Foundation pit construction method employing steel sheet piles as support cofferdam

A technology of steel sheet pile cofferdam and construction method, which can be used in basic structure engineering, excavation, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

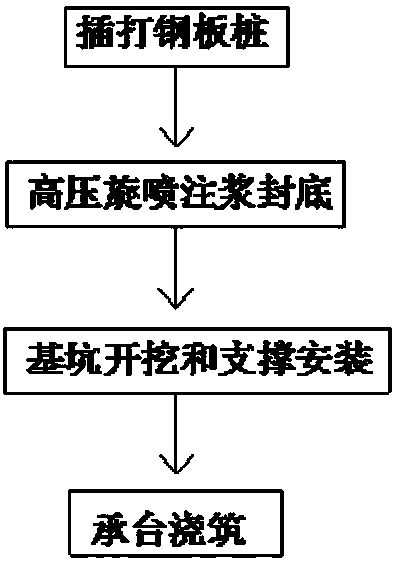

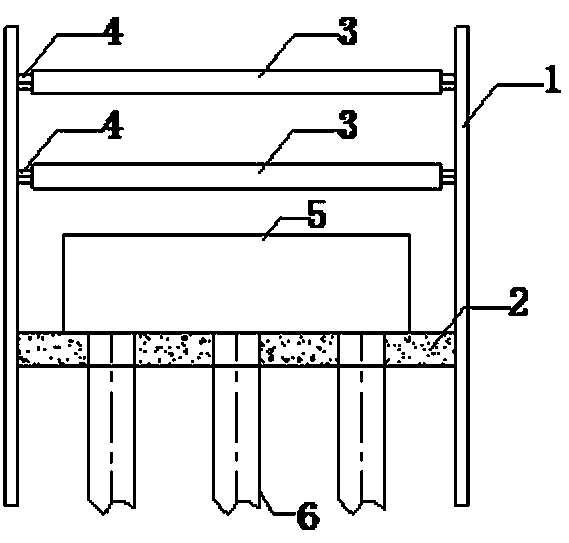

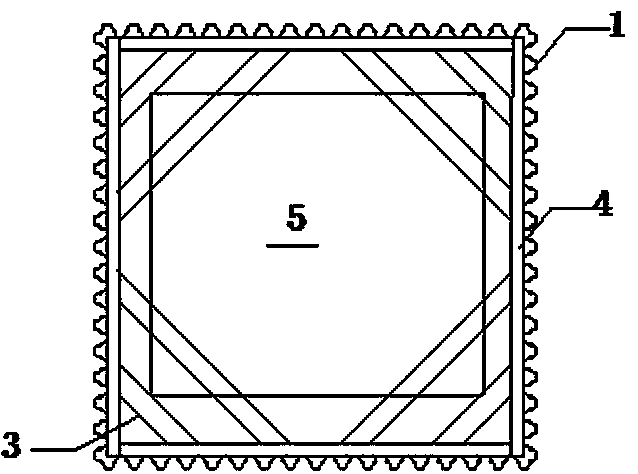

[0034] Such as Figure 1-3 , the present embodiment is the construction of bridge caps in a river, the caps are located in strong water-permeable sandy soil, the construction process includes foundation pit excavation and caps pouring, including the following steps in turn:

[0035] A. Insert and drive steel sheet piles to form steel sheet pile cofferdams;

[0036] B. Use the high-pressure rotary jet grouting method to seal the bottom surface of the foundation pit to be constructed;

[0037] C. Excavation of foundation pit and installation of support in cofferdam.

[0038] D. Cap pouring.

[0039] Described step A comprises the following steps:

[0040] (1) Determination of cofferdam structure, size and construction location as well as measurement and setting out

[0041] According to the structure, size and construction position of the cap to be constructed, the structure, size and construction position of the cofferdam are determined. Measurement and setting out of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com