Carbon nano-tube/ferromagnetism metal nanowire composite material, mfg. method and use thereof

A technology of carbon nanotubes and composite materials, applied in radiation-absorbing coatings, magnetic field/electric field shielding, electrical components, etc., can solve the problems of magnetic property damage, nano ferromagnetic powder surface is easy to be oxidized, etc., and achieve magnetic permeability improvement , Improved microwave absorption capacity, good oxidation resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1.1.8g Al 2 o 3 Add 20ml of absolute ethanol and stir quickly; add 2.08g of tetraethyl orthosilicate and 20ml of water; after tetraethyl orthosilicate is fully hydrolyzed, add Fe 2 (SO 4 ) 3 ·5H 2 O, the dosage is 1~-5g; place the suspension at 100°C under a nitrogen atmosphere to evaporate the solvent, and grind the product to a fine powder catalyst.

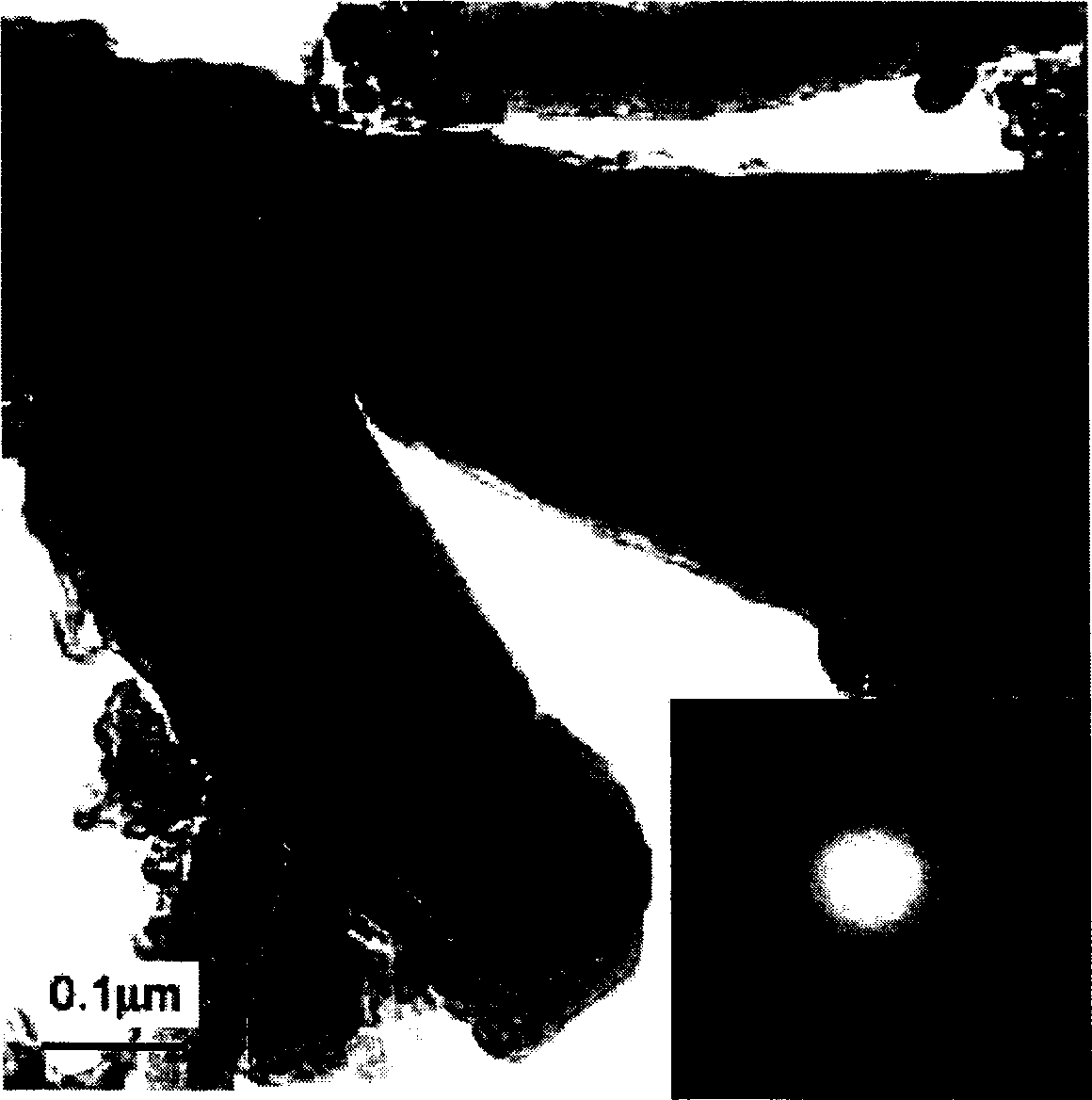

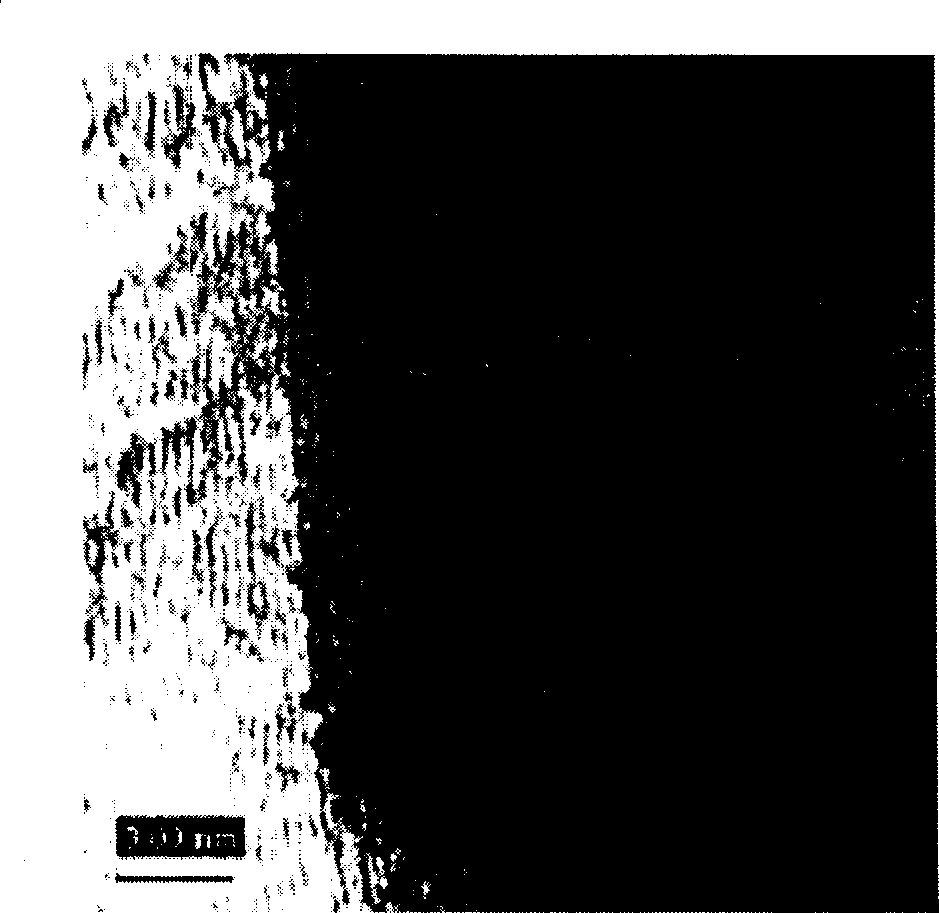

[0029] 2. The catalyst is roasted in argon at 750°C for 30-45 minutes; the temperature is raised to 930°C-950°C at 25°C / min, and at this time, the argon is replaced with methane (purity: 99.99%) with a flow rate of 1000-1200sccm, and the At 30 minutes, the argon flow rate was reduced to 200 sccm, and then within 36 minutes, the furnace temperature was lowered to 900°C, the methane gas was turned off, the argon protection was lowered to room temperature, and the cooling rate was 350°C / min. Multi-walled carbon nanotubes of crystalline iron nanowires.

[0030] 3. Crystallization treatment: Method 1, heat up to 750°C i...

Embodiment 2

[0033] 1. Weigh 0.35g of ferrocyanide powder and put it on one end of a quartz boat, put it in the temperature zone of the tubular heating furnace at about 600°C, place another quartz boat in the temperature zone of 850-900°C, and adjust the heating parameters of the tubular heating furnace so that The distance between the two temperature zones is about 8-10 cm.

[0034] 2. Heat the tube furnace to 900°C at a heating rate of 12.5°C / min, and keep warm for 10 minutes to complete the growth process. The atmosphere parameters are: argon 45sccm + hydrogen 10sccm.

[0035] 3. After the tube furnace is cooled to room temperature, collect the product of the quartz boat in the high temperature zone and carry out crystallization treatment according to step 3 of Example 1.

