Shockproof strip material of nuclear power station steam generator, and preparation method thereof

A technology for steam generators and anti-vibration strips, applied in the field of anti-vibration strip materials for CPR1000 steam generators in pressurized water reactor nuclear islands, martensitic stainless steel X6Cr13 materials, anti-vibration strip materials for steam generators in nuclear power plants and their preparation fields, which can solve the problem of steam generators Damage, pipe damage and rupture, shutdown for several months, etc., to achieve the effect of prolonging service life, ensuring safety and reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further described and understood by non-limiting examples below.

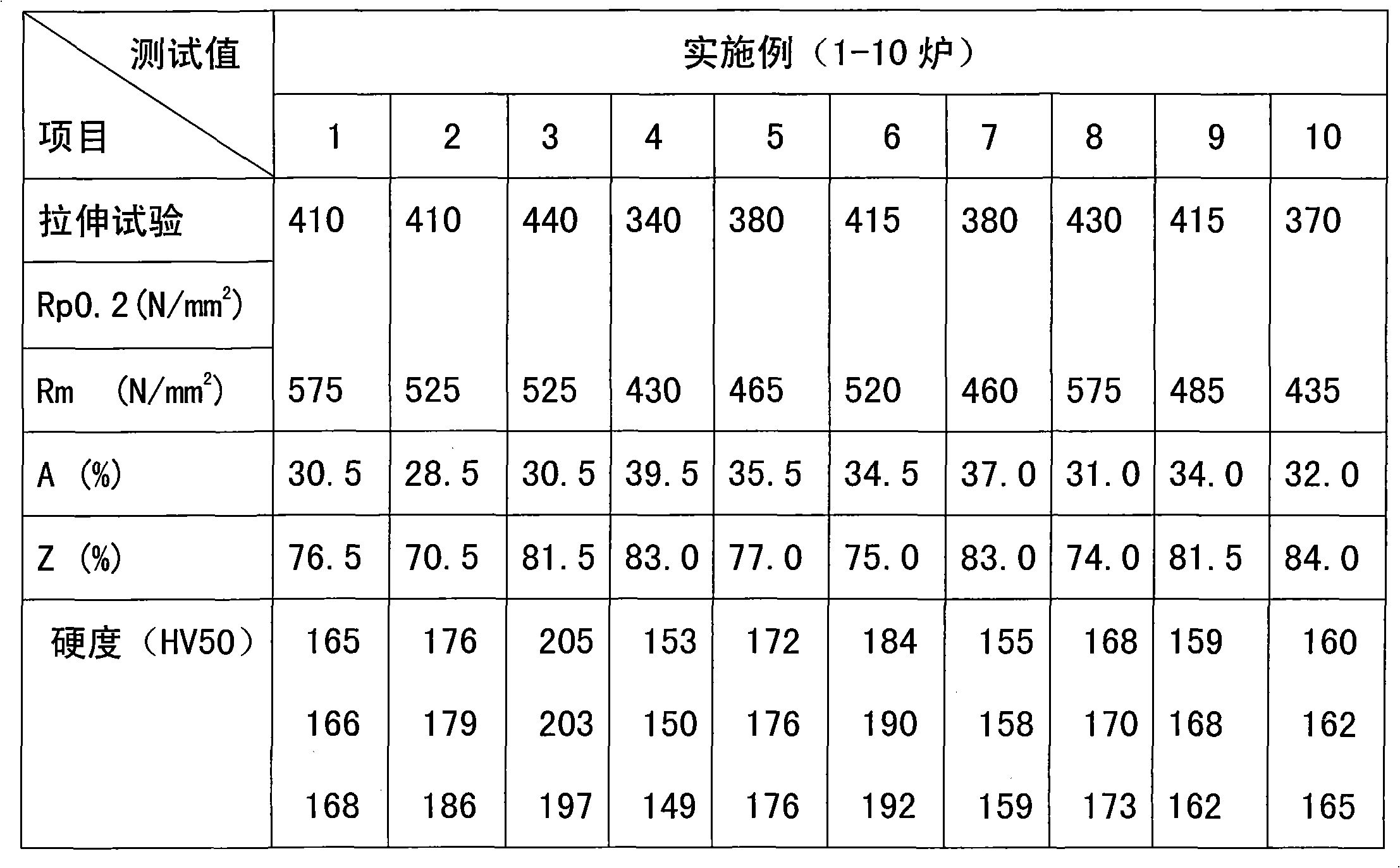

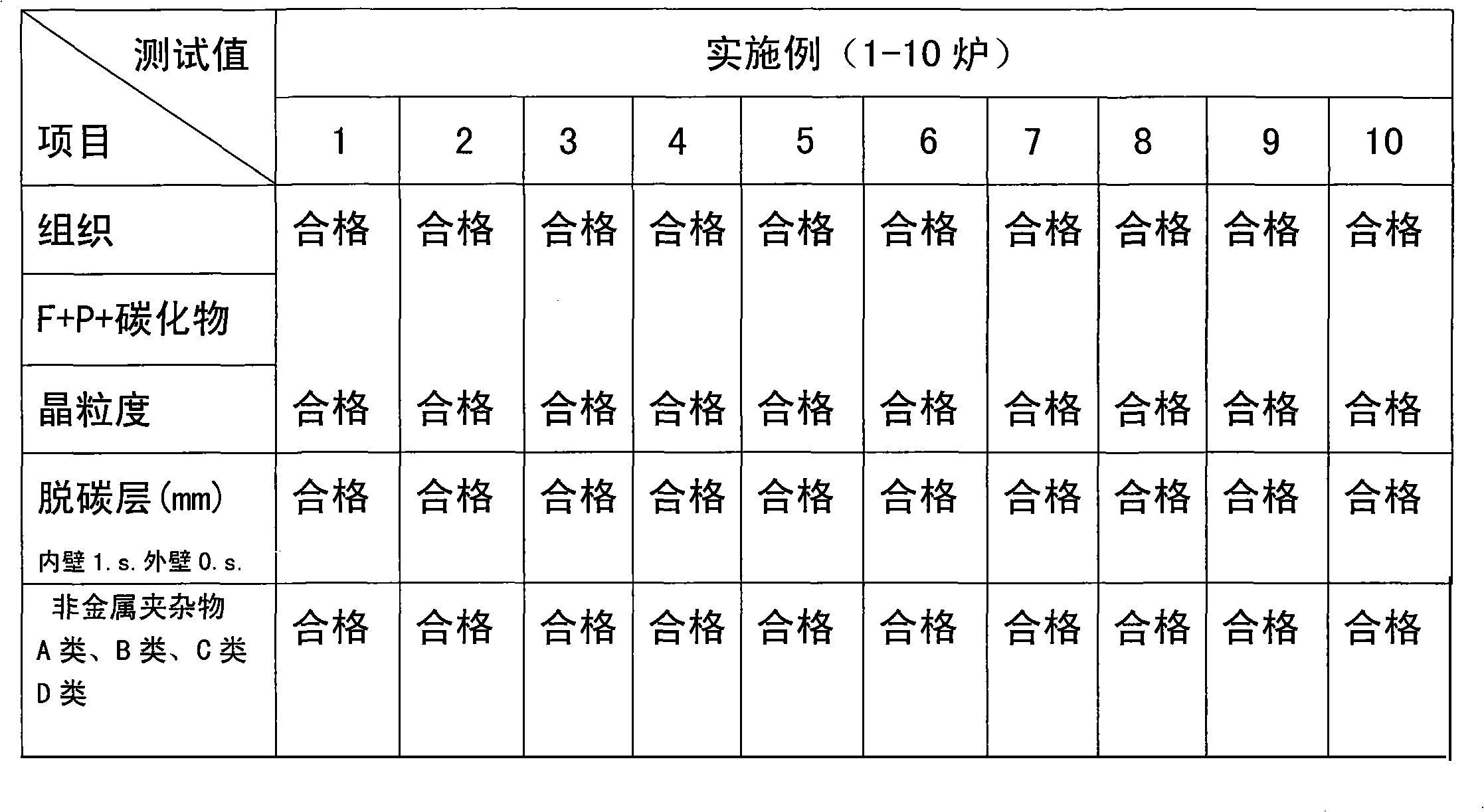

