Joint support and subchondral support system

a joint support and subchondral technology, applied in the field of joint support and subchondral support system, can solve the problems of inferior resultant material to native cartilage, large lesions, and unresolved diffuse diseases, and achieve the effect of enhancing the ability of trabecular bone to withstand and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

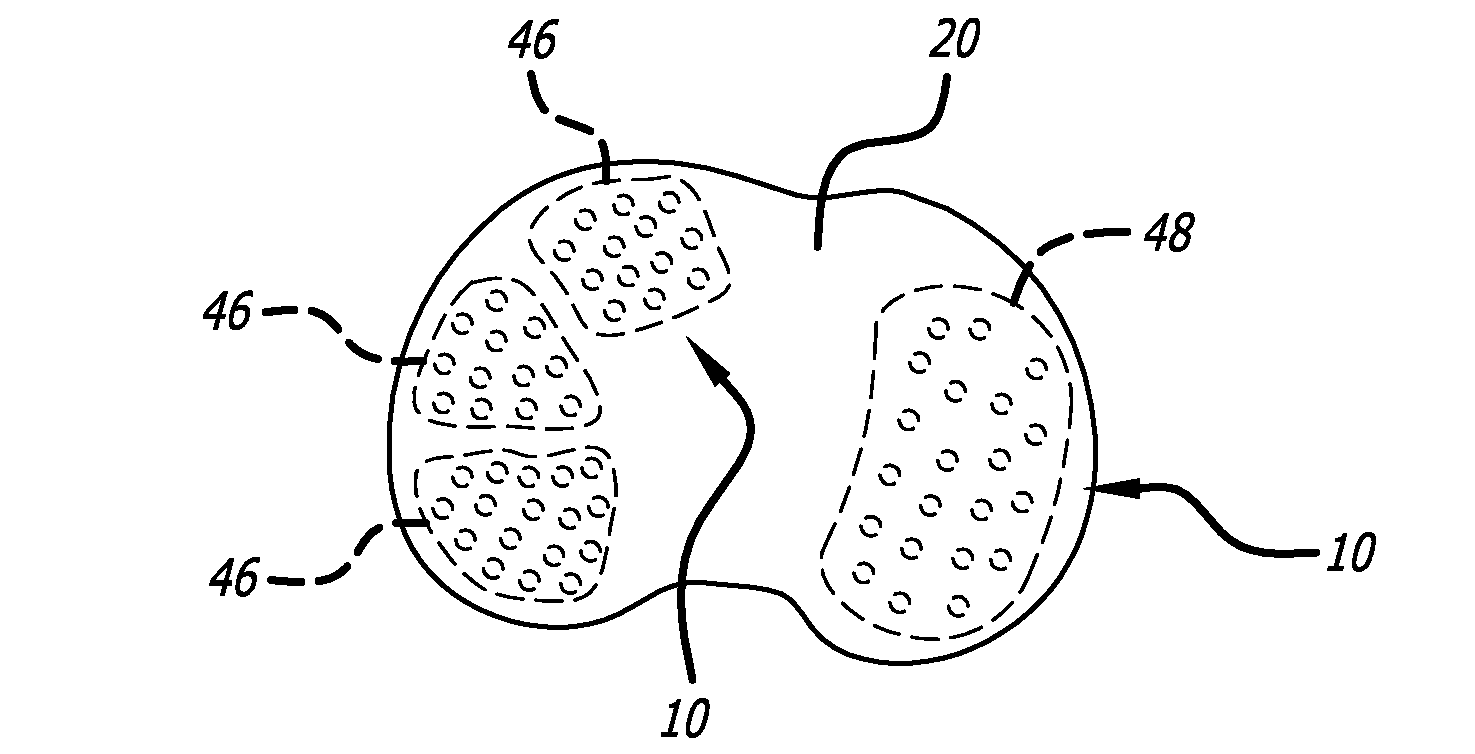

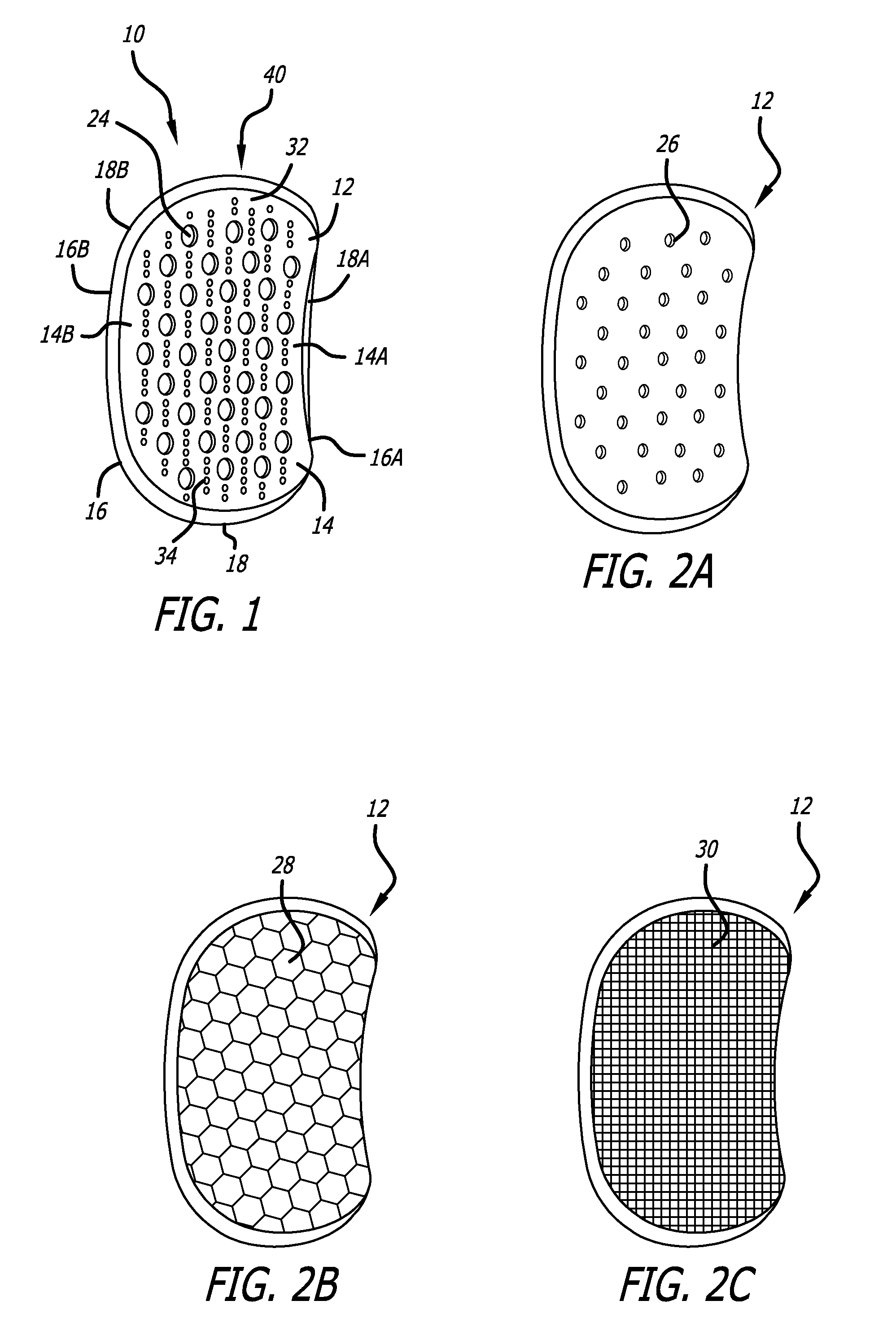

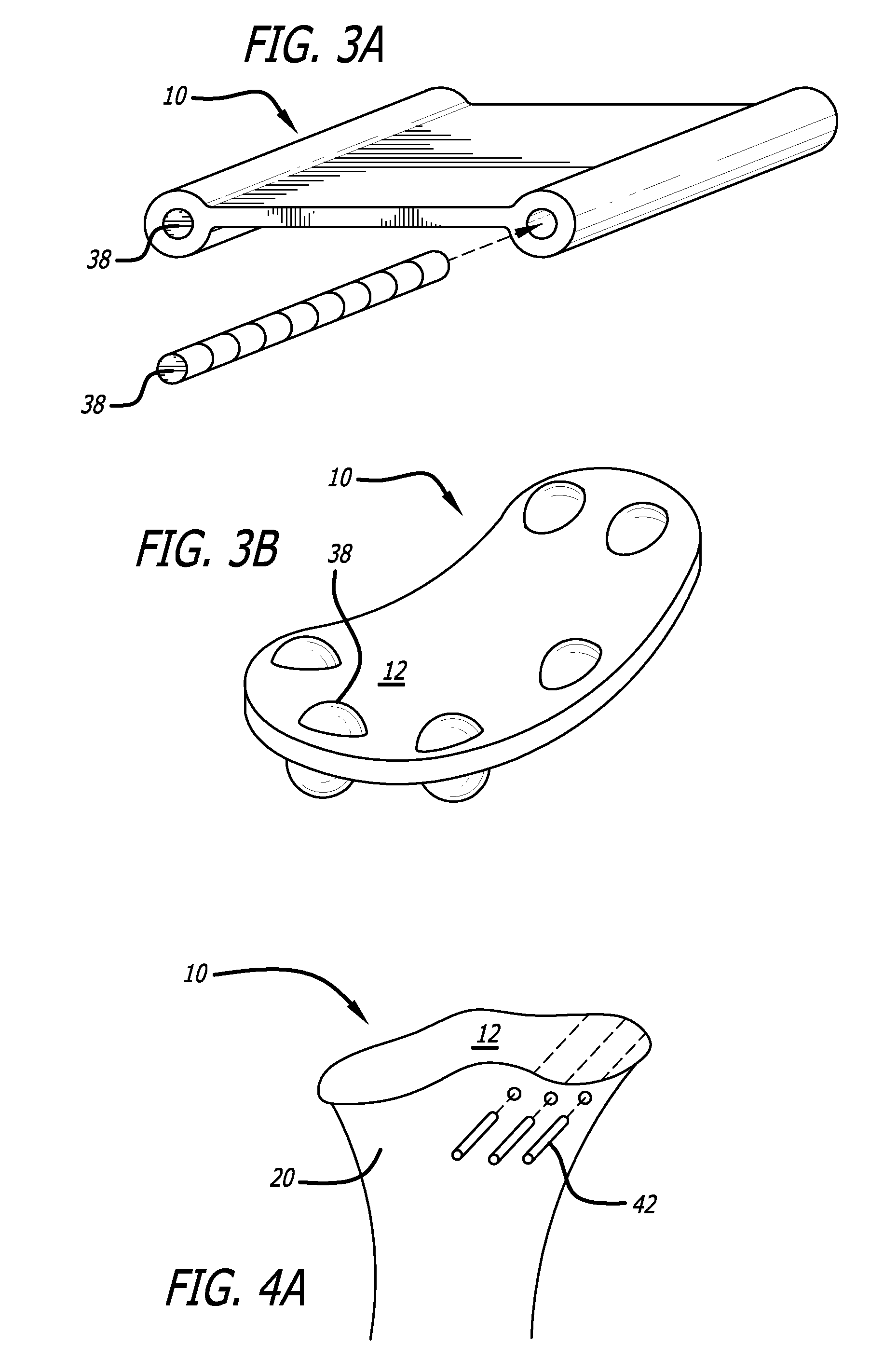

[0074]The joint support and subchondral support system or device 10 of the present invention is generally illustrated in FIG. 1. It is contemplated by the present invention that the joint support and subchondral support system is not a substitute for partial or total joint replacement, but may delay the need for joint replacement in active individuals with moderate osteoarthritis and / or arthroses. By sustaining subchondral bone homeostases, further joint deformity and disease progression may be delayed and / or avoided. The joint support and subchondral support system in accordance with the present invention enhances and reinforces the cartilage-bone complex in the presence of diseased cartilage or a cartilage defect. It treats the bony side of the equation by mechanical absorption of shear and compressive stresses that threaten cartilage-bone homeostasis.

[0075]A number of advantages of the joint support and subchondral support system in accordance with the present invention are evide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com