Fe@Fe3O4 nanoparticles having photothermal function, and preparation method and application thereof

A nanoparticle and functional technology, which is applied in the field of composite FeFe3O4 nanoparticles, can solve the problem of inability to accurately locate lesions, and achieve the effect of obvious photothermal effect, good dispersion and stability, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

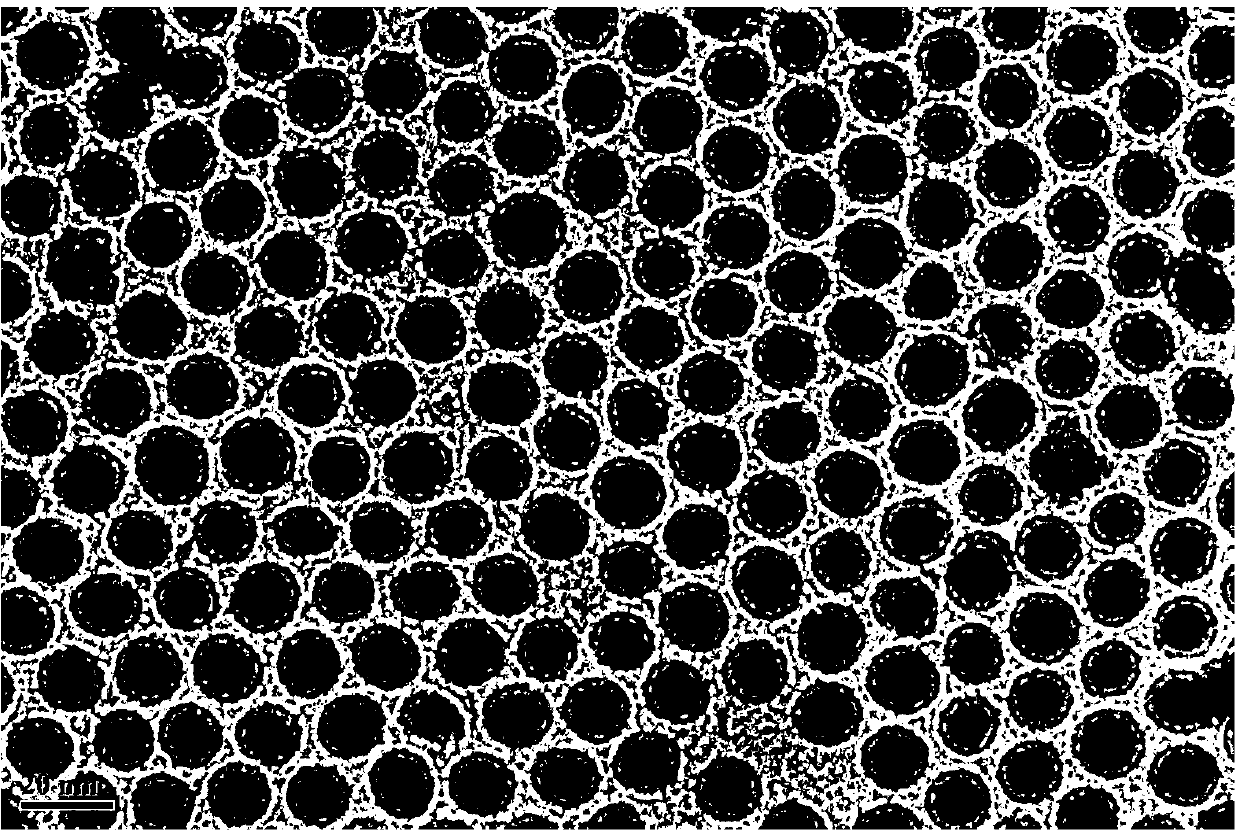

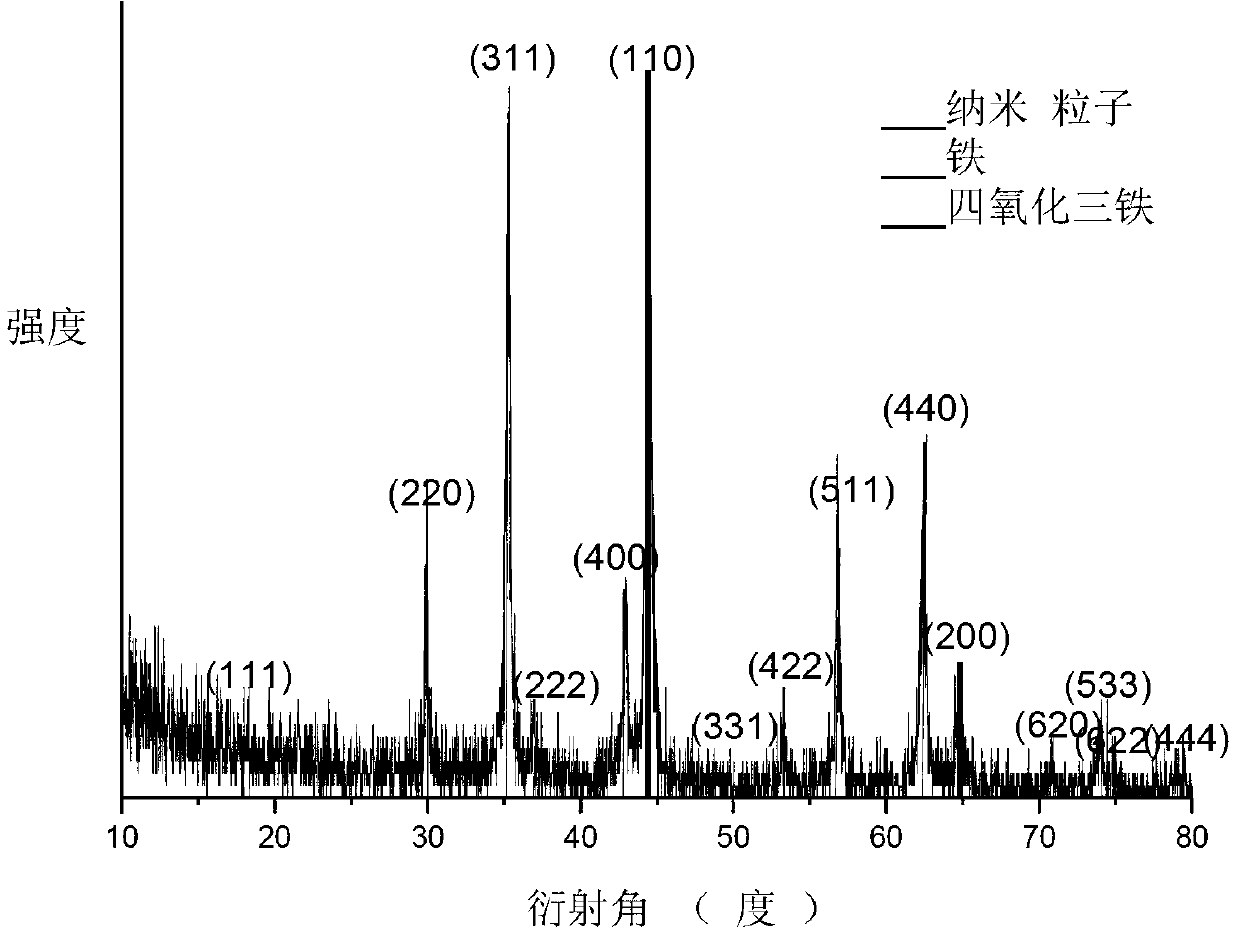

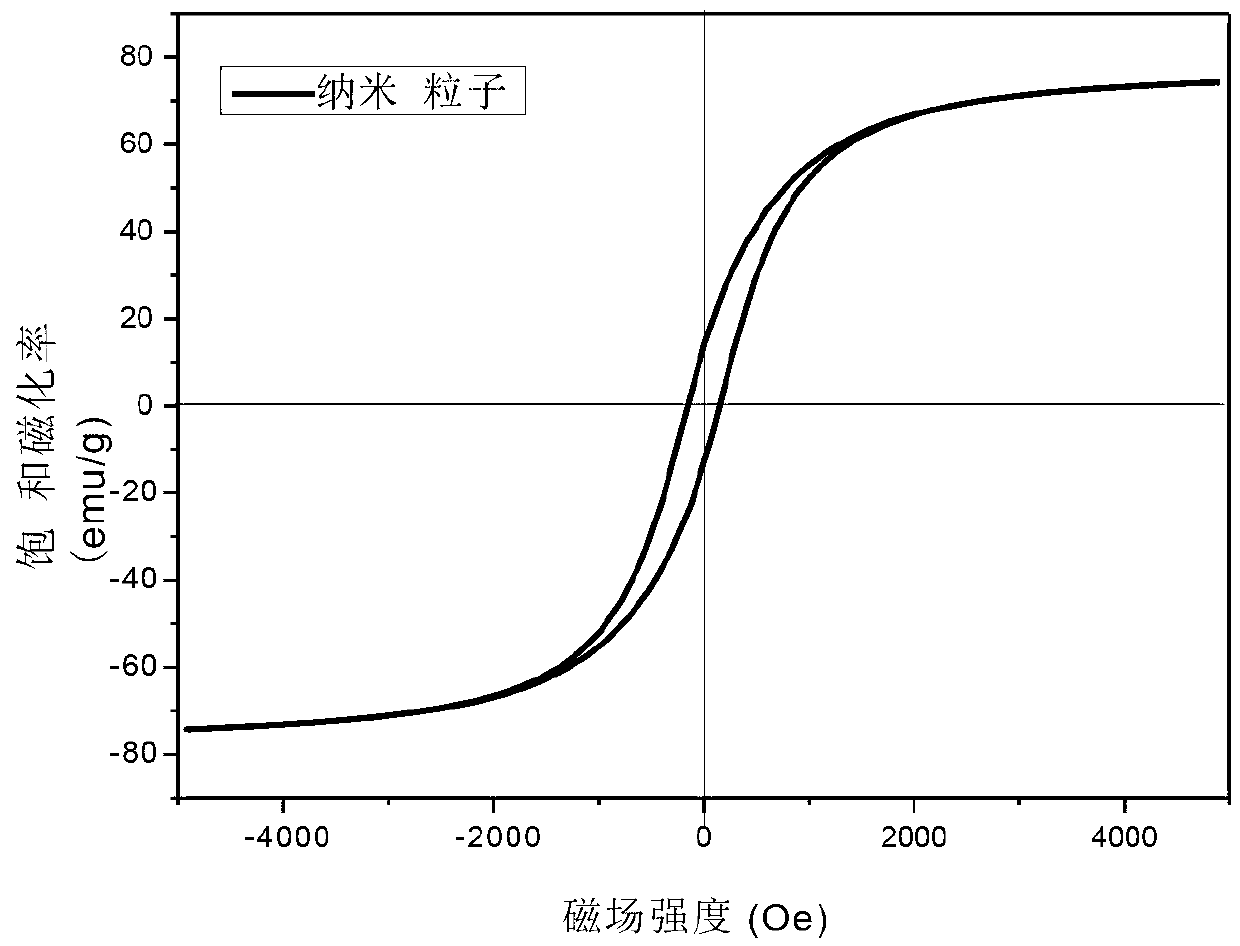

[0031] Take 10 mL of octadecene, add 0.3 mL of oleylamine, and stir. Exhaust the air and pass nitrogen to the device, then raise the temperature of the reactant, the temperature rises to 180°C, and quickly inject 0.35mL Fe(CO) 5 , reacted for 1h, then added 6mg of (CH 3 ) 3 NO, quickly raise the temperature to 250°C, react for 0.5h, and centrifuge after the reaction. You can get FeFe 3 o 4 Core-shell nanospheres. When modifying, dissolve 200 mg of polyethylene glycol monocarboxylic acid, 30 mg of N-hydroxysuccinimide, and 8 mg of dopamine in pyridine, and add 30 mg of 1-ethyl-(3-dimethylaminopropyl) carbon