Preparation method for superparamagnetism ferroferric oxide sub-micron hollow microsphere

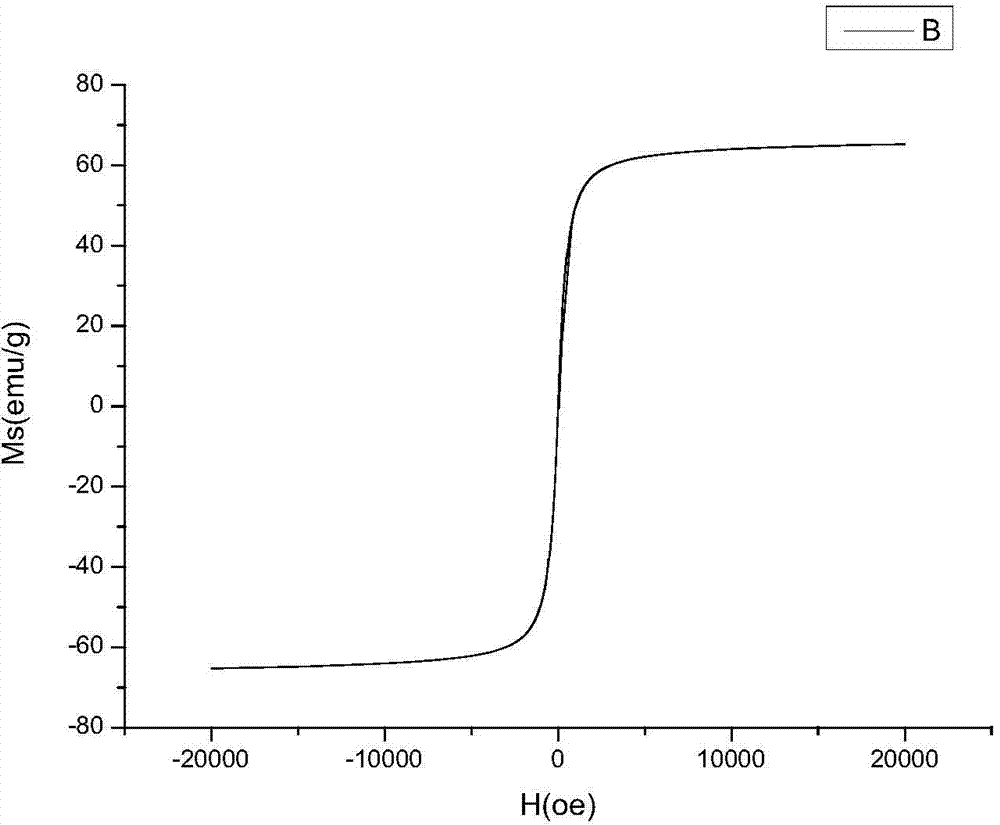

A ferroferric oxide and superparamagnetic technology, which is applied in the direction of iron oxide/iron hydroxide, magnetic properties of inorganic materials, ferrous oxides, etc., can solve the problems of low saturation magnetization, poor biocompatibility, easy collapse, etc. problems, to achieve the effect of excellent oxidation resistance, high saturation magnetization, and cost minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 8mmol trisodium citrate, 4mmolFeCl 3 .6H 2 O, 12 mmol NH 4 HCO 3 Dissolve in 80ml of distilled water, stir to dissolve with a magnet, add 2×10 -4 mmol polyacrylamide (PAM) and 1×10 -4 mmol polyethylene glycol (PEG). After the dissolution is complete, move it into a 100ml reaction kettle, react in an oven at 220°C for 8 hours, cool to room temperature and age, then wash twice with distilled water and absolute ethanol, centrifuge, and place in a vacuum oven at 50°C Dry to obtain the product.

