Connector for connecting sheet piles

a technology of connecting sheet piles and connecting profiles, which is applied in the direction of bulkheads/piles, haberdashery, etc., can solve the problems of large bending and torsional stresses of the connecting profile, and achieve the effect of reducing the bending and torsional stresses, facilitating the pre-assembly of the connecting profile, and ensuring the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

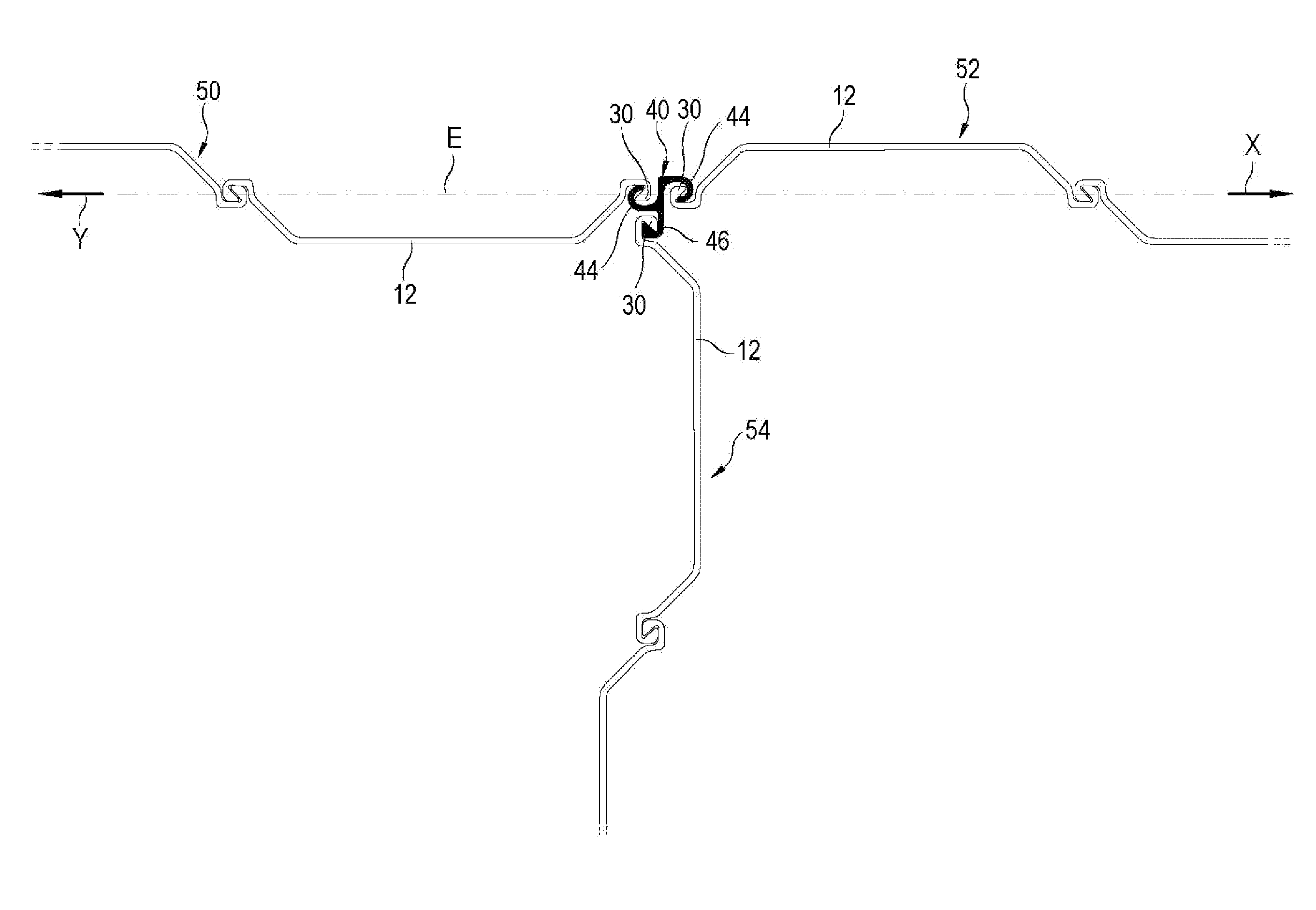

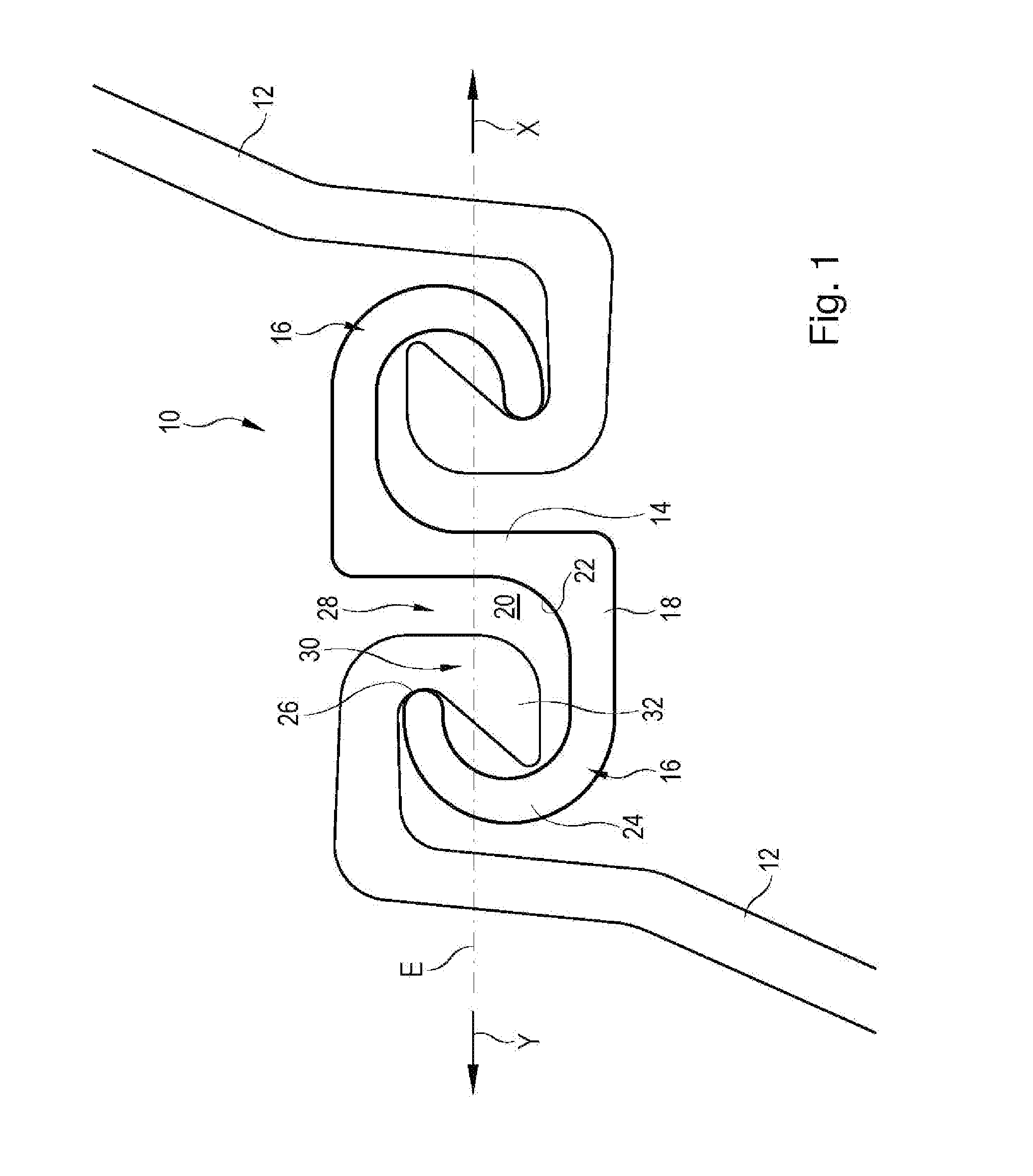

