Process for preparing nano granule with high shape anisotropic property

A particle and cobalt nanotechnology, which is applied in the field of preparation of magnetic functional nanoparticles, can solve the problems of uneven reaction, unsuitability for industrialized large-scale production, and inability to obtain nanoparticles, etc., to achieve low price, uniform particles, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

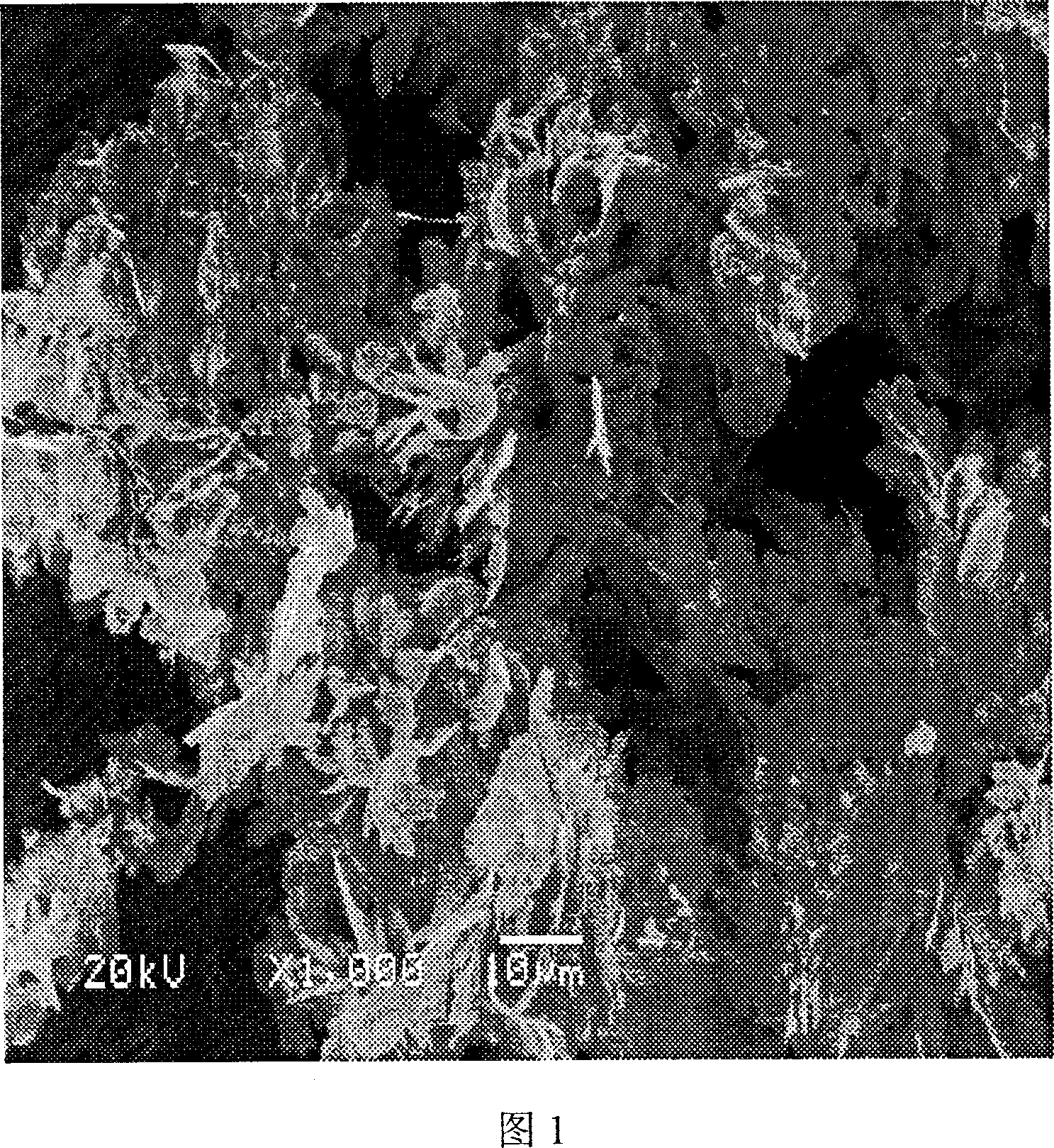

[0023] Embodiment 1. When preparing leaf-shaped cobalt nanosheets with a radial size of tens of microns, the specific process is as follows:

[0024] 1. Measure 0.1mol / L of CoCl 2 Pour 20ml of the solution into the reaction kettle, measure 2ml of the 0.1mol / L cetyltrimethylammonium bromide (CTAB) solution and pour it into the CoCl 2 In the solution, stir evenly to obtain a clear and transparent pink solution. Add 0.8ml of 25mol / L NaOH solution dropwise to this solution, stir and mix evenly to obtain a blue clear and transparent solution. At this time, add 2ml of N 2 h 4 ·H 2 O content is the hydrazine hydrate of 85%, stir evenly, screw on the reactor lid;

[0025] 2. Put the reaction kettle into an oven with a temperature of 180°C, take it out after keeping it warm for 1 hour, and open it after cooling to room temperature. There are silver gray powder and colorless solution in the reaction kettle;

[0026] 3. Washing and drying of cobalt nanoparticles. Pour off the colorl...

