Patents

Literature

101 results about "Dielectric gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dielectric gas, or insulating gas, is a dielectric material in gaseous state. Its main purpose is to prevent or rapidly quench electric discharges. Dielectric gases are used as electrical insulators in high voltage applications, e.g. transformers, circuit breakers (namely sulfur hexafluoride circuit breakers), switchgear (namely high voltage switchgear), radar waveguides, etc.

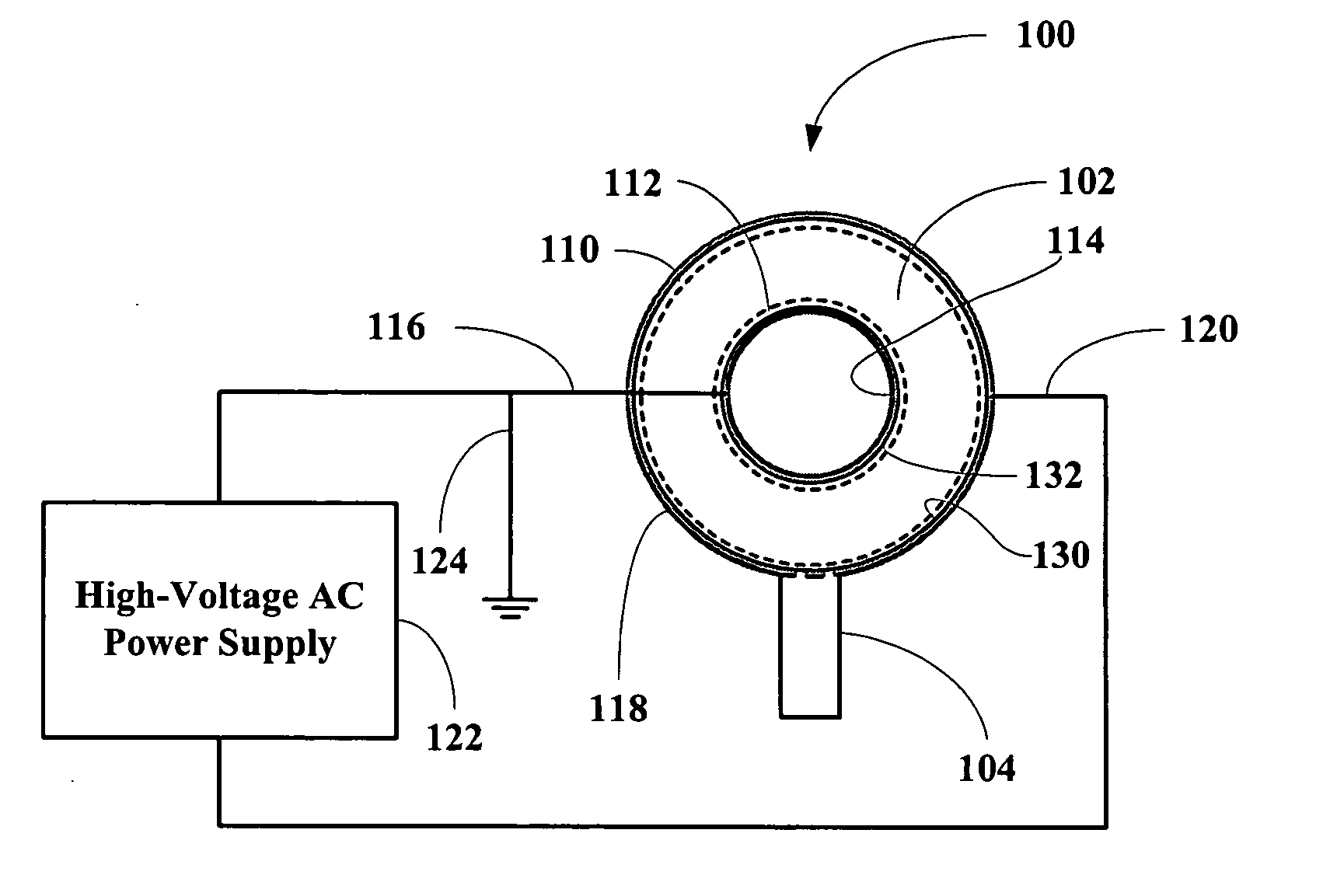

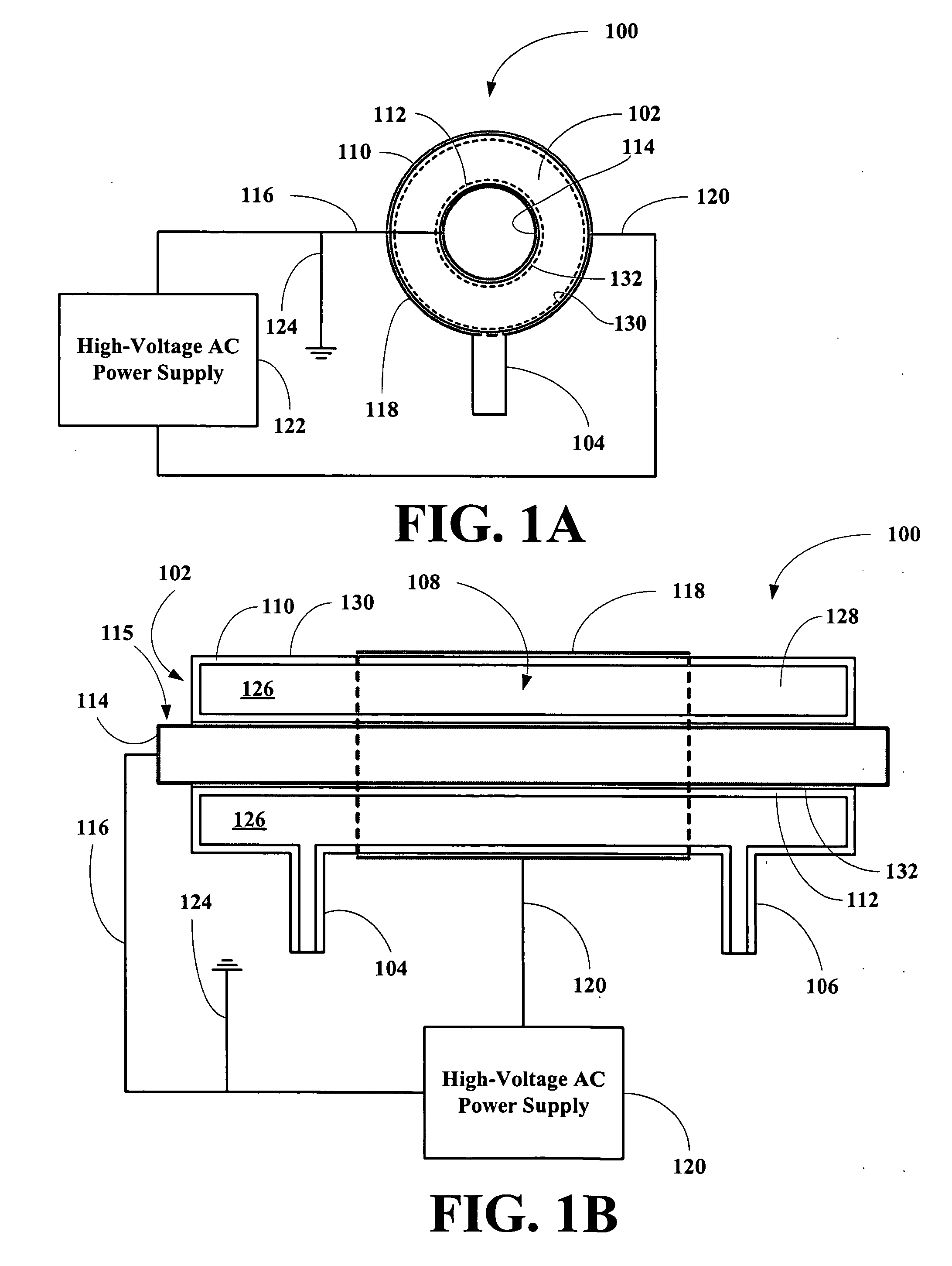

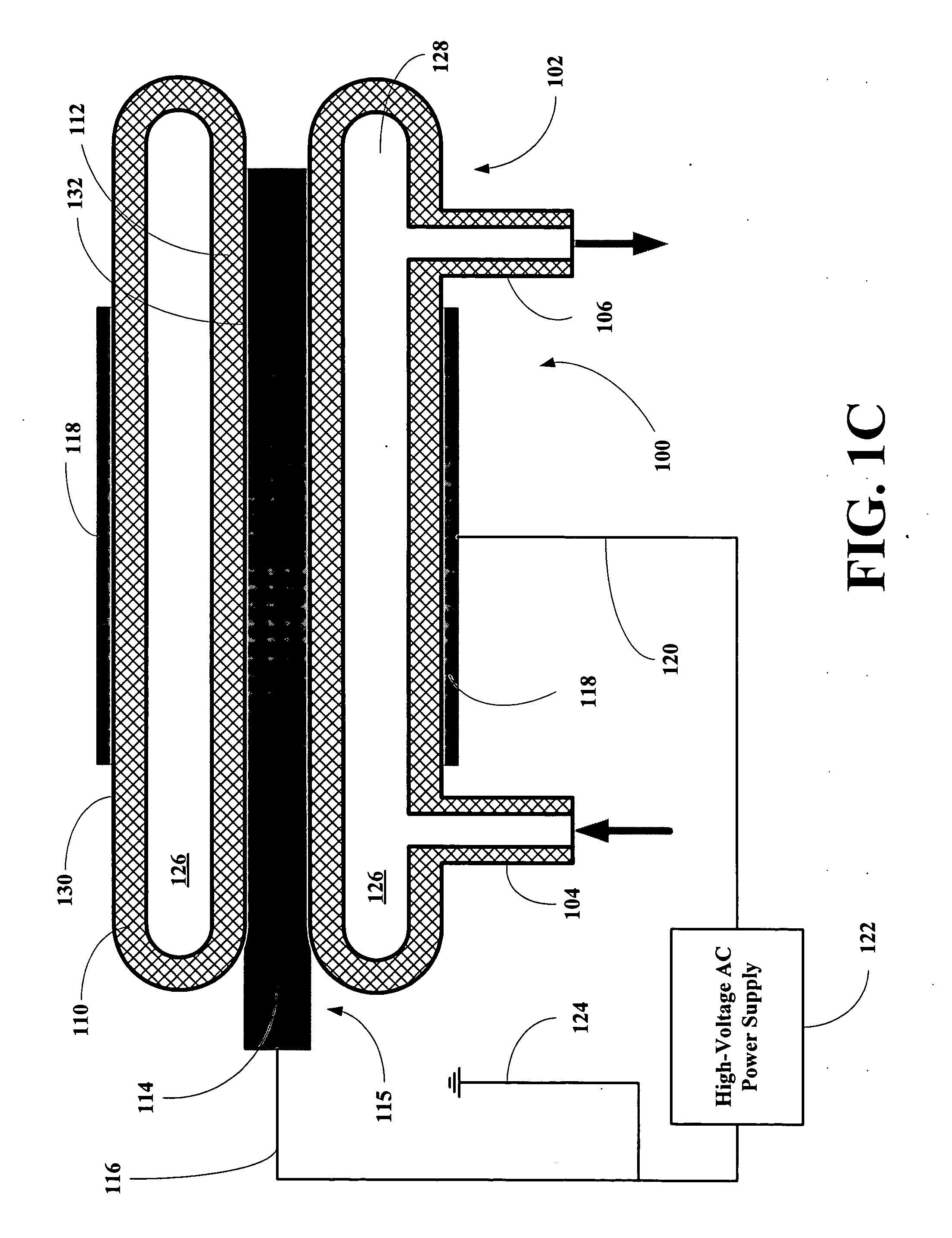

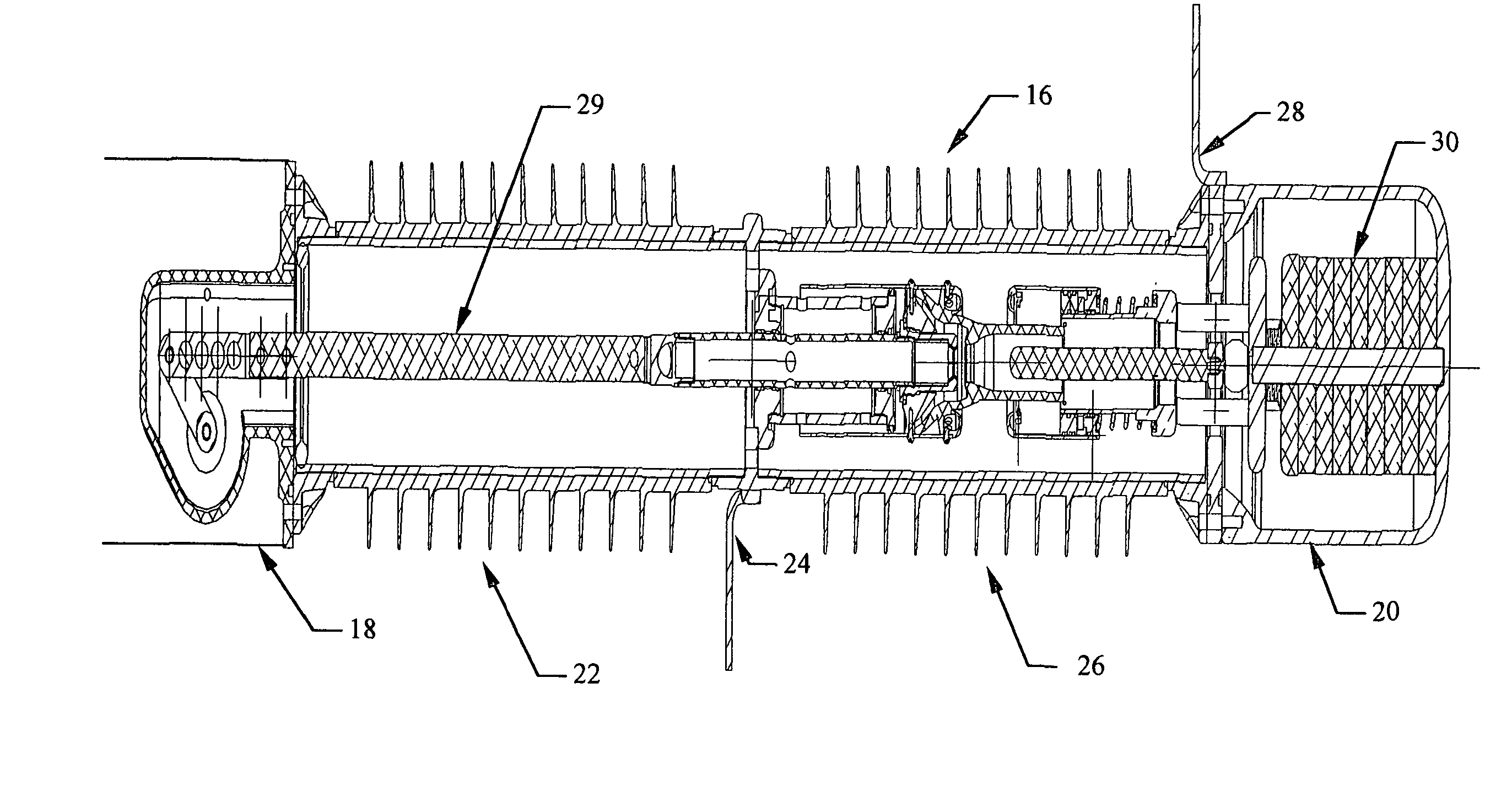

Ozone generator with dual dielectric barrier discharge and methods for using same

InactiveUS20050199484A1Electrical discharge ozone preparationEnergy based chemical/physical/physico-chemical processesPush pullEngineering

A new and novel ozone generator with a dual dielectric barrier discharge design is disclosed where high-purity ozone is generated and whose concentration can be varied over a wide range. The simplified design of the ozone generator cell possesses a gas inlet and outlet connected to an annular, sealed dielectric gas envelope that supports both inner and outer electrodes that do not come into contact with the gas. The design eliminates the need for gaskets, o-rings or other methods applied to seal the ozone cell and reduces problems associated with potential interaction resulting from material compatability issues. The applied high voltage is provided by a simple self-resonating, push-pull oscillating circuit whose efficiency is optimized through application of an appropriate impedance matching device. The ozone is concentration is adjusted by varying the pulse width duty cycle of the applied voltage and gas flow rate. The design configuration of the ozone generating cell also eliminates the need for forced air or liquid cooling by natural convective air currents and conductive means.

Owner:OLSTOWSKI FRANEK

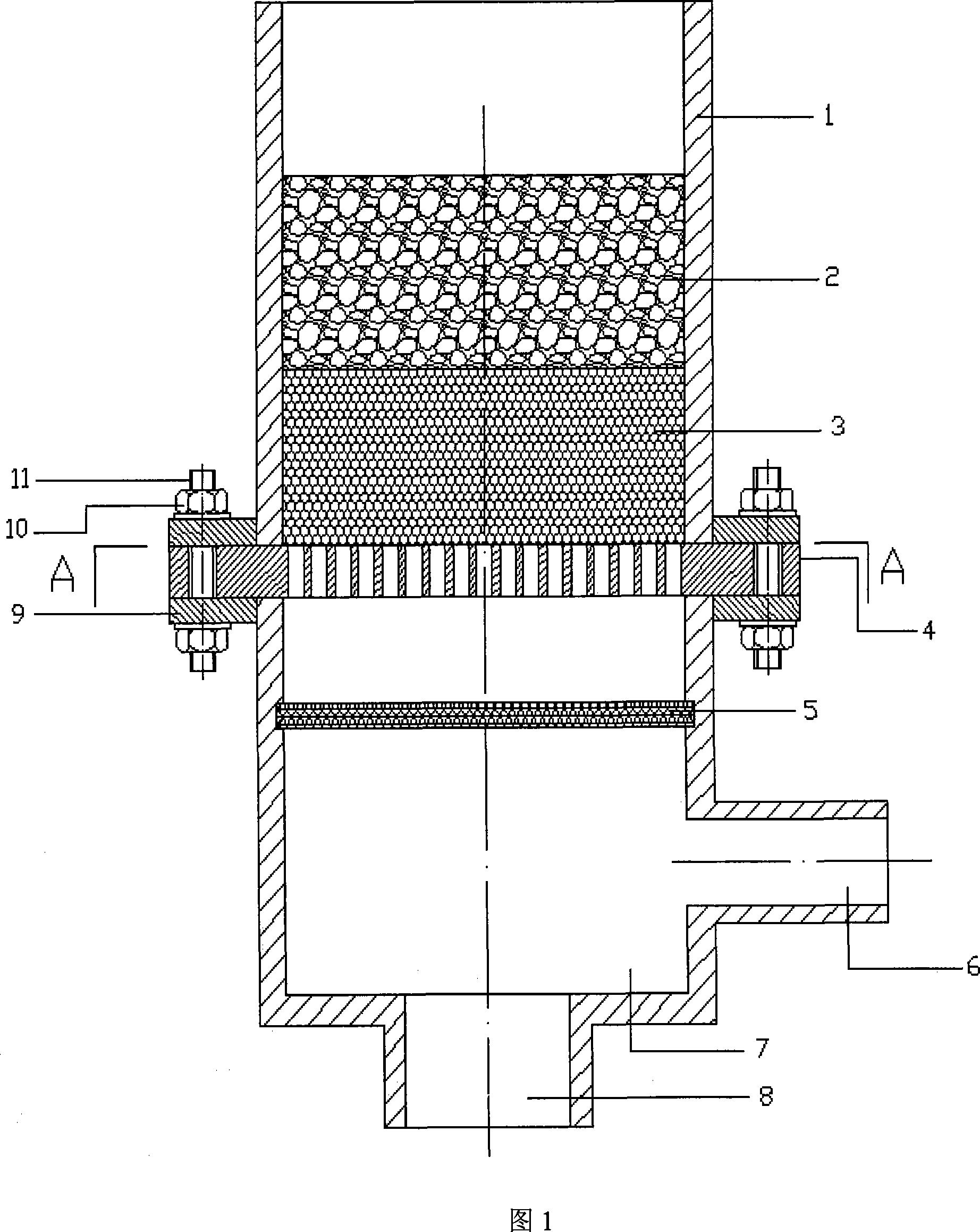

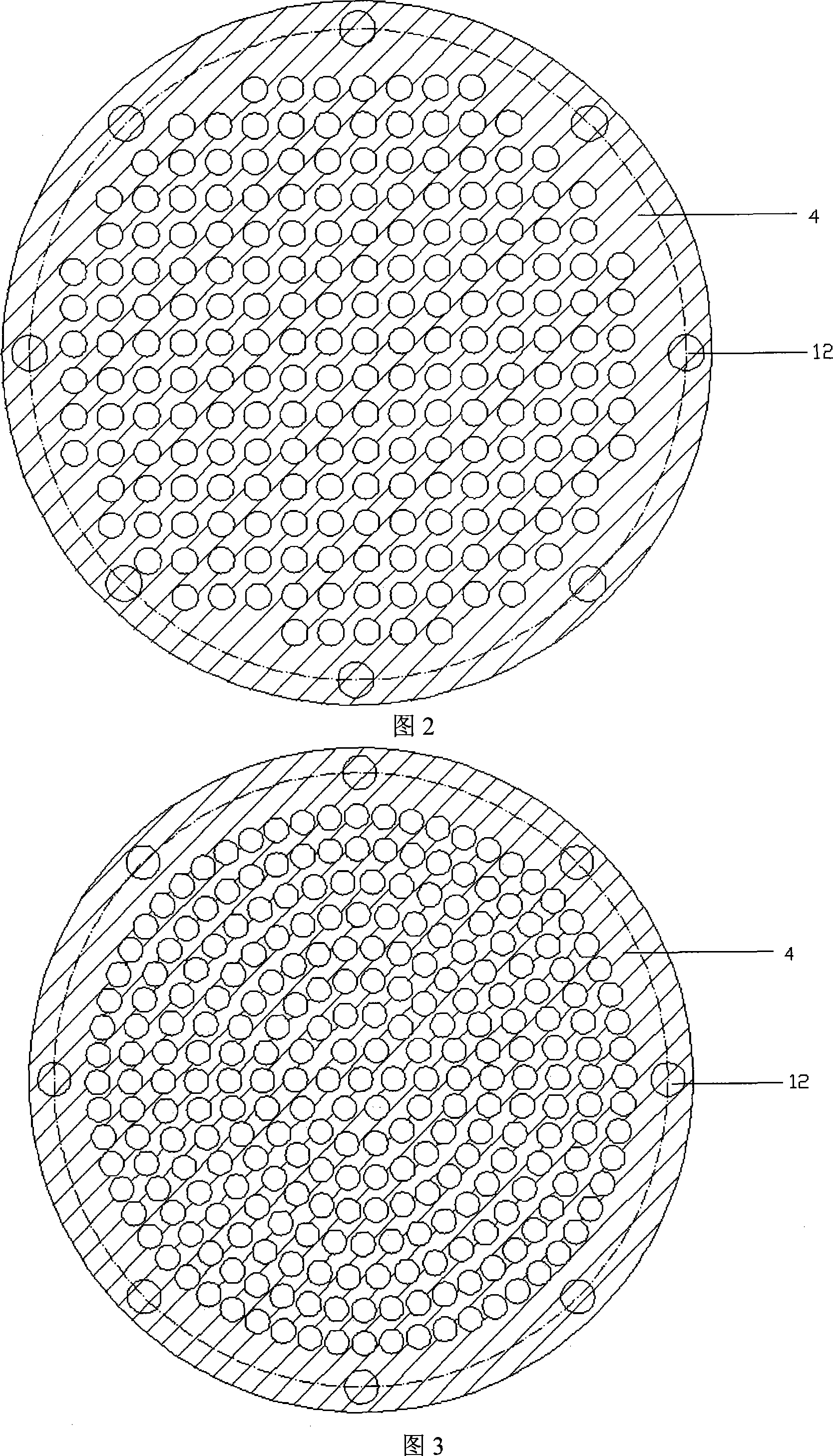

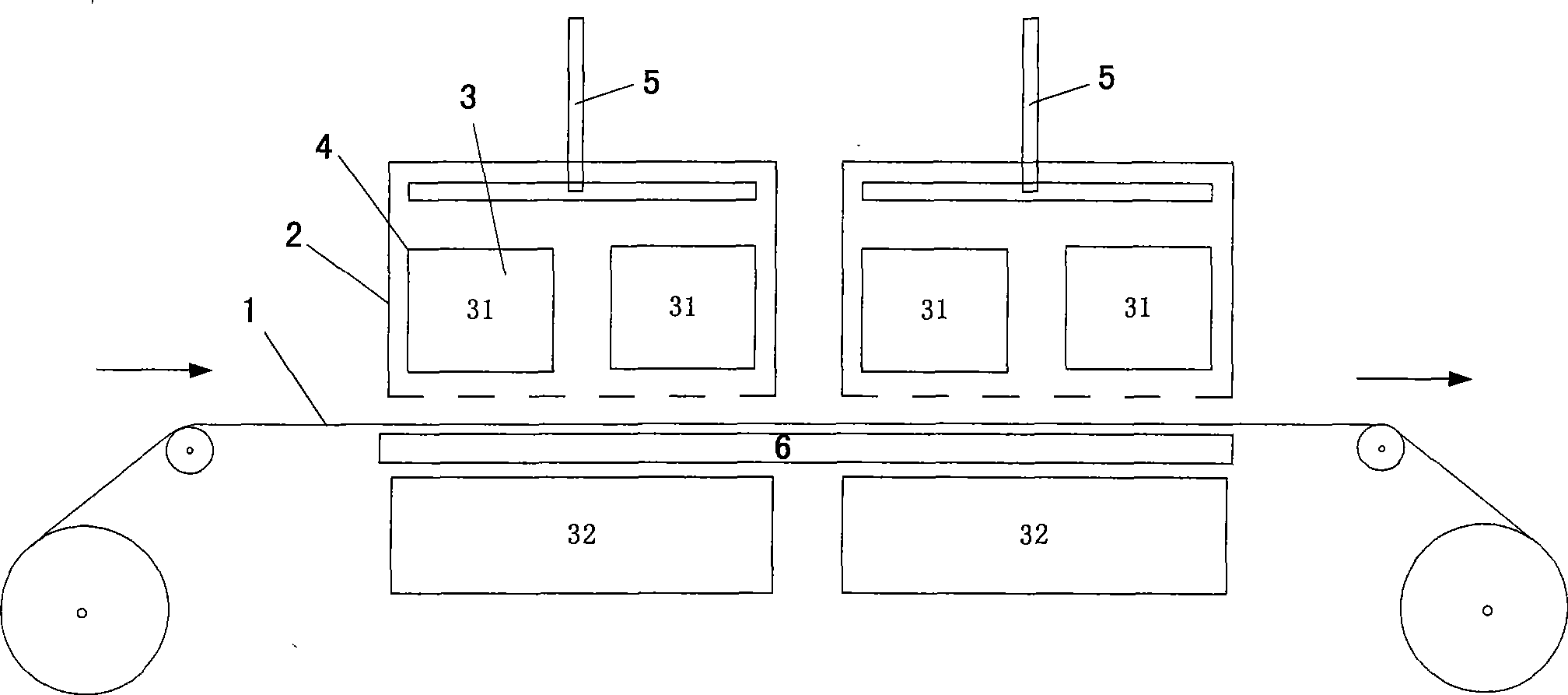

Sectional type porous ceramic dielectric gas fuel combusting device

InactiveCN101158469AImprove securityWide calorific value rangeGaseous fuel burnerDielectricCombustor

The invention relates to a multi-stage multi-aperture ceramic dielectric gas fuel inflamer which includes an inflamer shell, a dust-removing wire netting or a metal brush, an air pipeline, a premixing chamber and a fuel gas pipeline. The invention is mainly characterized in that the inflamer shell is divided into an upper part and a lower part with a multi-aperture plate as a boundary. The inner part of the empty cavity at the upper part of the inflamer shell is sequentially provided with a ceramic multi-aperture dielectric of the large-aperture area which is arranged above a ceramic multi-aperture dielectric of the small-aperture area and the ceramic multi-aperture dielectric of the small-aperture area is arranged on the multi-aperture plate. The dust-removing wire netting or the metal brush is arranged under the multi-aperture plate and in the inflamer shell. The multi-aperture plate is imbedded into the middle of the upper and lower parts of the inflamer shell. The surrounding of the multi-aperture plate extends to the outside of the inflamer shell. The invention has the advantage that the multi-stage multi-aperture ceramic dielectric gas fuel inflamer has a higher thermal value range, thereby both the gas of a low thermal value or bum gas fuel and the gas of a higher thermal value can be burnt. The multi-aperture plate added in the inflamer has played a good role of radiating and can effectively prevent backfire or explosion.

Owner:NORTHEASTERN UNIV

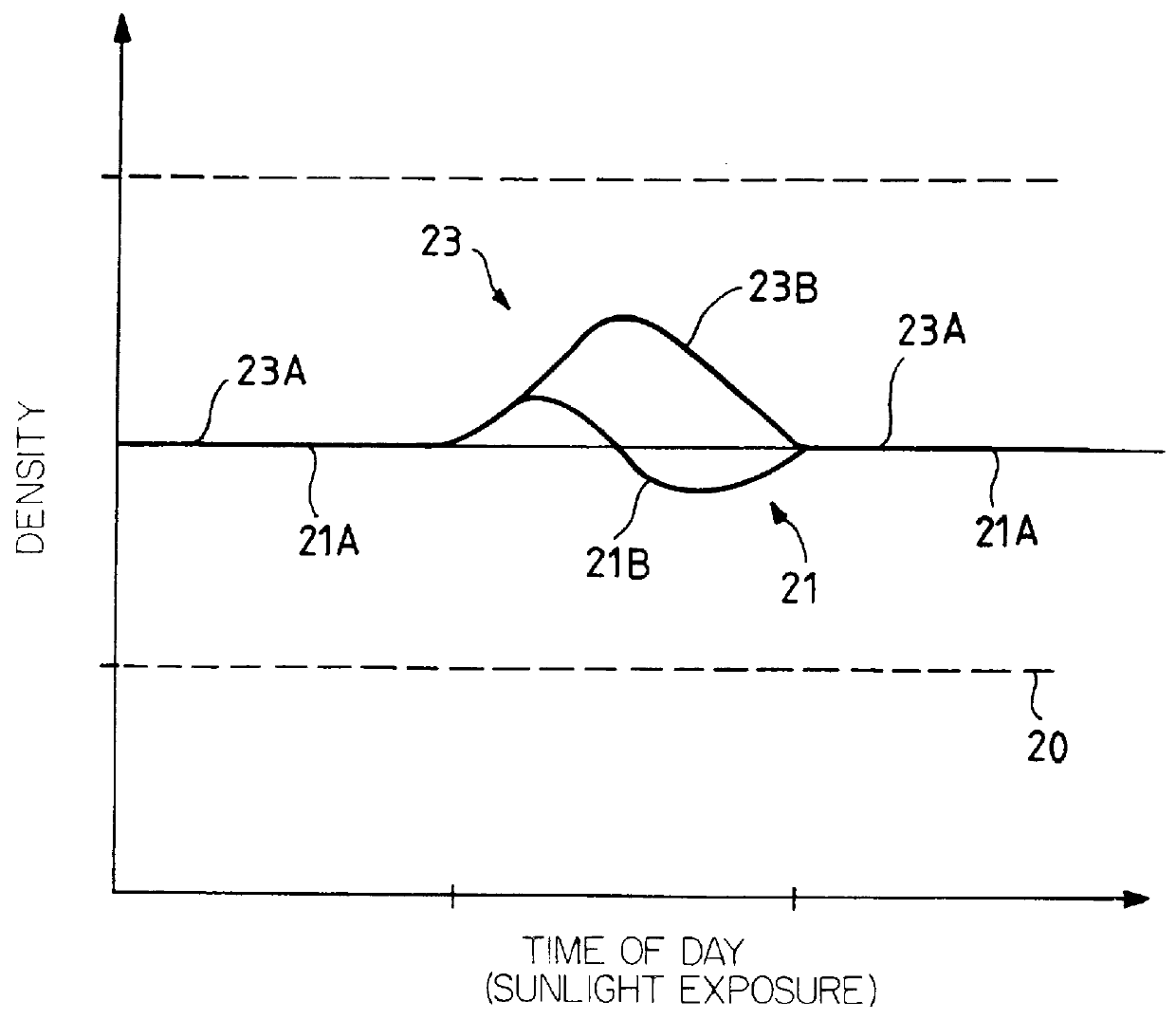

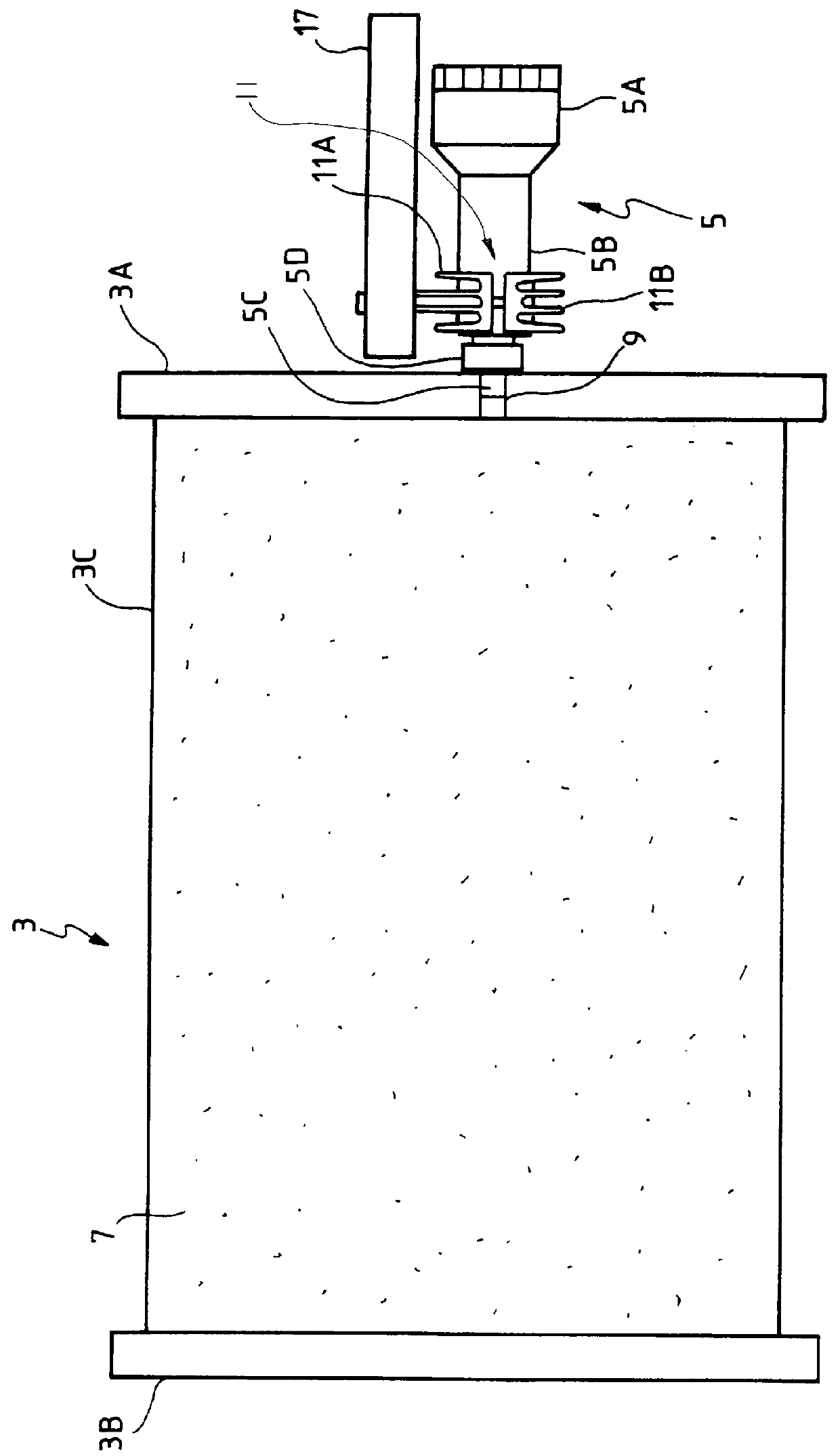

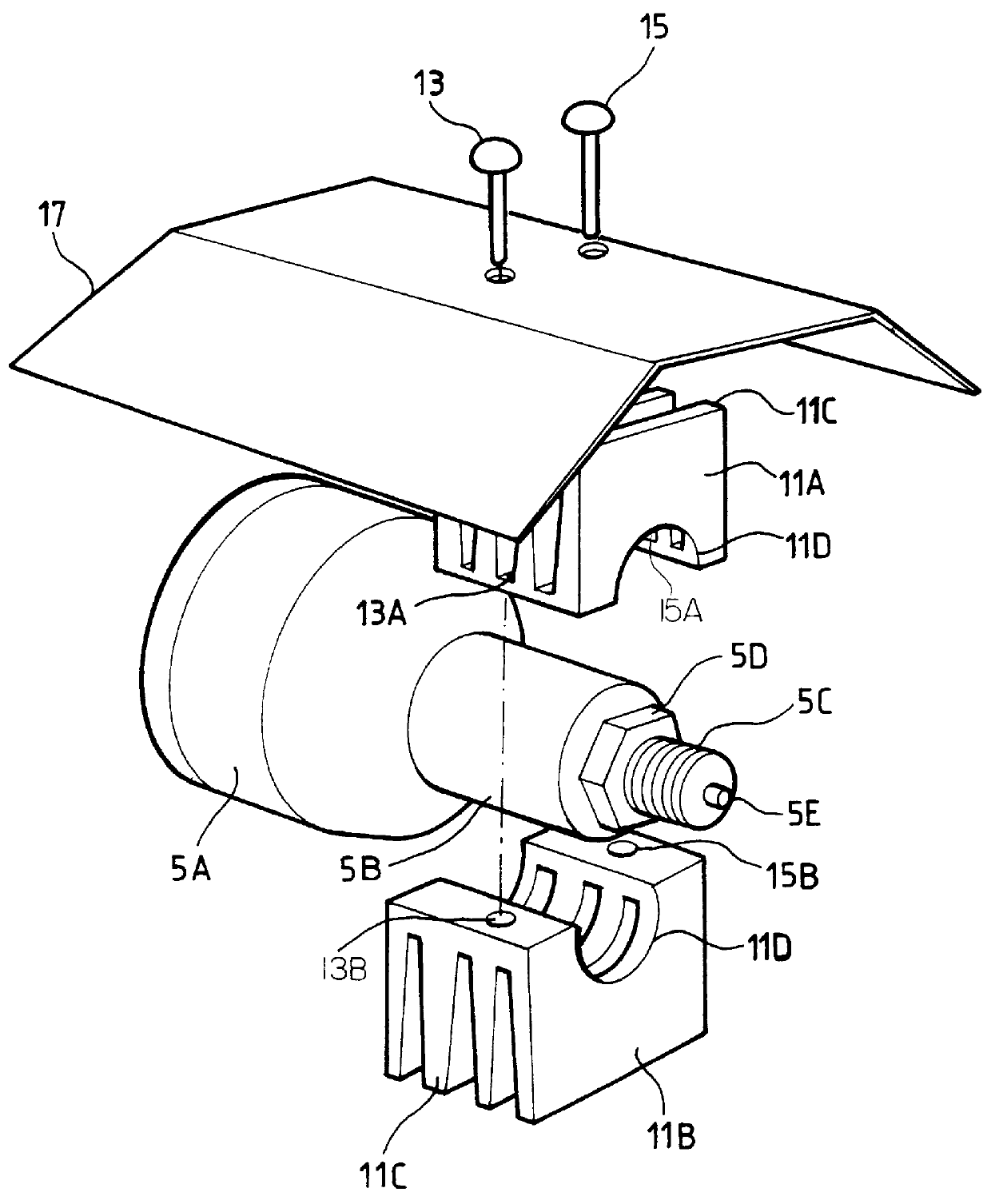

Density sensor for monitoring the rate of leakage from a switchgear case with improved reliability

InactiveUS6125692AImprove reliabilityThermometer detailsAnalysing fluids using sonic/ultrasonic/infrasonic wavesEngineeringSwitchgear

A density sensor for monitoring a rate of leakage from the case of electrical switchgear filled with dielectric gas under pressure, the sensor comprising a fixing support mounted from the outside in the thickness of the case and communicating with the dielectric gas. A radiator is placed around the fixing support of the density sensor, thereby enabling a measurement artifact that is due to the exposure of the case and of the sensor to solar radiation to be transformed in such a manner that any risk of untimely crossing of a low density threshold is eliminated.

