Low-temperature heat engine device

A low-temperature heating and supercharging device technology, which is applied in the direction of steam engine devices, mechanical equipment, machines/engines, etc., can solve the problems of low net output power, no phase change, and large amount of liquid in the expander, so as to achieve high mechanical efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

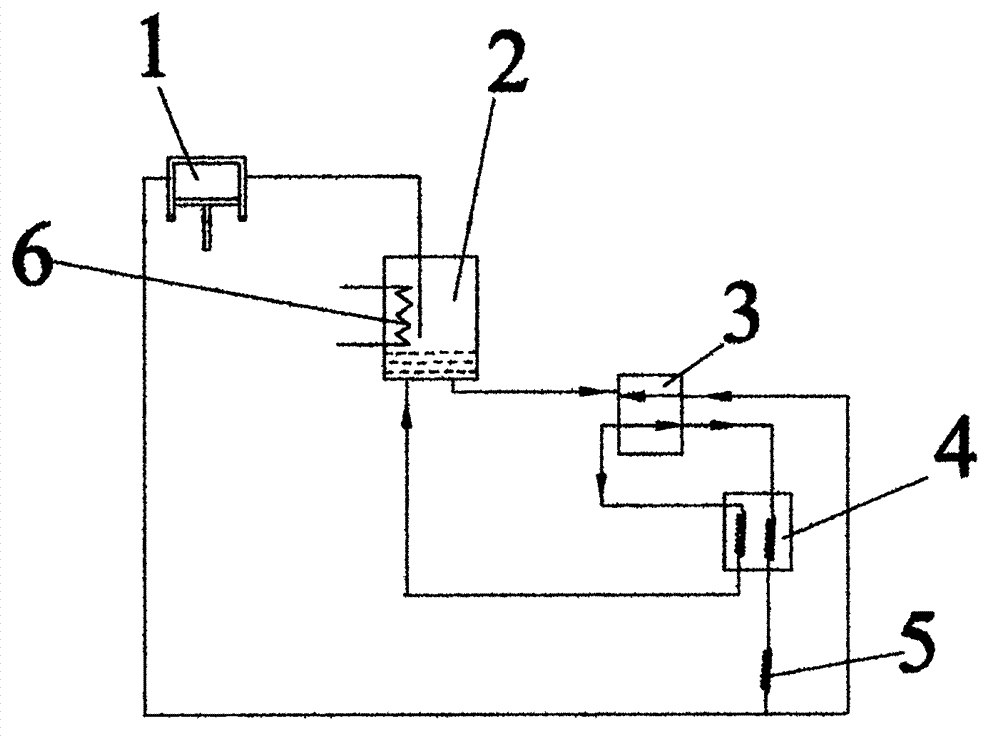

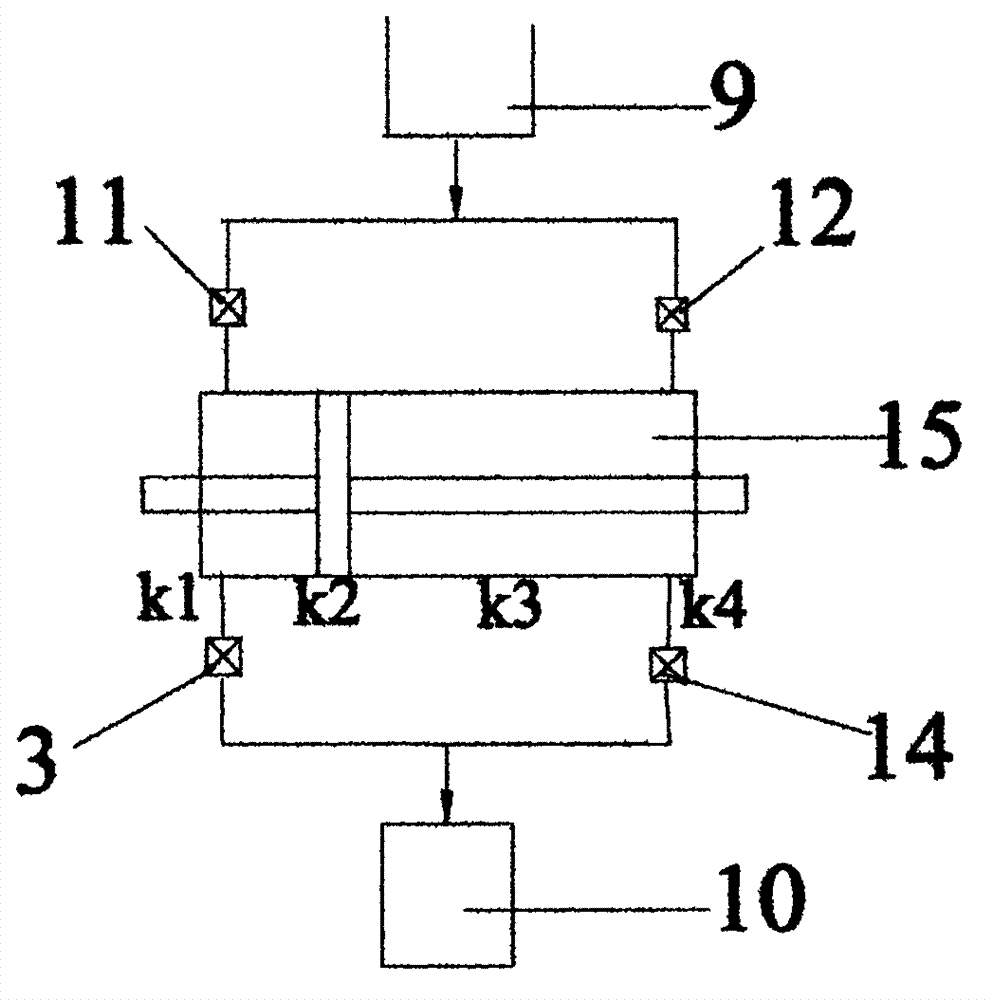

[0036] like figure 1 As shown, a low-temperature heat engine device provided in this embodiment includes a control system and a phase change work system 1 controlled by the control system, a heat absorber 5, a compression cooling depressurization system and a booster system, the heat absorber 5, a phase Work-changing system 1. The compression cooling depressurization system and the booster system are connected in sequence to form a closed loop that can absorb heat from the ambient temperature below 100°C and perform phase-change work. There is a mixed medium gas in the loop.