[0036] The specific process parameters of the above two embodiments can be flexibly designed under different implementation conditions. For example, the Fe in the catalyst can be 2 (SO 4 ) 3 ·5H 2 O is replaced ...

Embodiment 3

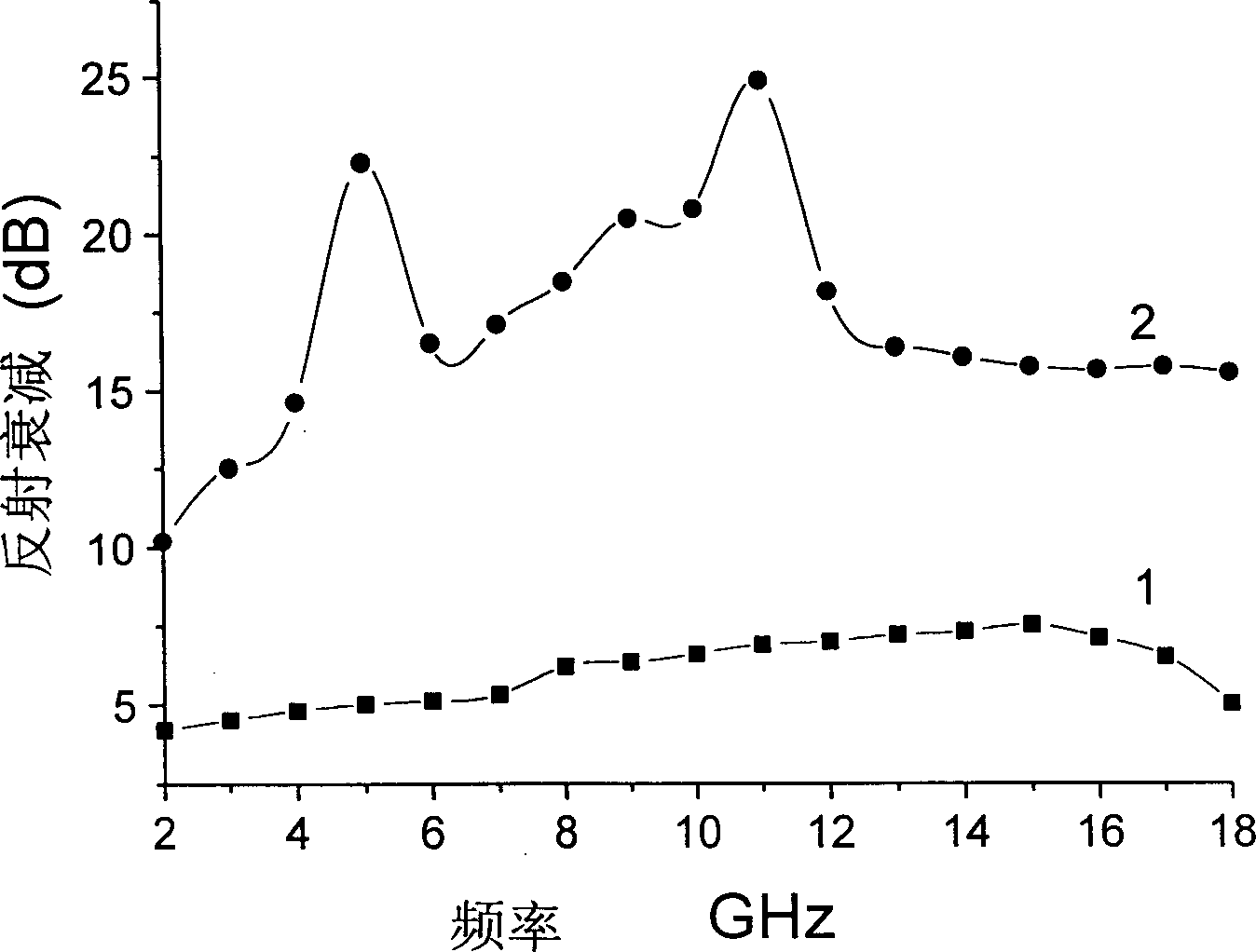

[0037] The carbon nanotubes filled with iron nanowires prepared in Example 1 or 2 were uniformly dispersed in an epoxy resin / ethanol solution, and cured in an oven at 90° C. to obtain a microwave absorbing material.

[0038]The real part of the magnetic permeability of carbon nanotubes / iron nanowires at 2-18GHz increases from 1.2 before crystallization to more than 2.0 after crystallization; the imaginary part of magnetic permeability rises from 0.3 before crystallization to more than 1.5; reflection attenuation From less than 7.5dB before crystallization to above 15dB after crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com