Owner:GEC ALSTHOM T & D SA +1

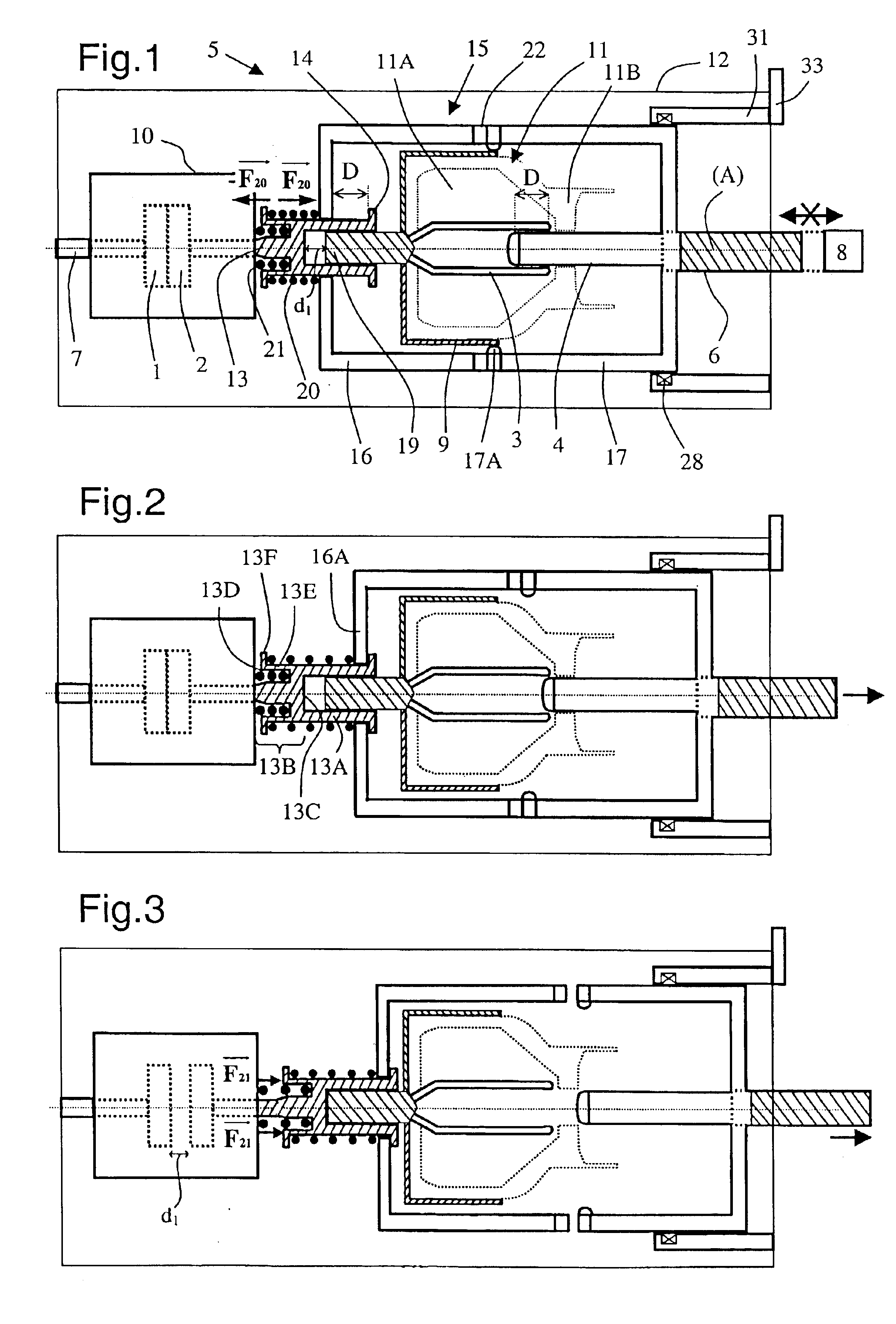

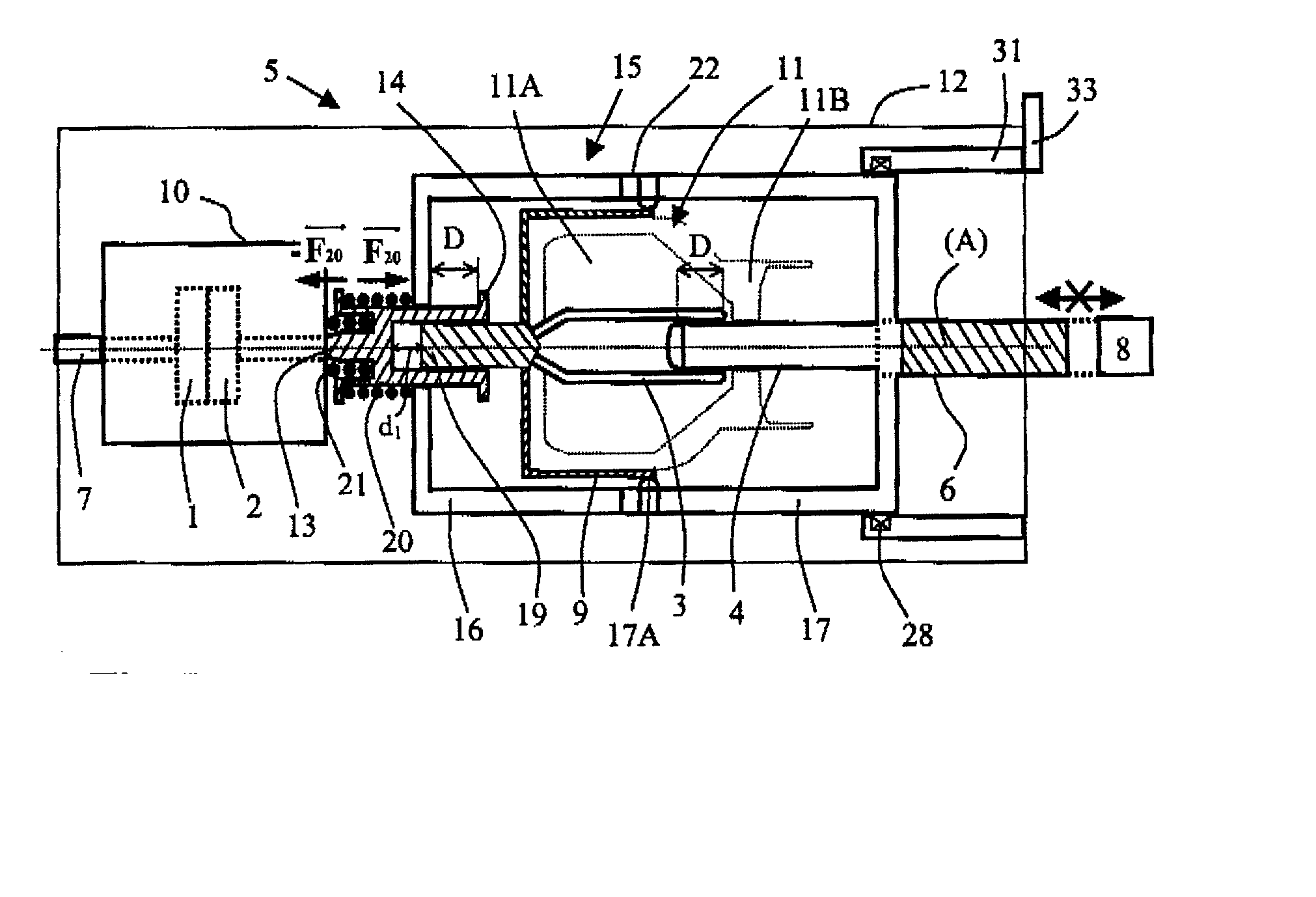

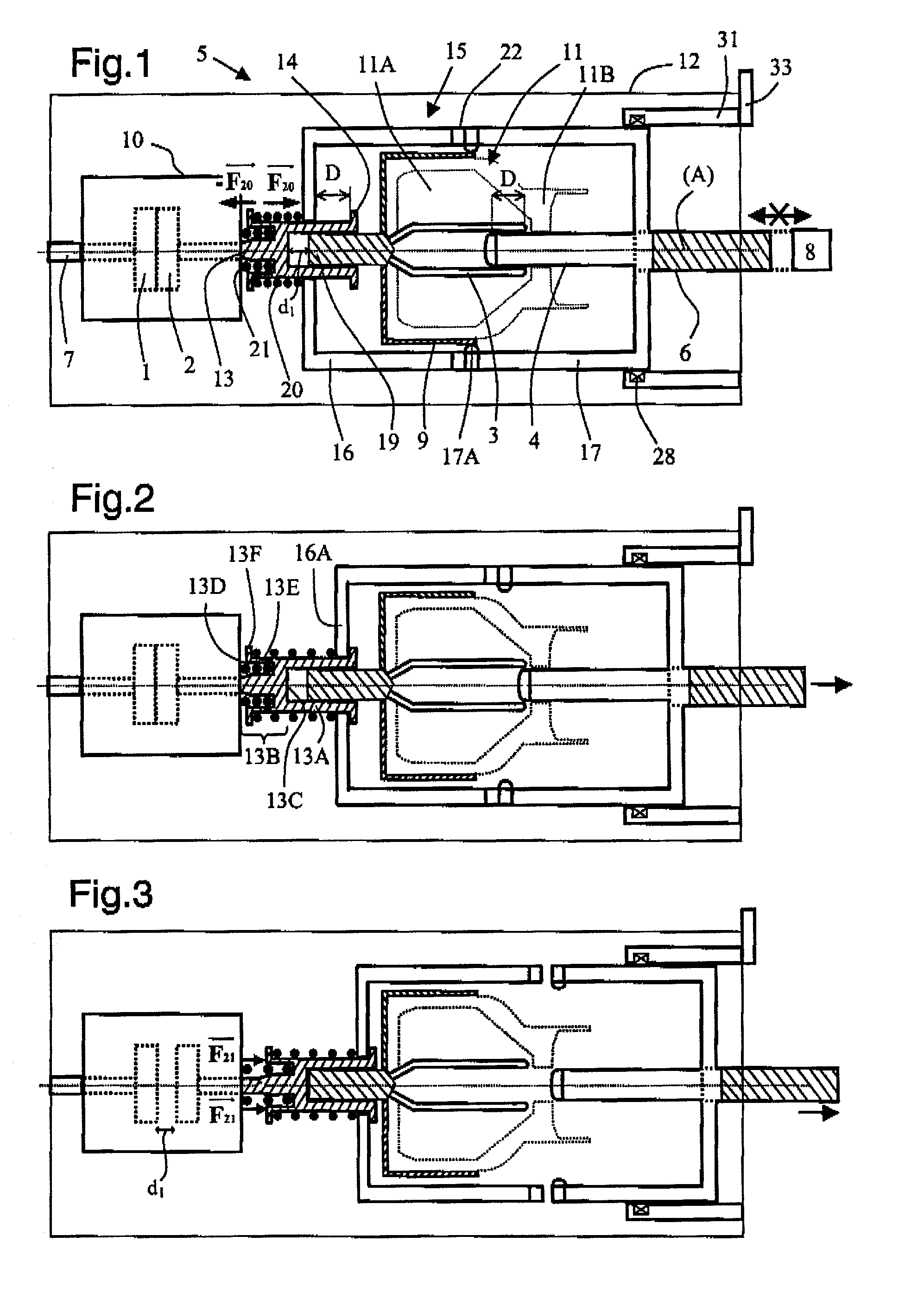

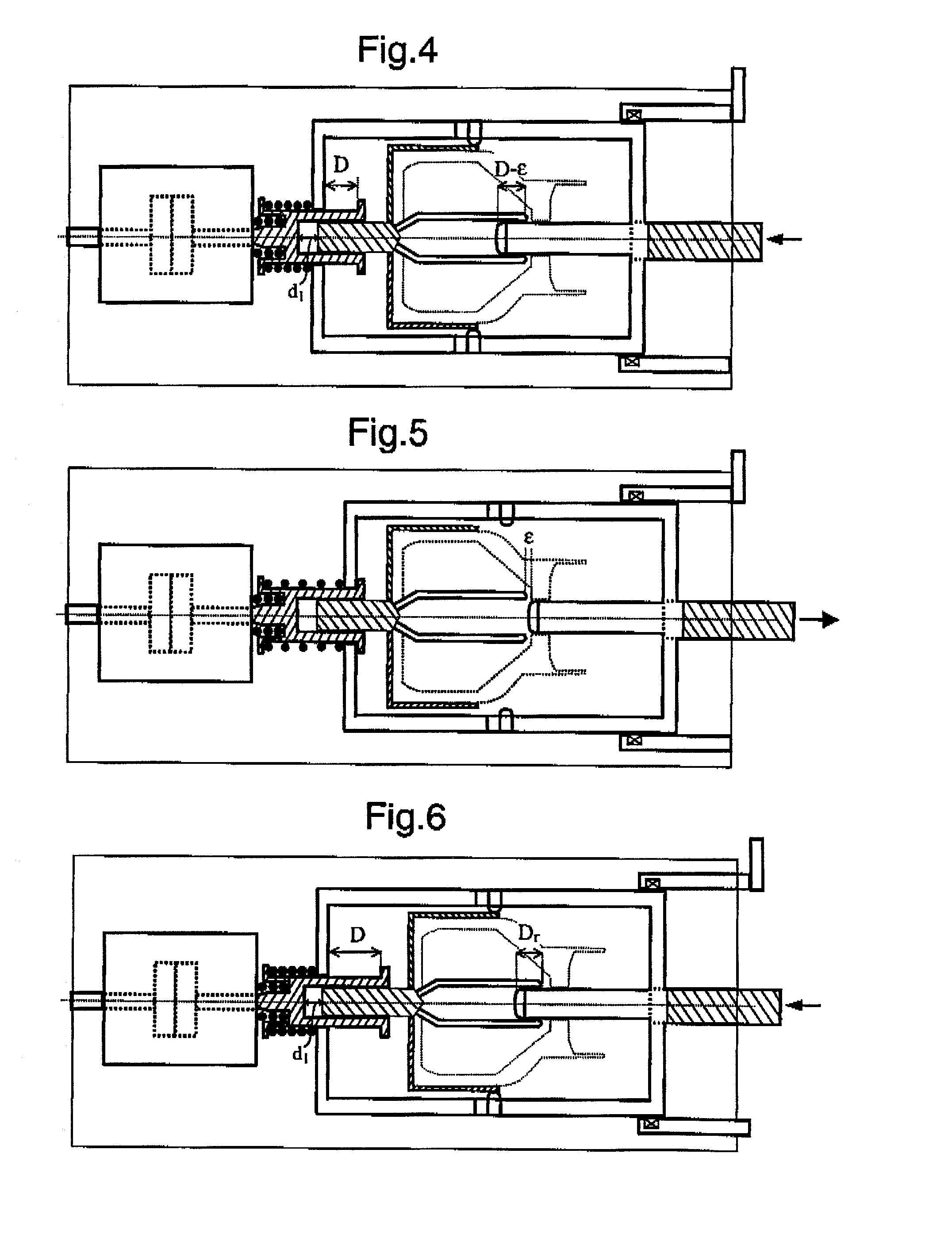

High-voltage interrupter device having combined vacuum and gas interruption

InactiveUS6593538B2High-tension/heavy-dress switchesAir-break switchesHigh voltageVacuum interrupter

Owner:ALSTOM TECH LTD

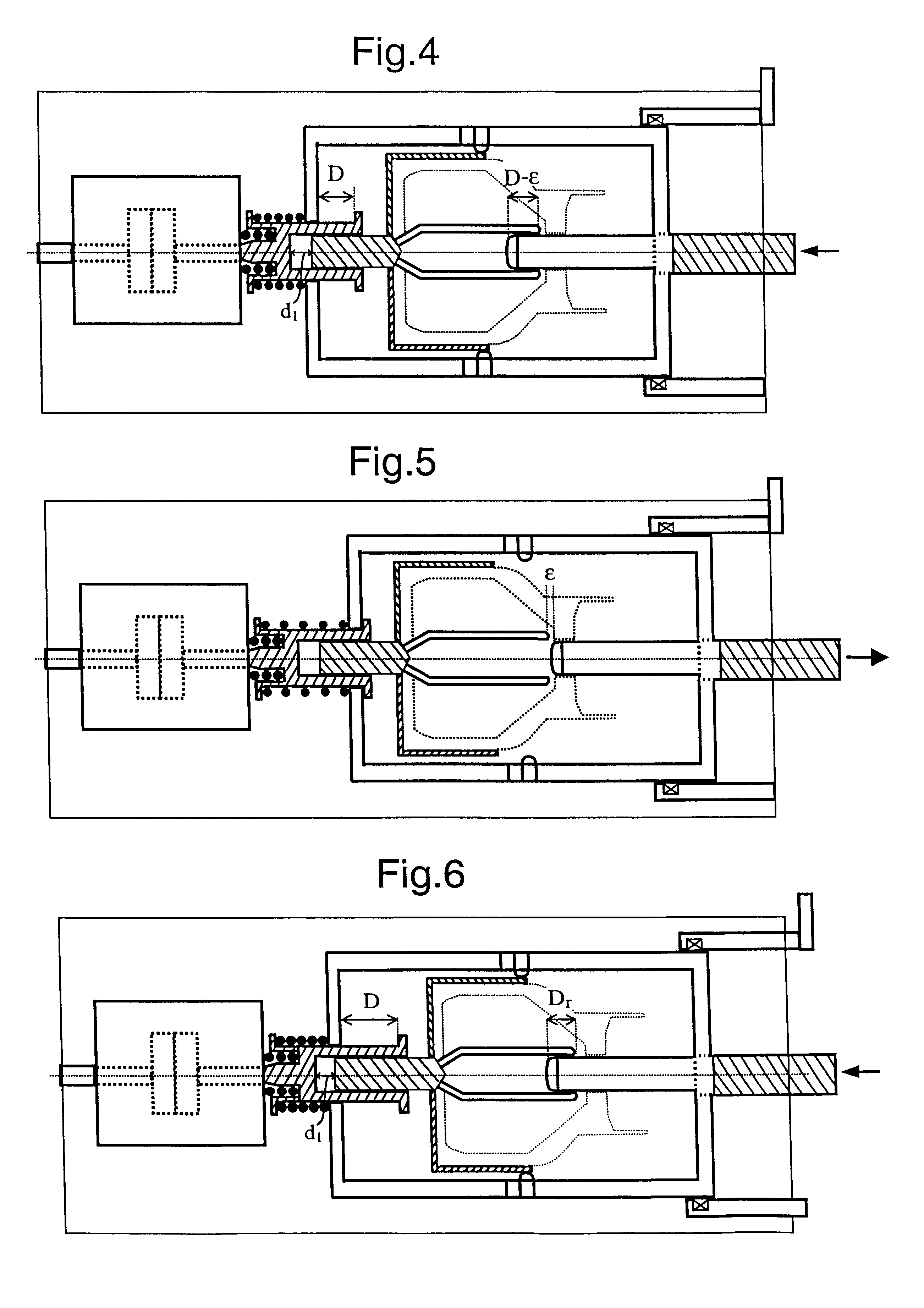

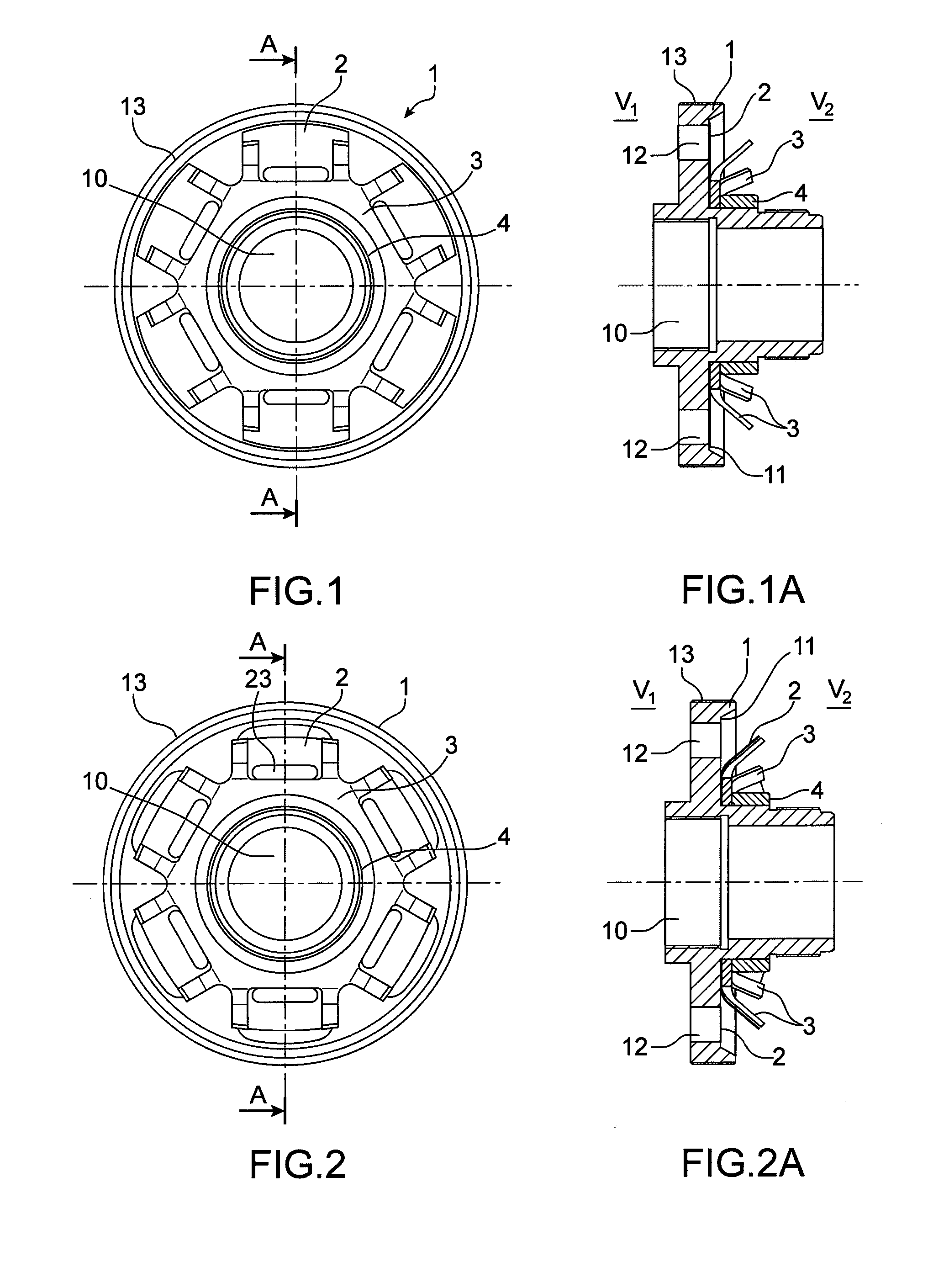

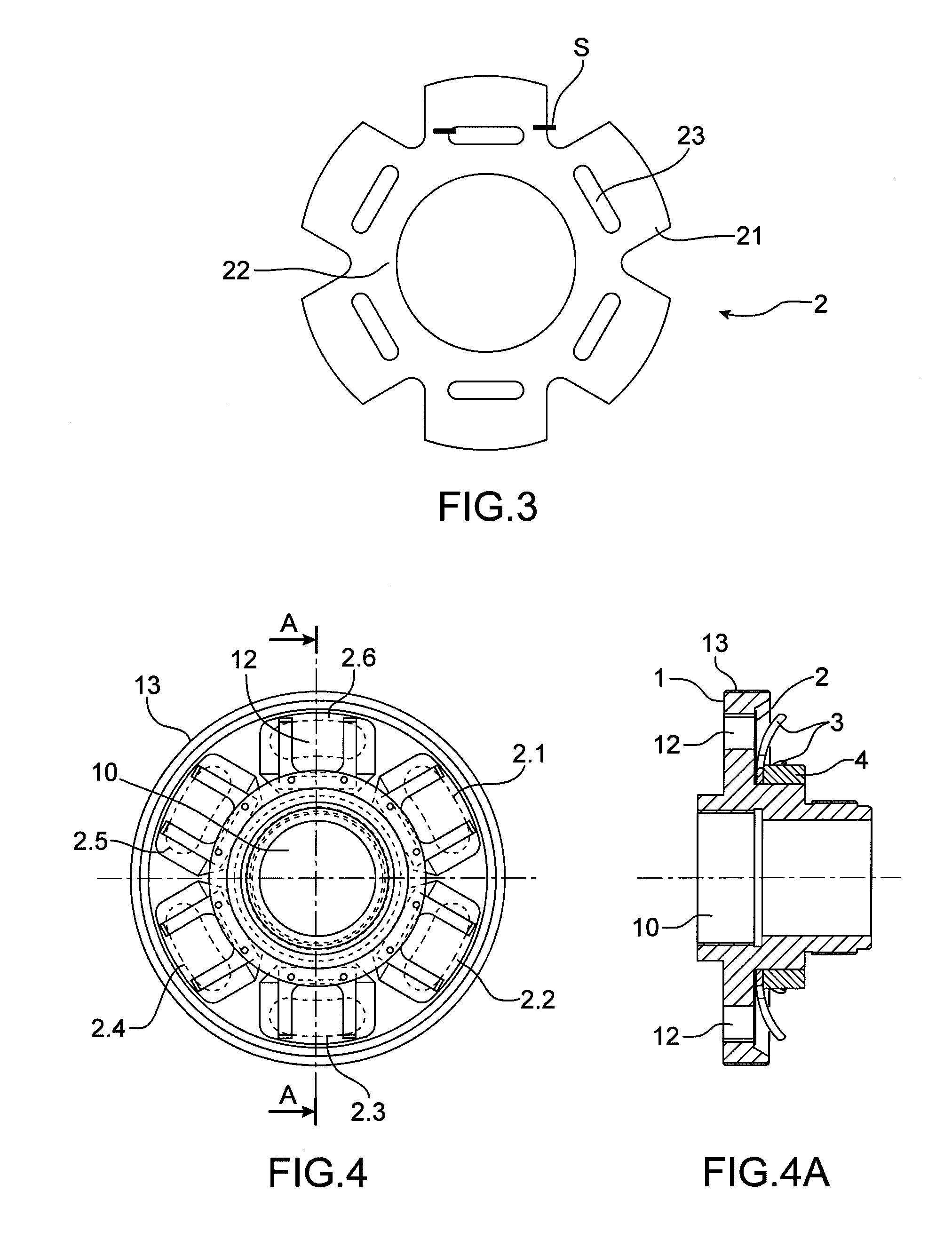

Relief valve for discharging a dielectric gas between two volumes of a high-voltage or medium-voltage interrupting chamber

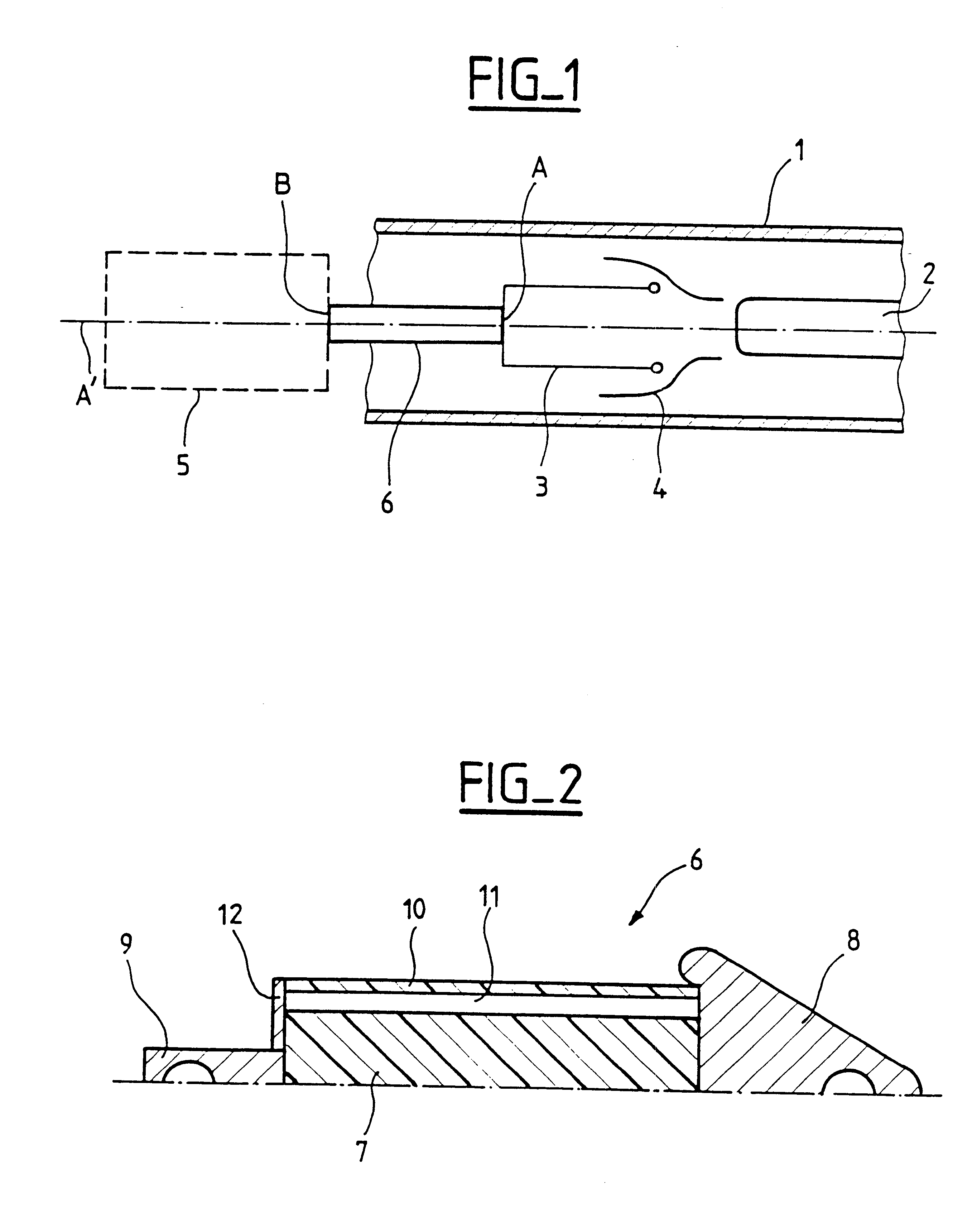

A relief valve for discharging a dielectric gas between two volumes (V1, V2) of a high-voltage or medium-voltage interrupting chamber. There is used as a closure member a flexible metal blade secured to the body, the closure member therefore being opened by deformation of the flexible blade from a closed position (FIG. 1) in which it is pressed against a closure member seat formed in the body to a fully open position in which it fits closely against a stop member secured to the valve body whilst remaining within its elastic limit, the open passage for the gas being open in this fully open position (FIG. 1A) and the return of the blade from its fully open position to its closed position being possible because of its flexibility.

