Construction method of large tube well fixed point precipitation, sealing bottom free concrete and steel sheet pile cofferdam deepwater bearing platform

A technology of back-sealing concrete and steel sheet pile cofferdam, which is applied in the direction of basic structure engineering, erection/assembly of bridges, bridges, etc., can solve the problems of large thickness of back-sealing concrete, difficult construction, and long construction period, so as to reduce construction difficulty and cost, The effect of reducing construction difficulty and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

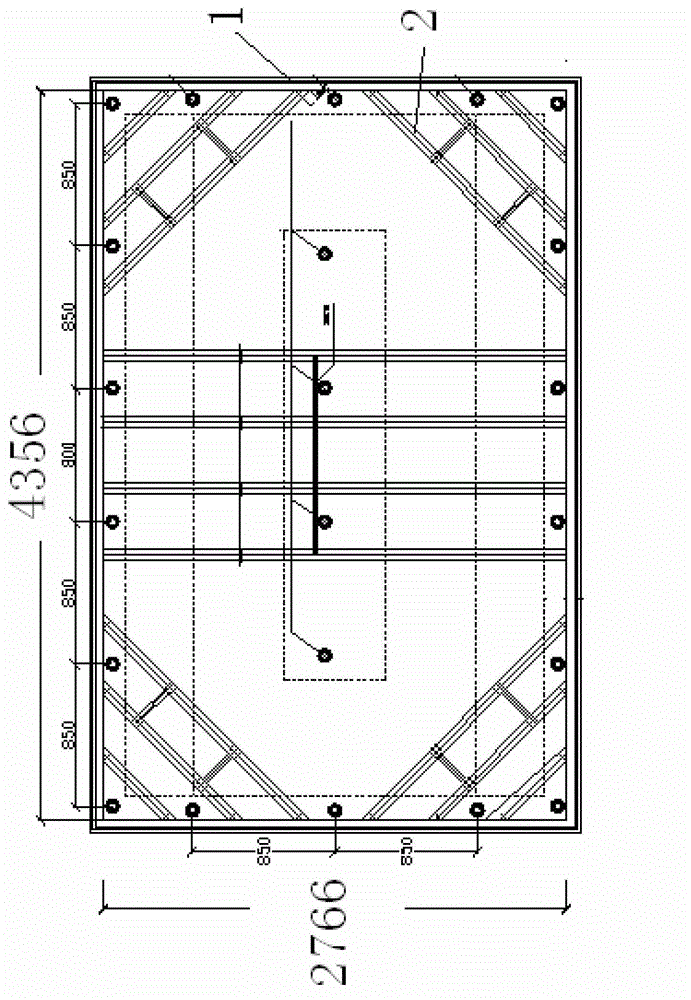

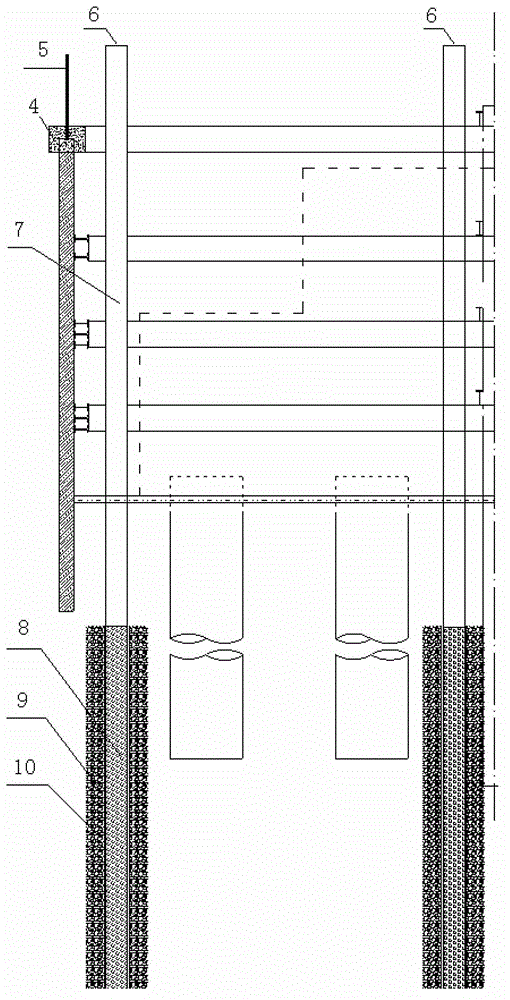

[0008] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment will be specifically described. This embodiment includes the following steps: 1. Insert steel sheet piles one by one into the underwater sand layer, and make the adjacent steel sheet piles occlude (the occlusion between the female socket and the male socket between the steel plates) to connect into a A closed cofferdam that is above the water surface, and steel bars are tied on the top of the cofferdam, concrete is poured into the cofferdam 4, and the top of the cofferdam 4 is provided with steel plates 5 upward; 2. A plurality of large tube wells 6 are evenly arranged along the inner circle of the cofferdam , the structure of the large tube well 6 is: the upper part is a steel pipe 7, the lower part is a filter pipe 8, the steel pipe 7 is arranged above the underwater sand layer, and the filter pipe 8 is below the sand layer; Bottom cloth 10, in order to avoid the water...

specific Embodiment

[0009] 1. The newly-built Songhua River Super Bridge of the Harbin-Qiqihar Railway Passenger Dedicated Line is located 50m downstream of the existing Binzhou Line in Harbin, in the main stream of the Songhua River between Daowai District and Songbei District, with a total length of 3065m. The span of the main bridge across the river is 77+3×156.8+77m four-line tied arch continuous beam, located in the main channel of Songhua River, with an average water depth of 10m. Among them, the size of the 39# cap: 24.9m*40.8m*9m, the elevation of the top surface of the cap is 111.7m, there are 40 bored piles under the cap, the diameter of the pile is 2m, and the length of the pile is 87m. The normal water level elevation of the water surface: 116.5m; the river bed elevation is 105.2m.

[0010] 2. The Songhua River is a wide and shallow plain-type channel, a national Class III waterway, with a bending radius of 500m and navigable for 1,000-ton ships. The Songhua River at the bridge site ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com