Sectional type porous ceramic dielectric gas fuel combusting device

A gas burner, porous ceramic technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of small pore size, tempering, and easy blocking of porous media, achieve effective anti-tempering or explosion, improve The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

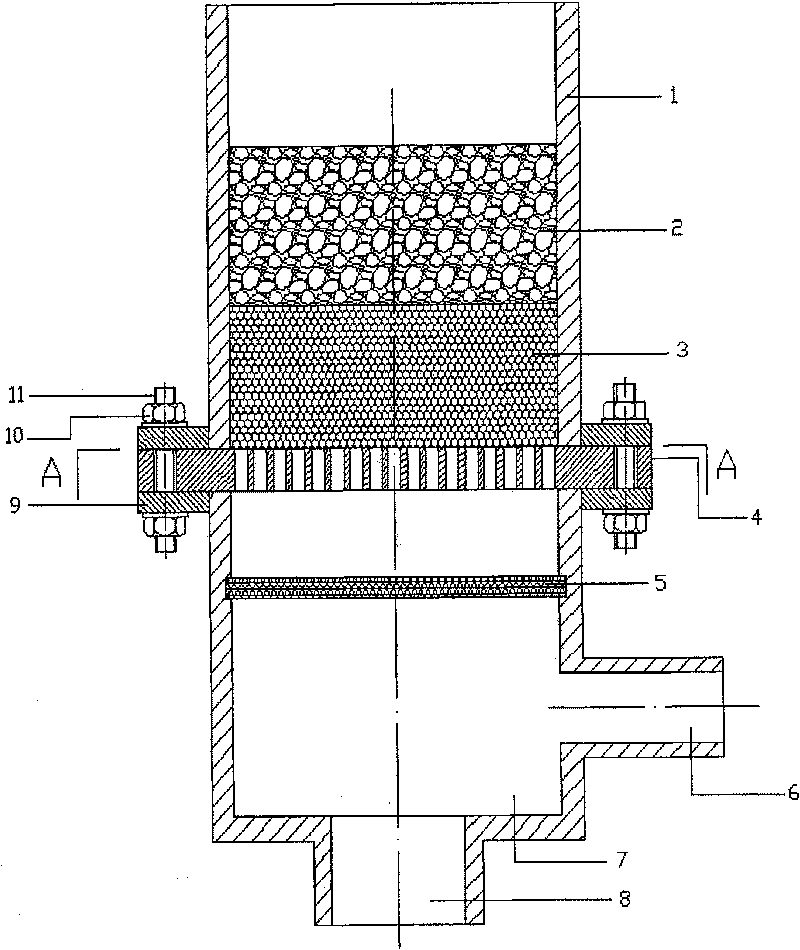

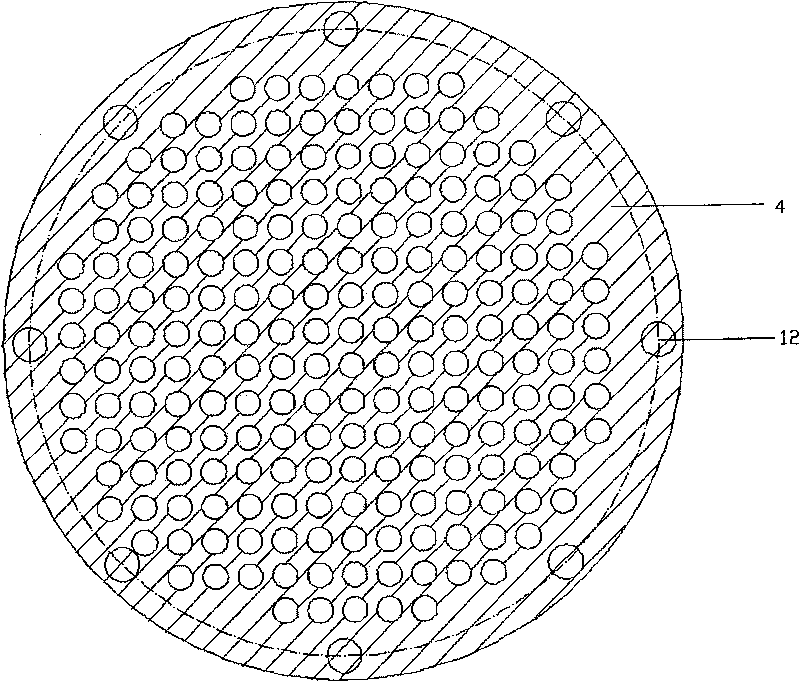

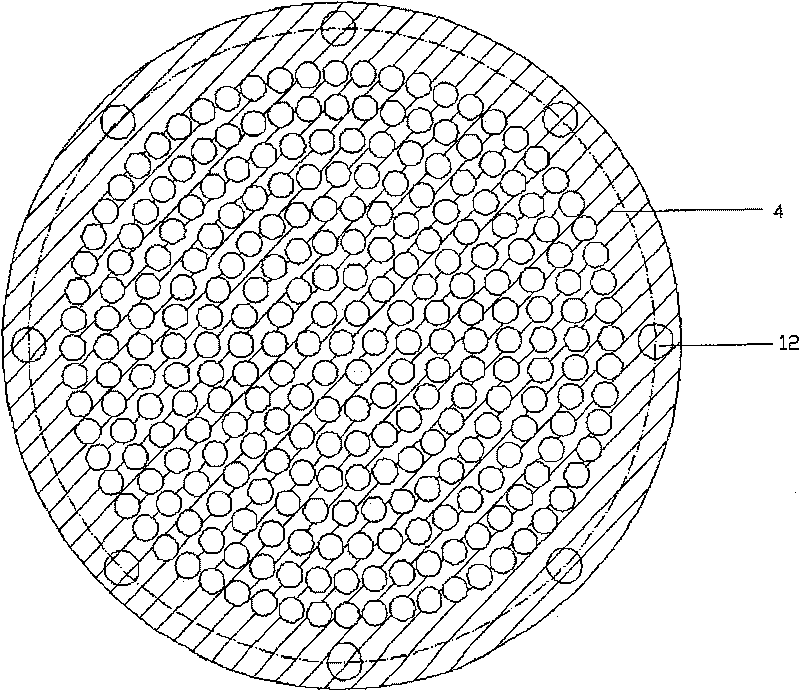

[0015] Example 1, such as figure 1 , figure 2 As shown, the burner is composed of a burner shell, a ceramic porous medium in the large hole area, a ceramic porous medium in the small hole area, a porous plate, a dust removal metal mesh, an air pipe, a premixing chamber, and a gas pipe. The burner shell is divided into upper and lower parts by a porous plate. Inside the cavity formed by the upper part of the burner shell, ceramic porous media in the large-pore area are arranged in sequence from top to bottom, and the ceramic porous media in the large-pore area are placed below On the ceramic porous medium in the small hole area, the two are in close contact. The ceramic porous medium in the small hole area is placed on the porous plate and is in close contact. There is a cavity between the upper surface of the ceramic porous medium in the large hole area and the top surface of the burner casing. The perforated plate is sandwiched between the upper and lower parts of the bur...

example 2

