Method of constructing cofferdam after integrally lowering multiple layers of inner bracings of steel sheet pile cofferdam

A technology of steel sheet pile cofferdams and steel sheet piles, applied in infrastructure engineering, construction, etc., can solve problems such as high construction costs, unbalanced internal and external water pressure, and low safety factor, so as to ensure construction quality, save construction costs, and avoid The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

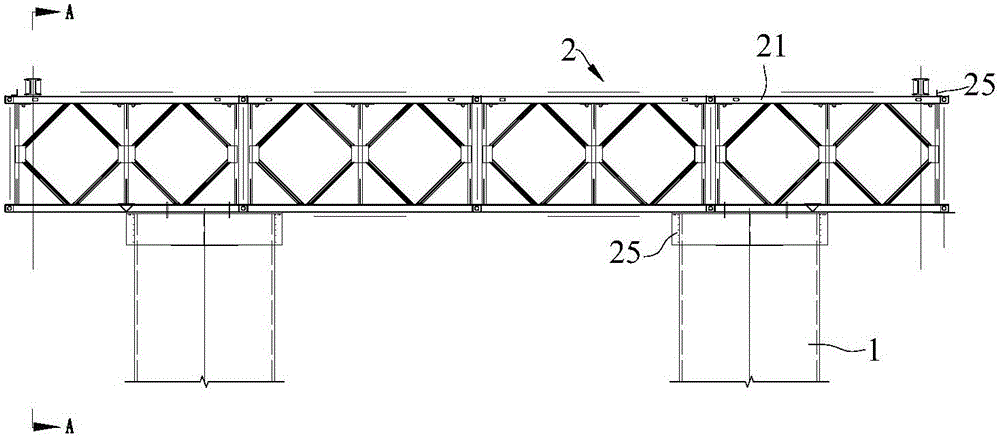

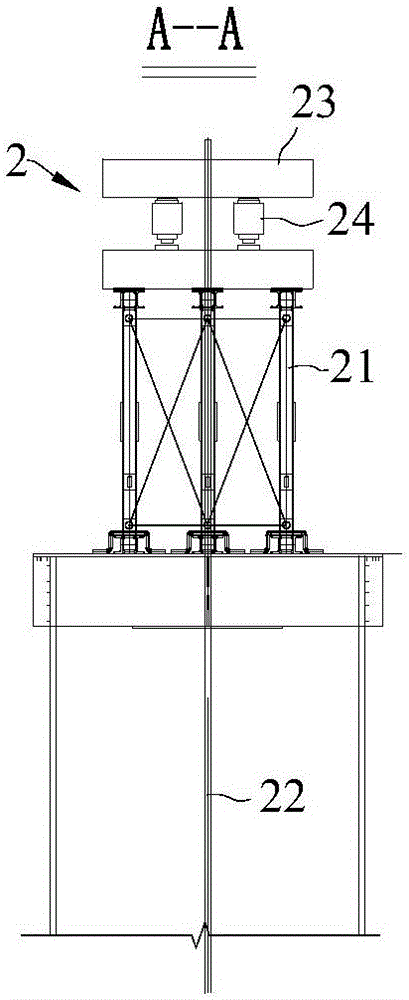

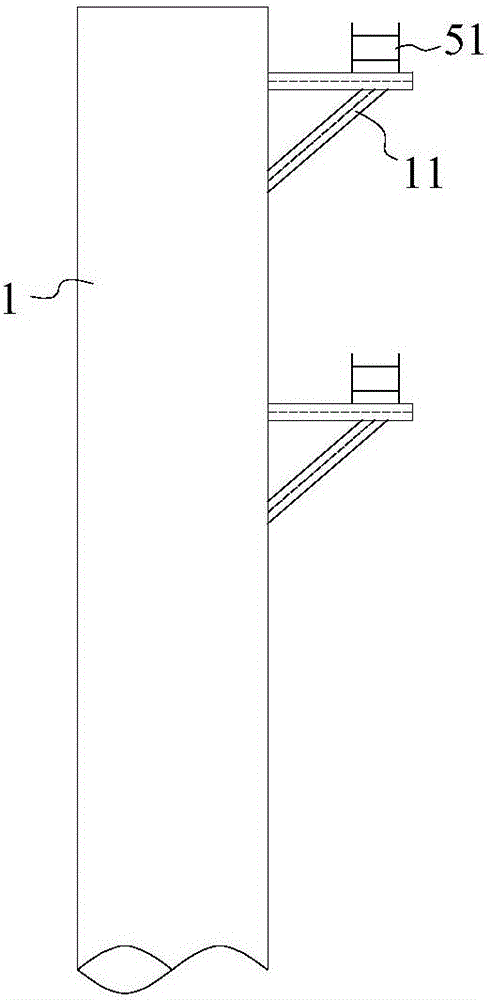

[0036] refer to Figure 1 to Figure 7 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, but the actual application direction of the present invention is not limited thereto.

[0037]The present invention provides a cofferdam construction method for steel sheet pile cofferdams firstly lowering multi-layer internal supports as a whole, comprising the following steps:

[0038] S10. Use the long-arm excavator or grab bucket to clean the riverbed surface to 50cm below the design elevation of the inner support, so as to ensure that the inner support can be lowered into place smoothly, and can reduce the amount of subsequent cofferdam suction mud and reduce the difficulty of mud suction. Accelerate the construction progress; connect the casing 1 of the pile foundation at the bottom of the high construction cap, and weld temporary corbels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com