Owner:ALSTOM TECH LTD

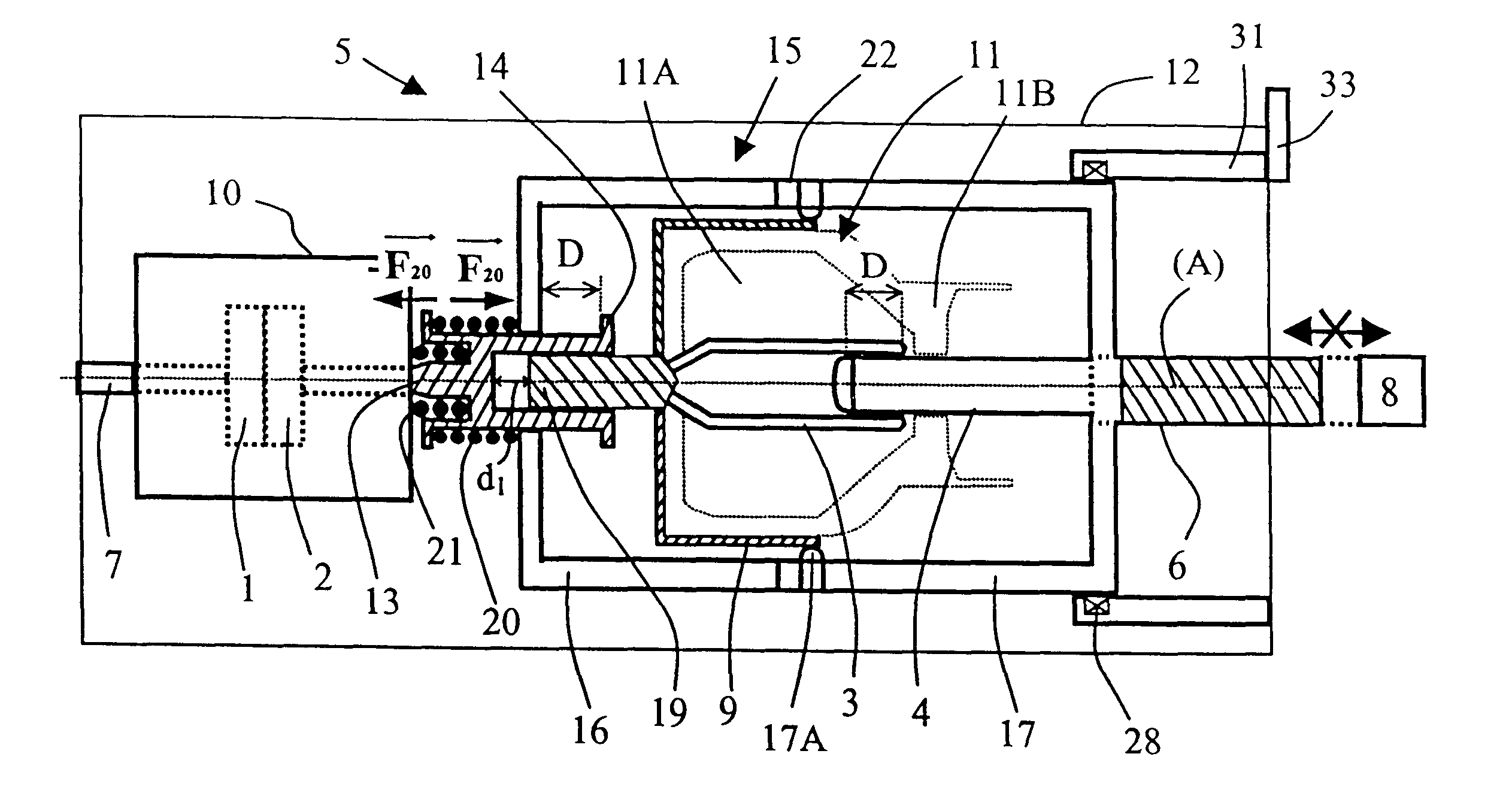

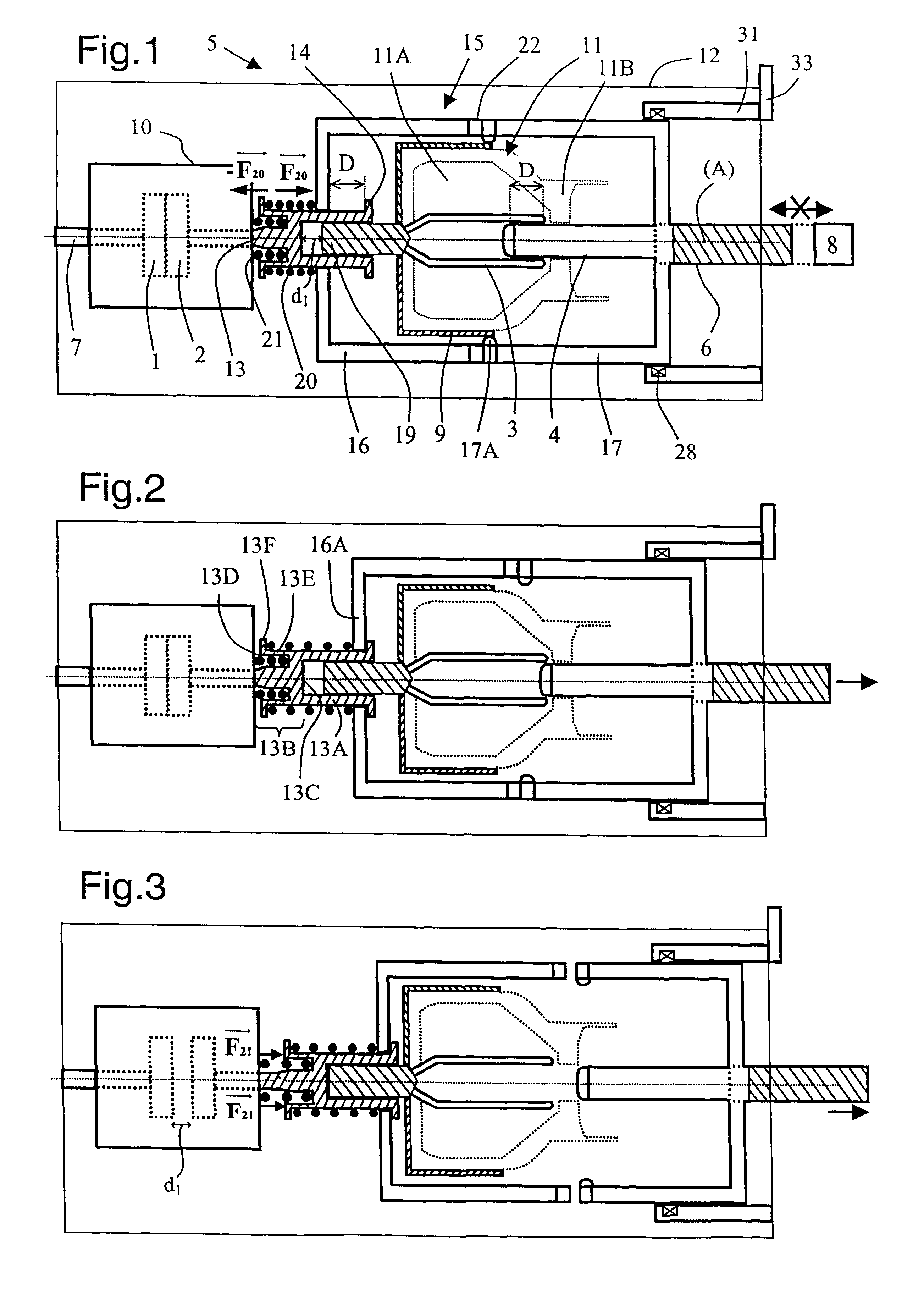

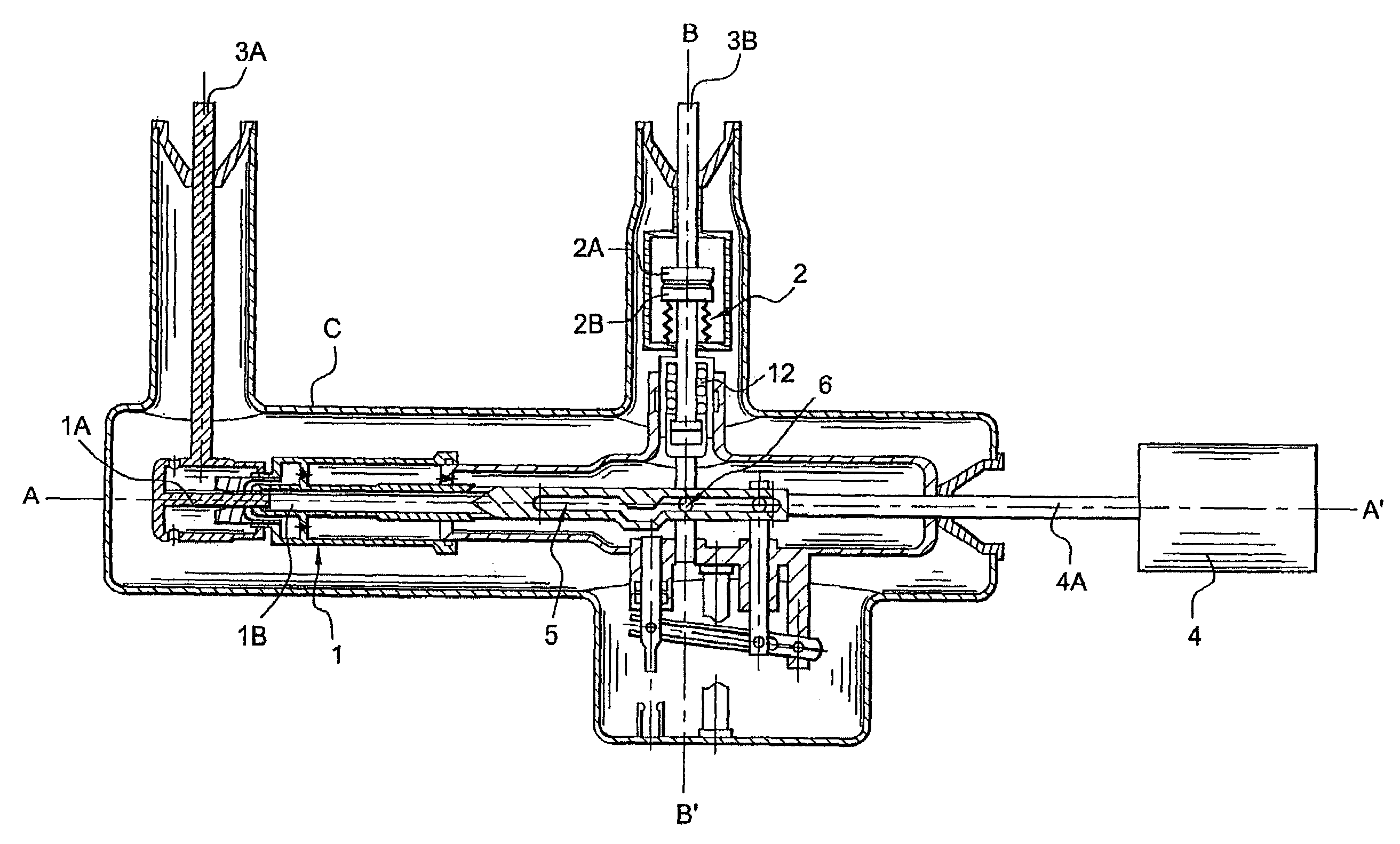

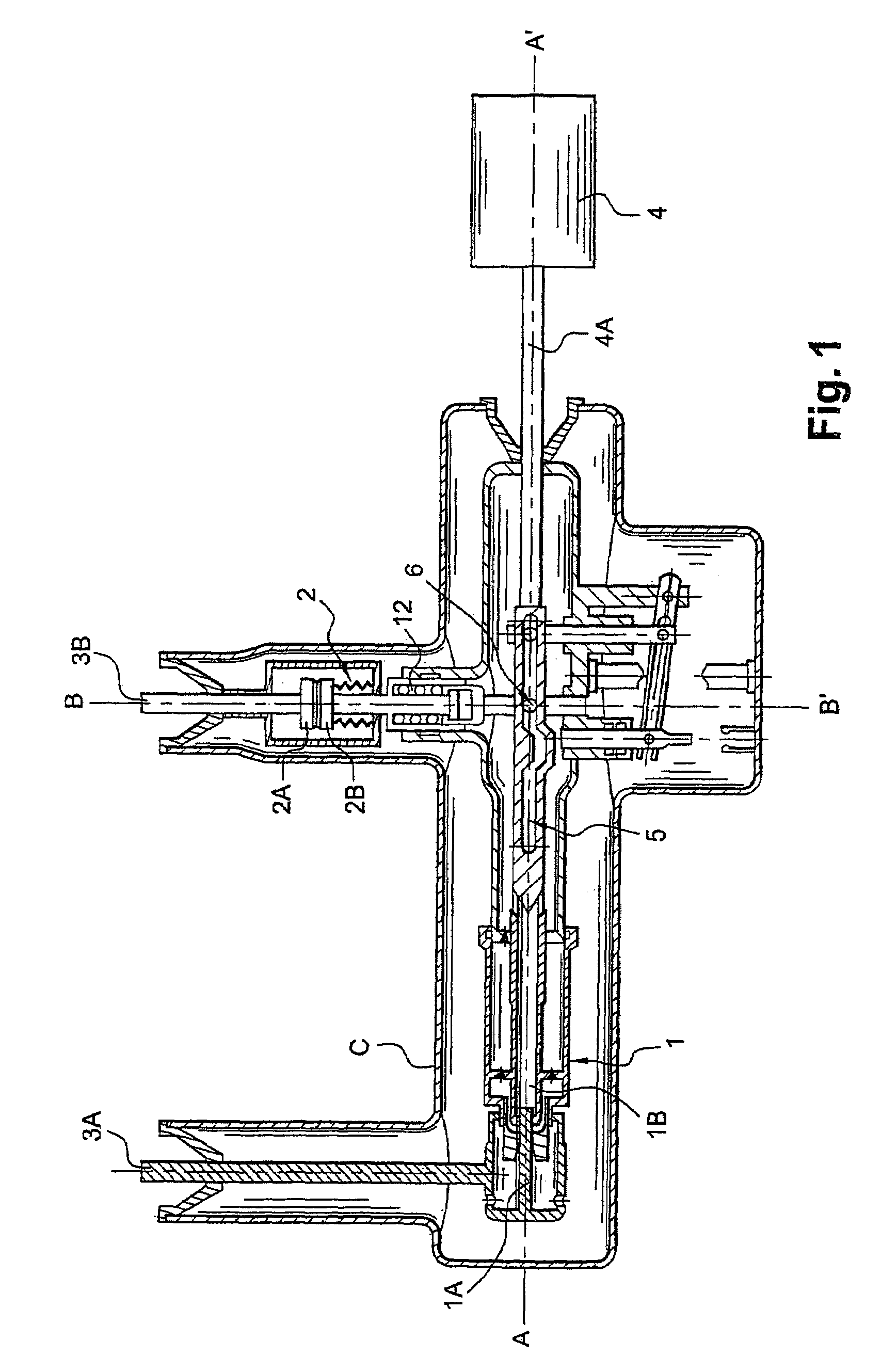

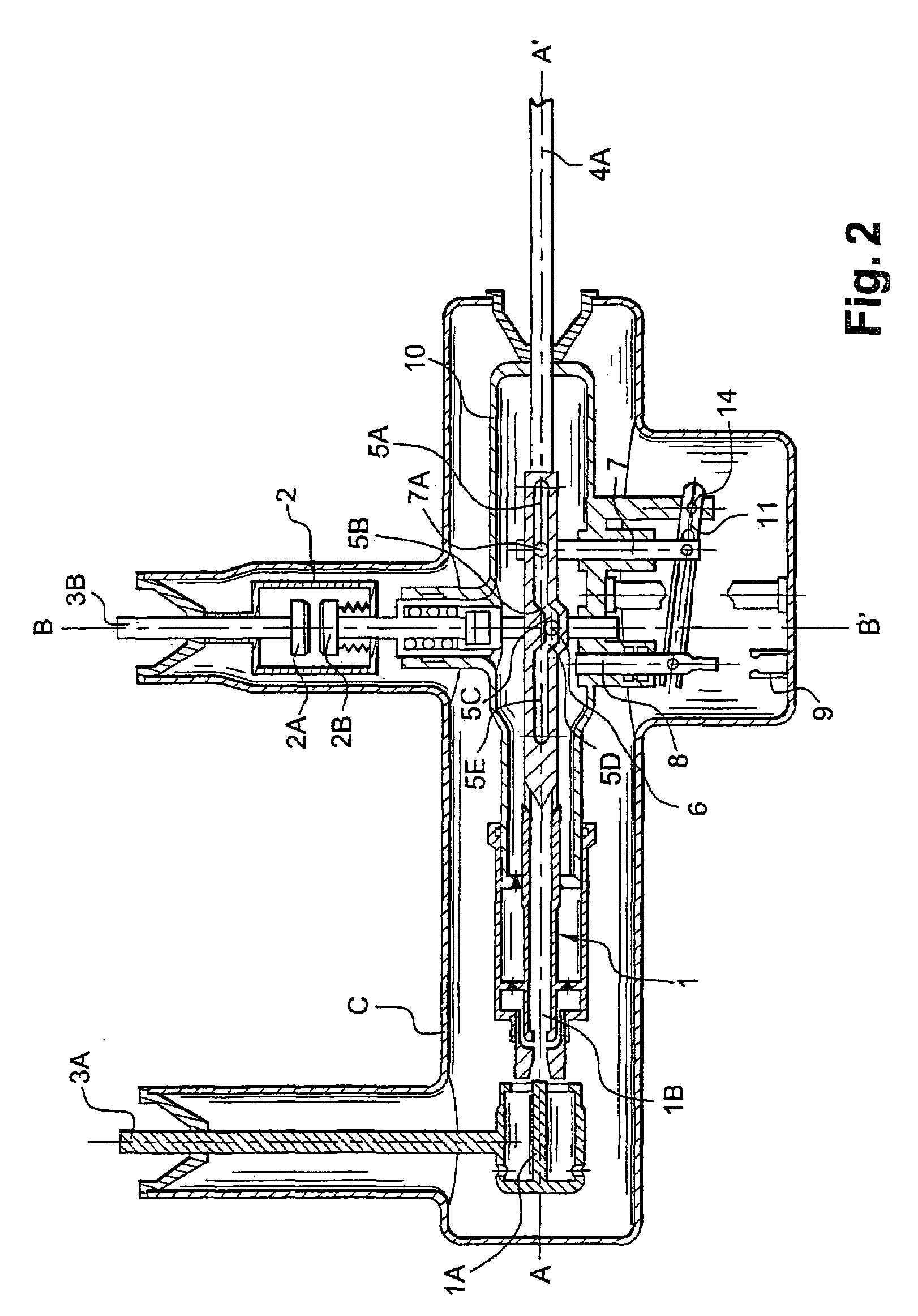

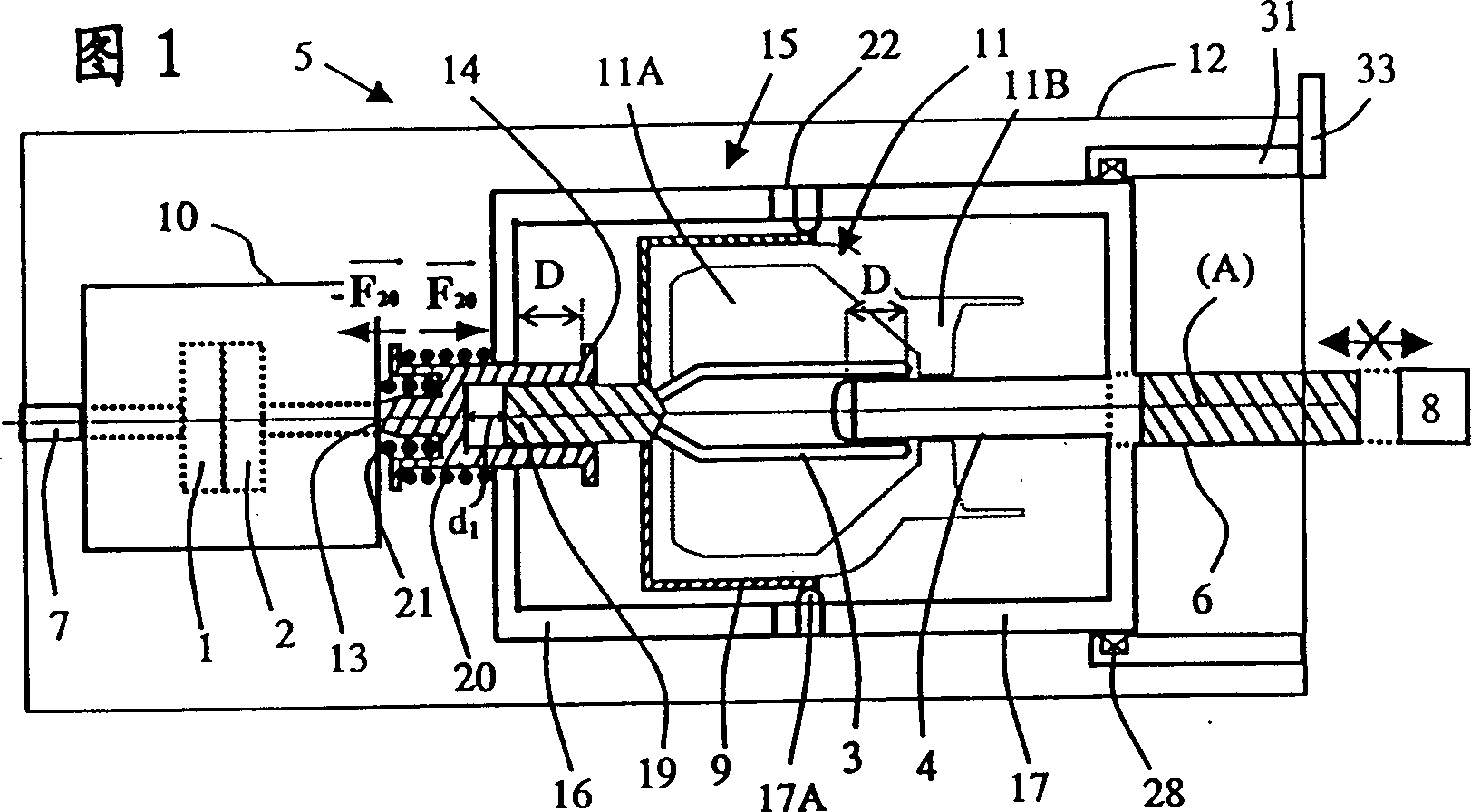

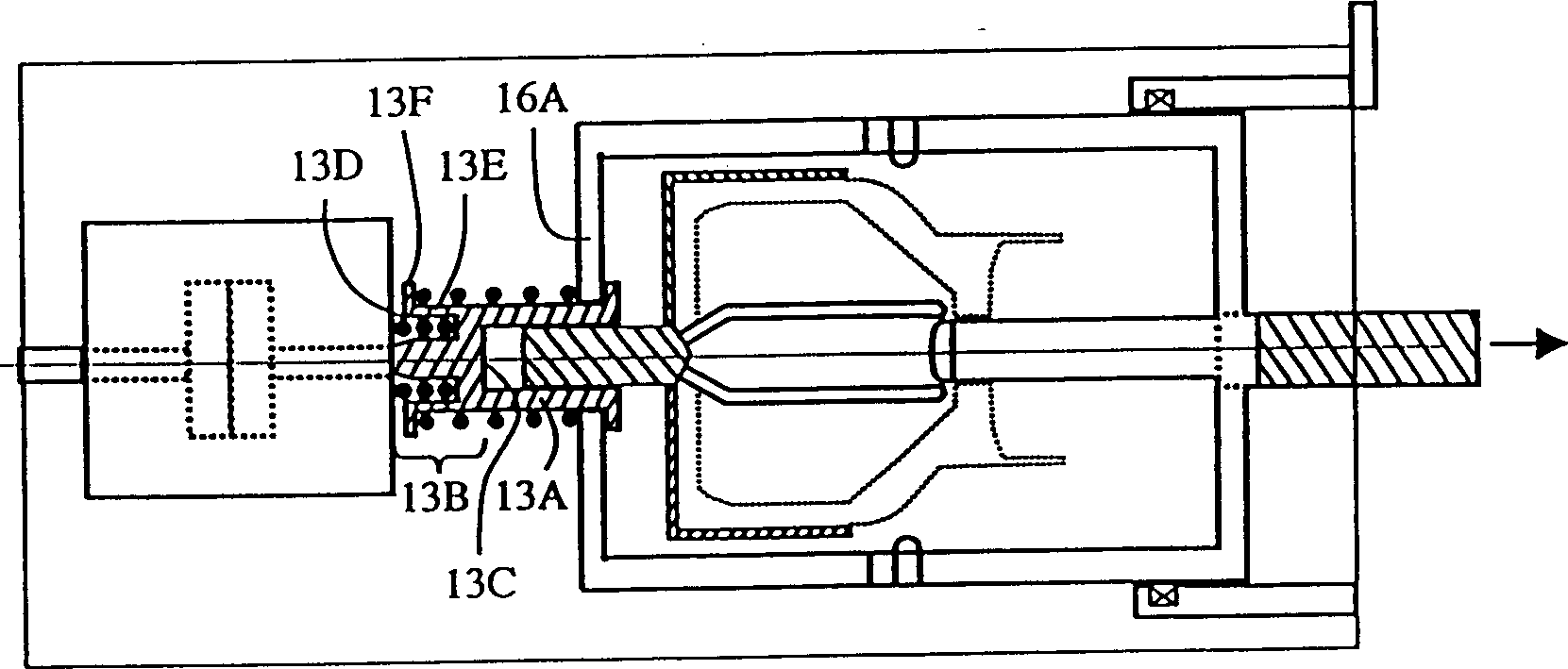

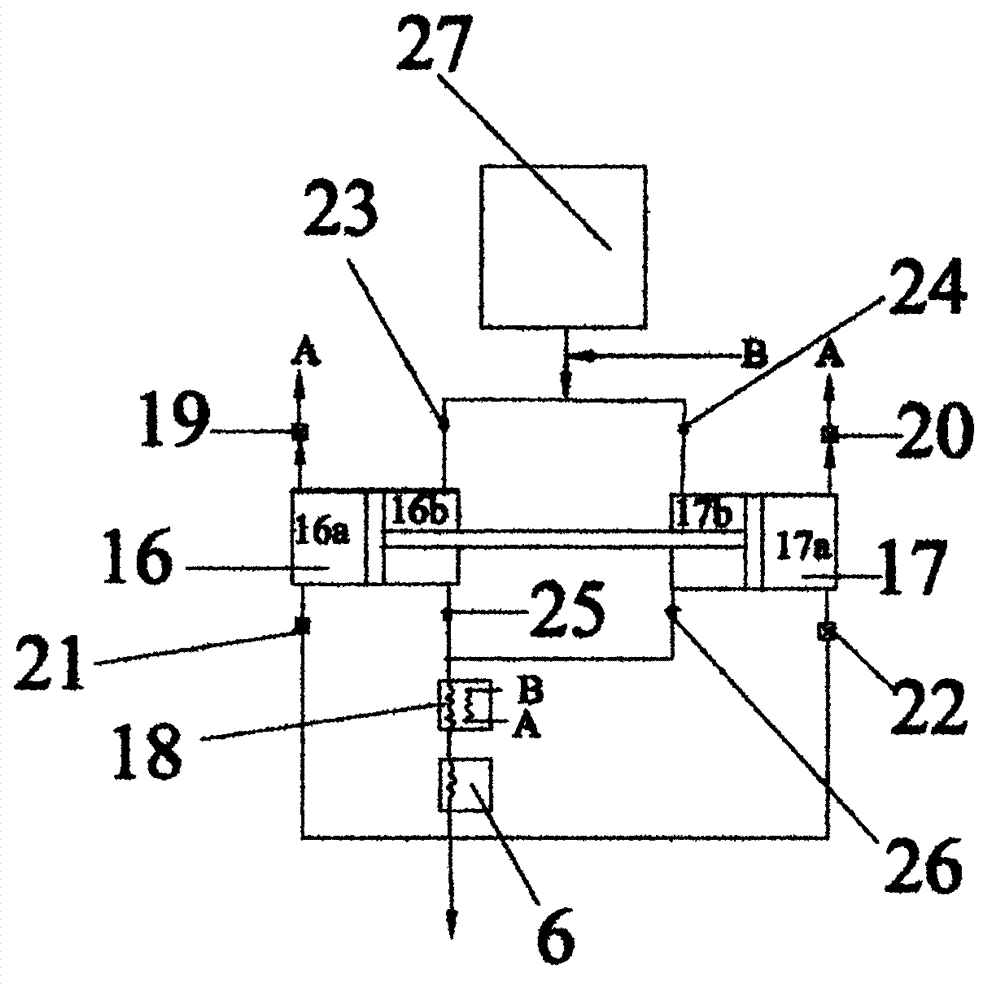

High-voltage hybrid circuit-breaker

ActiveUS7199324B2Light weightReduce the numberContact mechanismsHigh-tension/heavy-dress switchesEngineeringHigh pressure

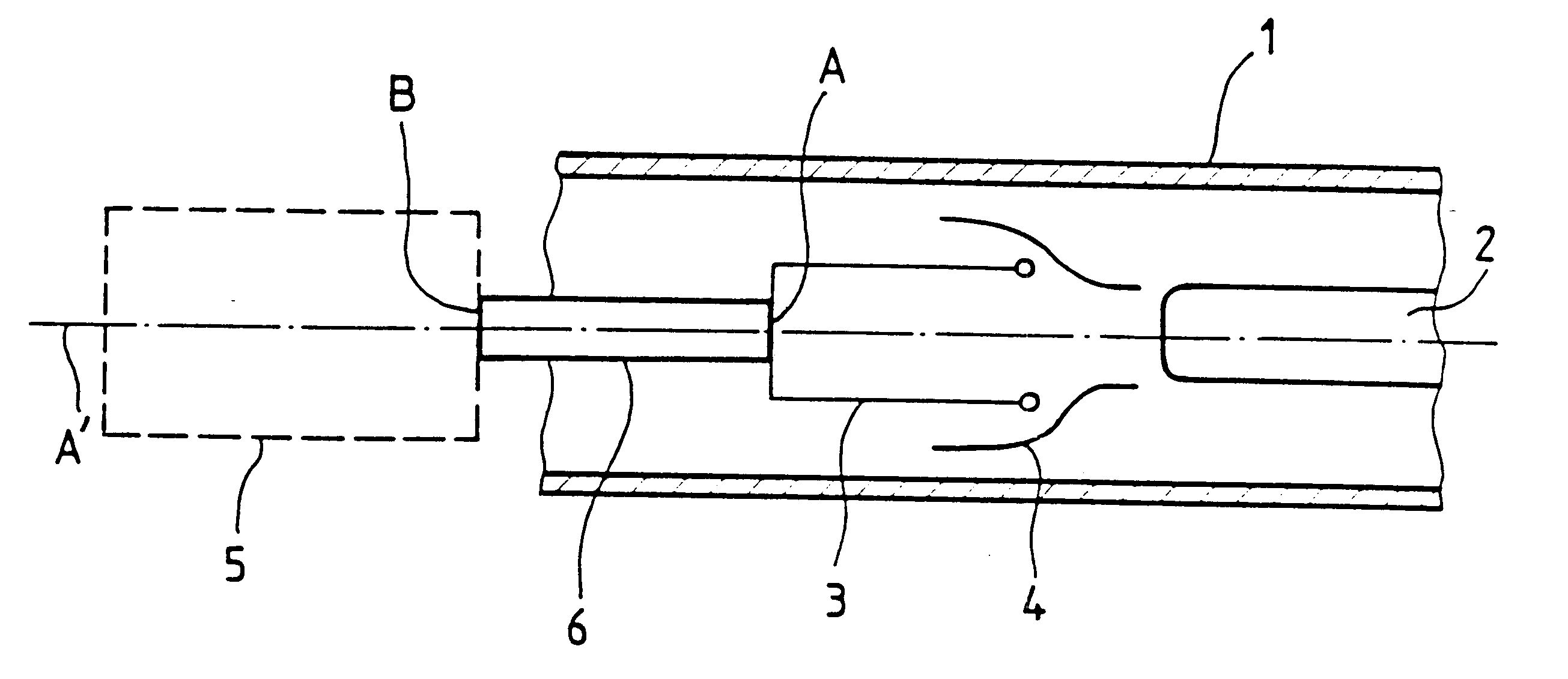

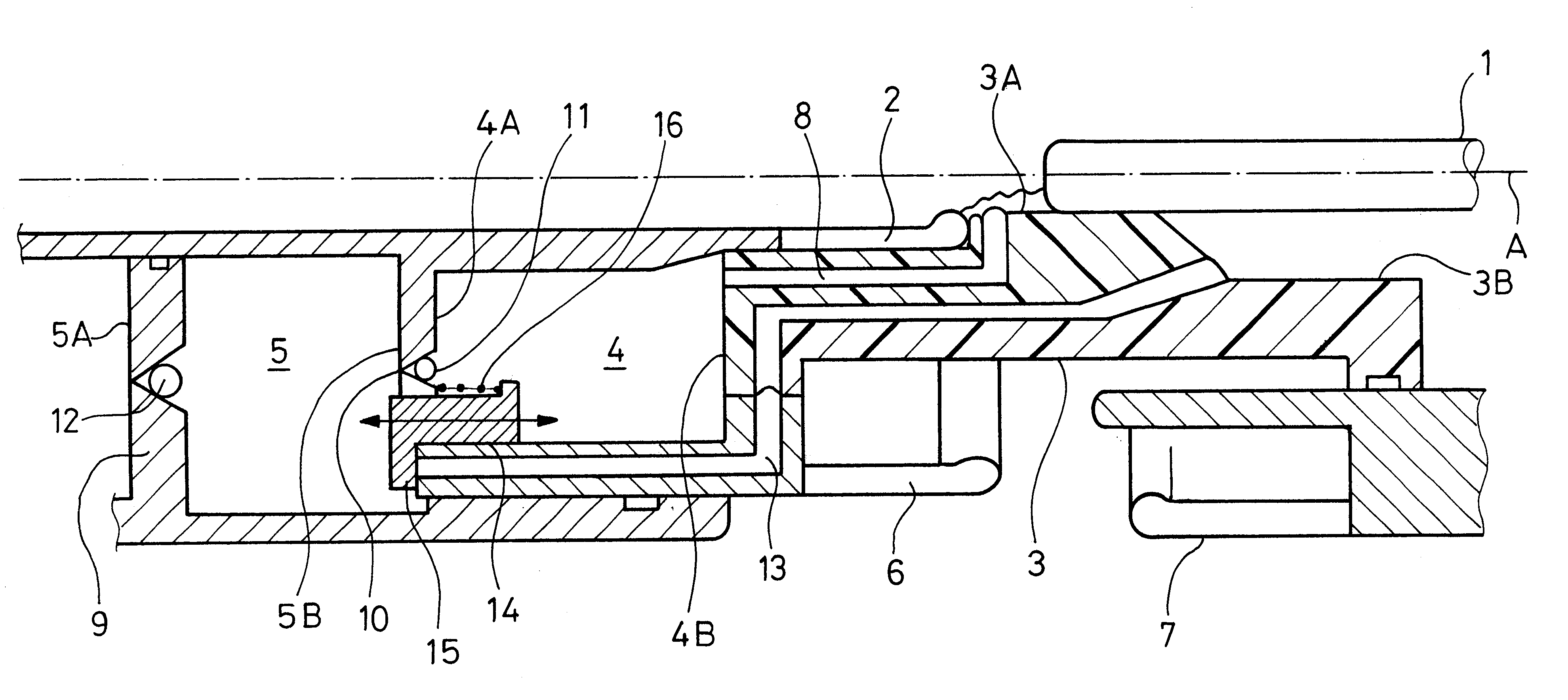

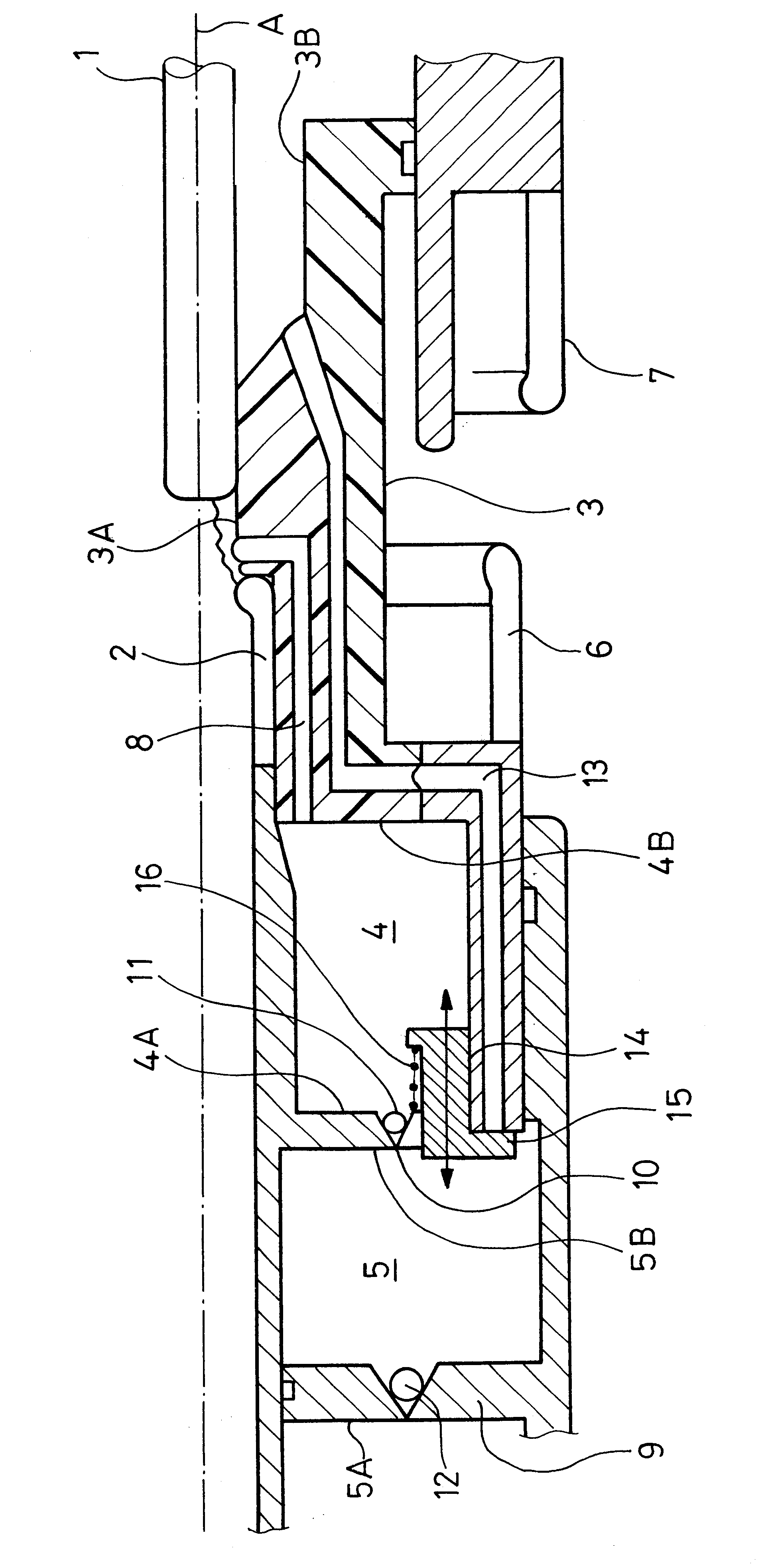

The invention relates to a hybrid circuit-breaker which, for each pole, comprises a dielectric-gas interrupting chamber (1) which contains a first contact (1A) and a moving second contact (1B) that are disposed longitudinally to a first axis (AA′) and in which the first contact (1A) is connected to a first terminal (3A) of the network, said interrupting chamber (1) being connected in series with a vacuum bottle (2) which contains a fixed contact (2A) and a moving contact (2B) that are disposed longitudinally to a second axis (BB′) and in which the fixed contact (2A) is connected to a second terminal (3B) of the network, actuating means acting via a single control (4) to move said moving contacts between respective open positions and respective closed positions. According to the invention, said actuating means comprise a re-closure arrangement for re-closing the moving contact (2B) of the vacuum bottle, which re-closure arrangement enables said single control (4) to perform such re-closure before the moving contact (1B) of said interrupting chamber reaches its open position.

