Production method of aluminum alloy bionic superhydrophobic surface

A super-hydrophobic surface and aluminum alloy surface technology, which is applied in the process of producing decorative surface effects, manufacturing microstructure devices, metal material coating processes, etc., can solve the problem of few applications and achieve the effect of enhancing hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific content of the present invention and its implementation are further described below.

[0037] A method for preparing an aluminum alloy biomimetic superhydrophobic surface according to the present invention, first, carry out the design of the biomimetic surface of an aluminum alloy substrate:

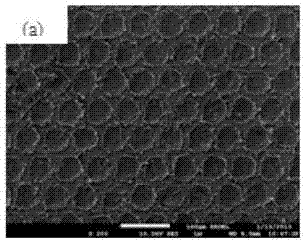

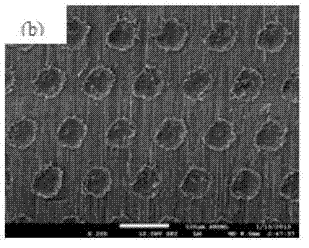

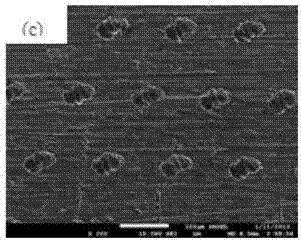

[0038] Based on natural biological materials, the surface of the structural characteristics of the microstructure distribution of natural biological composite materials is designed on the aluminum alloy substrate.

[0039] Design of biomimetic superhydrophobic surface with aluminum alloy substrate:

[0040] Aluminum alloy has broad application prospects in modern industry because of its low density, excellent thermal and electrical conductivity, high specific strength and excellent castability, but its poor hydrophobicity on the metal surface largely restricts its application in the modern industry. Industrial applications. The invention can improve the surface hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com