Trace rare earth element-containing iron-based nanocrystalline alloy

A technology of iron-based nanocrystals and rare earth elements, which is applied in the field of preparation of iron-based amorphous nanocrystalline alloy materials, can solve the problems of restricting large-scale production and development, difficult processes, etc., and achieves good comprehensive performance of products and excellent preparation process The effect of simple process and reasonable composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

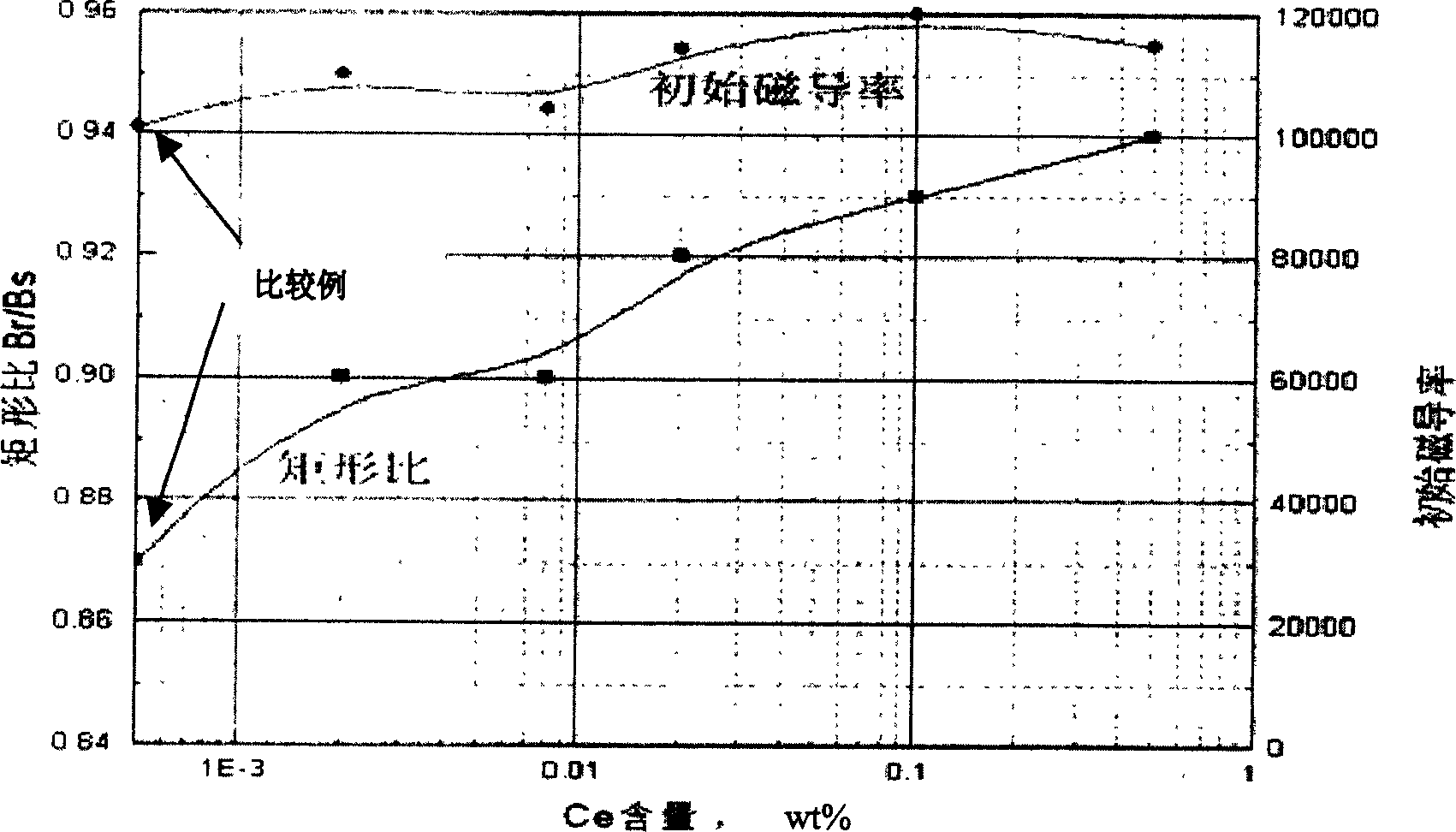

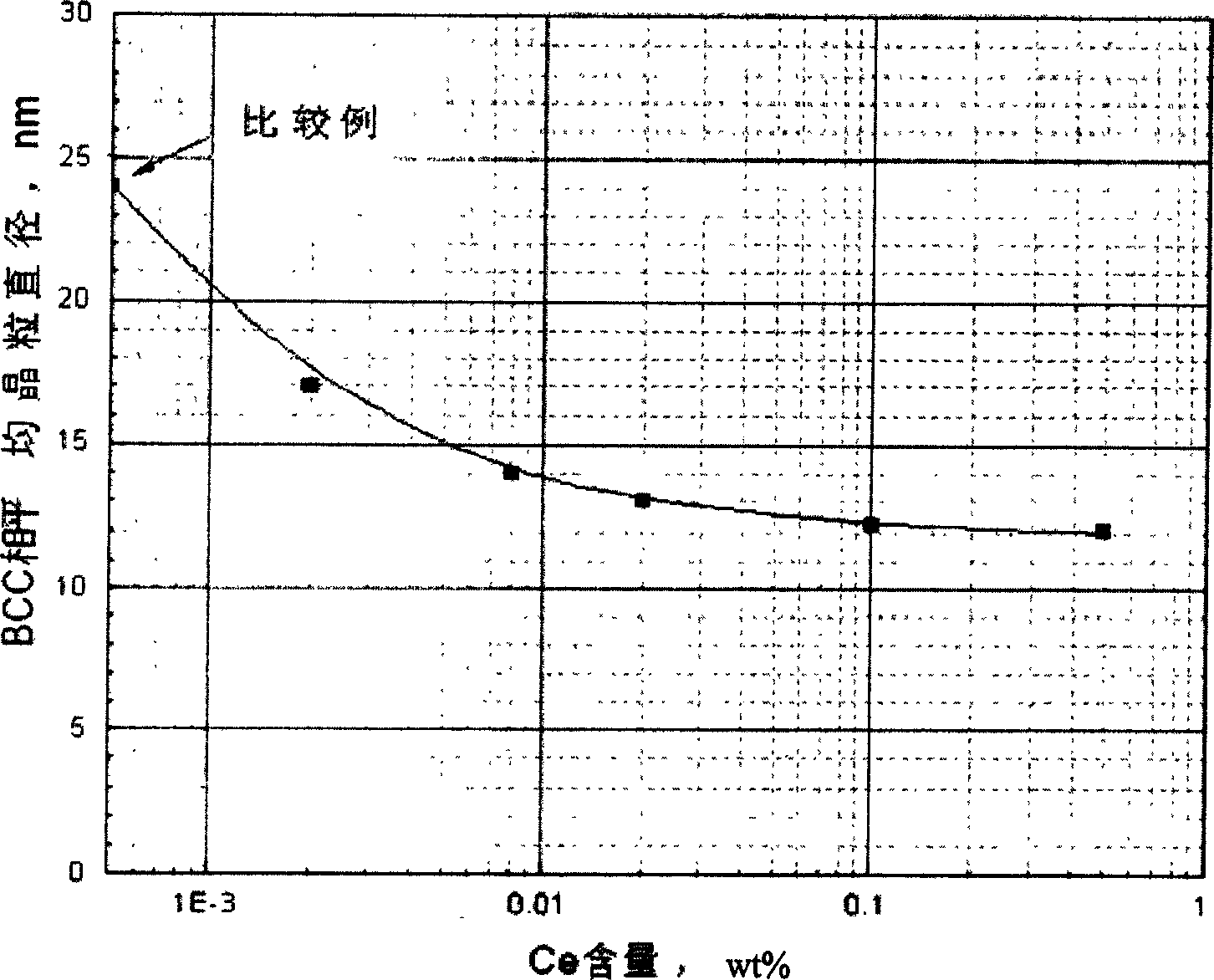

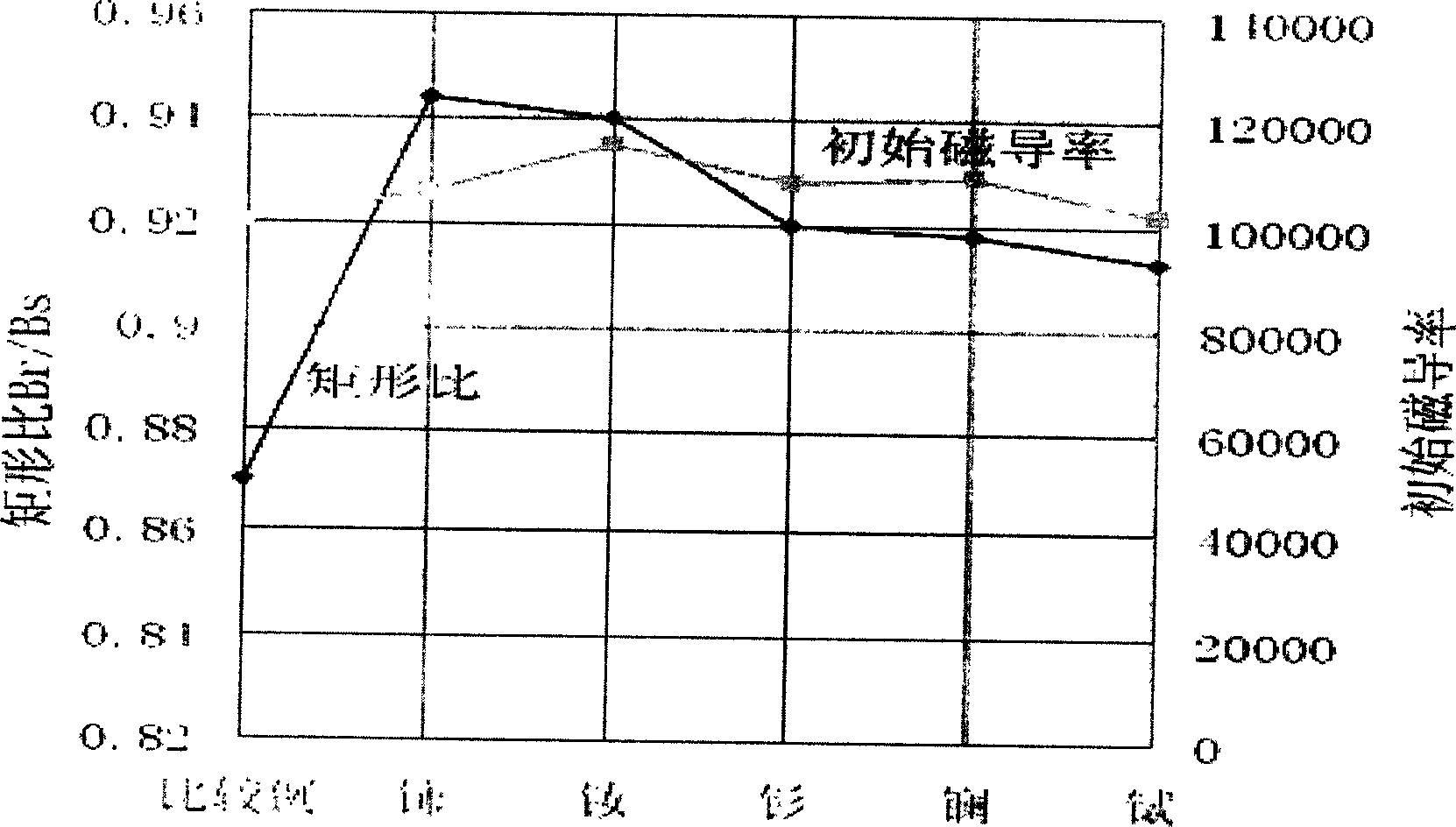

[0024] Using the composition of the trace rare earth iron-based nanocrystalline alloy material of the present invention, we prepared a total of 4 sets of experimental examples. For the convenience of comparison, we also made a set of comparative examples of the prior art. The concrete composition of the embodiment of comparative test is all list 1. The test methods all adopt the same preparation process: firstly, the materials are prepared according to the requirements of the ingredients, and the melting is carried out in a vacuum induction furnace.

[0025] Then the smelted master alloy melt is introduced into the strip-making equipment, and the nozzle for spraying amorphous thin strips is installed at the bottom of the strip-making equipment, and the molten steel is sprayed onto the high-speed rotating cooling roll to make the master alloy melt Form an amorphous thin strip with a thickness of 0.02 mm, then wind the amorphous thin strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com