[0044] The steam generator anti-vibration strip material of the nuclear power plant of the present invention has prepared ten furnace examples, the furnace numbers are: 105-5575, 5576, 5577, 5578, 5579, 5581, 5582, 5583, 5584, 5585, embodiment 1-10 furnace anti-vibration strip The ingredients and content of the material are calculated by weight %, as follows:

[0045] First furnace: C: 0.03%, Si: 0.4%, Mn: 0.5%, P: 0.009%, S: 0.002%, Cr: 13%, Ni: 0.4%, N: 0.03%, Xt: 0.0%,

[0046] Second furnace: C: 0.04%, Si: 0.30%, Mn: 0.60%, P: 0.01%, S: 0.015%, Cr: 11.50%, Ni: 0.5%, N: 0.04%, Xt: 0.06%,

[0047] Third furnace: C: 0.05%, Si: 0.50%, Mn: 0.70%, P: 0.02%, S: 0.01%, Cr: 12.50%, Ni: 0.55%, N: 0.02%, Xt: 0.04%,

[0048] Fourth furnace: C: 0.06%, Si: 0.60%, Mn: 0.40%, P: 0.009%, S: 0.002%, Cr: 13.50%, Ni: 0.30%, N: 0.03%, Xt: 0.06%,

[0049]Fifth furnace: C: 0.067%, Si: 0.70%, Mn:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com