Owner:ALSTOM TECH LTD

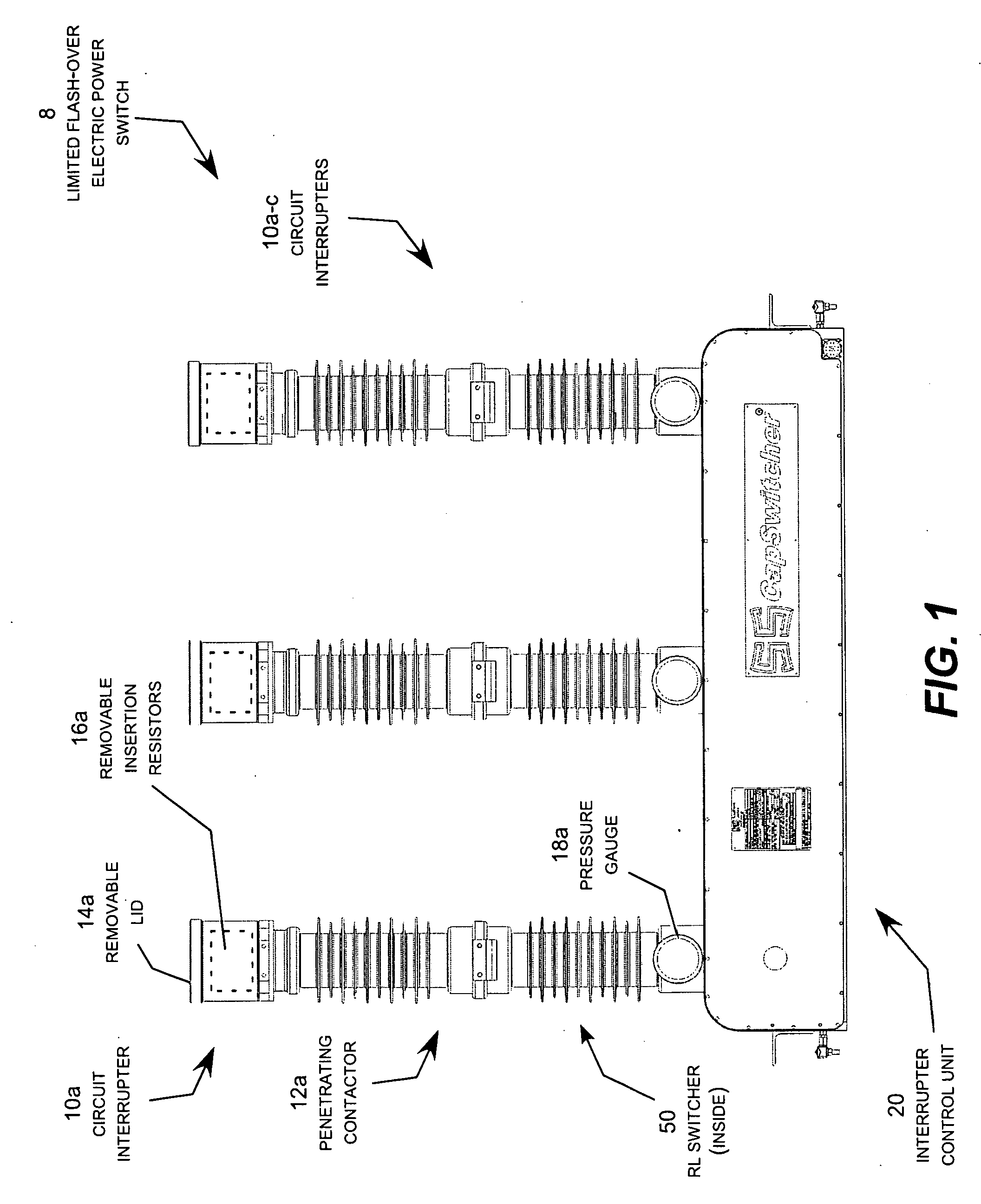

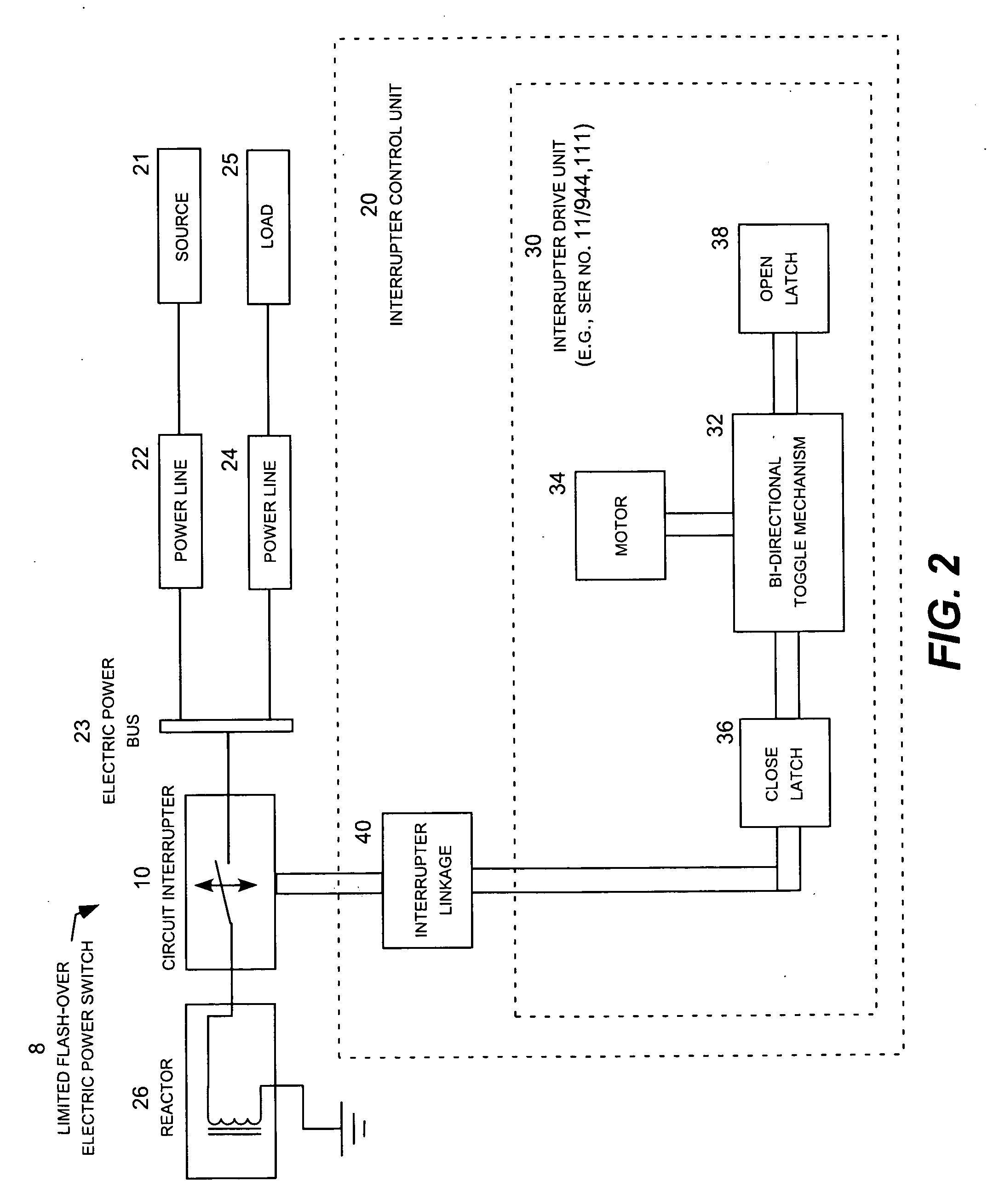

Limited flash-over electric power switch

ActiveUS20100193474A1Minimize damageProlong lifeHigh-tension/heavy-dress switchesAir-break switchesElectricityElectric power system

A limited flash-over electric power switch uses a dielectric gas regulator and a flash-over arrestor to greatly diminish the occurrences of high voltage flash-over during operation of a circuit interrupter. The dielectric gas regulator prevents the flow of the dielectric gas into the arc gap during an initial portion of the opening stroke of the interrupter contacts. Once the arc gap is sufficiently wide to greatly diminish the likelihood of a high voltage flash-over, the dielectric gas regulator allows the dielectric gas to flow into the arc gap to extinguish the arc. The flash-over arrestor snubs out incipient flash-over that may occur as the arc attempts to reform across the arc gap. The flash-over arrestor may be a conductive ring located on the interior surface of the nozzle in the region of the orifice.

Owner:SOUTHERN STATES

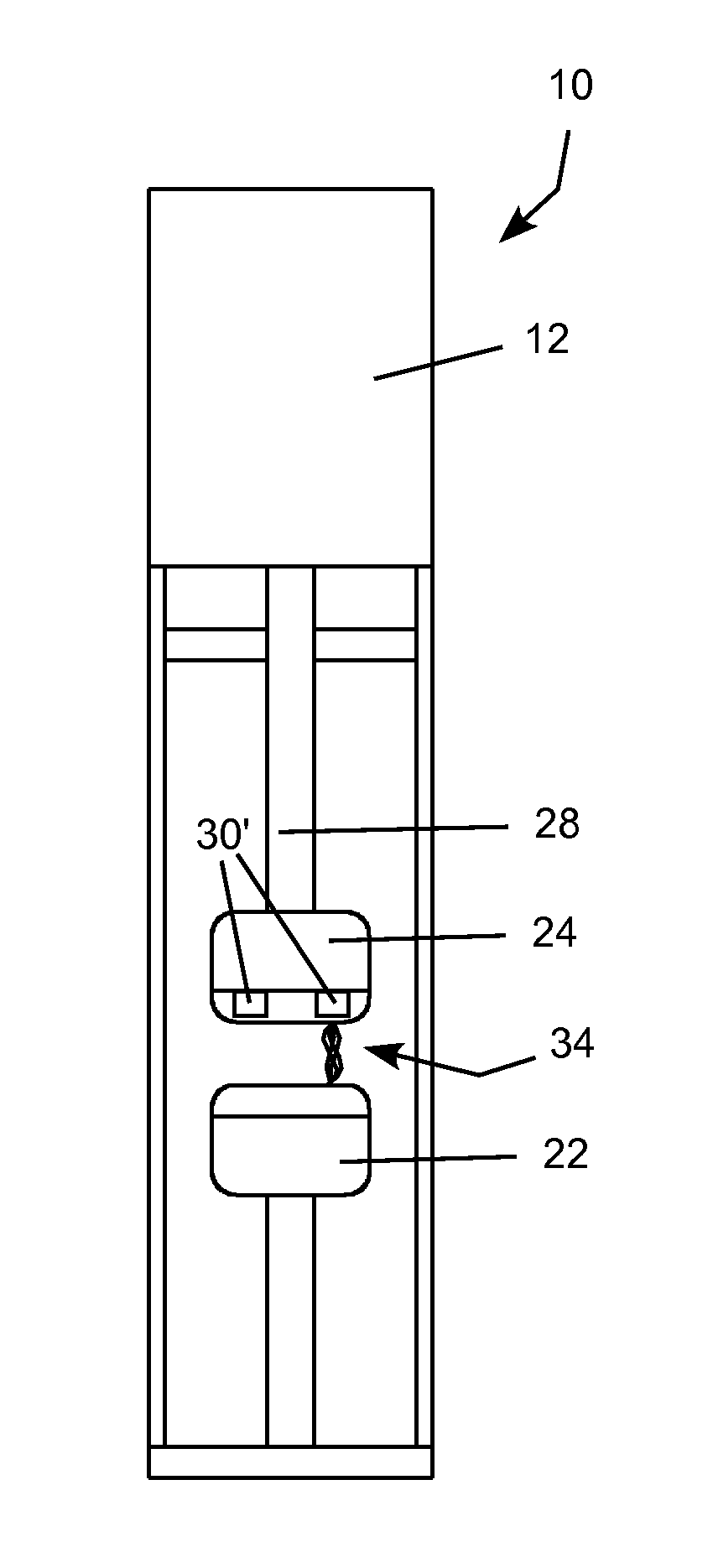

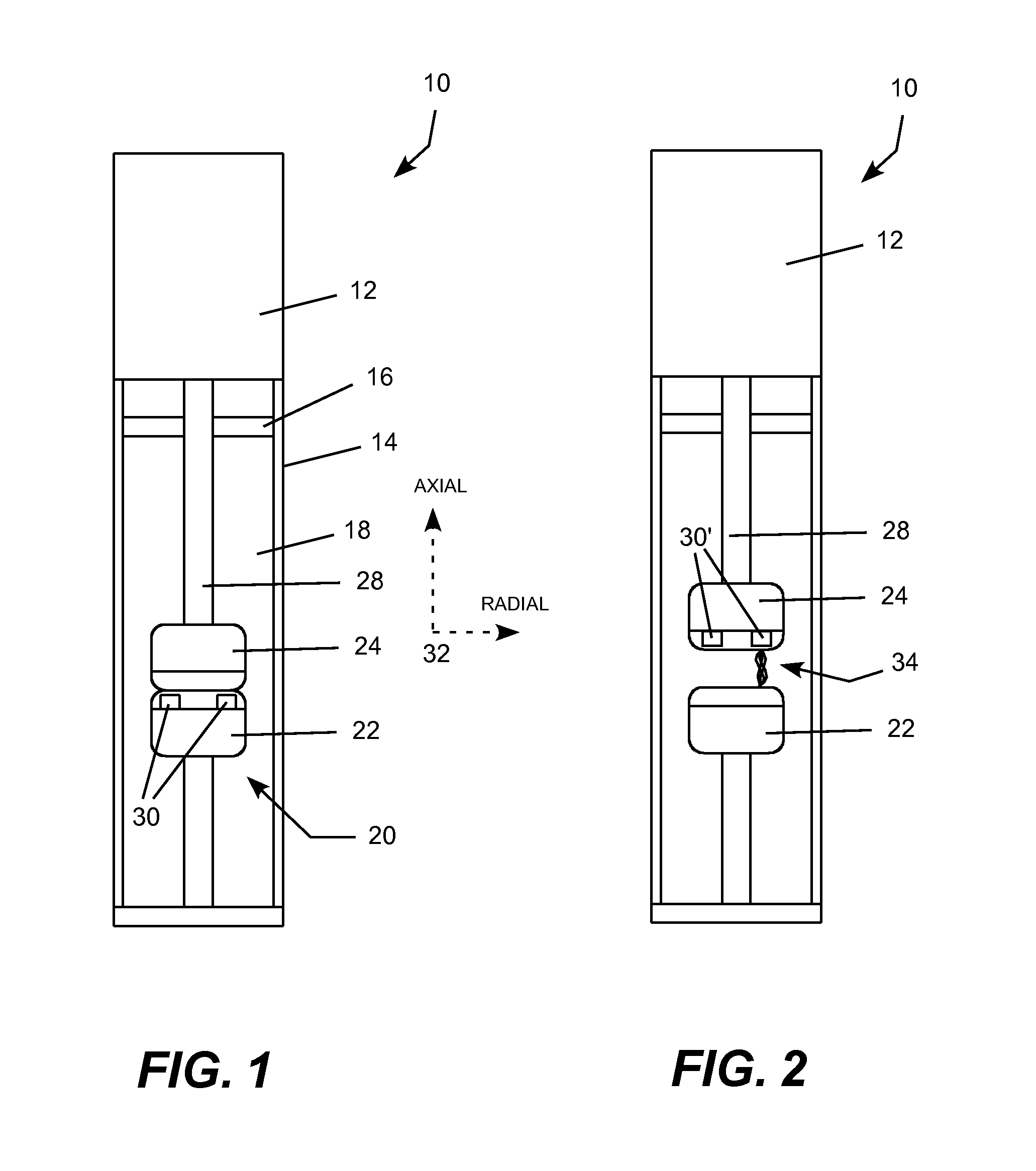

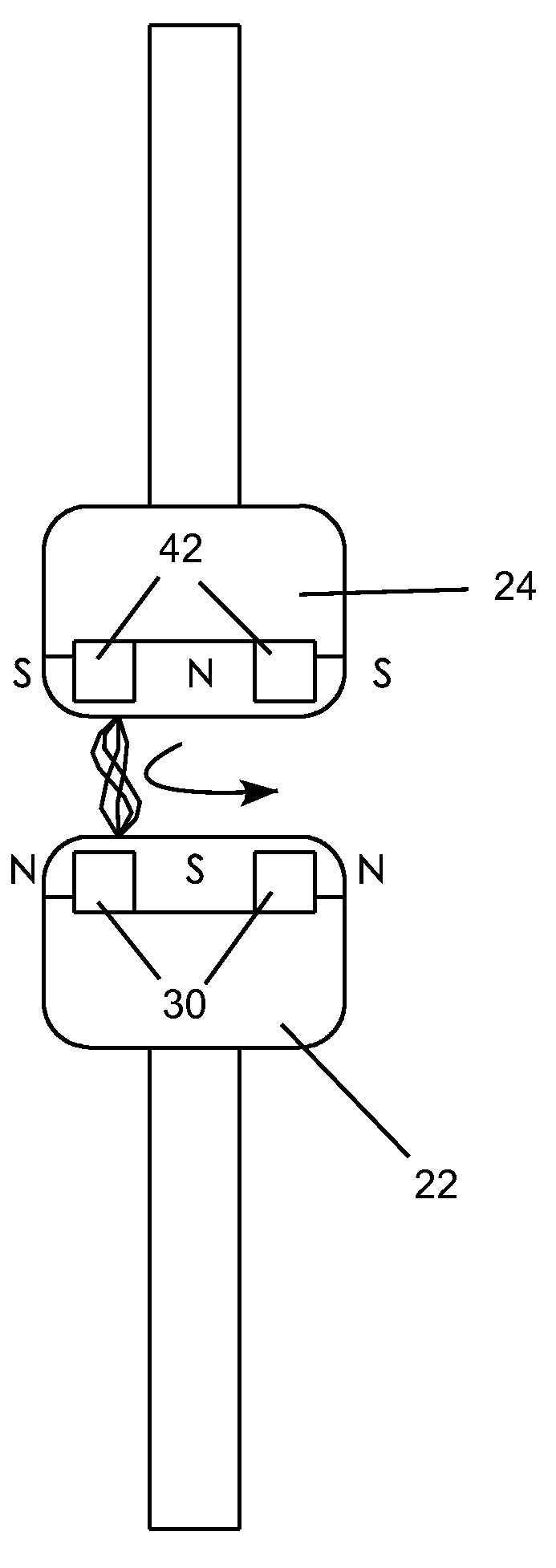

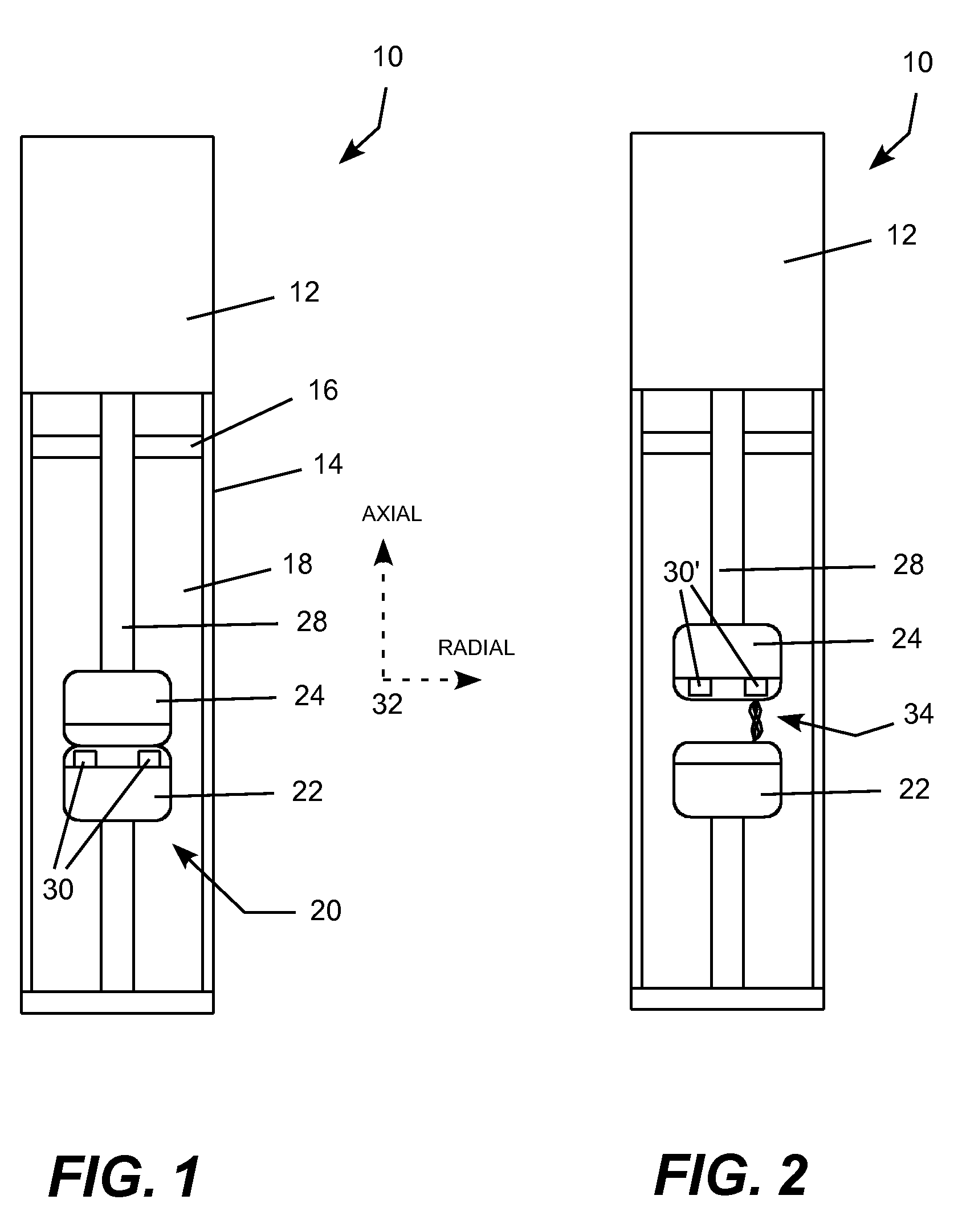

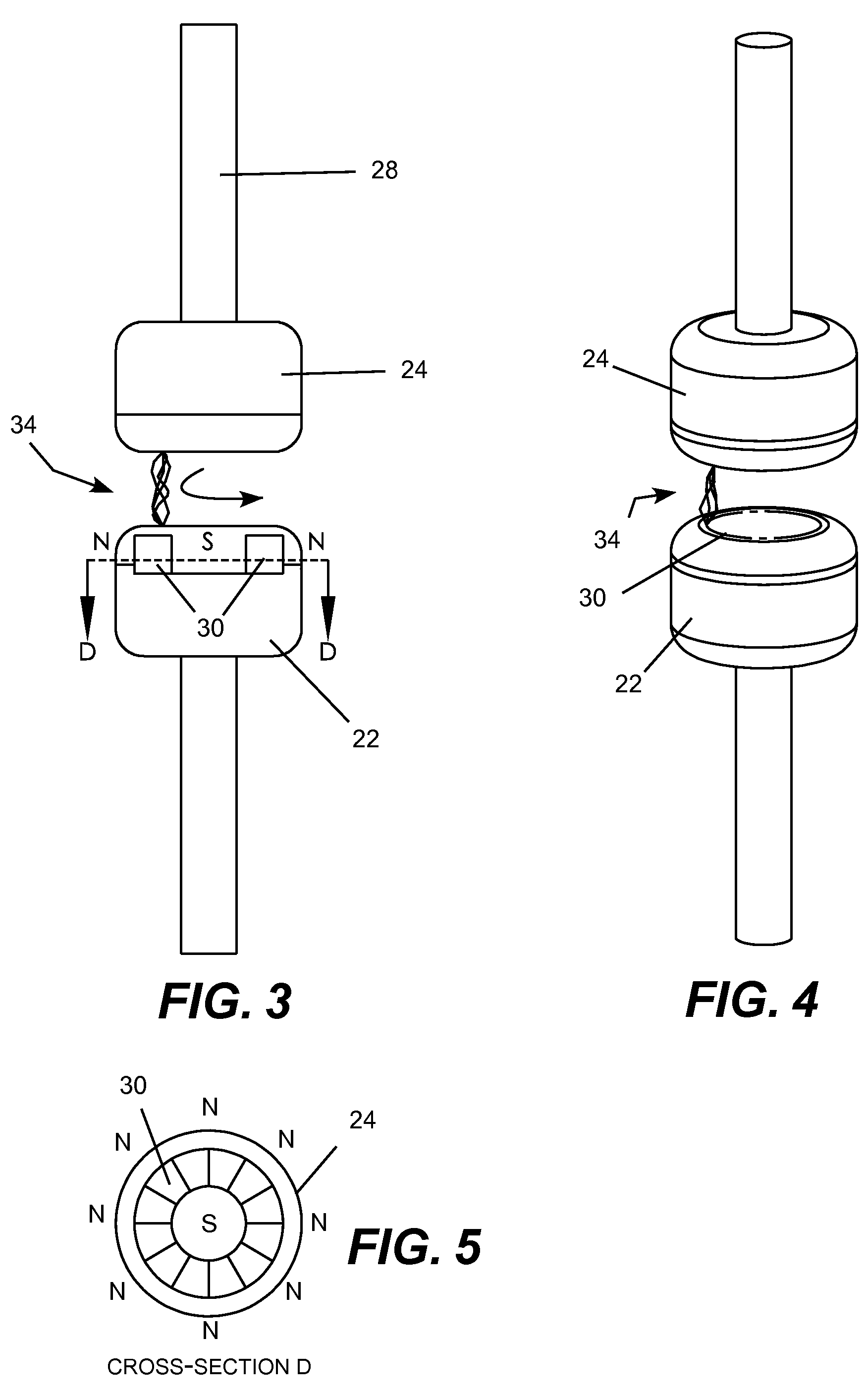

Magnet interrupter for high voltage switching

ActiveUS20110042354A1Less-robust partLow operating energyHigh-tension/heavy-dress switchesAir-break switchesMagnetic tension forceRadial plane

A magnetic interrupter consisting of a stationary and moving butt contacts that open an electric circuit in dielectric gas (e.g., SF6) contained in a sealed, pressurized insulating housing. One or both of the contacts contain a magnet with poles spaced apart in a radial plane perpendicular to the axial direction to spin the arc in the radial plane about the center of the contacts. Permanent magnets may be used to spin the arc so that the magnetic field is not affected by the magnitude of the arcing current, which makes the magnetic interrupter suitable for interrupting currents below fault level currents. One or both of the magnets may also be a field coil and a permanent magnet may be used in combination with a field coil.

Owner:SOUTHERN STATES

High-voltage or medium-voltage switch device with combined vacuum and gas breaking

InactiveUS6849819B2Emergency protective arrangements for automatic disconnectionHigh-tension/heavy-dress switchesElectricityHigh pressure

A hybrid high-voltage or medium-voltage breaker device includes an enclosure filled with a dielectric gas, a vacuum switch, a gas switch and an operating rod. The vacuum switch includes a fixed first arc contact and a second arc contact which can move in translation in an axial direction of the enclosure. The gas switch includes a fixed or quasi-fixed third arc contact and a fourth arc contact which can move in translation. The operating rod is connected to the fourth contact. The device also includes a connection arrangement for electrically connecting the second and third contacts and a displacement arrangement connected to the connection arrangement and to the rod which separates the second and fourth contacts from the first and third contacts, respectively.