dicarboxylate After the imine hydrochloride was stirred magnetically for 30 minutes at room temperature, it was added to FeFe 3 o 4 For oily nanomaterials, shake overnight on a shaker, centrifuge after the reaction, and disperse the obtained samples in water, using 0.5W / cm 2 808nm laser, test its light-to-heat conversion performance.

Embodiment 2

[0033] Take 20 mL of octadecene, add 0.3 mL of oleylamine, and stir. Ventilate the device with nitrogen, then raise the temperature of the reactant, the temperature rises to 180°C, and quickly inject 0.7mL Fe(CO) 5 , reacted for 1h, then added 6mg of (CH 3 ) 3NO, quickly raise the temperature to 250°C, react for 0.5h, and centrifuge after the reaction. You can get FeFe 3 o 4 Core-shell nanospheres. When modifying, dissolve 200 mg of polyethylene glycol monocarboxylic acid, 30 mg of N-hydroxysuccinimide, and 8 mg of dopamine in pyridine, and add 30 mg of 1-ethyl-(3-dimethylaminopropyl) carbon dicarboxylate After the imine hydrochloride was stirred magnetically for 30 minutes at room temperature, it was added to FeFe 3 o 4 For oily nanomaterials, shake overnight on a shaker, centrifuge after the reaction, and disperse the obtained samples in water, using 0.5W / cm 2 808nm laser, test its light-to-heat conversion performance.

Embodiment 3

[0035] Take 20 mL of octadecene, add 0.3 mL of oleylamine, and stir. Ventilate the device with nitrogen, then raise the temperature of the reactant, the temperature rises to 180°C, and quickly inject 0.7mL Fe(CO) 5 , reacted for 0.5h, then added 6mg of (CH 3 ) 3 NO, quickly raise the temperature to 250°C, react for 0.5h, and centrifuge after the reaction. You can get FeFe 3 o 4 Core-shell nanospheres. When modifying, dissolve 200 mg of polyethylene glycol monocarboxylic acid, 30 mg of N-hydroxysuccinimide, and 8 mg of dopamine in pyridine, and add 30 mg of 1-ethyl-(3-dimethylaminopropyl) carbon dicarboxylate After the imine hydrochloride was stirred magnetically for 30 minutes at room temperature, it was added to FeFe 3 o 4 For oily nanomaterials, shake overnight on a shaker, centrifuge after the reaction, and disperse the obtained samples in water, using 0.5W / cm 2 808nm laser, test its light-to-heat conversion performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com