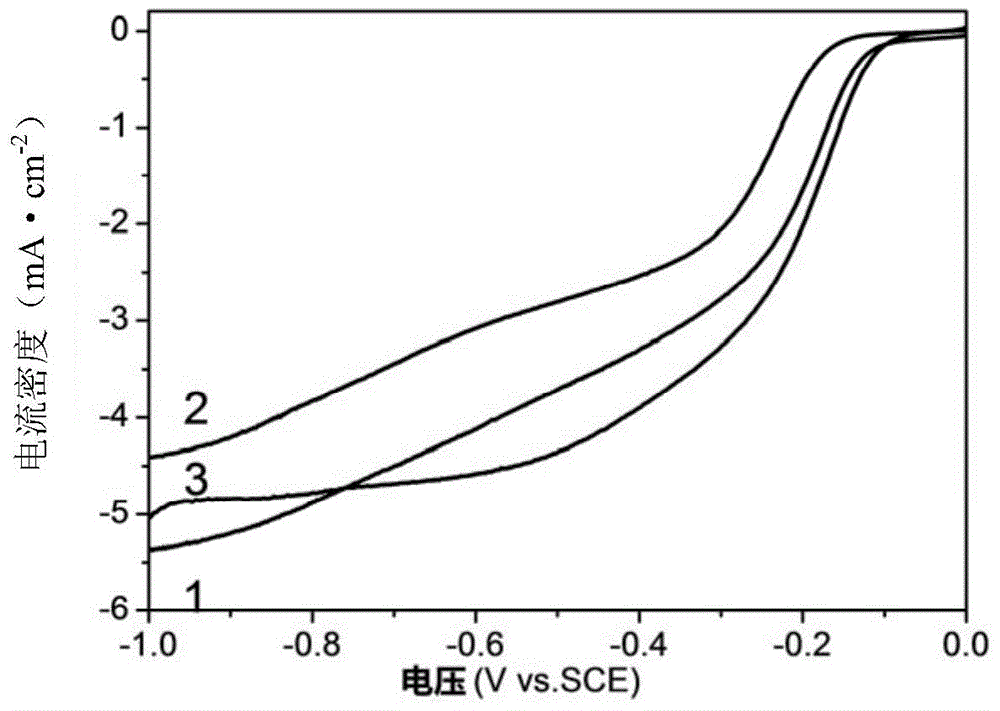

[0071] Preparation of the nitrogen-doped porous graphene-modified glassy carbon electrode prepared in Example 2: The nitrogen-doped porous graphene electrocatalyst prepared in Example 2 was replaced by the nitrogen-doped porous graphene electrocatalyst prepared in Example 1, using the method of implementing The preparation method of the glassy carbon electrode modified by the nitrogen-doped porous graphene electrocatalyst prepared in Example 1 can obtain the desired electrode.

[0072] Preparation of commercial Pt / C modified glassy carbon electrode: Weigh 4 mg of commercial Pt / C (purchased from Johnson-Matthey, UK, with a mass ratio of 40%), drop 35 μL of 5wt% Nafion solution, and then disperse it in In ethanol with a volume of 1mL, ultrasonically disperse for 60min in an ultrasonic instrument with a frequency of 50KHz and a power of 150W to obtain a uniformly dispersed ink. Take 5μL of ink and drop-coat it on the surface of a glassy carbon electrode with a diameter of 5mm, and...

Embodiment 3

[0080] A heteroatom-doped porous graphene electrocatalyst, the specific preparation method is:

[0081] (1) synthesis of graphene oxide: same as embodiment 1;

[0082] (2) synthesis of graphene oxide with holes on the surface: same as embodiment 1;

[0083] (3) Graphene oxide with holes on the surface mixed with dibenzyl disulfide

[0084] 20mg of graphene oxide with holes on the surface prepared in step (2), 100mg of dibenzyl disulfide and ethanol were first ultrasonically mixed for 60min (frequency is 50KHz, power is 150W), and then stirred and mixed for 12h (stirring speed is 500r / min) , to obtain a coating solution with a concentration of 30% by mass, and then apply the coating solution to the surface of copper foil by scraping method, and freeze-dry (the temperature is -48°C, the drying time is 24h), and the obtained solution loaded on the substrate is Solid films of graphene oxide dibenzyl disulfide with pores on the surface;

[0085] (4) Plasma preparation of heteroa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com