Owner:ALSTOM TECH LTD

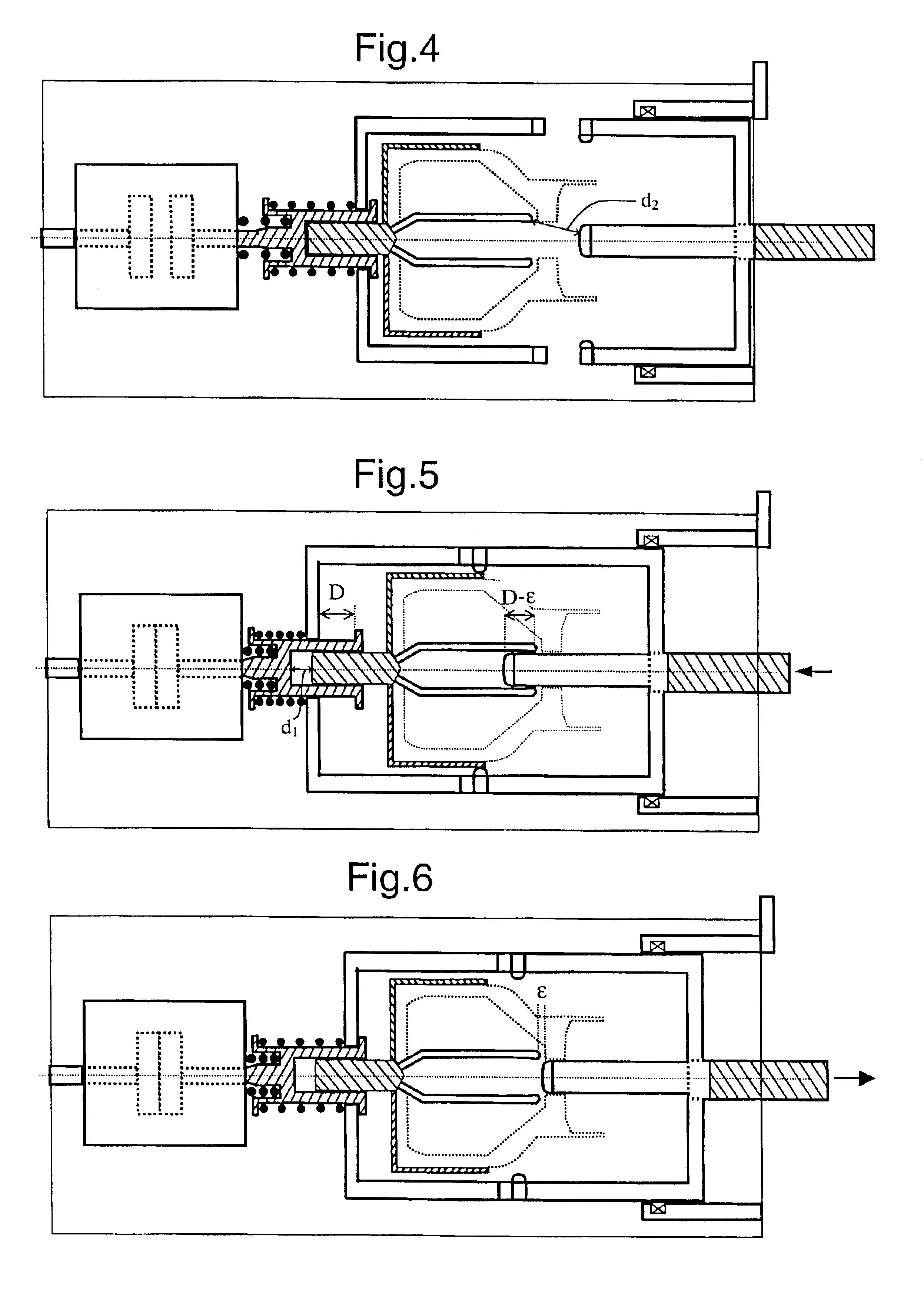

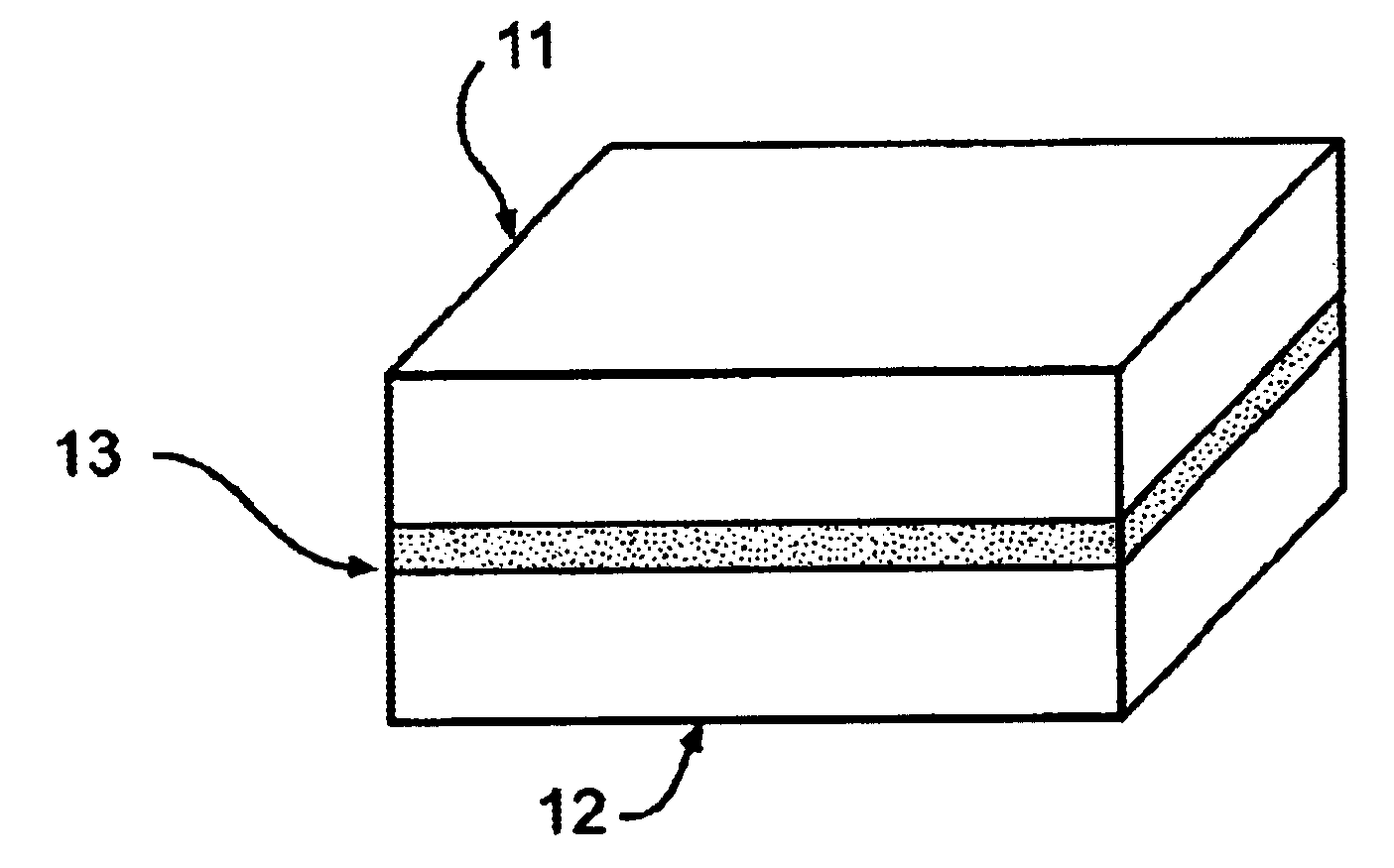

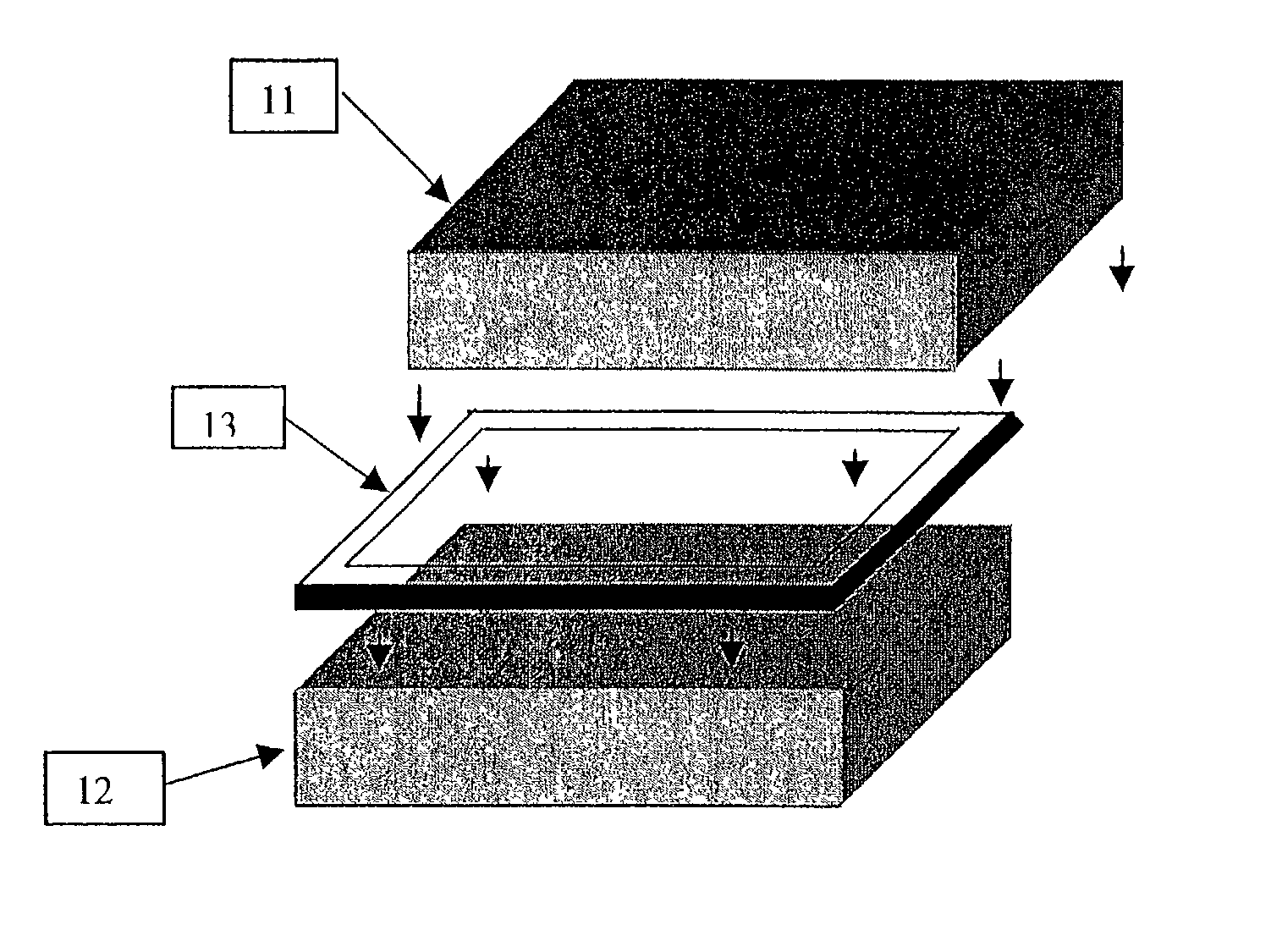

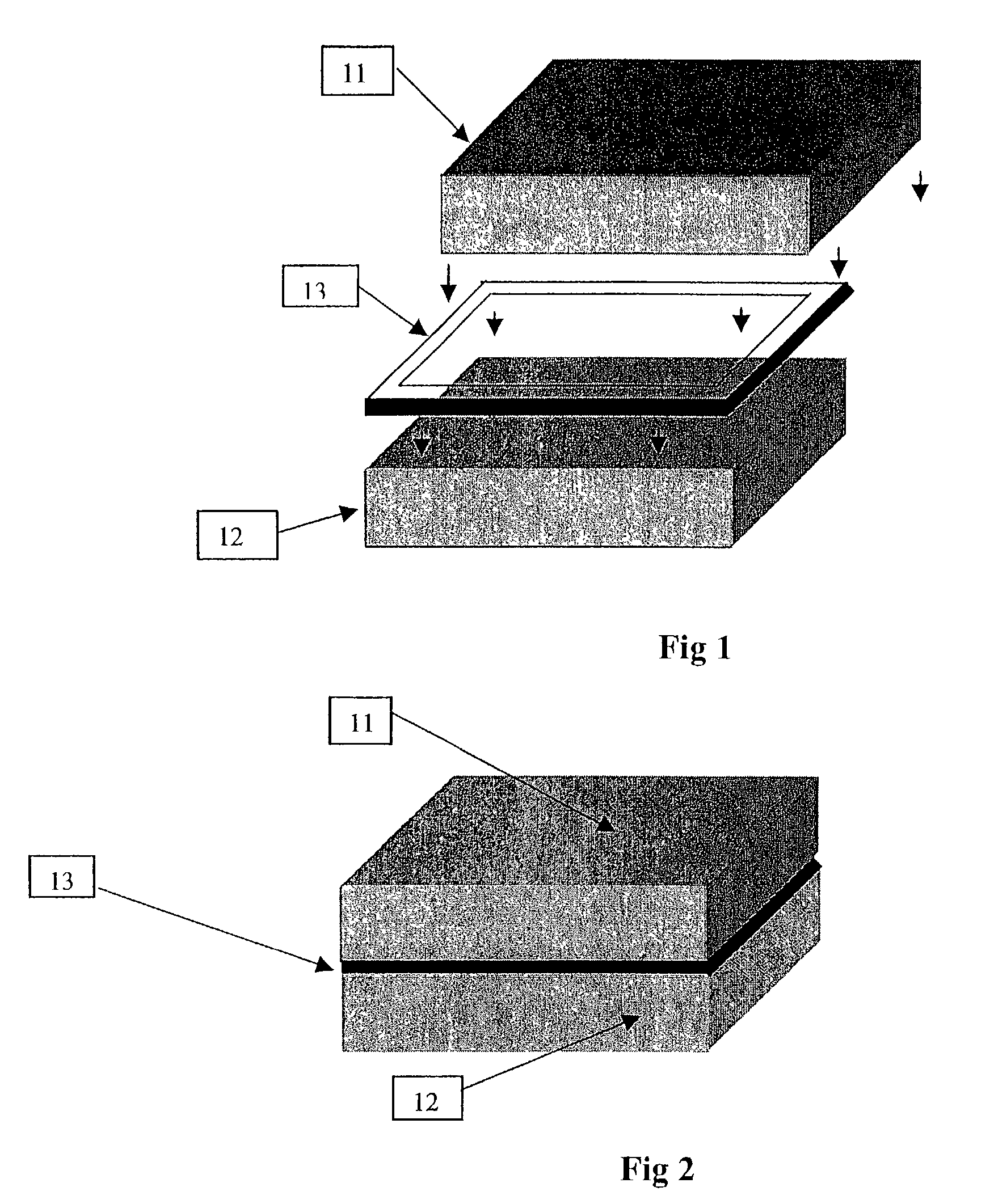

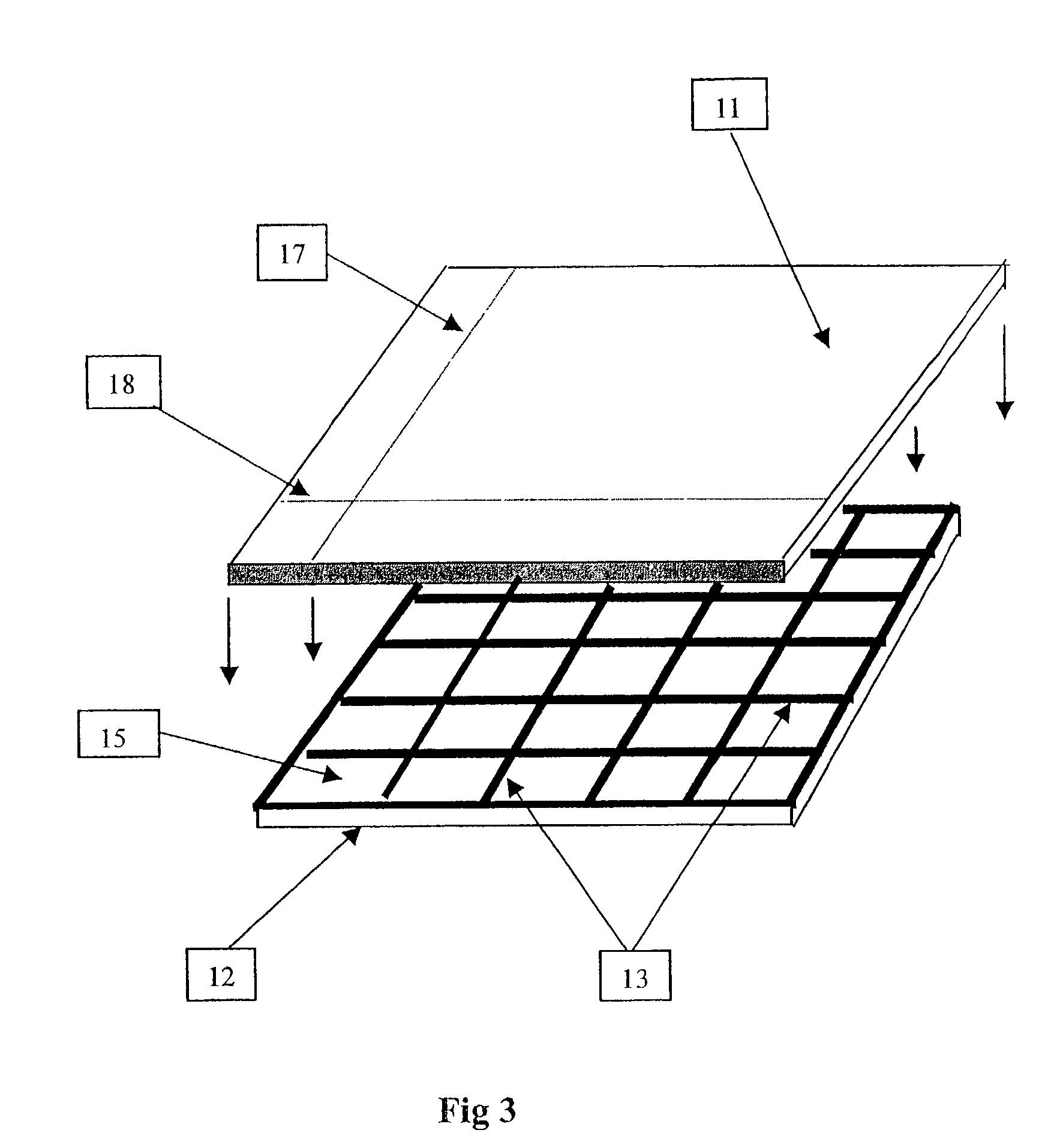

Micro-gap gas filled dielectric capacitor

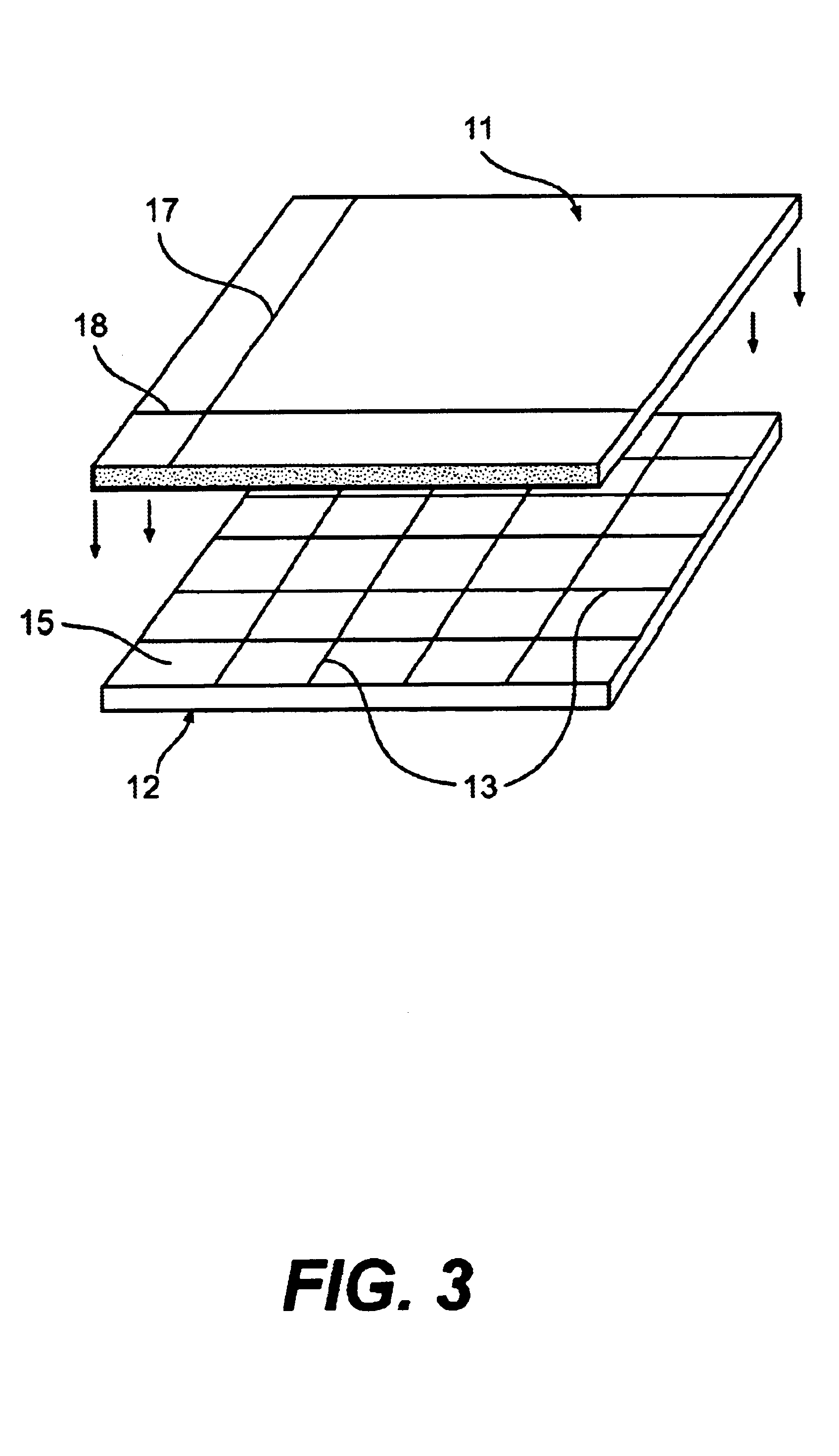

InactiveUS6775124B2Improve performanceFixed capacitor dielectricStacked capacitorsDielectricPlanar electrode

The gas dielectric capacitor for high frequency applications. The capacitor has first and second planner electrodes separated by an adhesive having solid particles, which establish the distance between electrodes. An adhesive is formed along peripheral edges of the planner electrodes. The capacitor may include air, vacuum, or any number of other dielectric gases, which may be under pressure. A method is disclosed for manufacturing an array of capacitors having a pressurized gas dielectric.

Owner:MIND FUSION LLC

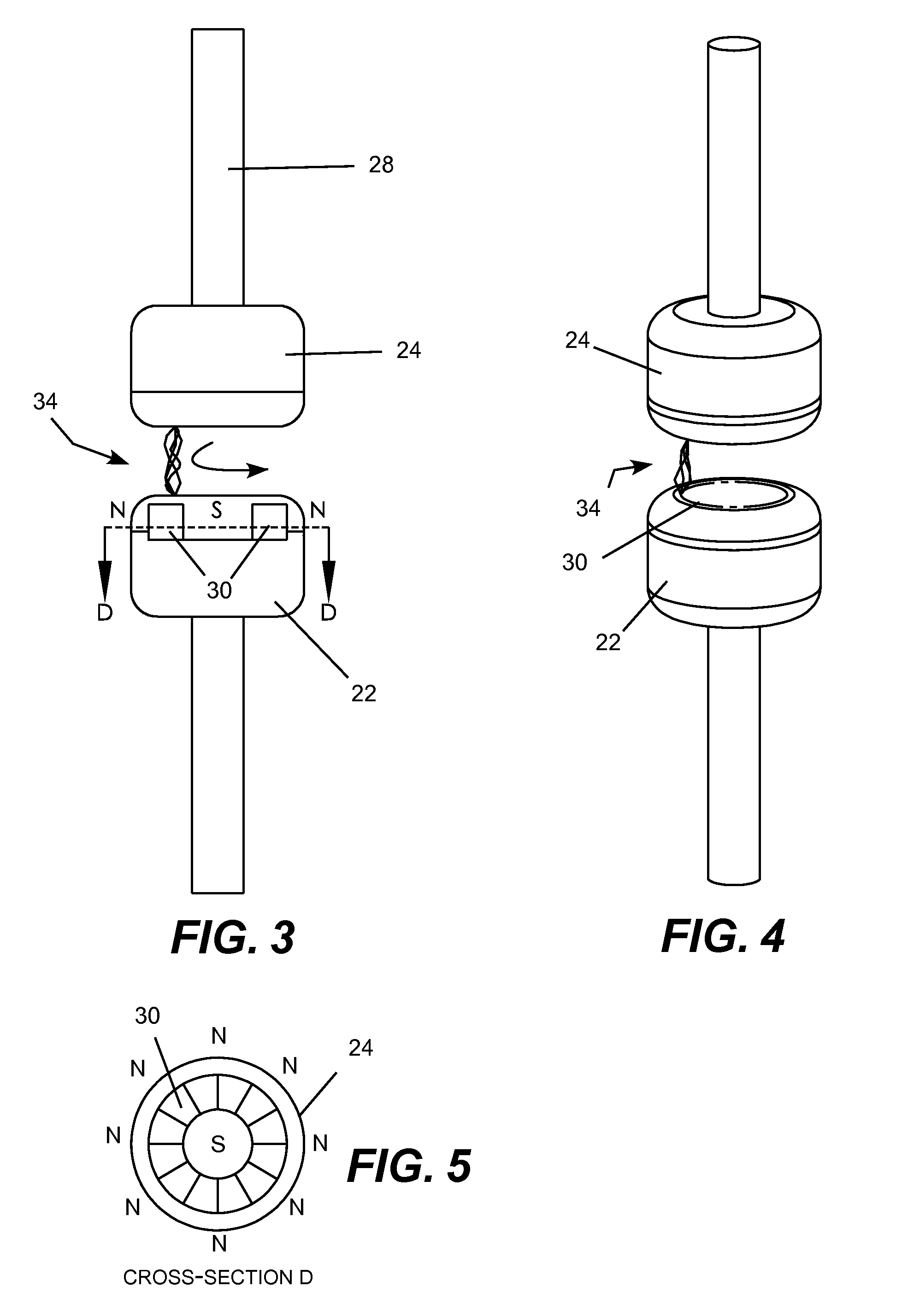

High-voltage interrupter device having combined vacuum and gas interruption

The hybrid-type interrupter device for high or medium voltage comprises: a casing filled with a dielectric gas; a vacuum interrupter having a first arcing contact which is fixed and a second arcing contact which can be moved in translation in the axial direction of the casing; means provided to exert a certain force on the second contact while the vacuum interrupter is allowing current to pass; a gas interrupter having a third arcing contact which is fixed and a fourth arcing contact which can be moved in translation; and a drive rod connected to the fourth contact. The device further comprises: connection means electrically interconnecting the second and third contacts, and capable of being moved in translation together with the second contact; displacement means connected to the connection means and to the rod for displacing them so as to separate the second and fourth contacts from the first and third contacts respectively, said displacement means comprising dead-stroke link means which make it possible to displace the rod over a determined dead stroke while also acting on the connection means to keep the vacuum interrupter closed during this displacement.

Owner:ALSTOM TECH LTD

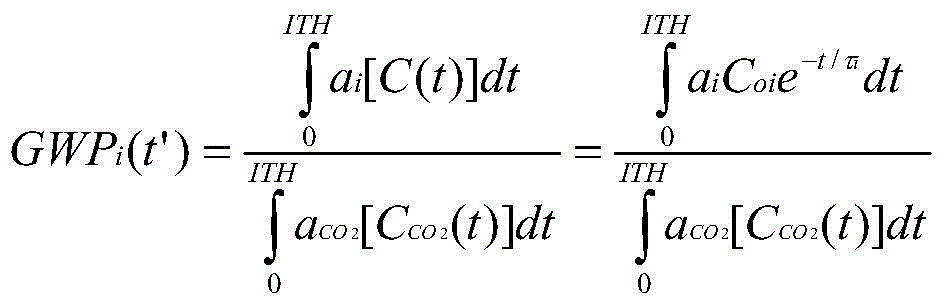

Fluorinated nitriles as dielectric gases

An electrical device containing a dielectric fluid, the dielectric fluid comprising heptafluoroisobutyronitrile or 2,3,3,3-tetrafluoro-2-(trifluoromethoxy) propanenitrile.

Owner:3M INNOVATIVE PROPERTIES CO

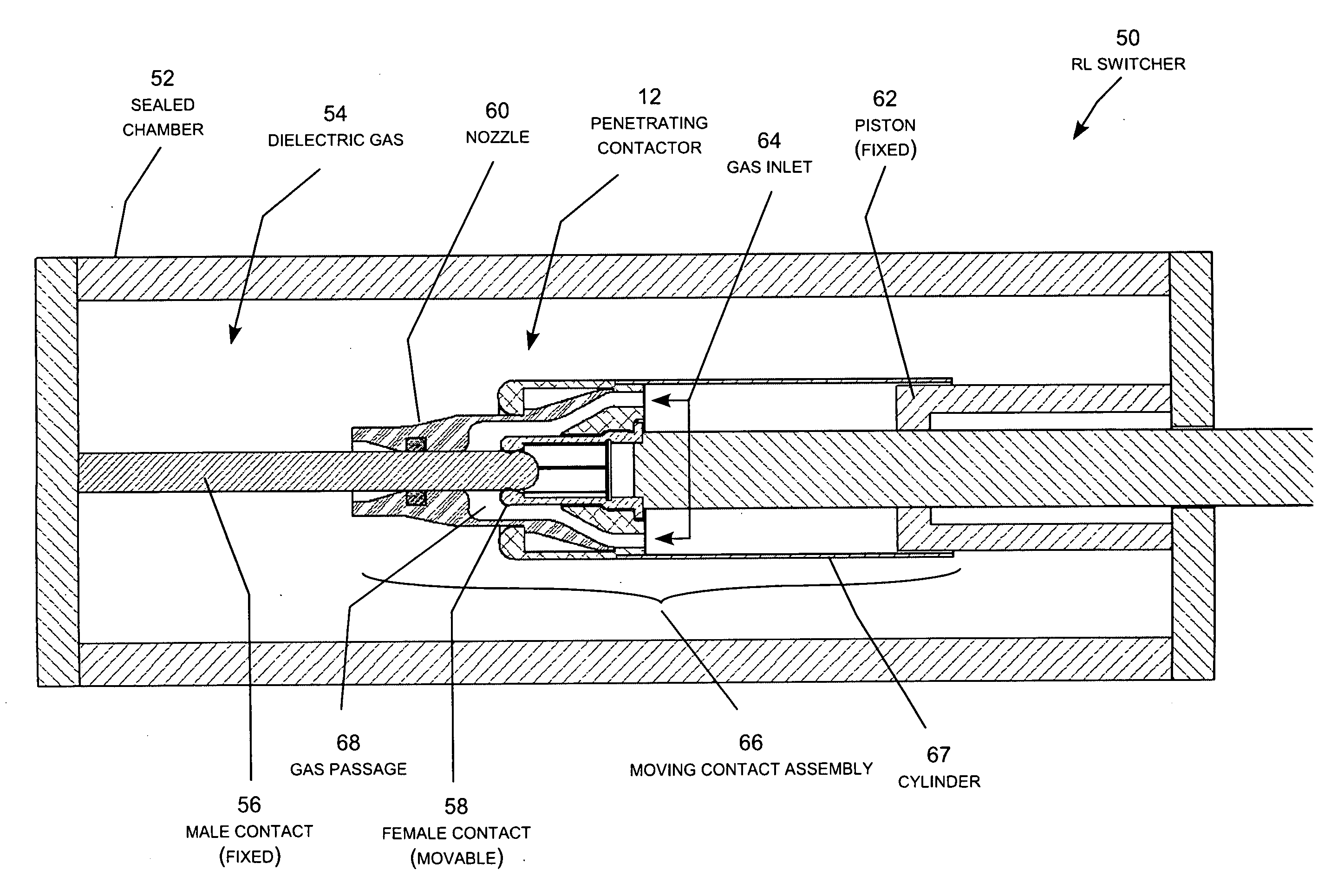

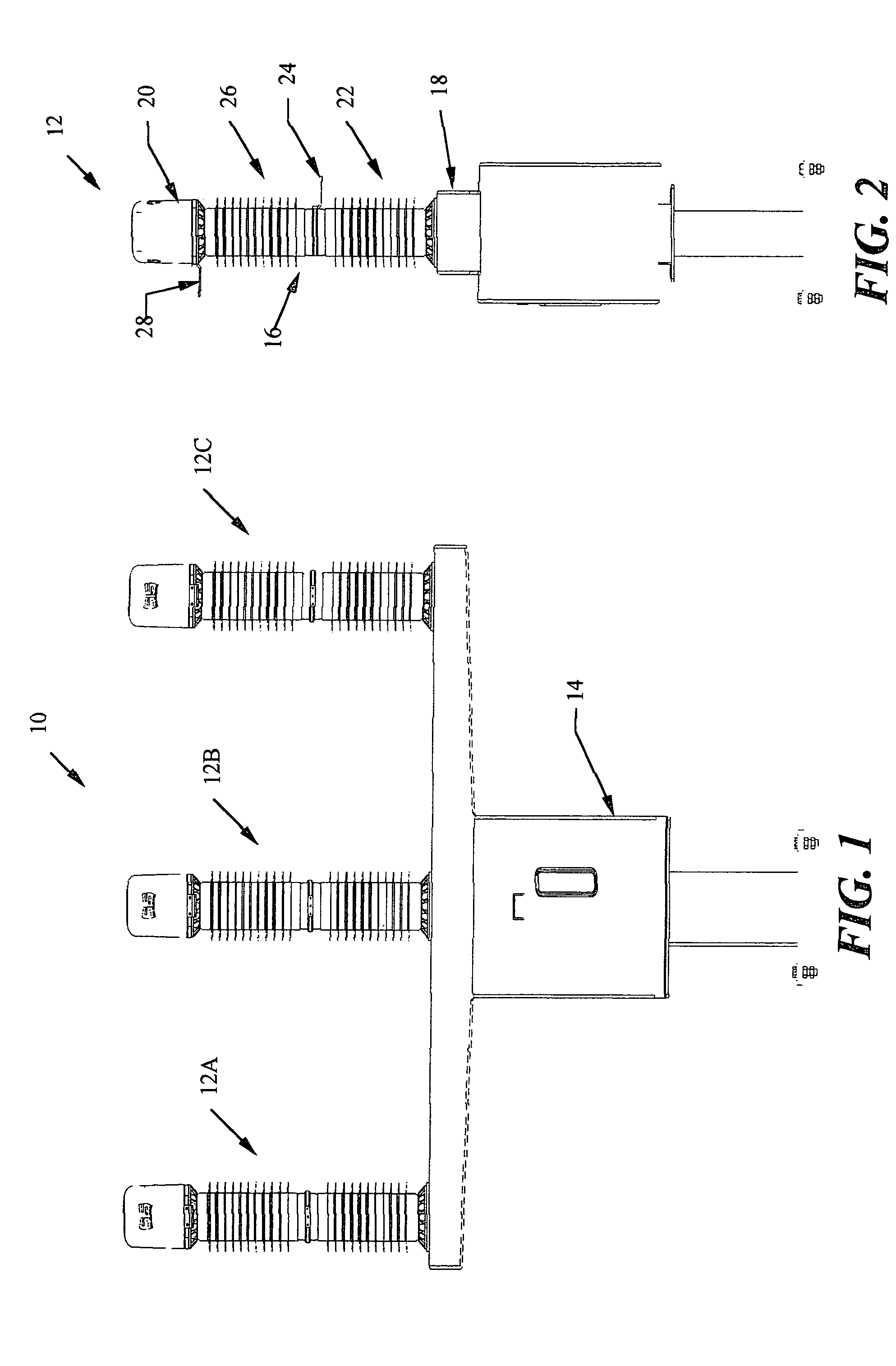

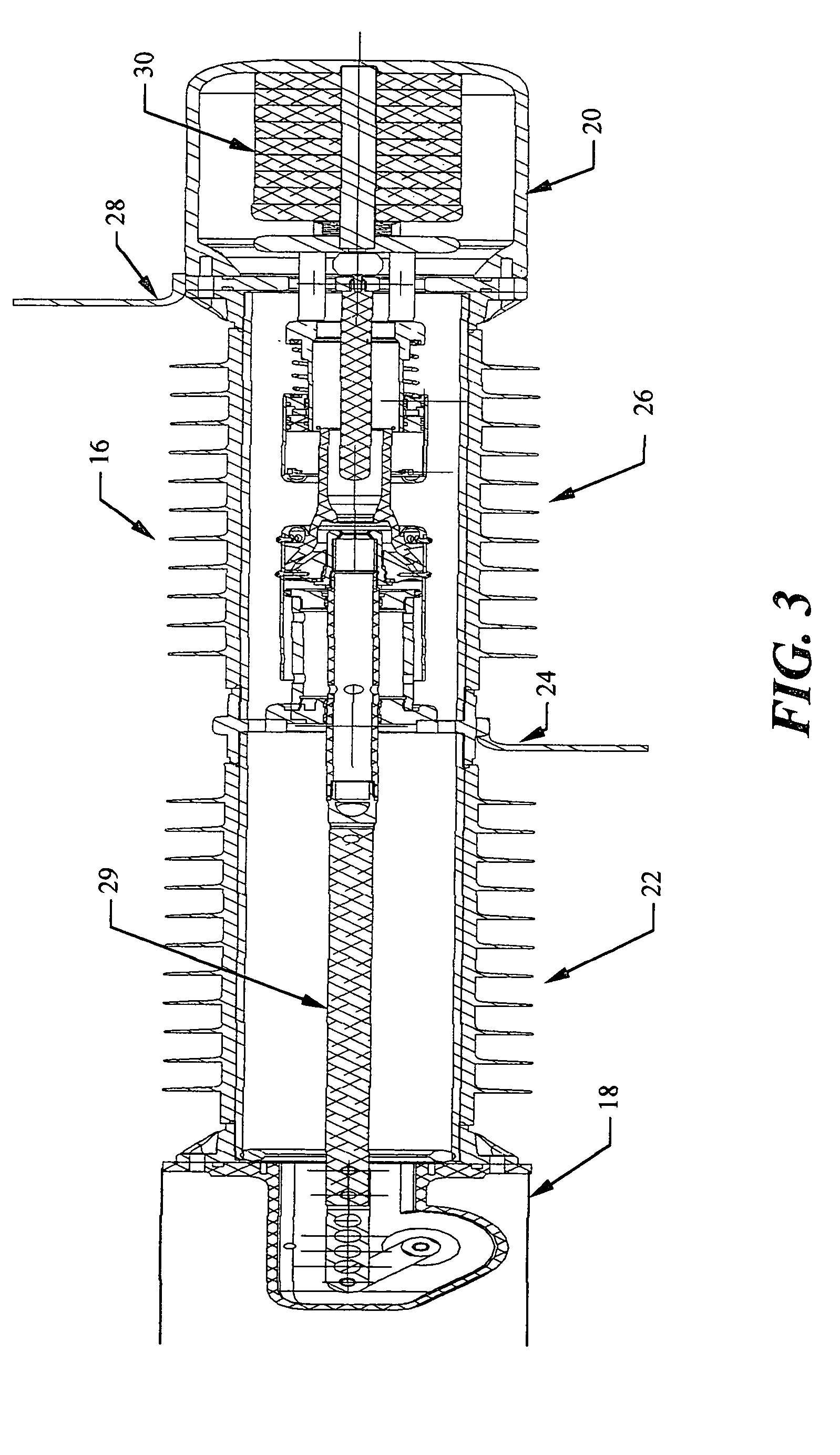

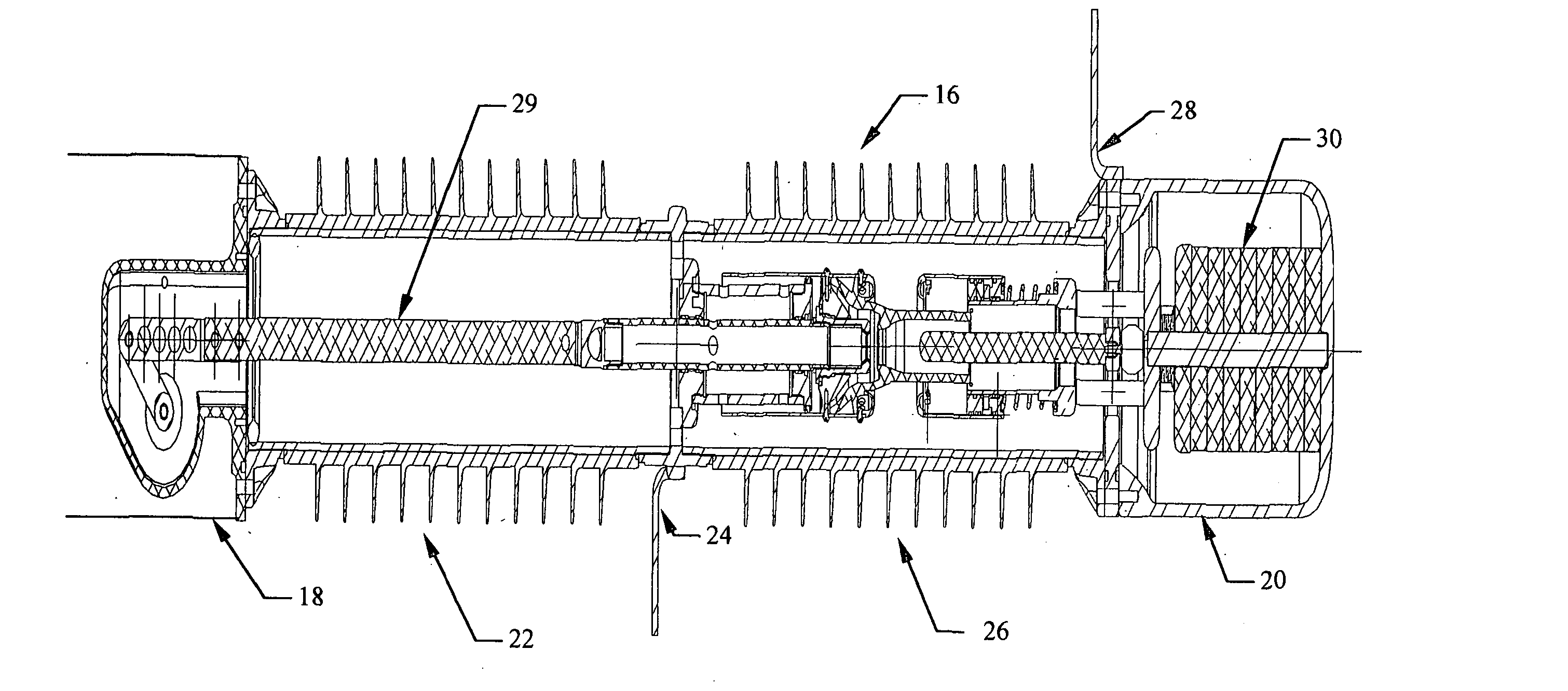

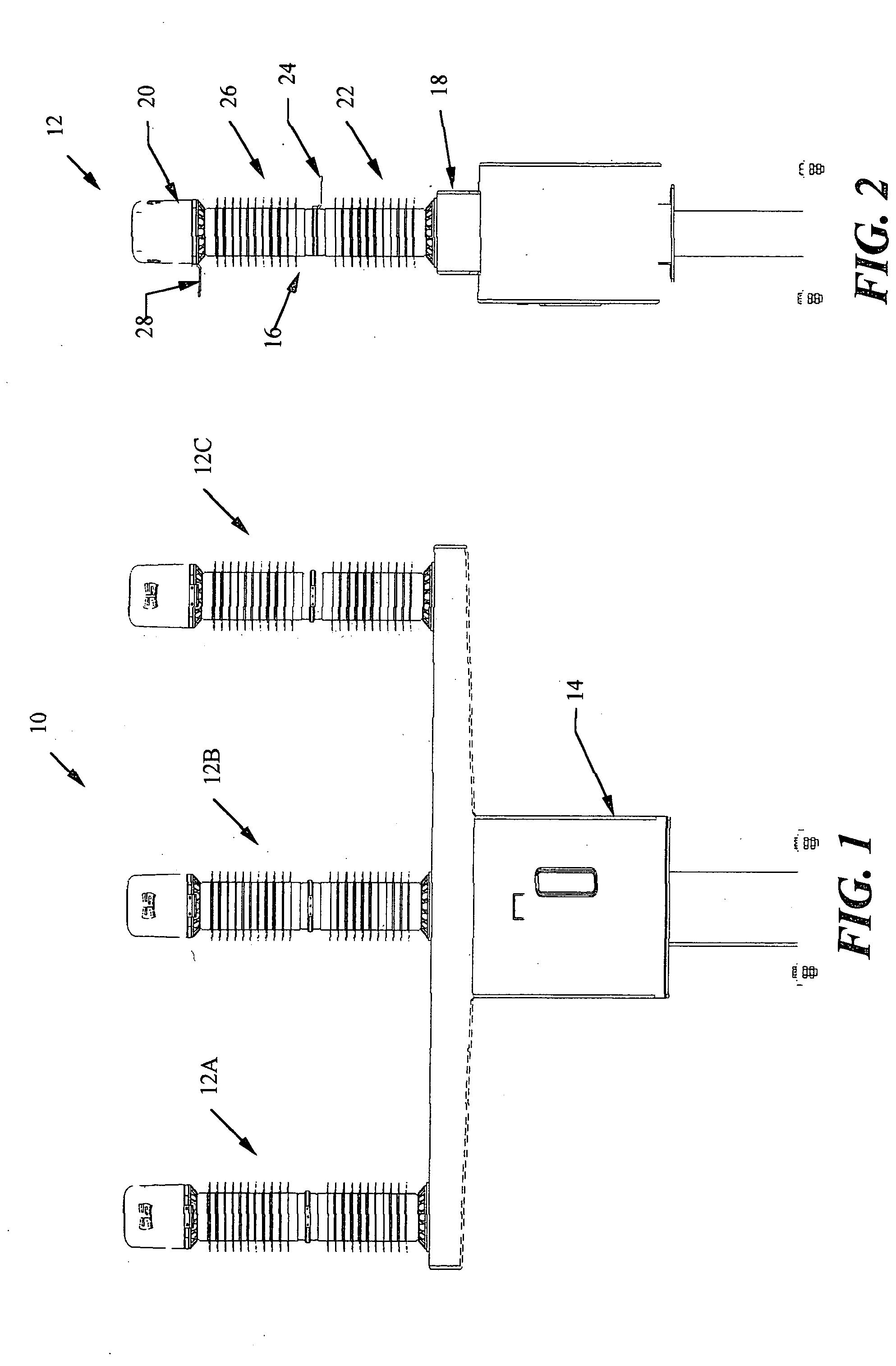

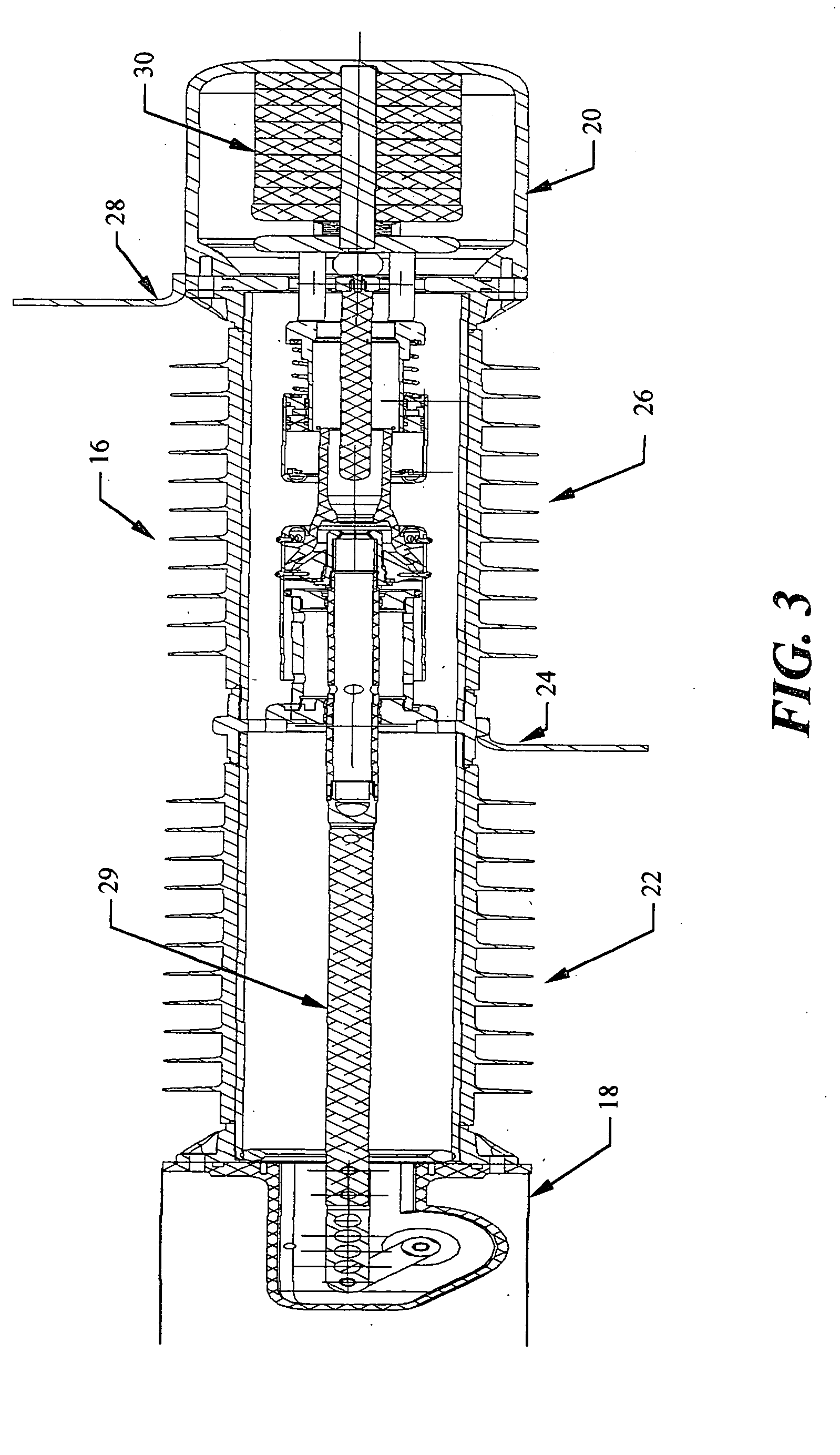

Capacitor switch with internal retracting impedance contactor

ActiveUS7078643B2Easy to removeEasy to replaceHigh-tension/heavy-dress switchesAir-break switchesElectrical impedanceCapacitor

A capacitor switch including a power contactor and an impedance contactor located within a relatively slender container filled with dielectric gas. The container may be a “dead tank” or an insulator. For the insulator configuration, the switch also includes a conductive cap housing a charging impedance located on the end of the insulator. The power contactor includes a relatively fixed probe contact and a linearly moving socket. The impedance contactor is ring-type butt contactor surrounding the penetrating contactor that includes a retracting (but otherwise fixed) contact that surrounds the fixed probe, and a traveling ring contact that surrounds and moves with the moving socket contact. The impedance contactor closes before the power contactor on the closing stroke to introduce the charging impedance into the circuit. A puffer mechanism retards the expansion of the retracting contact on the opening stroke, which causes the impedance contactor to open before the power contactor.