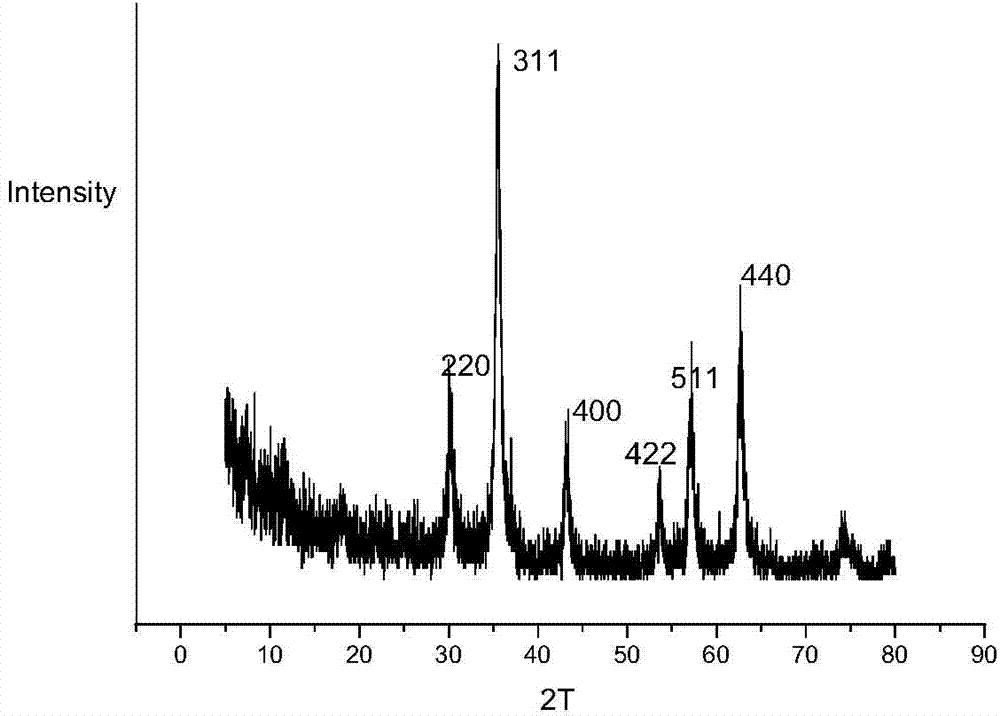

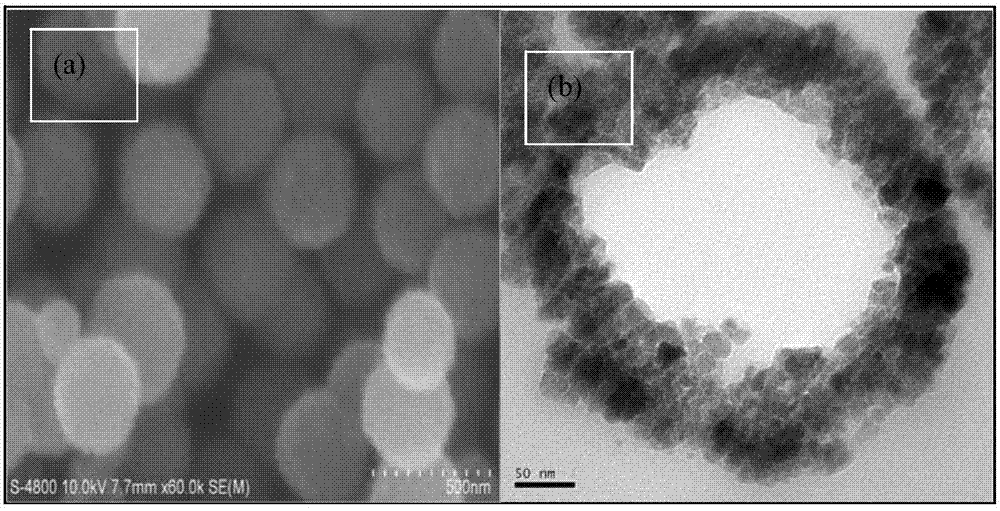

[0021] The ferric iron tetroxide submicron hollow microsphere of the present invention is subjected to X-ray powder diffraction (XRD), and the result is obtained by figure 1 It can be seen that all diffraction peaks are related to Fe 3 o 4 (JCPDS79-0419) corresponds, Fe does not appear 2 o 3 The characteristic diffraction peaks (110), (210), (211), etc., indicate that the product is pure Fe 3 o 4 . Scanning electron microscopy (SEM) and transmission electron microscopy ...

Embodiment 2

[0023] 10mmol trisodium citrate, 4mmol FeCl 3 .6H 2 O, 8 mmol NH 4 Dissolve AC in 60ml of distilled water, stir and dissolve with a magnet, add the same amount of PAM and PEG as the surfactant in the above Example 1, and after the dissolution is complete, transfer it into a 100ml reactor, and react in an oven at 220°C for 8 hours , cooled to room temperature and aged, then washed twice with distilled water and absolute ethanol, centrifuged, and dried in a vacuum oven at 50°C to obtain the product. The morphology and properties of the obtained product are similar to Example 1.

Embodiment 3

[0025] 8mmol trisodium citrate, 4mmol FeCl 3 .6H 2 O. Dissolve 6 mmol of urea in 60 ml of distilled water, stir and dissolve with a magnet, add the same amount of PAM and PEG as the surfactant in Example 1 above, and after the dissolution is complete, transfer it to a 100 ml reaction kettle and react in an oven at 180°C , reacted for 8 hours, cooled to room temperature and aged, then washed twice with distilled water and absolute ethanol, centrifuged, and dried in a vacuum oven at 50°C to obtain the product. The morphology and properties of the obtained product are similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com