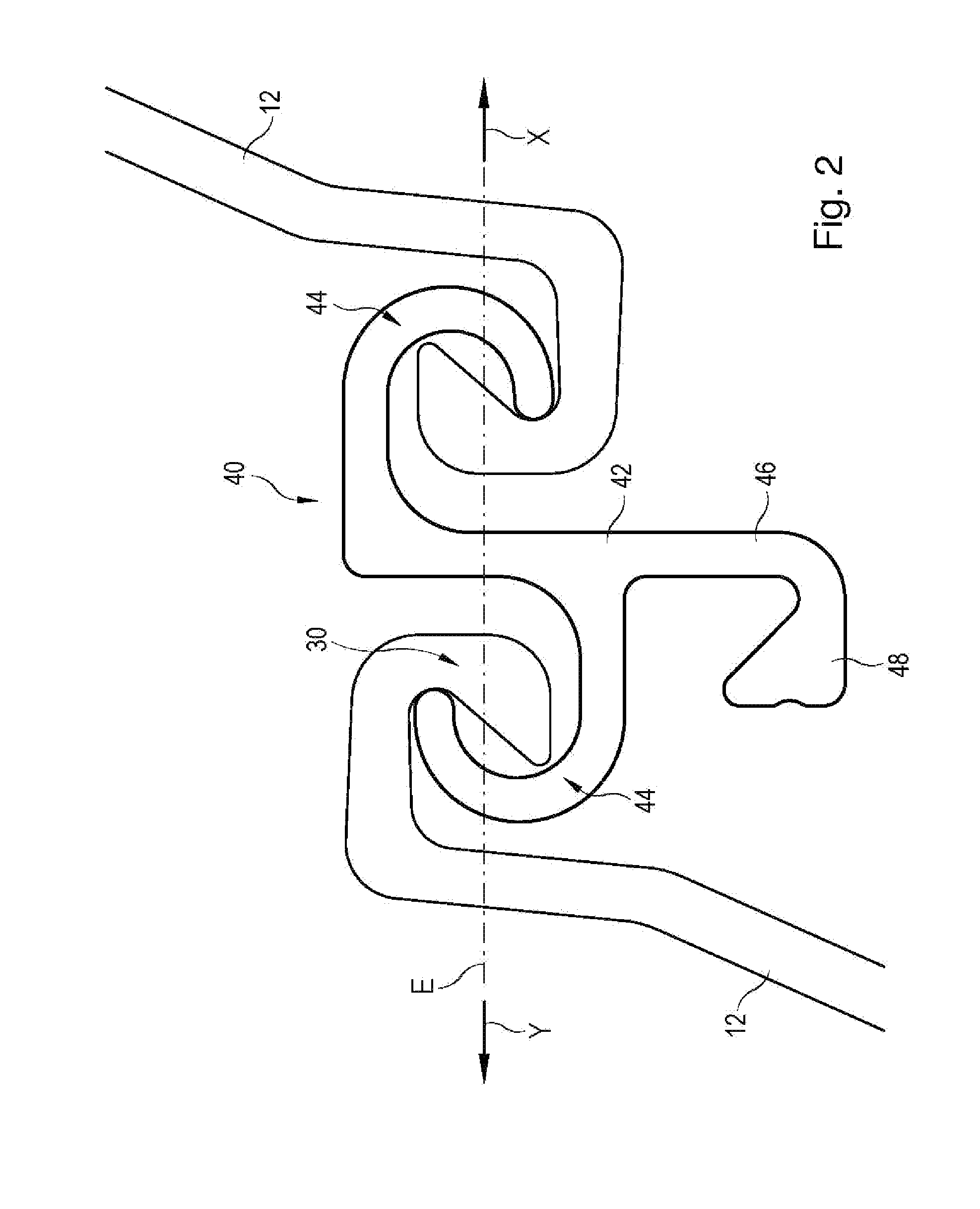

[0021]FIG. 1 is a plan view of a first exemplary embodiment of a connecting profile 10 of the invention for interconnecting two Larssen sheet piles 12 along two main coupling directions X and Y.

[0022]The connecting profile 10 has a central strip 14, on which two identically designed hooked profiles 16 are provided. Each hooked profile 16 has a substantially straight connecting section 18, which extends approximately at right angles to the flat side of the central strip 14. That side of the connecting section 18 which points outwardly is flat and merges flush into the longitudinal edge of the central strip 14. That side of the connecting section 18, which delimits the inner chamber 20 merges into the flat side of the central strip 14 forming a radius 22. This design firstly increases the strength of the transition between the connecting section 18 and the central strip 14 and secondly diverts the forces acting on the hooked profile 16 uniformly into the central strip 14.

[0023]The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com