Owner:SOUTHERN STATES

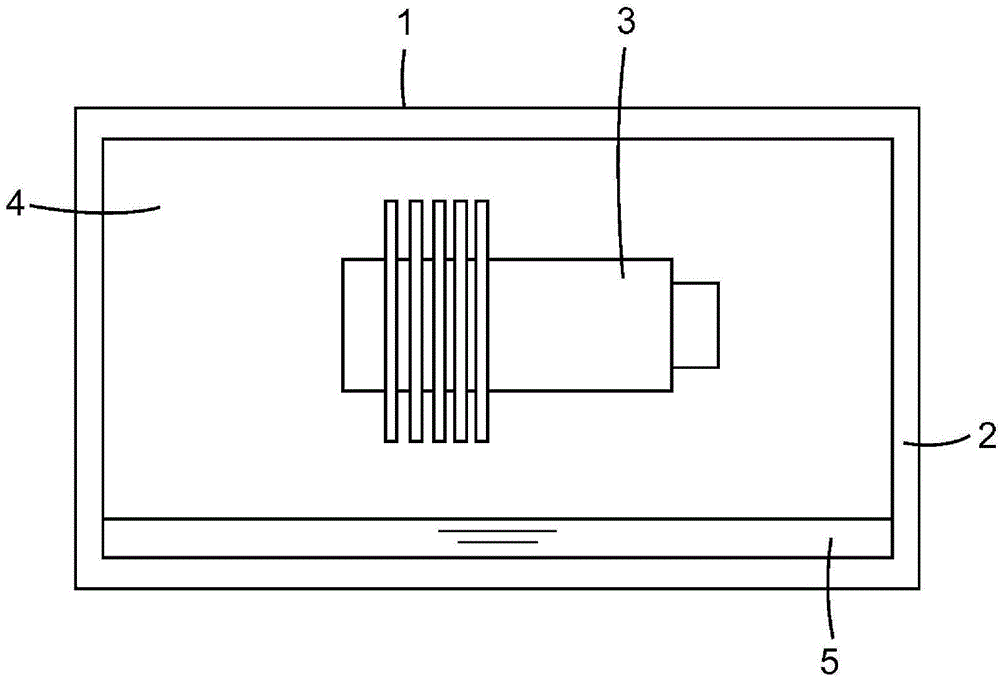

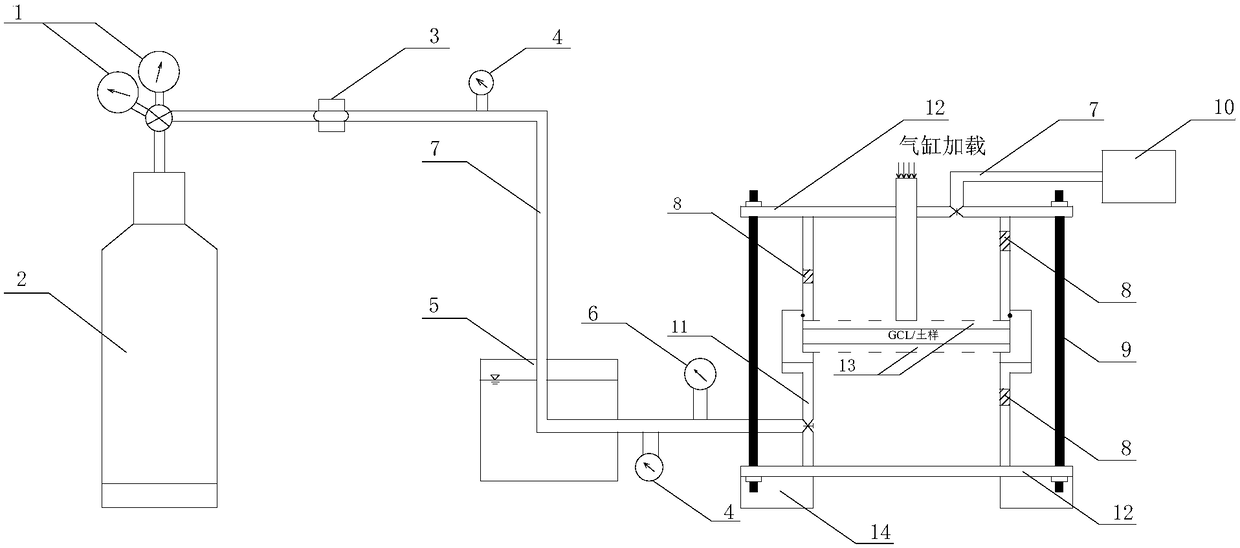

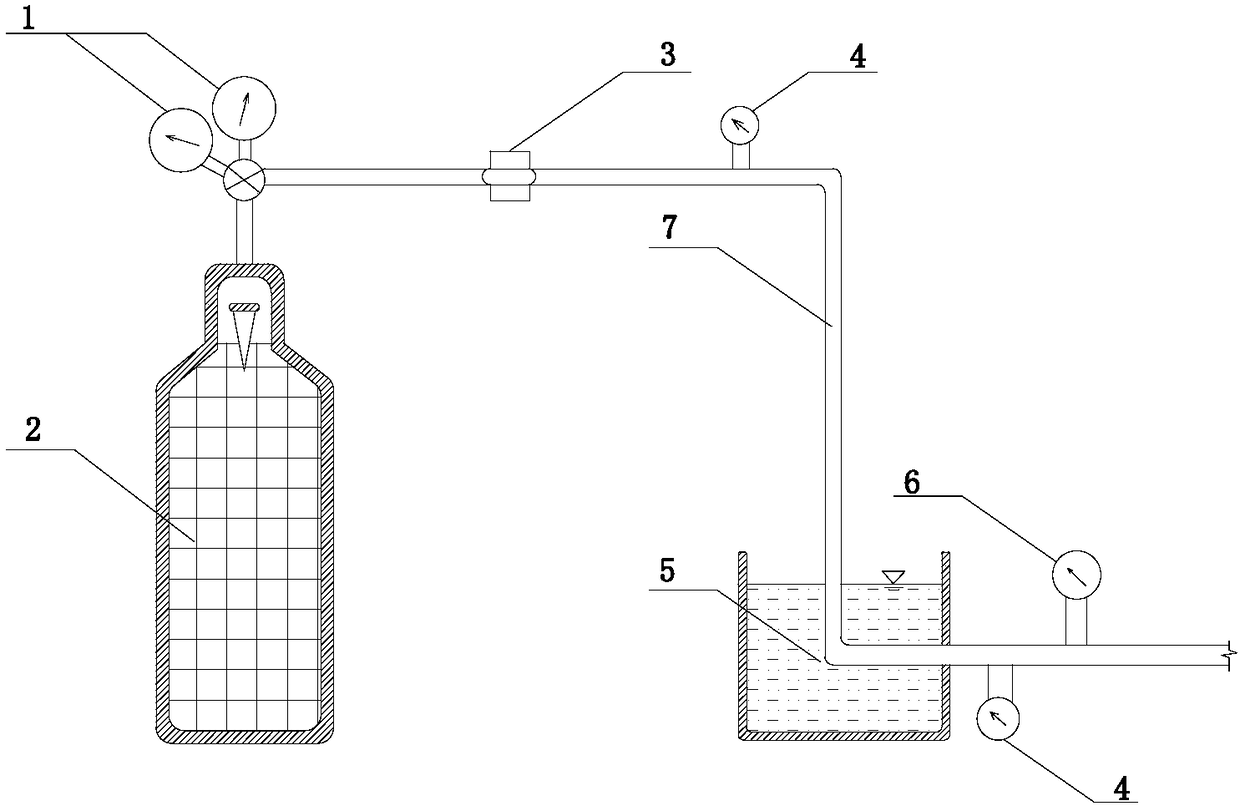

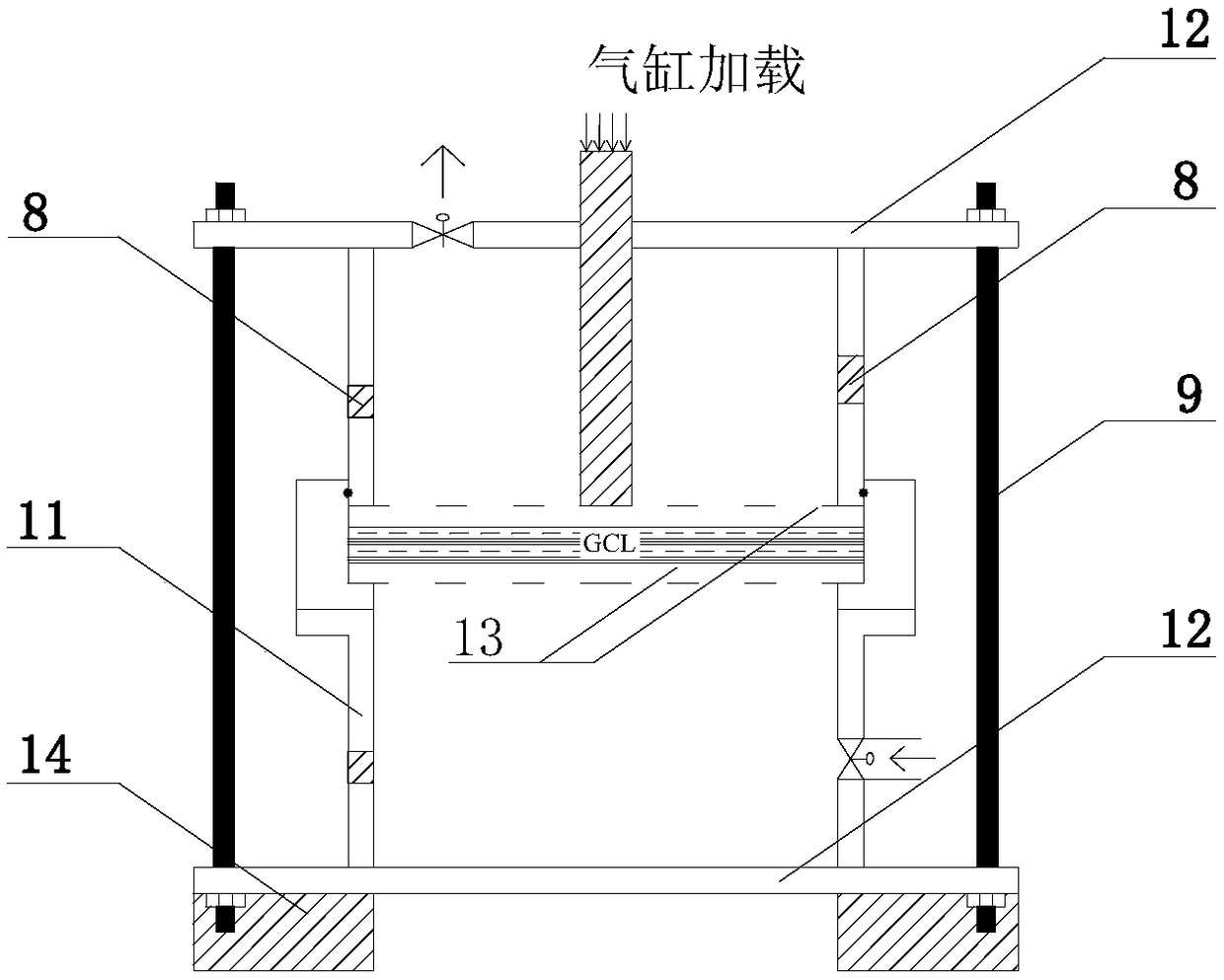

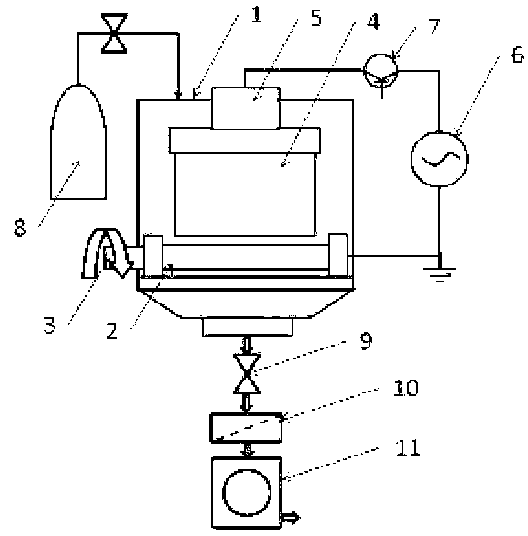

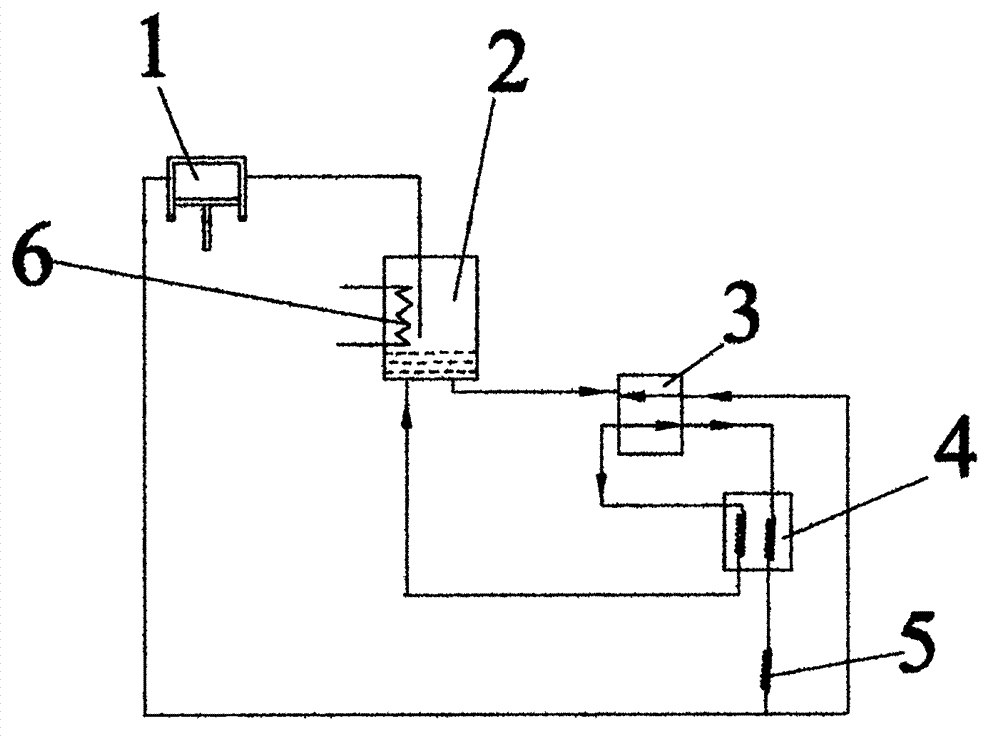

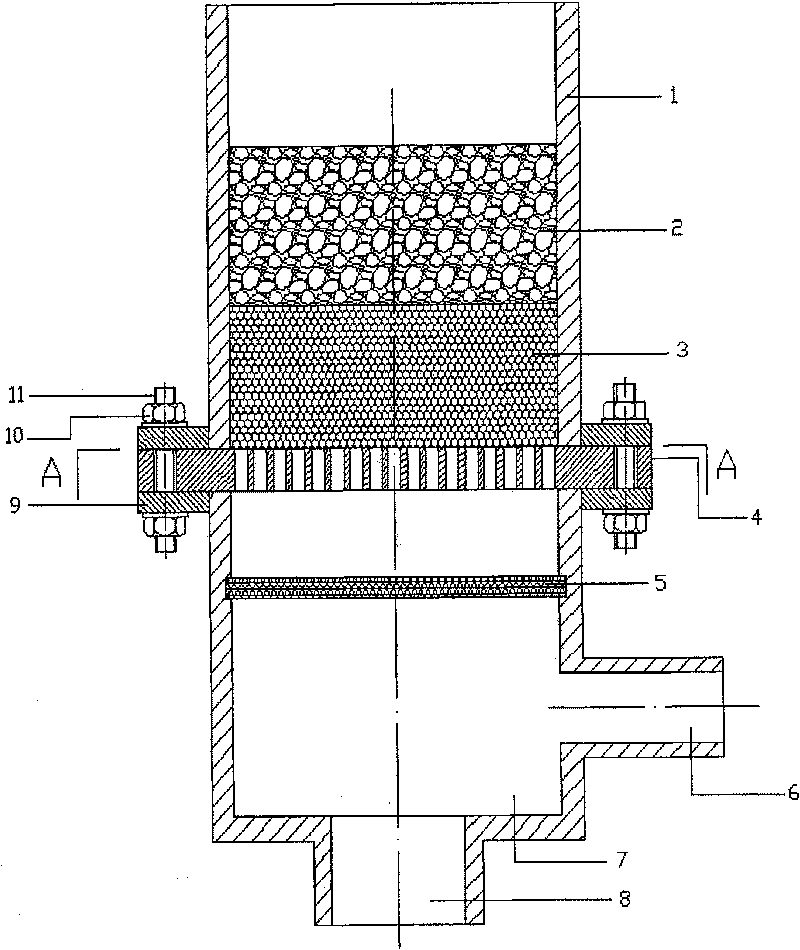

Experimental device for testing diffusion coefficient and osmotic coefficient of unsaturated dielectric gas

PendingCN108344668ASurface/boundary effectPermeability/surface area analysisWater bathsOsmotic coefficient

The invention discloses an experimental device for testing a diffusion coefficient and an osmotic coefficient of an unsaturated dielectric gas. The device mainly comprises a gas-supplying device, a main body reaction device and an outlet gas processing device. The gas-supplying device comprises a water-bath heating device for heating transmitted gas, simulating the temperature generated by landfill refuse degradation and temperature variation generated by the external temperature change; the main body reaction device is composed of three parts of a lower chamber, a middle chamber and an upperchamber, which are used for simulating refuse landfill gas, landfill covering soil (or GCL) and soil sample upper environment. The upper part is loaded to a porous stainless steel plate through an aircylinder to apply pressure to a soil sample (or GCL), so as to simulate the soil pressure at the upper part of the landfill covering soil (or GCL). The outlet gas collecting device is mainly composedof a gas collecting bottle, can be used for collecting and treating the gas after reaction, and the situation that the gas after experiment pollutes the air is avoided. The device is simple in structure and wide in application range.

