700MPa-tensile strength steel for large heat input welding structure and manufacturing method thereof

A technology of large heat input welding and tensile strength, applied in the direction of temperature control, etc., can solve the problems of increasing manufacturing costs and achieve the effects of increased strength, excellent welding performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below by way of examples.

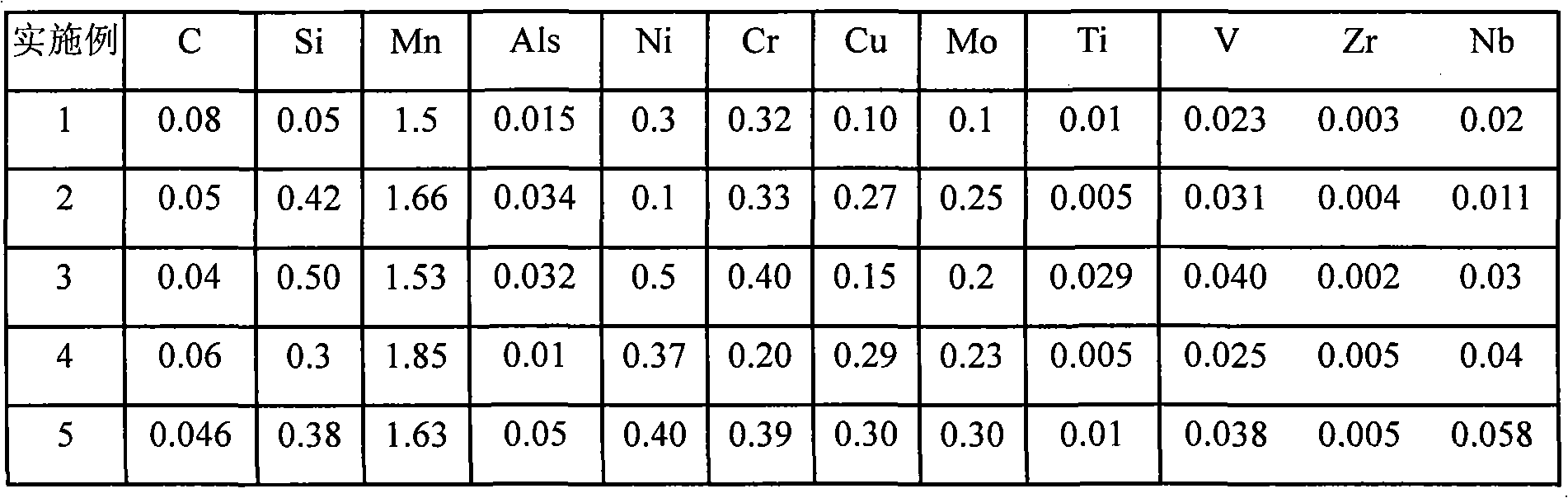

[0028] The embodiment of the present invention is smelted by the above-mentioned smelting process, its chemical composition is shown in Table 1, its rolling process is shown in Table 2, the tempering temperature is 600°C, and the welding heat simulation is carried out on the Gleeble3800 thermal simulator, and the heat input is 60KJ / cm , -20 ℃ HAZ zone impact toughness and as-rolled mechanical properties are shown in Table 3.

[0029] Table 1 The smelting composition Wt% of the steel grade of the embodiment of the present invention

[0030]

[0031] The rolling process of table 2 embodiment steel of the present invention

[0032]

Example

Finished Thickness

mm

℃

re-crystallize

Rolling temperature

℃

Not recrystallized

Rolling temperature

℃

Not recrystallized

Finishing temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com