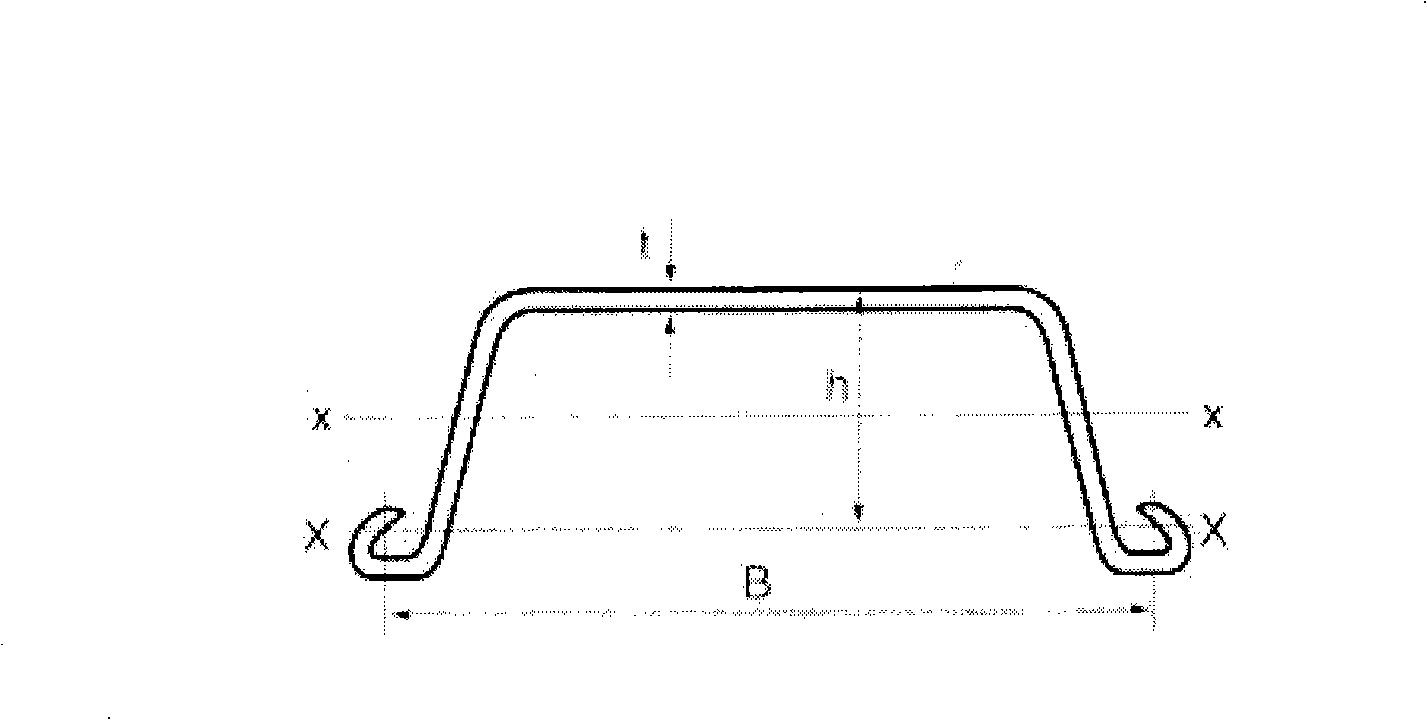

Hot-rolled U shaped metal sheet pile and microalloying production method

A technology of micro-alloying and production methods, applied in the direction of temperature control, etc., can solve the problems of difficult control, unstable weldability, increased production costs, etc., and achieve the effects of improving welding performance, increasing utilization rate, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The proportion of the chemical composition of the steel is as follows: C 0.17, Mn 0.91, Si0.40, P 0.018, S 0.012, Als 0.020, V 0.073, N 0.0029, and the rest are Fe and unavoidable impurities.

[0028] The production method sequentially includes 120t converter smelting, refining outside the furnace, continuous casting, heating, and universal rolling. The parameters of each step are:

[0029] During smelting, control the smelting temperature to 1660°C~1680°C; during out-of-furnace refining, control out-of-furnace refining time to ≥30min; add aluminum, manganese, and iron for pre-deoxidation, then add alloys MnFe, VFe or VN alloys in sequence, and then Feed Al wire for final deoxidation, feed Si-Ca wire for calcium treatment; the purpose of feeding Si-Ca wire for calcium treatment is to denature the inclusions in the steel; during continuous casting, the pouring temperature is 1570 ° C ~ 1580 ° C, The continuous casting superheat is controlled at 15-35°C, and the casting s...

Embodiment 2

[0032] The proportion of the chemical composition of the steel is as follows: C 0.19, Mn 1.15, Si0.27, P 0.010, S 0.011, Als 0.030, V 0.095, N 0.0028, and the rest is Fe and unavoidable impurities.

[0033] The preparation method is the same as in Example 1.

Embodiment 3

[0035] The proportion of the chemical composition of the steel is as follows: C 0.21, Mn 1.04, Si0.32, P 0.008, S 0.017, Als 0.030, V 0.030, N 0.0025, and the rest is Fe and unavoidable impurities.

[0036] Table 2: Mechanical performance test of the product

[0037] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com