[0020] The structure of the burner is the same as Example 1. The difference is: the ceramic material in the large-pore area is calcium oxide-based zirconia, with an average pore diameter of 4 mm, a porosity of 85%, and the arrangement of the pores is disordered; the ceramic material in the small-pore area is calcium oxide-based zirconia, with an average pore diameter of 4 mm. The hole is 0.4mm, the porosity is 80%, and the arrangement of the holes is disordered; the material of the porous plate is low carbon steel alloy, the average pore size is 4mm, and the porosity is 83%. The arrangement of the holes is straight-through and arranged in a ring around the center. The axial section of the burner shell is square, and its material is cast iron. The premix chamber is fitted with stainless steel dust removal metal brushes.

[0021] Burner application: the combustion gas is coke oven gas, and the gas flow rate is 800m 3 / h, the air flow rate is 1500m 3 / h. The content of unbur...

example 3

[0022] Example 3: The burner structure is the same as Example 2. The difference is: silicon carbide is used as the ceramic material in the large-pore area, silicon carbide is used as the ceramic material in the small-pore area, and metal aluminum is selected as the porous plate material, with an average pore diameter of 3mm and a porosity of 84%. The axial section of the burner shell is hexagonal, and its material is high-temperature resistant stainless steel.

[0023] Burner application: the combustion gas is natural gas, and the gas flow rate is 2000m 3 / h, the air flow is 3000m 3 / h. Burning effect is the same as Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com