Owner:ZHEJIANG UNIV

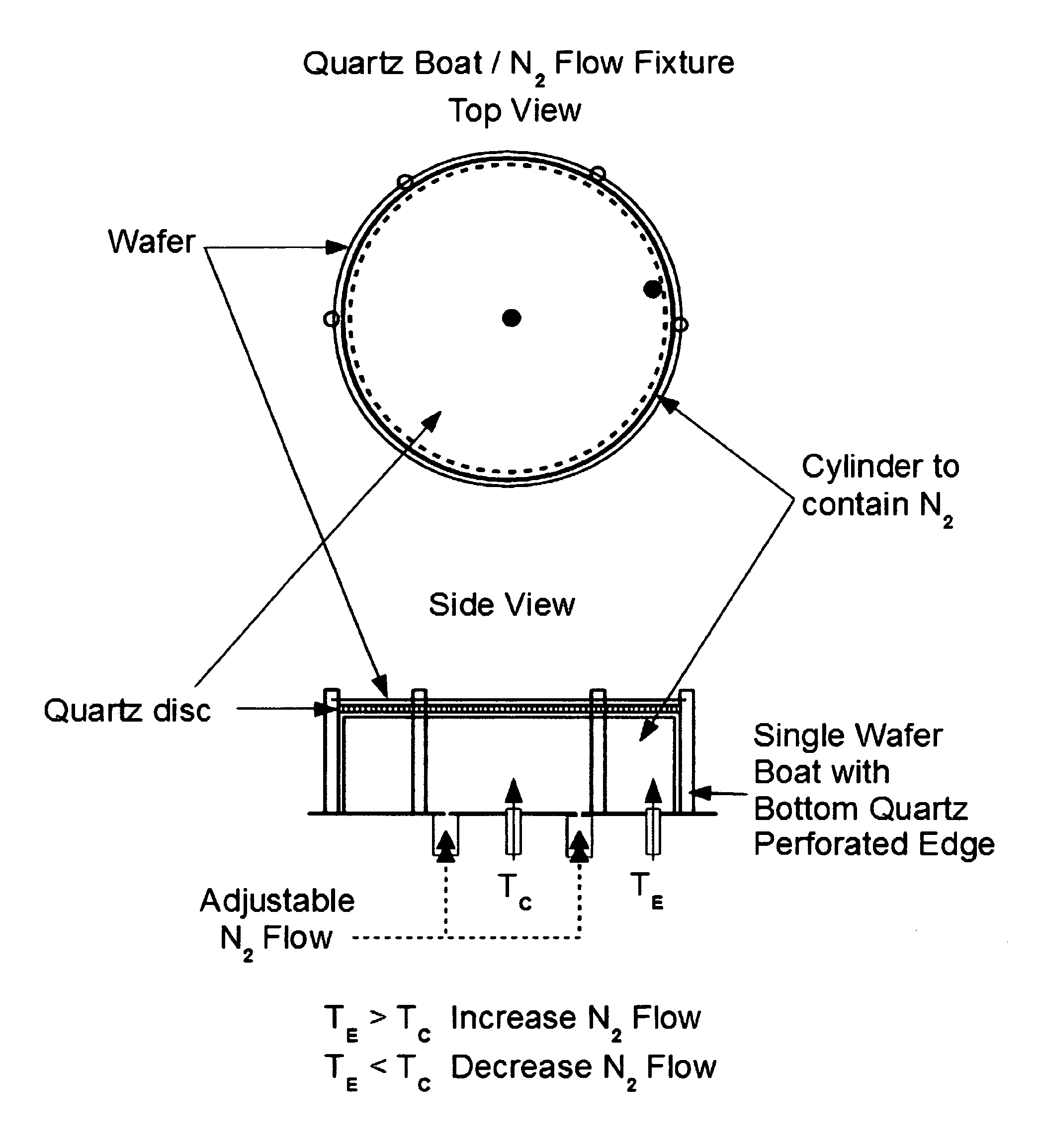

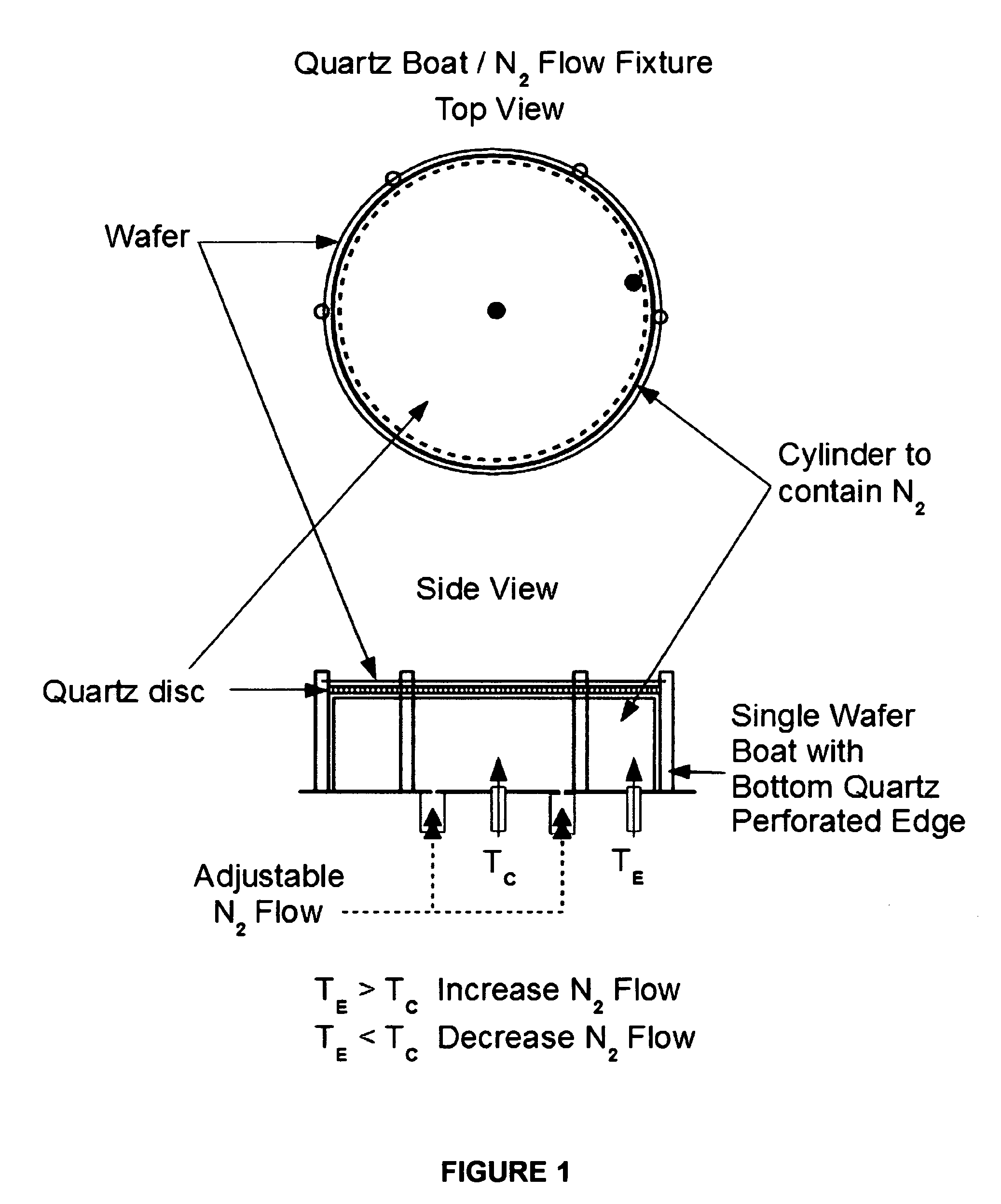

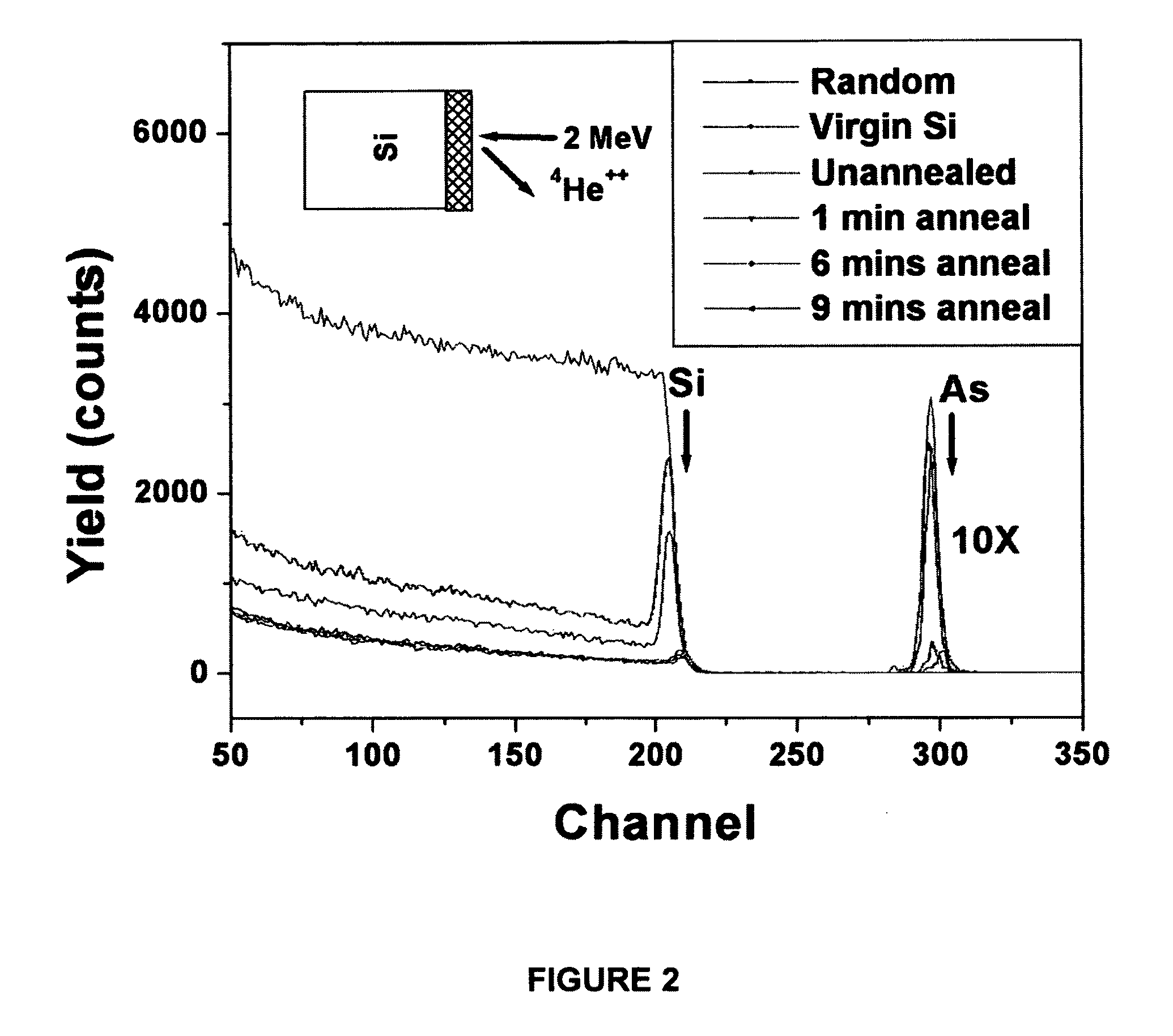

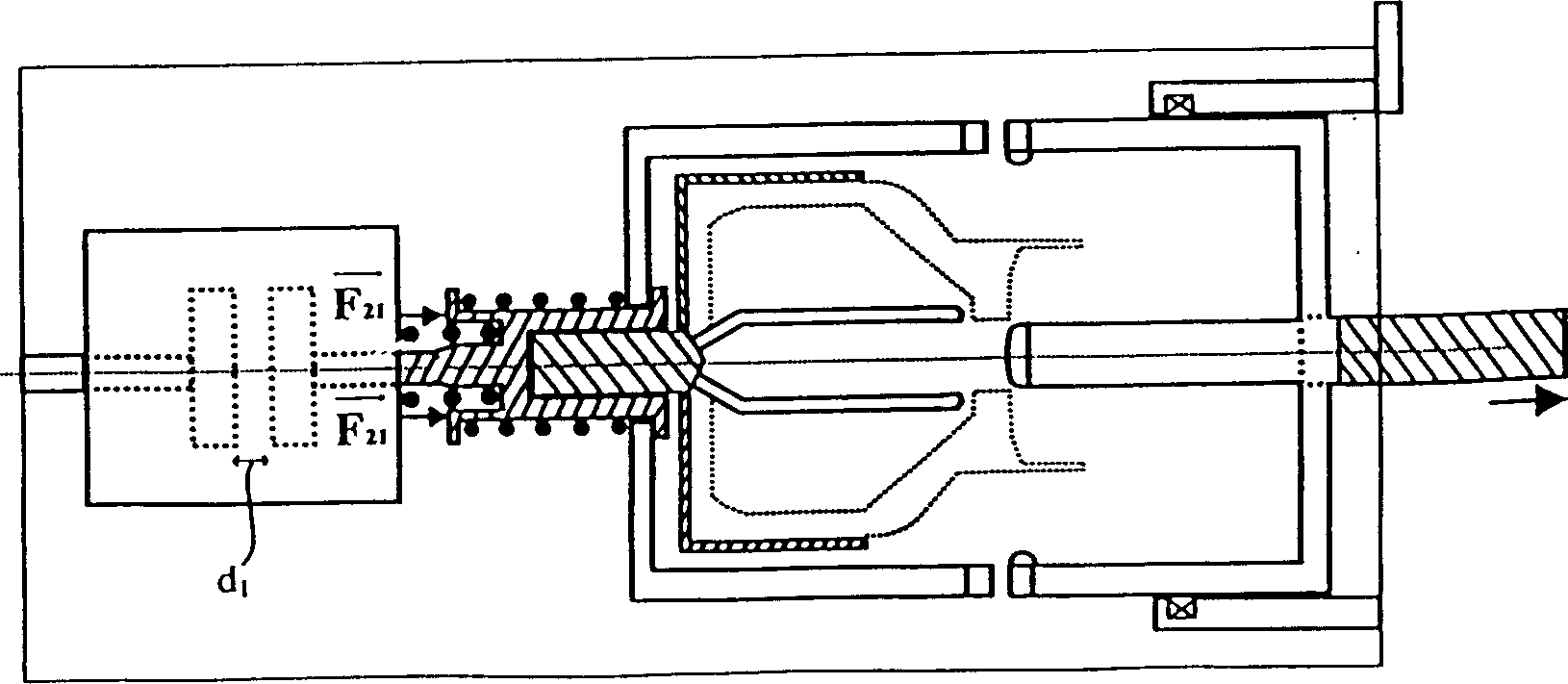

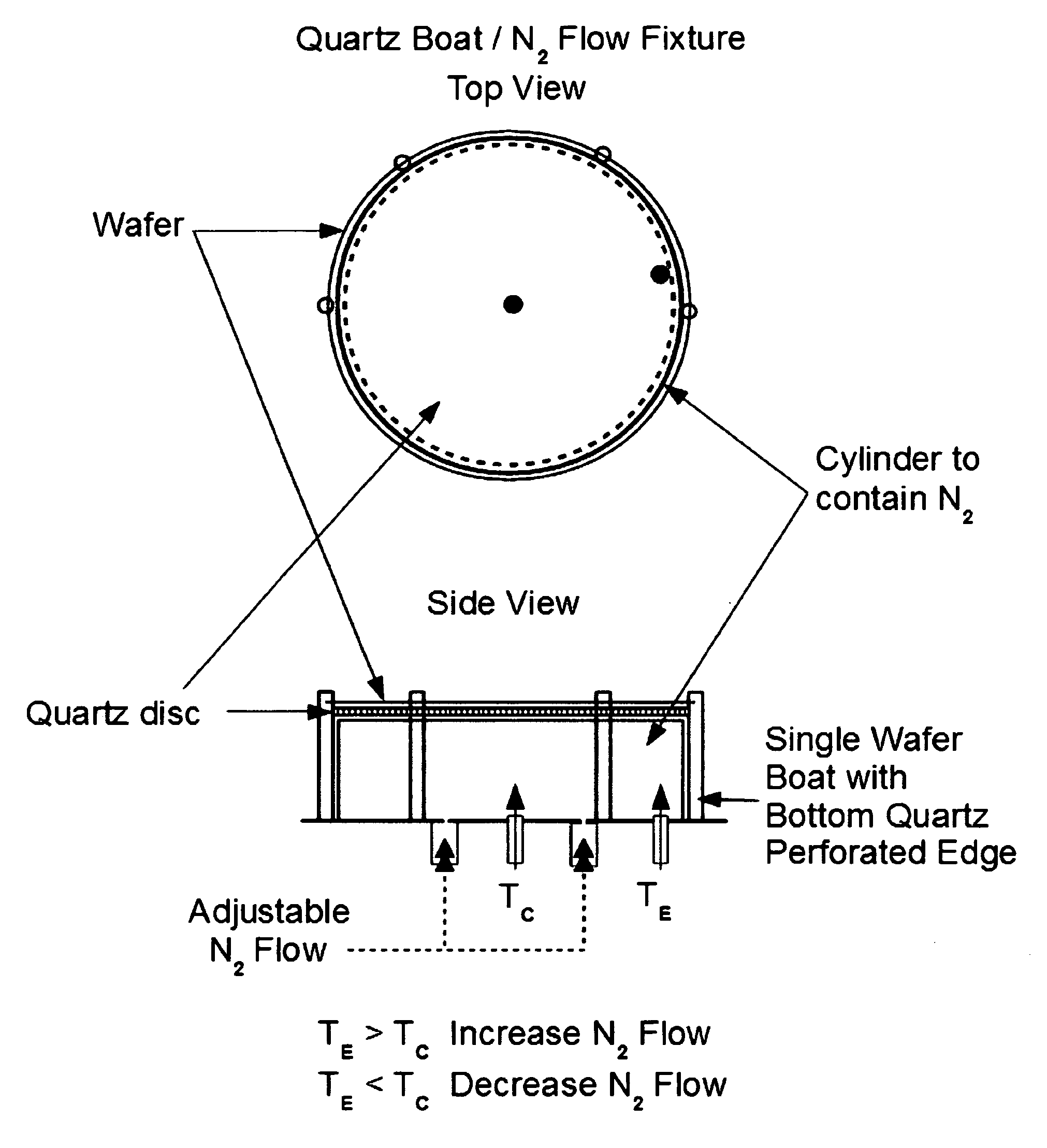

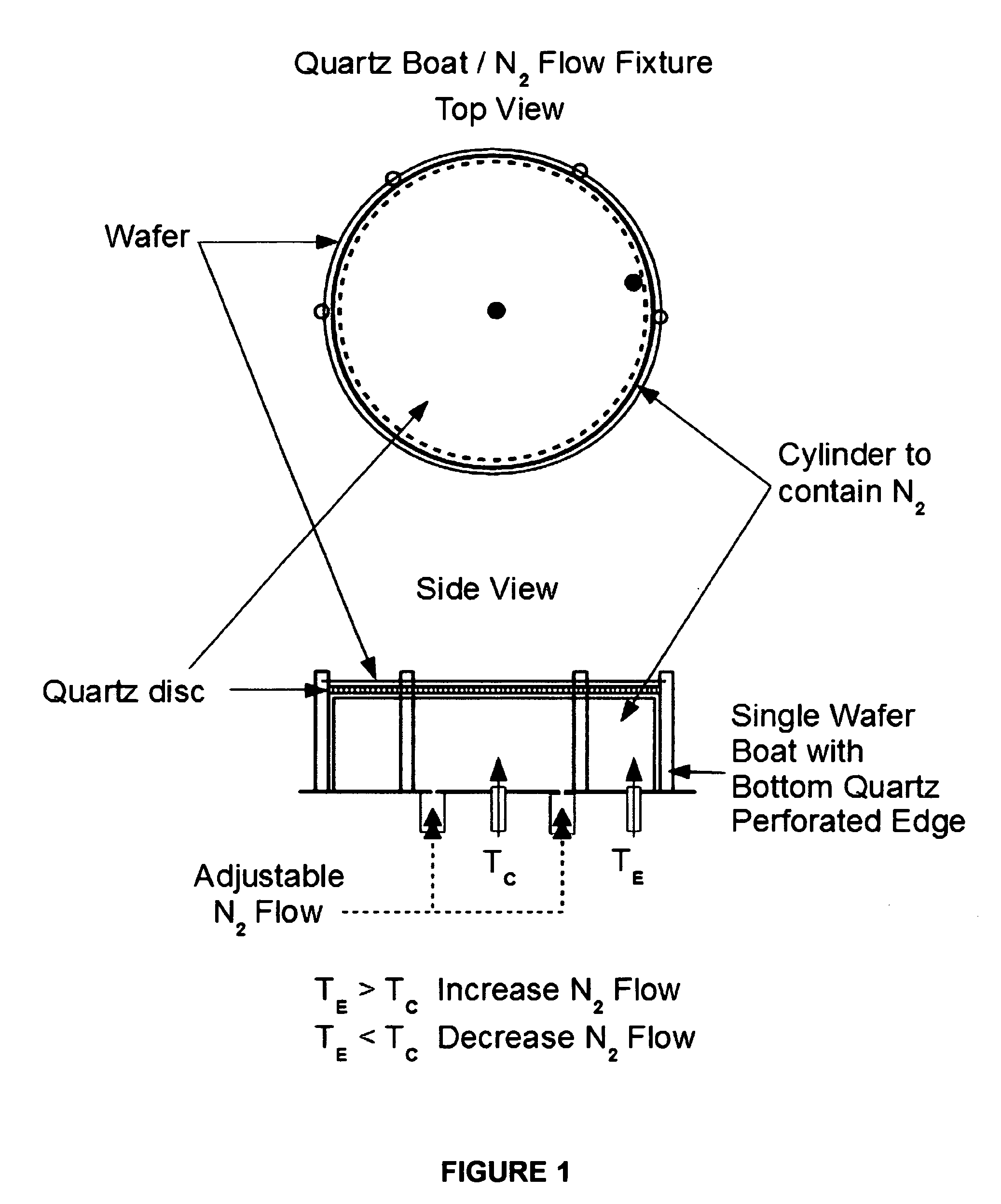

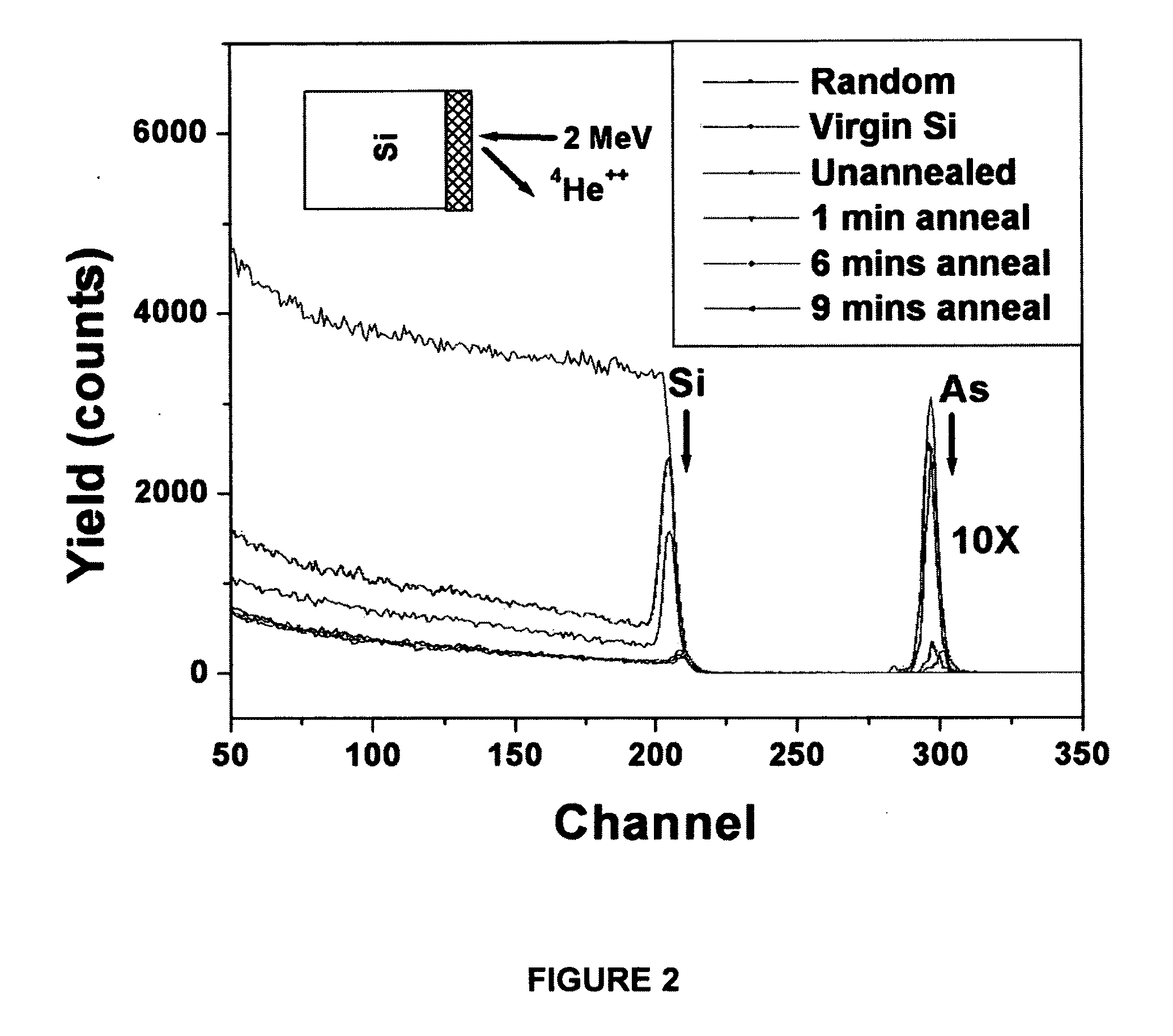

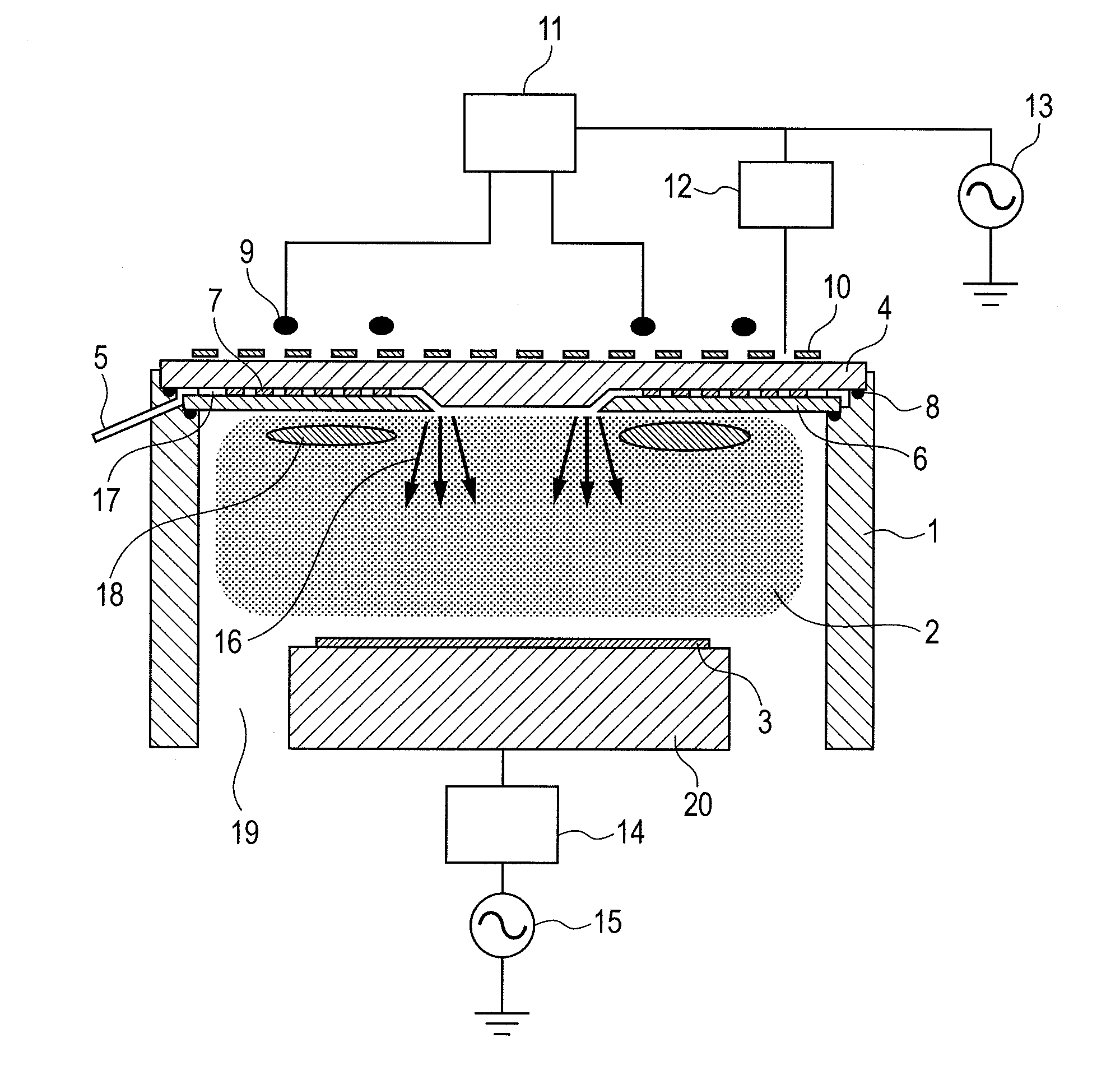

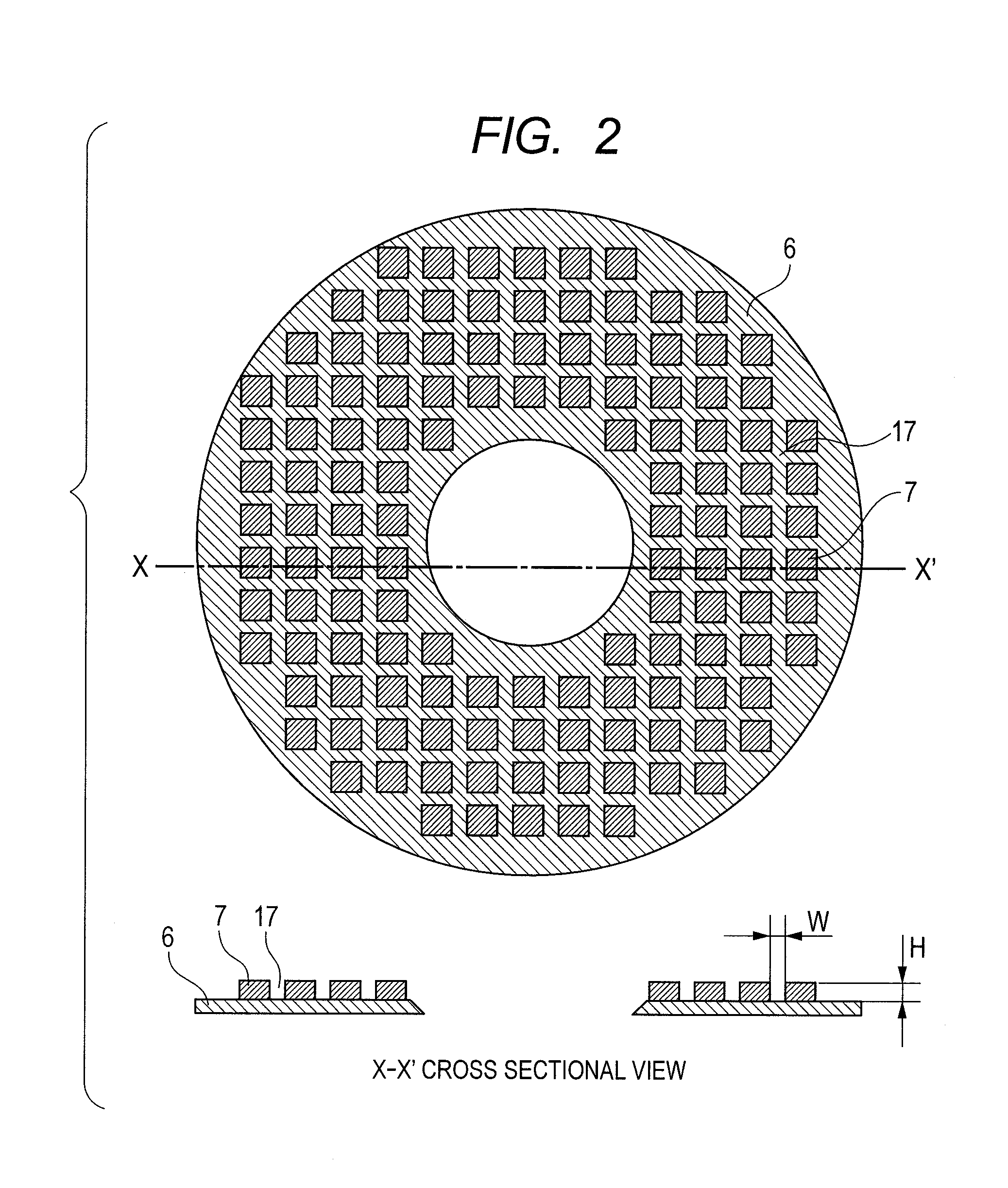

Method and apparatus for uniform microwave treatment of semiconductor wafers

ActiveUS7939456B2Radiation pyrometrySemiconductor/solid-state device testing/measurementElectricityTwo temperature

A microwave heating system comprises a microwave applicator cavity; a microwave power supply to deliver power to the applicator cavity; a dielectric support to support a generally planar workpiece; a dielectric gas manifold to supply a controlled flow of inert gas proximate to the periphery of the workpiece to provide differential cooling to the edge relative to the center; a first temperature measuring device configured to measure the temperature near the center of the workpiece; and, a second temperature measuring device configured to measure the temperature near the edge of the workpiece. The gas flow is controlled to minimize the temperature difference from center to edge, and may be recipe driven or controlled in real time, based on the two temperature measurements. The method is particularly useful for monolithic semiconductor wafers, various semiconducting films on substrates, and dielectric films on semiconducting wafers.

Owner:APPLIED MATERIALS INC

Method and device for preparing boron-doped nano silicon material

InactiveCN103232040AControl spacingReduce sizeMaterial nanotechnologySilicon compoundsNano siliconNanoparticle

The invention discloses a method and a device for preparing a boron-doped nano silicon material. The method comprises the following steps of: placing a rod-like raw material serving as an electrode raw material in a spark discharge chamber; applying a voltage to the electrode raw material by using a pulse power supply and generating sparks under the protection of a dielectric gas or liquid material; partially melting and gasifying the electrode raw material; injecting the molten and gasified electrode raw material into a dielectric gas or liquid to form nanoparticles; and separating and collecting the nanoparticles by using a filter cloth-containing particle collection device. By the method and the device provided by the invention, the spark discharge area of the electrode raw material can be improved, so that the capacity for preparing the nanoparticles is improved; the requirement on scale production is met; and the distance among electrode raw materials can be controlled so as to control the size of the formed nanoparticles and improve the particle size distribution uniformity.

Owner:苏州金瑞晨科技有限公司

High voltage or medium voltage switch device composed of vacuum and gas circuit breaker

InactiveCN1477662AEasy to separateHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

A hybrid high-voltage or medium-voltage breaker device comprises: an enclosure filled with a dielectric gas, a vacuum switch comprising a fixed first arc contact and a second arc contact which can move in translation in the axial direction of the enclosure, a force being exerted on the second contact when the vacuum switch allows current to flow, a gas switch comprising a fixed or quasi-fixed third arc contact and a fourth arc contact which can move in translation, and an operating rod connected to the fourth contact. The device further comprises: a connection arrangement for electrically connecting the second and third contacts, and which are moved in translation conjointly with the second contact, and a displacement arrangement connected to the connection arrangement and to the rod to move them to separate the second and fourth contacts from the first and third contacts, respectively, comprising a dead travel connecting arrangement for moving the rod over a particular dead travel at the same time as operating on the connection arrangement to hold the vacuum switch closed during that movement, and which thereafter acquire a movement in translation which is independent of the movement acquired simultaneously by the connection arrangement.

Owner:ALSTOM TECH LTD

Micro-gap gas filled dielectric capacitor

InactiveUS20030095371A1Improve performanceFixed capacitor dielectricStacked capacitorsDielectricPlanar electrode

The gas dielectric capacitor for high frequency applications. The capacitor has first and second planner electrodes separated by an adhesive having solid particles, which establish the distance between electrodes. An adhesive is formed along peripheral edges of the planner electrodes. The capacitor may include air, vacuum, or any number of other dielectric gases, which may be under pressure. A method is disclosed for manufacturing an array of capacitors having a pressurized gas dielectric.

