Anchor rod sheet pile combined structure and method for reinforcing high filling body on one side of slope

A technology of combined structure and filling body, applied in sheet pile walls, underwater structures, infrastructure engineering, etc., can solve the problems of insufficient tension of tie rods, poor overall stability, etc., to ensure stability and ecology, and improve frictional connection ability. , to avoid the effect of slope disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

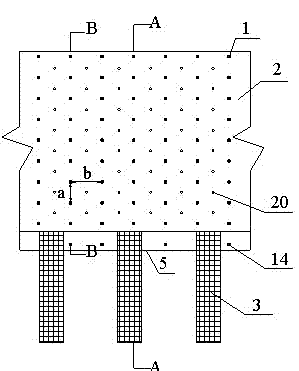

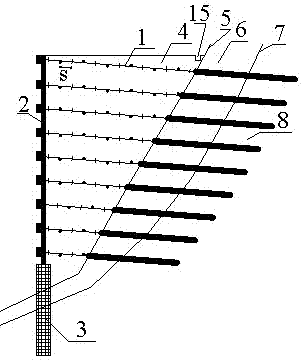

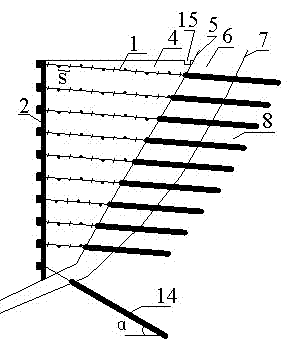

[0041] Such as Figure 1 to Figure 5 As shown in the figure, an anchor sheet pile composite structure is used to fix the filling body 4 to the stable bedrock 8 on one side of the slope, including three main components: the foundation pile 3, the concrete baffle 2, and the welded anchor 3. Slope design conditions such as upright, inclined or stepped grading on the side of the slope. The foundation pile 3 uses reinforced concrete poured on site to stabilize the bedrock 8 deeply and expose a small amount of the original surface, about 1m. The baffle plate 2 is connected to form the basis of the overall support. The depth, cross-sectional size, and reinforcement strength of the foundation pile 3 to penetrate into the stable bedrock 8 need to be determined through the stability calculation of the filling body shearing out along the bottom or the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com