Embodiment 2

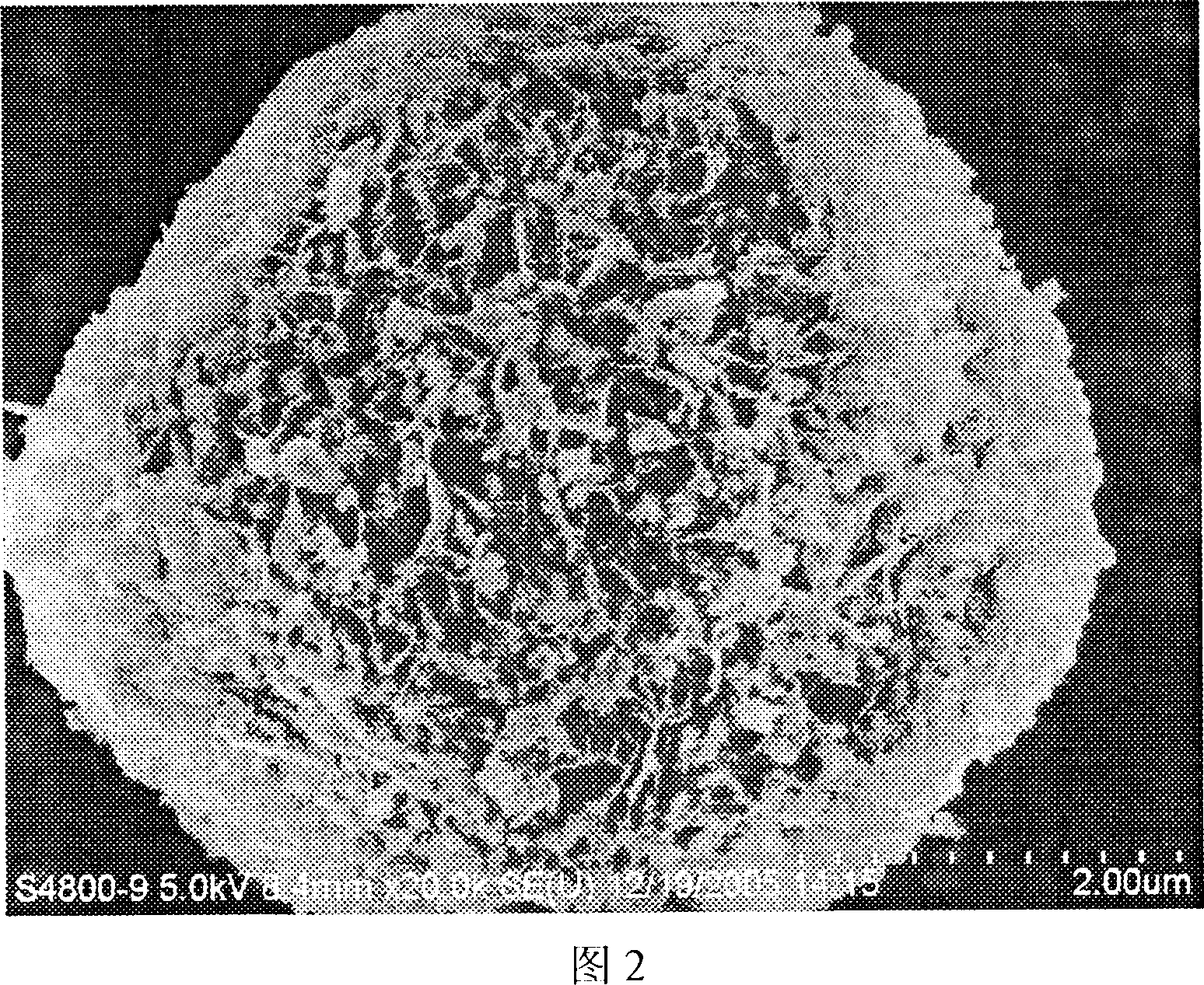

[0028] Embodiment 2. When preparing cobalt nanosheets with a radial size of several hundred nanometers, the specific process is as follows:

[0029] 1. Measure 0.1mol / L of CoCl 2 Pour 20ml of the solution into the reaction kettle, measure N 2 h 4 ·H 2 2ml of hydrazine hydrate with 85% O content was poured into CoCl 2 solution, stir evenly, and cover the lid of the reaction kettle;

[0030] 2. Put the reaction kettle into an oven with a temperature of 180°C, take it out after keeping it warm for 1 hour, and open it after cooling to room temperature. There are black powder and colorless solution in the reaction kettle;

[0031] 3. Washing and drying of cobalt nanoparticles. This step is the same as the process in Example 1.

[0032] The particles obtained in this example are sheet-like cobalt nanoparticles with a radial size of several hundreds of nanometers, as shown in FIG. 2 .

