Rare earth permanent magnetic powder and bonded magnet

一种稀土永磁、稀土元素的技术,应用在磁性物体、磁性材料、无机材料磁性等方向,能够解决粘度过大、非晶形成能力不强等问题,达到利于平衡运用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The main preparation process is as follows:

[0041] (1) First, a certain composition of samarium-iron alloy ingredients is smelted through intermediate frequency, electric arc, etc. to obtain alloy ingots, and the ingots are initially crushed to obtain alloy blocks of several mm;

[0042] (2) After the alloy block is melted by induction, the alloy liquid passes through the nozzle to the rotating water-cooled copper wheel, and the samarium-iron alloy powder obtained after quenching;

[0043] (3) The prepared flaky samarium-iron alloy powder is crushed and sieved to remove the superfine powder to obtain a powder with a particle size of 10-100 μm;

[0044] (4) Anneal the obtained samarium-iron alloy powder at 750°C for 5-30 minutes to homogenize the grain structure, and then nitriding at about 450°C for 30 minutes, the nitrogen source is industrial pure nitrogen, a mixture of hydrogen and ammonia, etc.;

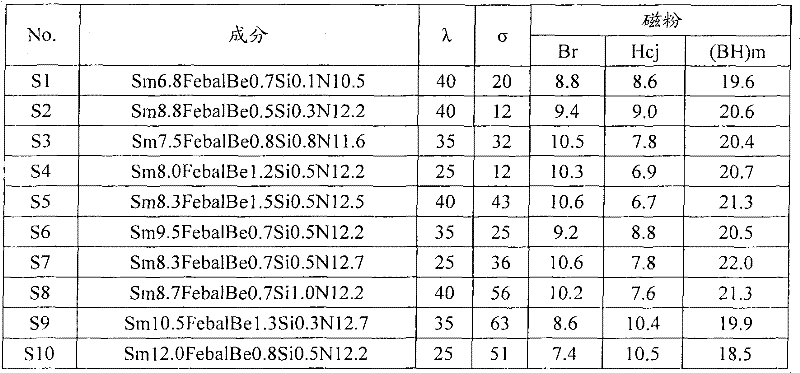

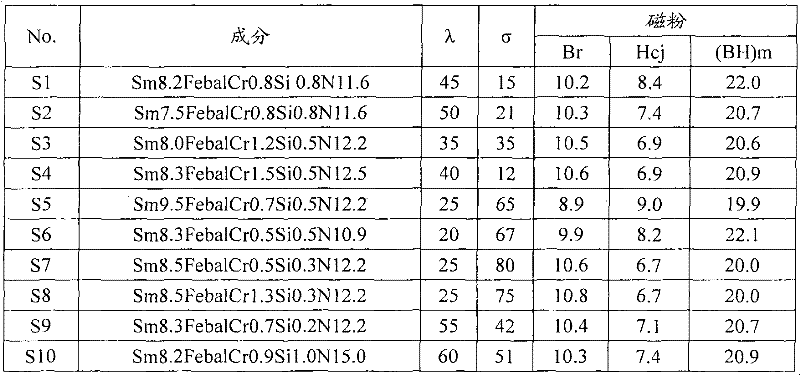

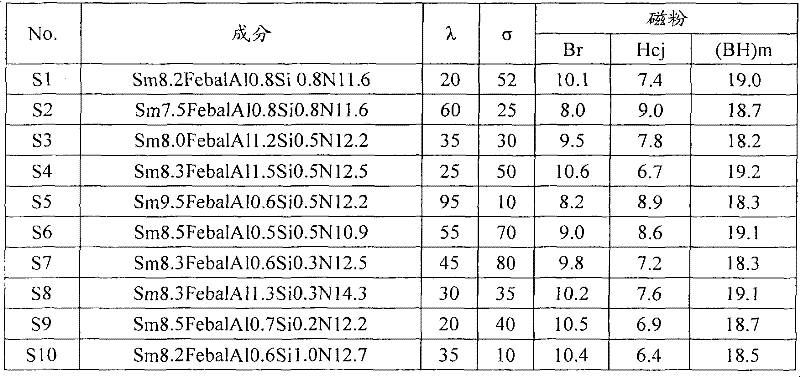

[0045] (5) Through the above preparation, the magnetic powder show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com