Owner:MIND FUSION LLC

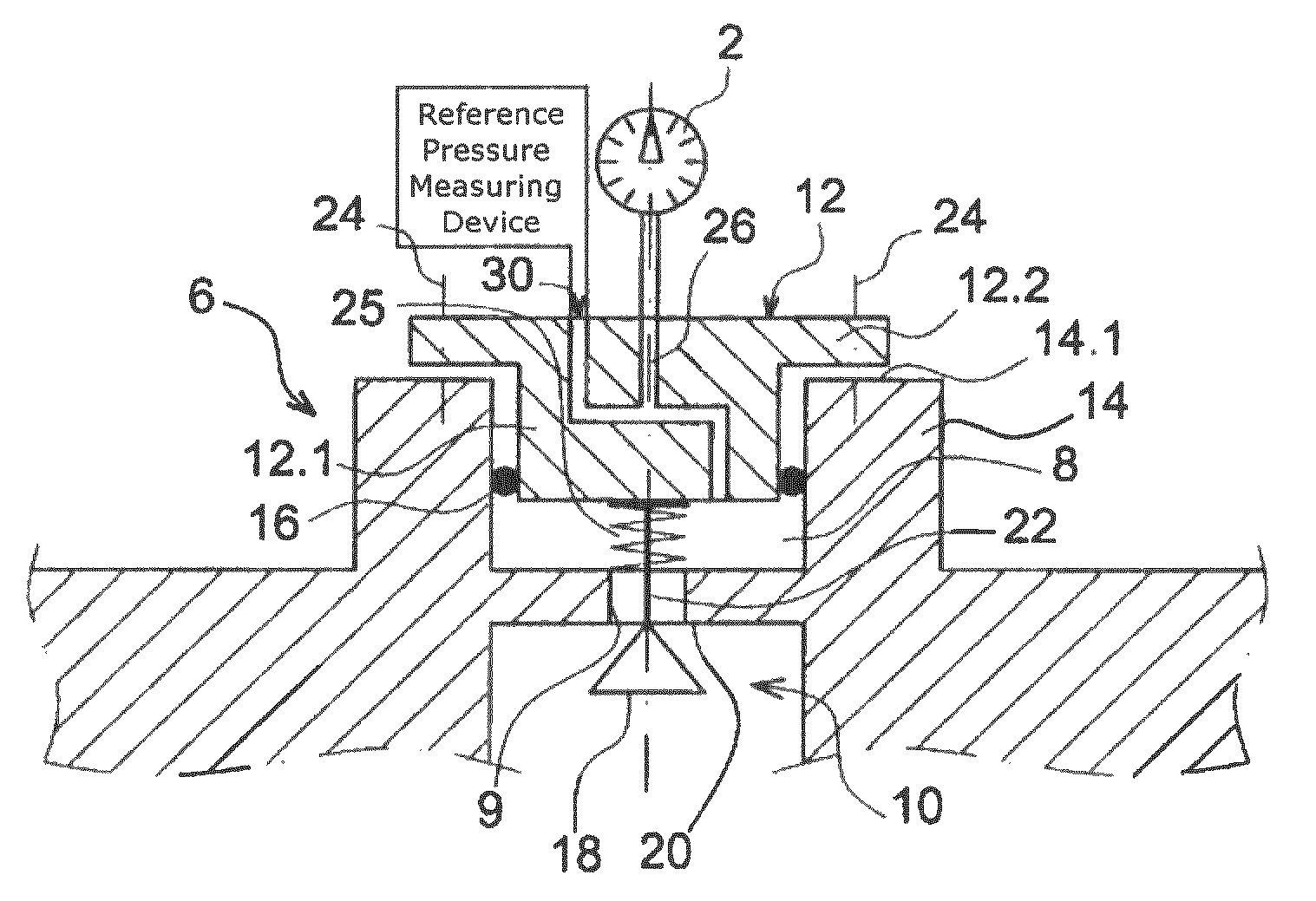

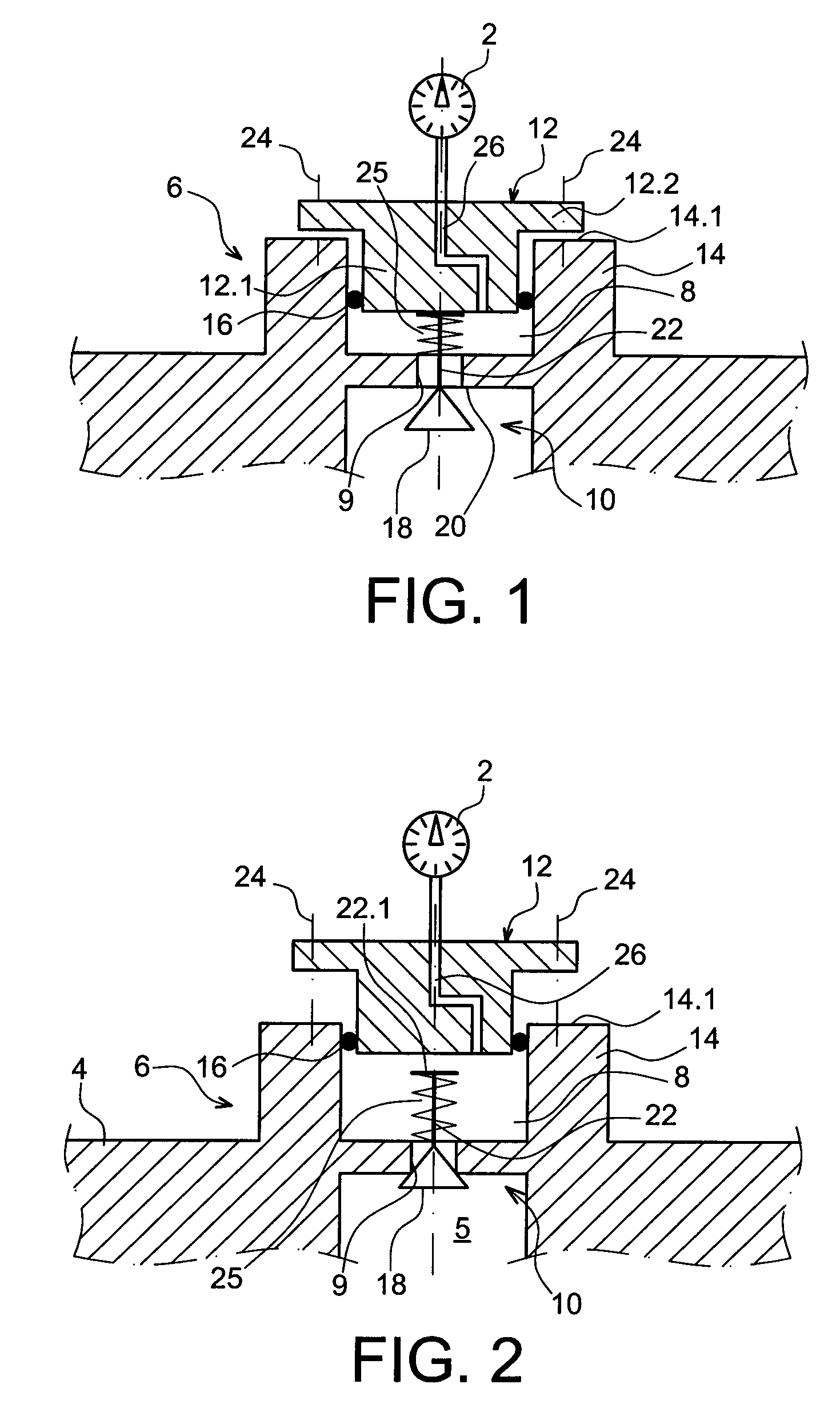

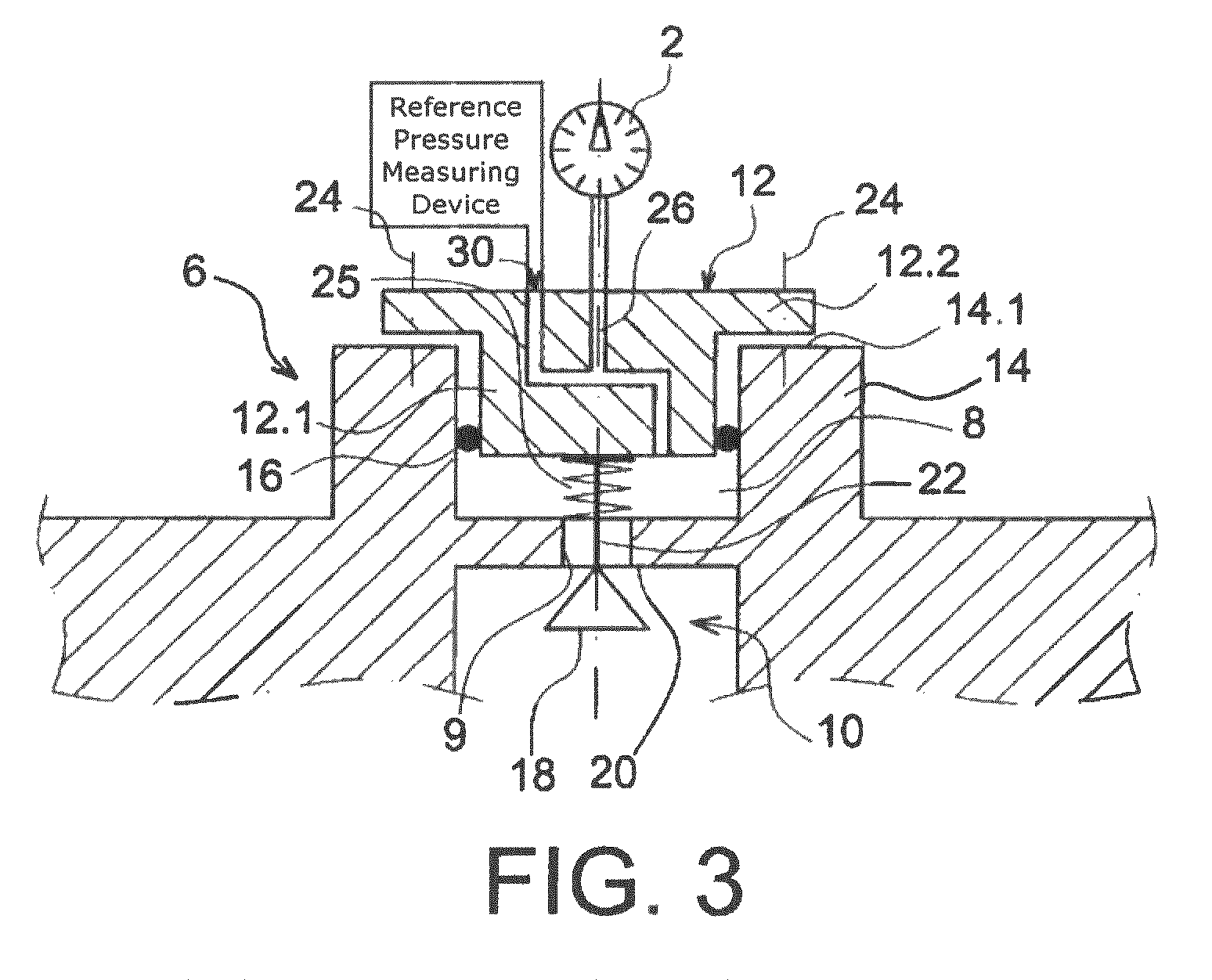

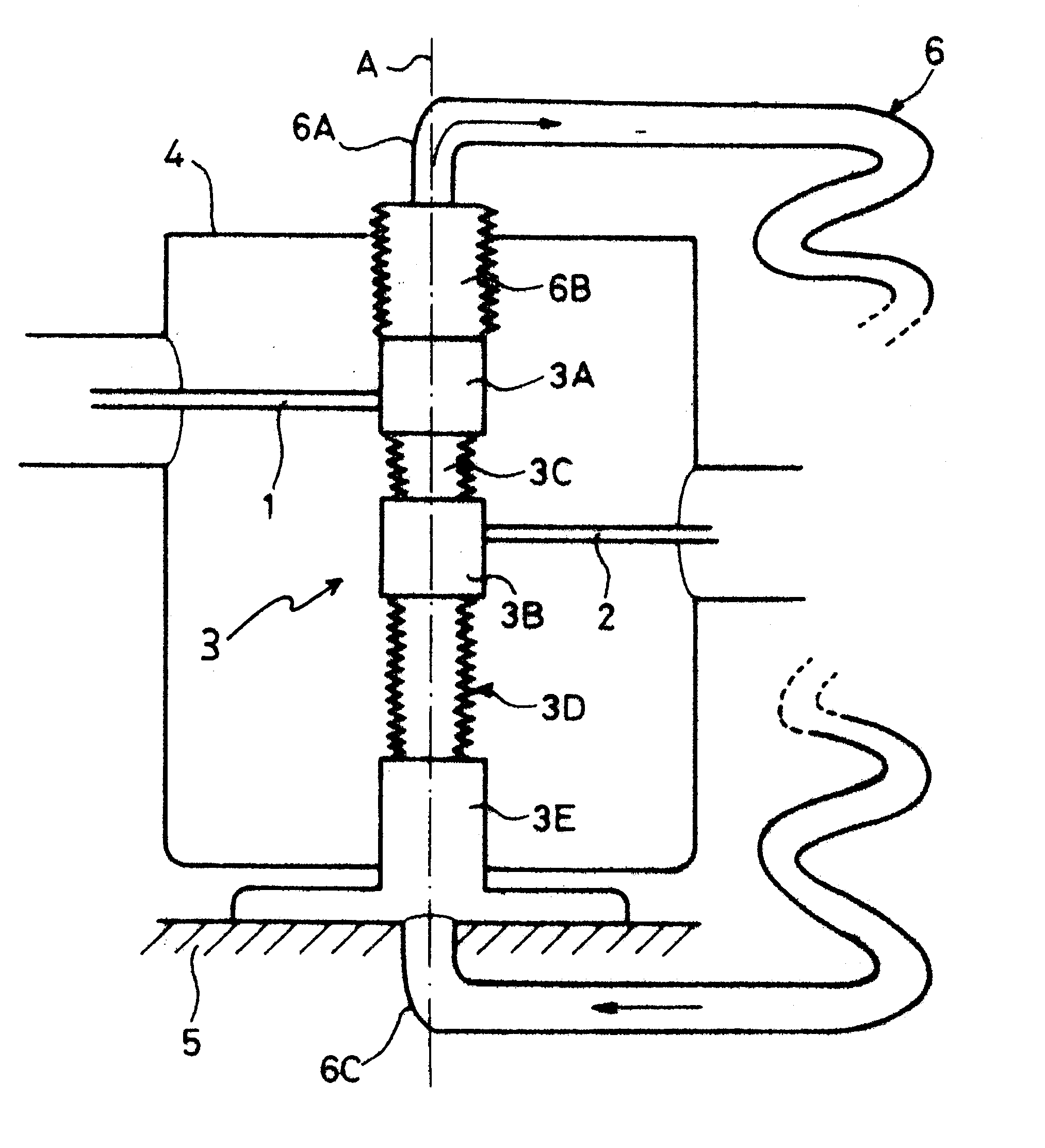

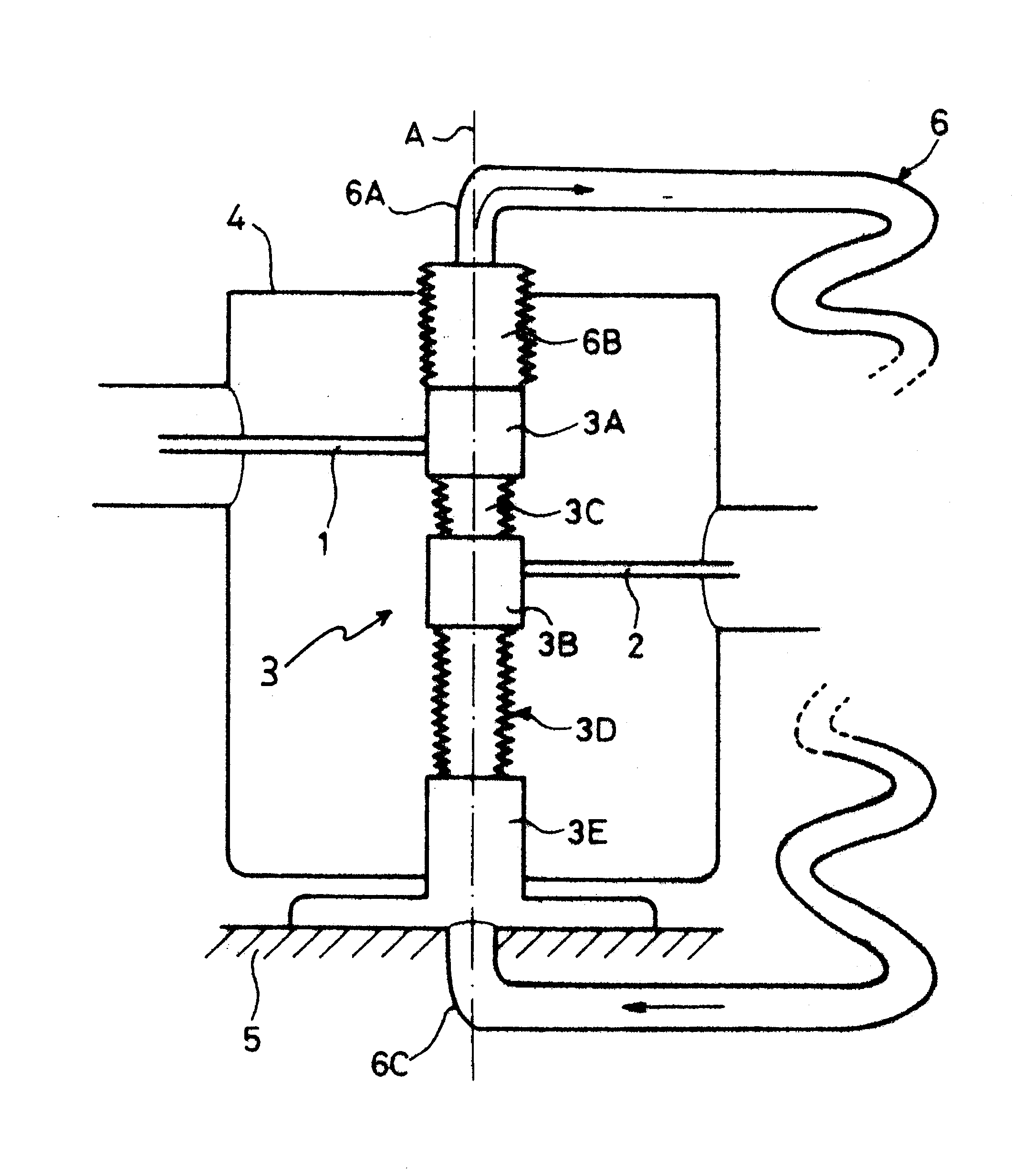

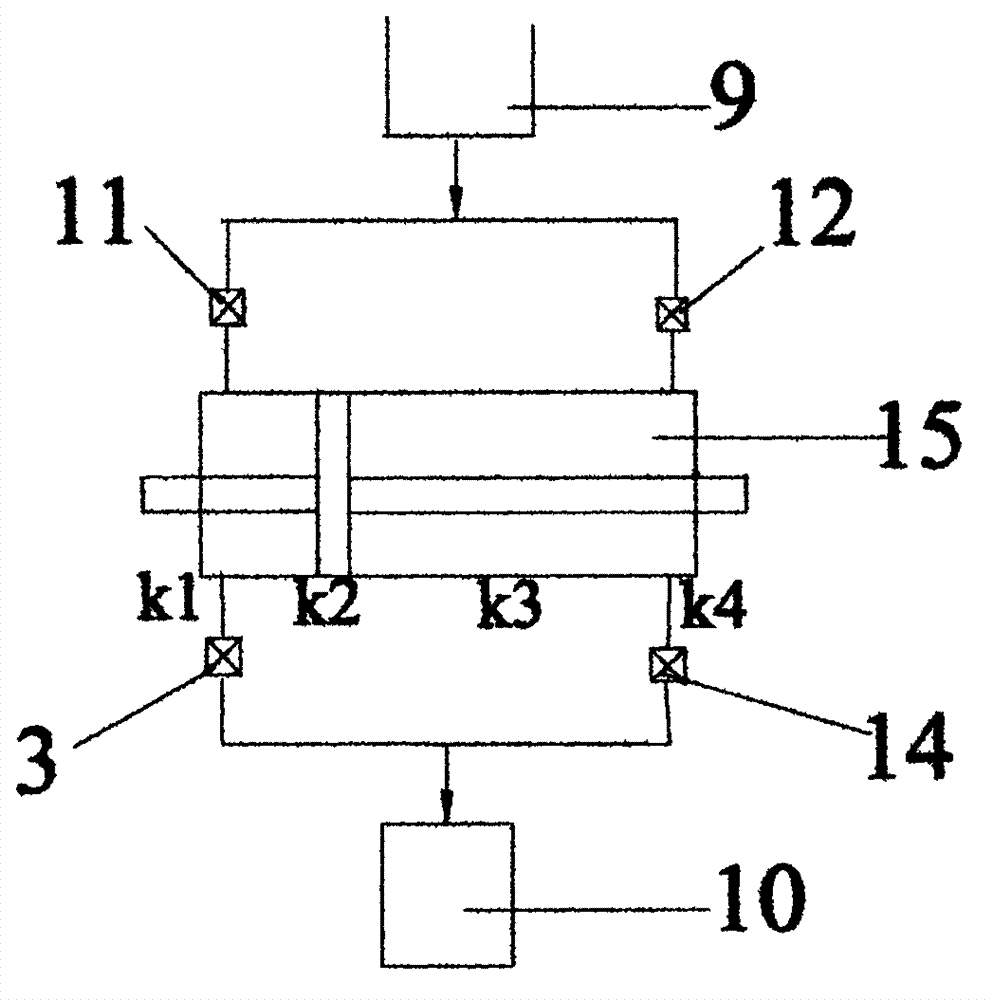

Checking apparatus for checking operation of a densimeter for medium-voltage and high-voltage electrical equipment, and a method of checking operation of a densimeter

ActiveUS7937985B2Simple and robustFluid pressure measurementHigh-tension/heavy-dress switchesElectrical devicesClosed chamber

Checking apparatus for checking operation of a densimeter for medium-voltage or high-voltage equipment having metal casing (4) that is filled with a dielectric gas under pressure; the apparatus comprises a closed chamber (8) suitable for being put into communication with an internal space (5) of the casing (4), and isolation means (10) for isolating the chamber (8) in gastight manner from the internal space (5), in which apparatus said closed chamber (8) has a volume that can be caused to vary, and in which apparatus the densimeter is suitable for detecting at least one pressure threshold in said chamber.

Owner:ALSTOM TECH LTD

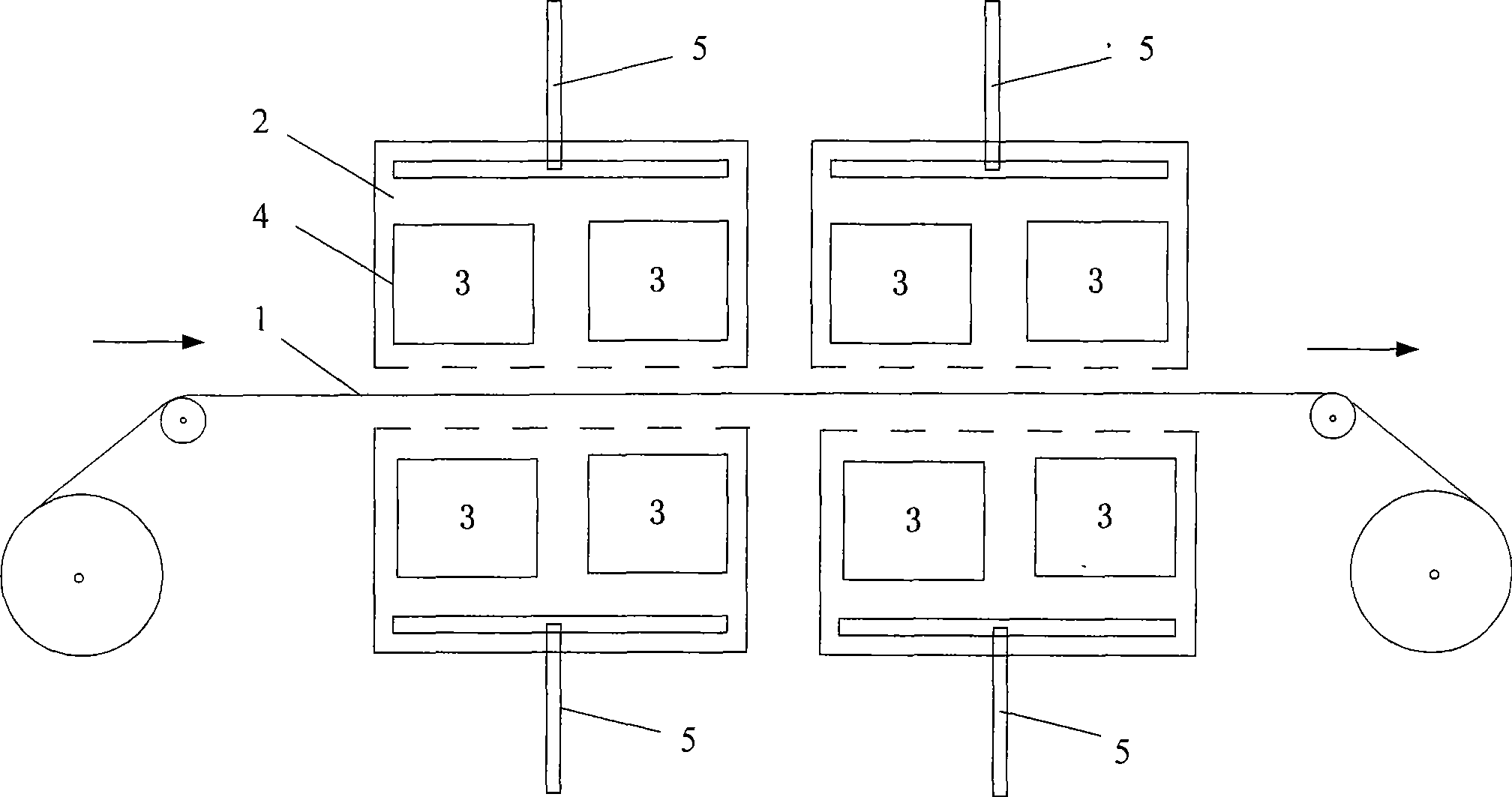

Normal atmosphere plasma strip steel film coating process

InactiveCN101376968AProduction process is environmentally friendlyLess investmentChemical vapor deposition coatingPlasma techniqueHigh pressureAlternating current

The invention discloses a normal pressure plasma strip steel film coating process; a base plate coil is decoiled and enters into a normal pressure plasma film coating unit; two electrodes are adopted, wherein, a high-voltage electrode is arranged above a steel sheet and covered by a barrier layer; a running base plate is arranged below the high-voltage electrode, grounded or arranged above a grounding electrode, and separated by an insulating substance; AC or DC with the frequency between 200Hz to 20KHz is fed between the two electrodes by feeding an organic precursor and carrier gas thereof with the flow more than 0.01sccm as well as reactant gas with the flow more than 1sccm; a dielectric layer or an insulating layer obstructs the current and produces dielectric discharge; medium obstructs the discharge and generates plasma; the steel sheet is coated with film when passing the plasma area. The whole process is environment protective, can realize a plurality of film coated products, and has simpler process and low investment compared with strip steel vacuum film coating.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnet interrupter for high voltage switching

ActiveUS8274007B2Less-robust partLower average energyHigh-tension/heavy-dress switchesAir-break switchesRadial planeEngineering

A magnetic interrupter consisting of a stationary and moving butt contacts that open an electric circuit in dielectric gas (e.g., SF6) contained in a sealed, pressurized insulating housing. One or both of the contacts contain a magnet with poles spaced apart in a radial plane perpendicular to the axial direction to spin the arc in the radial plane about the center of the contacts. Permanent magnets may be used to spin the arc so that the magnetic field is not affected by the magnitude of the arcing current, which makes the magnetic interrupter suitable for interrupting currents below fault level currents. One or both of the magnets may also be a field coil and a permanent magnet may be used in combination with a field coil.

Owner:SOUTHERN STATES

Capacitor switch with internal retracting impedance contactor

ActiveUS20050128662A1Easy to removeEasy to replaceHigh-tension/heavy-dress switchesAir-break switchesEngineeringElectrical impedance

A capacitor switch including a power contactor and an impedance contactor located within a relatively slender container filled with dielectric gas. The container may be a “dead tank” or an insulator. For the insulator configuration, the switch also includes a conductive cap housing a charging impedance located on the end of the insulator. The power contactor includes a relatively fixed probe contact and a linearly moving socket. The impedance contactor is ring-type butt contactor surrounding the penetrating contactor that includes a retracting (but otherwise fixed) contact that surrounds the fixed probe, and a traveling ring contact that surrounds and moves with the moving socket contact. The impedance contactor closes before the power contactor on the closing stroke to introduce the charging impedance into the circuit. A puffer mechanism retards the expansion of the retracting contact on the opening stroke, which causes the impedance contactor to open before the power contactor.

Owner:SOUTHERN STATES

Power station switch with a radiator/heat-exchanger

InactiveUS6492609B1Low costHigh currentSubstation/switching arrangement cooling/ventilationHigh-tension/heavy-dress switchesPower stationMetal

A power station switch having high nominal current, the switch comprising a break chamber containing a dielectric gas under pressure and mounted inside a protective sheath which may optionally carry a general flow of cooling air, and a radiator / heat-exchanger situated outside said sheath and connected to said break chamber in which said gas under pressure is put into continuous circulation. Said gas under pressure as cooled in the radiator / heat-exchanger is returned to the break chamber via a metal case of the break chamber that is designed to be grounded.

Owner:ALSTOM TECH LTD

Method and apparatus for uniform microwave treatment of semiconductor wafers

ActiveUS20110076787A1Easy temperature controlHeating evenlyRadiation pyrometryMuffle furnacesTwo temperatureEngineering

A microwave heating system comprises a microwave applicator cavity; a microwave power supply to deliver power to the applicator cavity; a dielectric support to support a generally planar workpiece; a dielectric gas manifold to supply a controlled flow of inert gas proximate to the periphery of the workpiece to provide differential cooling to the edge relative to the center; a first temperature measuring device configured to measure the temperature near the center of the workpiece; and, a second temperature measuring device configured to measure the temperature near the edge of the workpiece. The gas flow is controlled to minimize the temperature difference from center to edge, and may be recipe driven or controlled in real time, based on the two temperature measurements. The method is particularly useful for monolithic semiconductor wafers, various semiconducting films on substrates, and dielectric films on semiconducting wafers.

Owner:APPLIED MATERIALS INC

Drive rod for a high-voltage circuit-breaker

InactiveUS6583375B2Easy to implementHigh-tension/heavy-dress switchesAir-break switchesHigh pressureSwitchgear

The drive rod for high-voltage switchgear that is insulated with a dielectric gas comprises a segment made of an electrically-insulating material and two metal end pieces fixed to respective ends of the segment, as well as a thermal shield that is made of an electrically-insulating material, that is disposed between the end pieces, and that surrounds the insulating segment while being spaced apart therefrom to define an annular gap serving to be filled with the dielectric gas. In this way, the insulating segment of the rod is protected against thermal attack from electric arcs.

Owner:ALSTOM TECH LTD

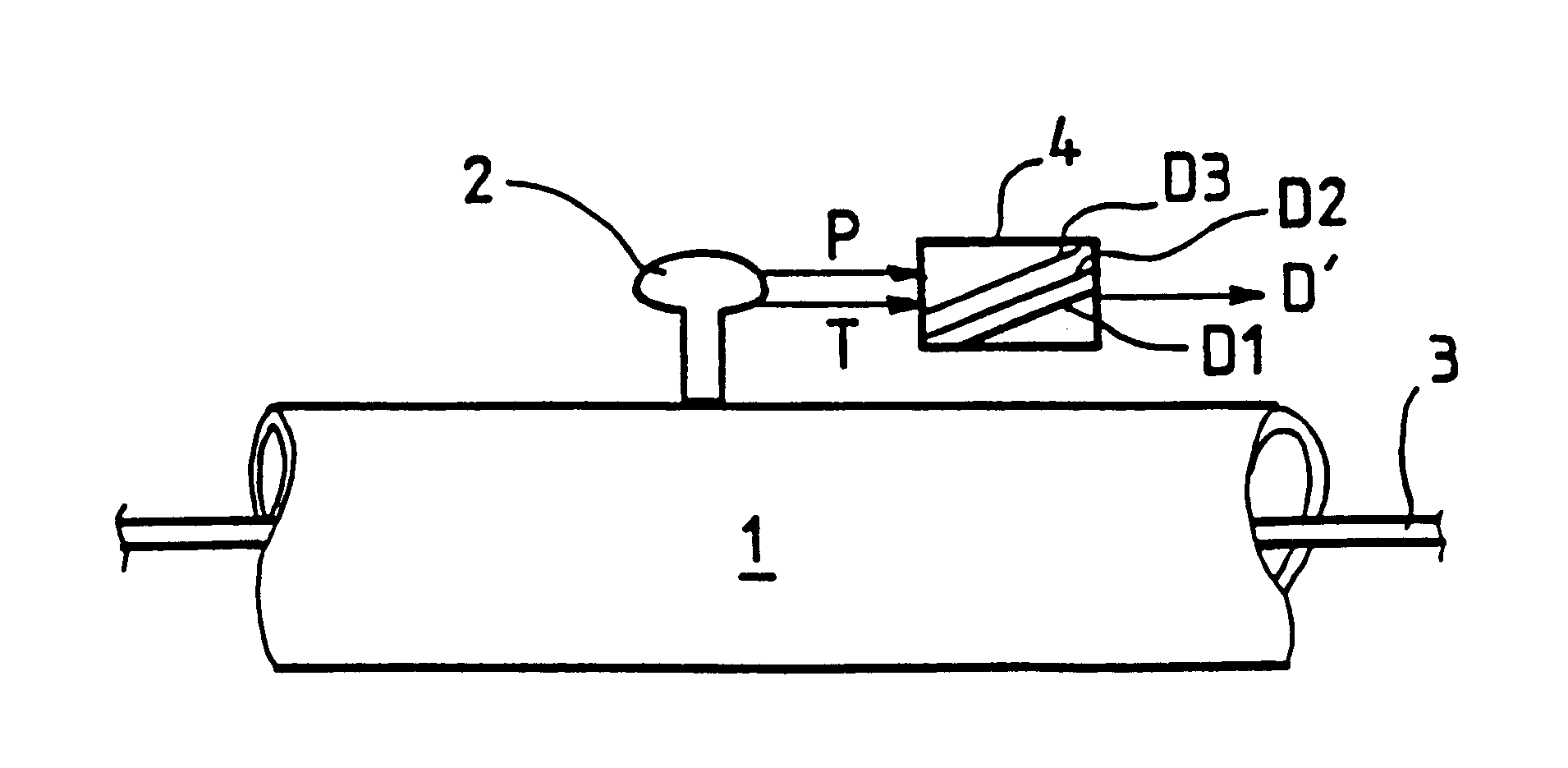

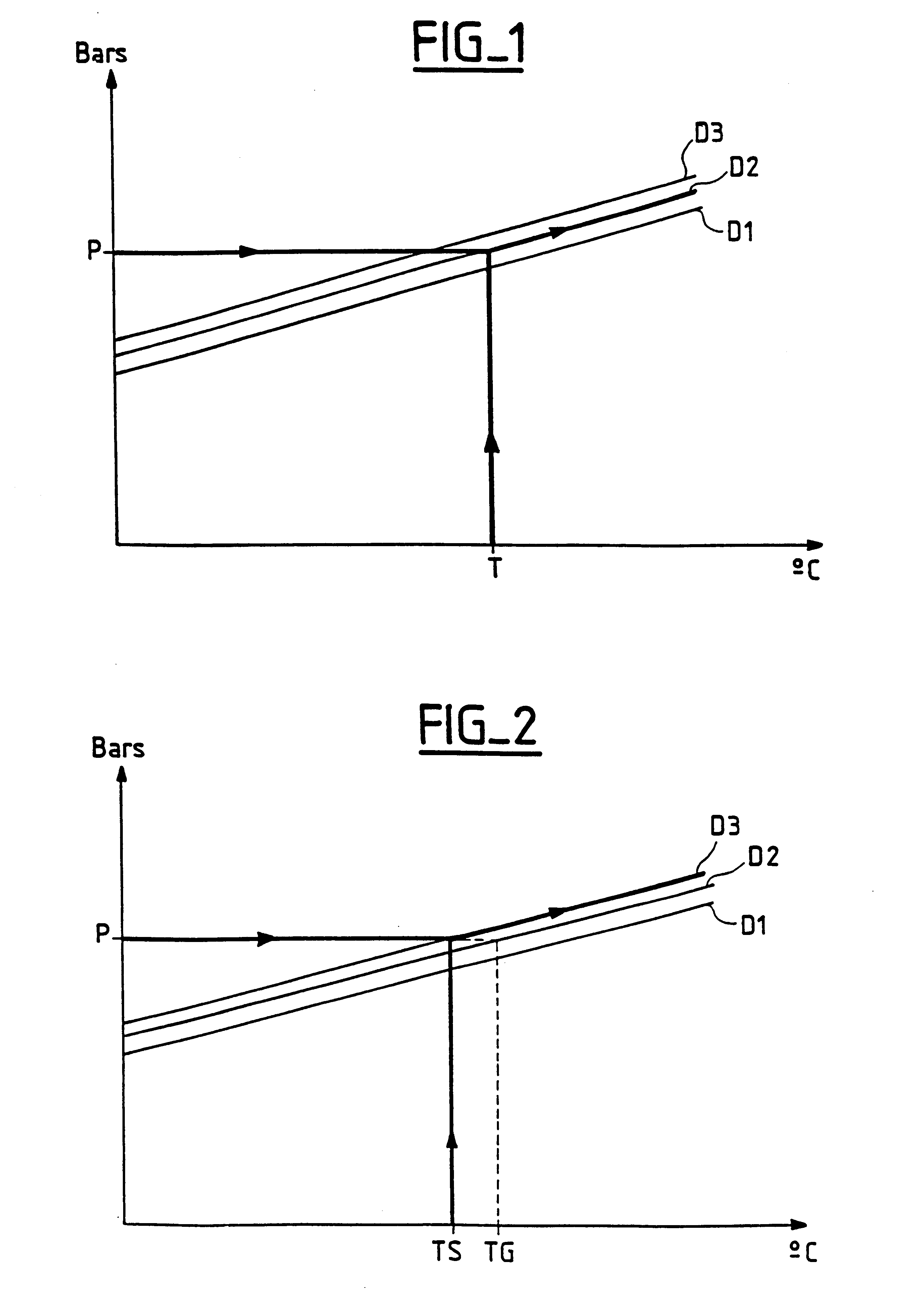

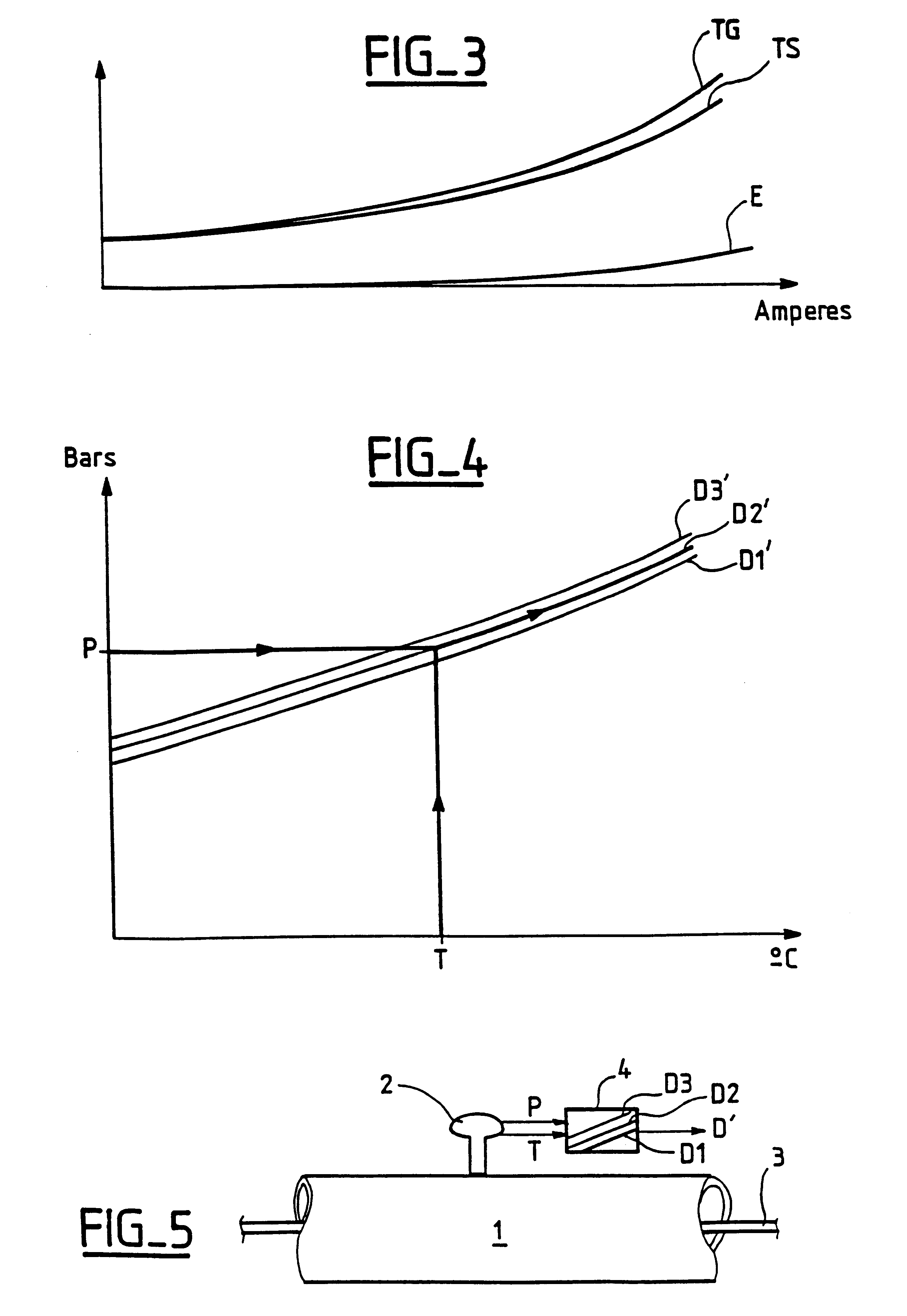

Method of measuring the density of a dielectric gas in a buried metal-clad line

InactiveUS6367308B1Analysing fluids using sonic/ultrasonic/infrasonic wavesSwitchgear arrangementsElectricityElectrical conductor

A method of measuring the density of a dielectric gas under pressure in a buried metal-clad electricity line consists in measuring the pressure and the temperature of the dielectric gas by means of a sensor mounted on the case of the line, and in compensating the pressure measurement as a function of the temperature measurement using constant density curves that have been corrected on the basis of a curve representing the difference between the temperature at the surface of the case of the line and the mean temperature of the gas inside the line for increasing amounts of current carried by the line conductor.

Owner:ALSTOM SA

Low-temperature heat engine device

The invention belongs to the technical field of heat engines and particularly relates to a low-temperature heat engine device which comprises a control system, a phase change working system, a heat absorber, a compression cooling and depressurization system and a pressurization system, wherein the heat absorber, the phase change working system, the compression cooling and depressurization system and the pressurization system are controlled by the control system and are sequentially connected to form a loop capable of absorbing heat in the environment temperature smaller than 100 DEG C and capable of performing phase change working, and the loop contains mixed dielectric gases. Compared with the prior art, gas phase change working is performed so that output power of the systems is remarkably increased. In the working process of the systems, the gases are liquefied after phase change working so that in the circulating process of the systems, not massive external work is needed to be consumed to liquefy the gases through a compressor. Most consumed matters in the balance exchange process of the pressurization system are cold capacity generated by the dielectric gases in the process. Therefore, output power of the systems is remarkably increased, consumed external work is remarkably reduced, and the low-temperature heat engine device can be achieved completely.

Owner:谢瑞友

Circuit-breaker including a channel for emptying the piston-driven compression chamber

InactiveUS6624371B2High dielectric strengthAvoid emptyingHigh-tension/heavy-dress switchesAir-break switchesEngineeringPiston

A circuit-breaker includes two contacts which are disposed in an interrupting space filled with a dielectric gas under pressure and between which an electric arc strikes during circuit-breaker opening, a thermal blast chamber communicating directly with the interrupting space, and a piston-driven compression chamber communicating with the thermal blast chamber. The piston-driven compression chamber communicates with the interrupting space via a discharge channel that is separate from the thermal blast chamber and that is closed by a discharge valve. The discharge valve is disposed between the thermal blast chamber and the piston-driven compression chamber in a manner such that the discharge valve opens to enable the gas under increased pressure in the piston-driven compression chamber to be discharged towards the interrupting space via the channel when the increase in the pressure of the gases in the thermal blast chamber is larger than the increase in the pressure of the gases in the piston-driven compression chamber.

Owner:ALSTOM TECH LTD

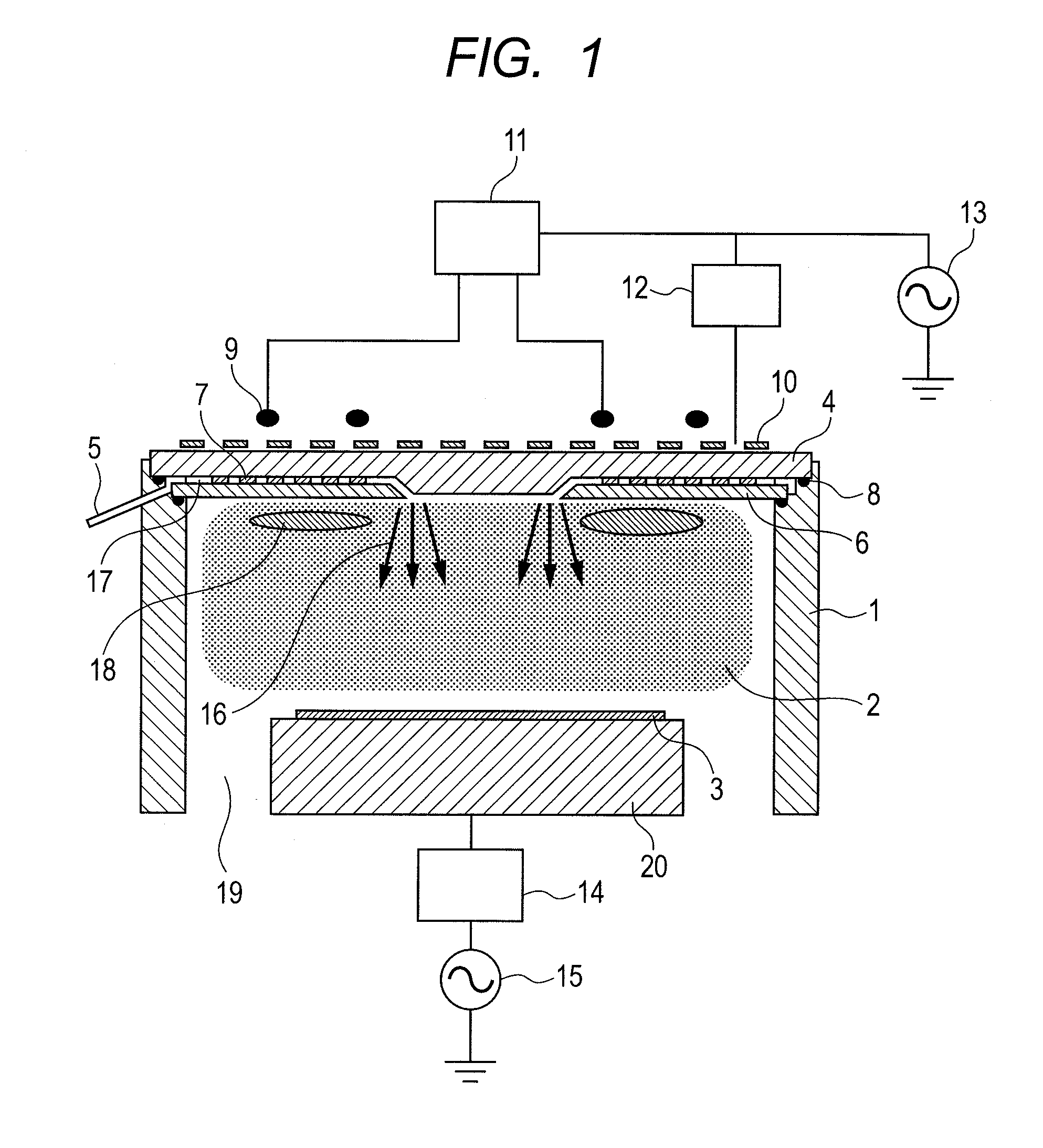

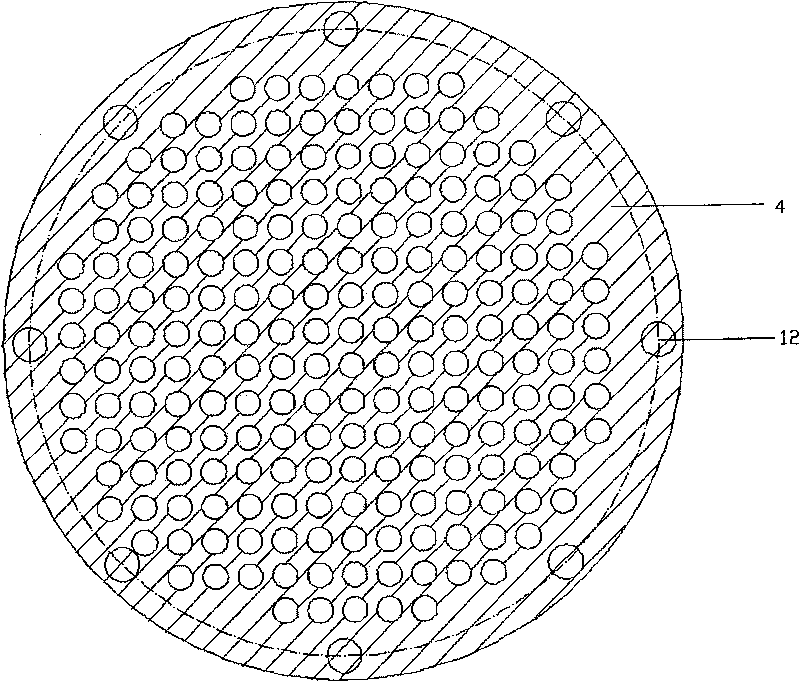

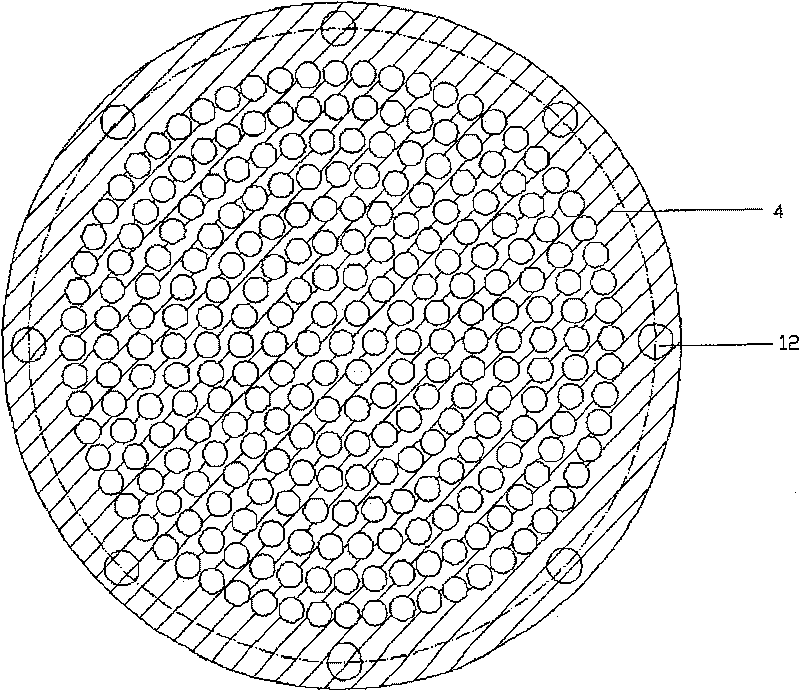

Plasma processing apparatus

InactiveUS20130000847A1High dielectric constantUniform plasma treatmentElectric discharge tubesSemiconductor/solid-state device manufacturingElectricityDielectric

There is provided a plasma processing apparatus enabling uniform plasma processing over the entire surface of a sample, without causing abnormal discharge even when the electromagnetic field strength is strong as in the case of the inductive coupling method. The plasma processing apparatus includes a process chamber, a first dielectric vacuum window, an inductive coil, a radio-frequency power supply, a gas supply unit, and a sample holder. The gas supply unit includes a second dielectric gas guide plate and a third dielectric island member. The second dielectric gas guide plate is located near below the vacuum window, and has a gas inlet port in the center. The third dielectric island member is provided in a gap between the vacuum window and the gas guide plate. The dielectric constant of the third dielectric is higher than the dielectric constant of the first and second dielectrics.

Owner:HITACHI HIGH-TECH CORP

Sectional type porous ceramic dielectric gas fuel combusting device

InactiveCN101158469BImprove securityWide calorific value rangeGaseous fuel burnerDielectricCombustor

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com