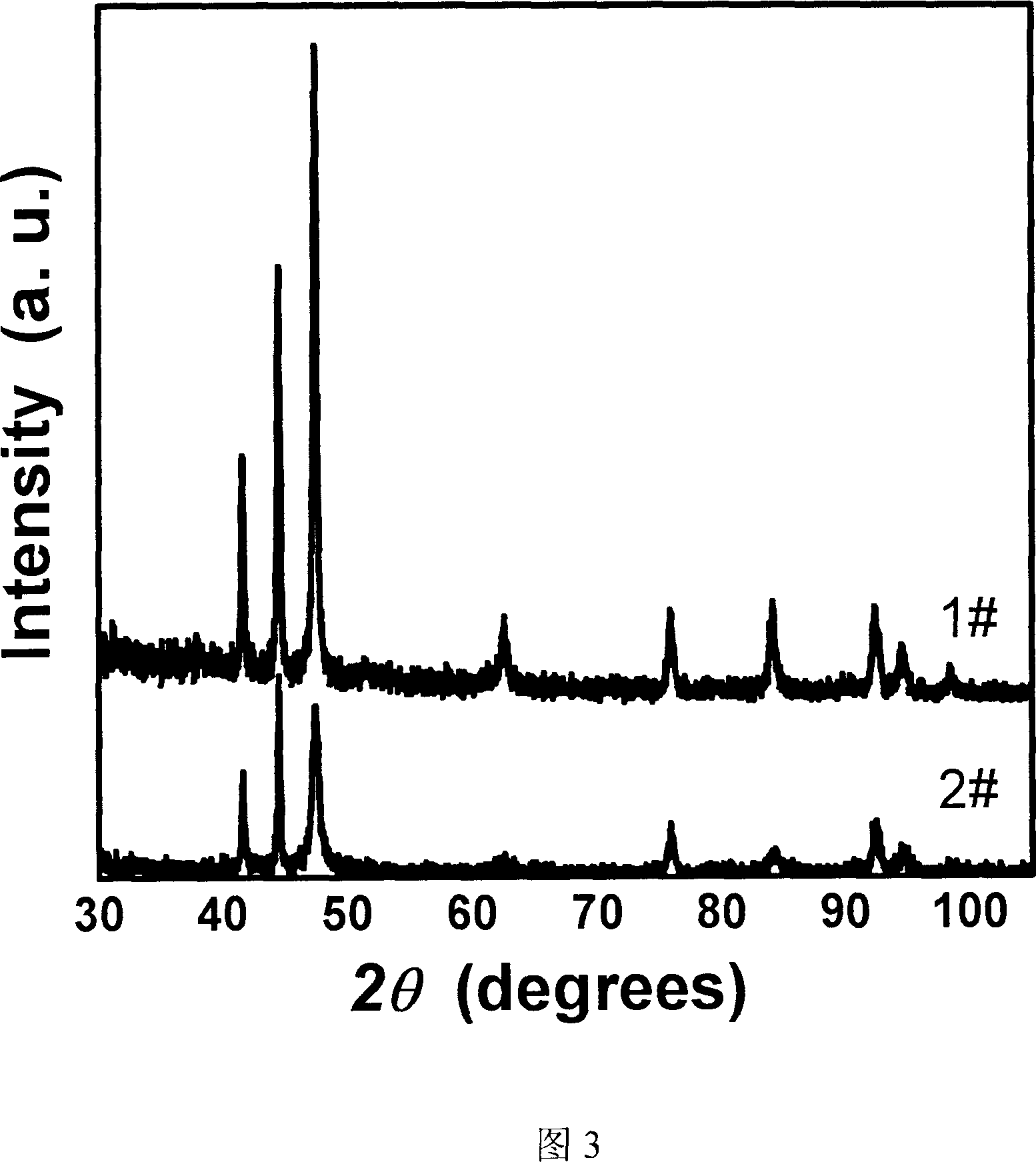

[0033] Carry out X-ray diffraction to the particle gained in embodiment 1 and embodiment 2, i...

Embodiment 3

[0034] Embodiment three, preparation binary alloy Fe 0.1 co 0.9 Flaky nanoparticles, the specific process is as follows:

[0035] 1. Weigh 0.2mmol of FeSO 4 ·7H 2 O and 1.8 mmol of CoCl 2 ·6H 2 O is put into the reaction kettle, pour 20ml distilled water into the reaction kettle, stir it with a glass rod and make it dissolve completely, obtain a clear and transparent solution, add dropwise 1.5ml of NaOH solution of 25mol / L in this solution, stir and mix, Obtain blue clear and transparent solution, now add 2ml N 2 h 4 ·H 2 O content is the hydrazine hydrate of 85%, stir evenly, screw on the reactor lid;

[0036] 2. Put the reaction kettle into an oven with a temperature of 180°C, take it out after 2 hours of heat preservation, and open it after cooling to room temperature. The reaction kettle contains gray-black powder and colorless solution;

[0037] 3.Fe 0.1 co 0.9 The steps of washing and drying the alloy nanoparticles are the same as those in Example 1. The prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com