[0037] Among them, the phase change work is a process in which the internal energy of the mixed medium gas is reduced and liquefied during the expansion and work process of the mixed medium gas controlled by the control system. Most of the gas is liquefied into a low-temperature and low-pressure vapor-liquid mixture, that is, the medium gas is liquefied by doing work, not by external compression.

[003...

Embodiment 2

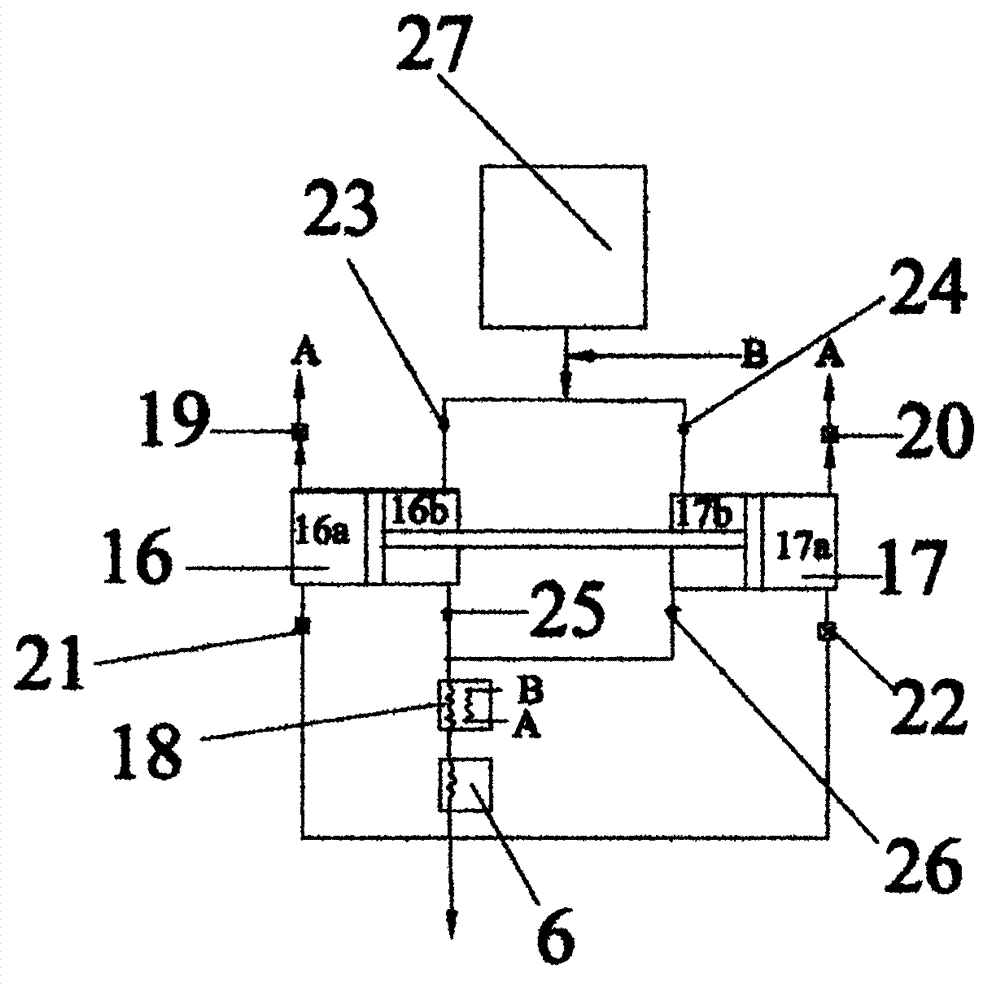

[0050] like Figure 4 As shown, the difference from Embodiment 1 is that the present embodiment provides a low-temperature heat engine device whose compression, cooling and decompression system includes a connected compressor 7, a refrigerator 6 and a cooling decompression chamber 2, and the refrigerator 6 is placed in the cooling and decompression chamber 2, and the two ends of the compressor 7 are respectively connected with the phase change work system 1 and the cooling and decompression chamber 2. The rest are the same as in Embodiment 1, and will not be repeated here. The compressor 7 can further increase the pressure difference between the two sides of the phase change work system 1 .

[0051] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com