Titanium-silicon molecular sieve/tripolite composite catalyst and preparation

A technology of titanium-silicon molecular sieves and composite catalysts, which is applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemical methods, etc., can solve the problems of high use cost, difficult separation, small particles, etc., and achieve easy operation control and improved catalytic performance , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

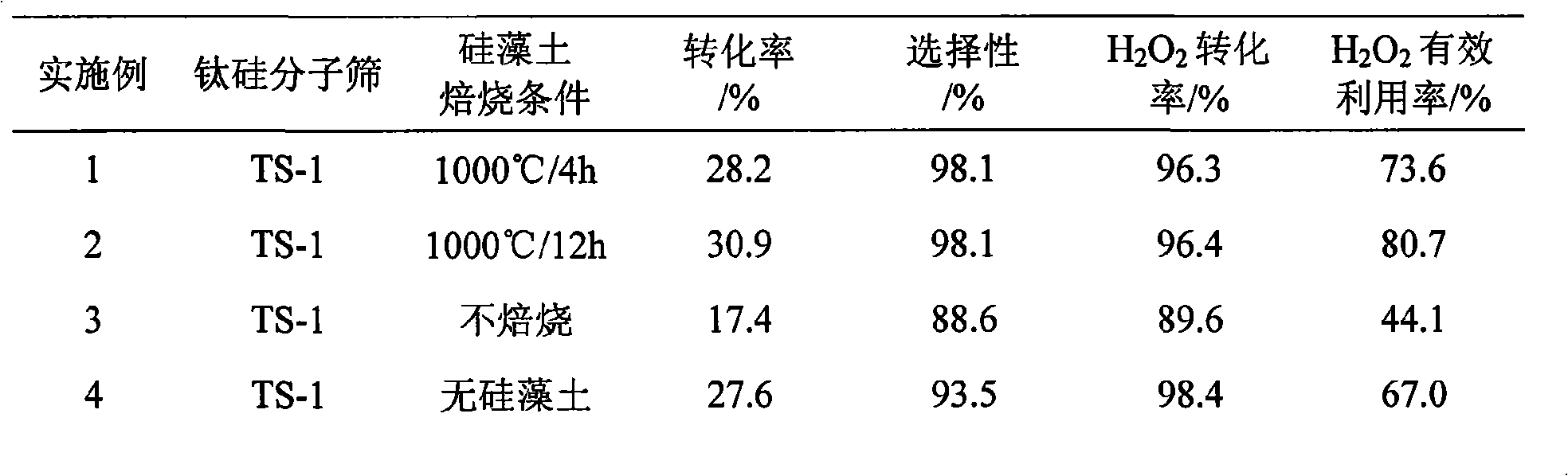

Embodiment 1

[0027] Put 10g of diatomaceous earth in a 100mL Erlenmeyer flask, add 100mL of 40% sulfuric acid, install a reflux device at the mouth of the bottle, heat it to 80°C in a water bath, keep it warm for 4 hours, cool to room temperature, and titrate to the pH value with 20% sodium hydroxide solution for 10. Continue to heat up to 90°C, keep warm for 0.5h, then cool to room temperature, wash with deionized water until neutral, then wash with 100mL absolute ethanol, filter, dry the filter cake in an oven at 110°C for 14h, The heating rate of h was raised from room temperature to 1000°C and kept at this temperature for 4h.

[0028] Mix 3.6g of TS-1 and 5.4g of treated diatomaceous earth evenly, press into tablets, and crush to 20-40 mesh. The hydroxylation reaction of phenol is carried out in a fixed-bed glass reactor with an inner diameter of 15mm, and the amount of catalyst is 7g. It is placed in the constant temperature section of the reactor, and both ends are closed with broke...

Embodiment 2

[0030]The difference from Example 1 is that the calcination time of diatomaceous earth at 1000° C. is extended to 12 hours, and other conditions are the same as in Example 1. Catalyst evaluation conditions are shown in Example 1, and reaction evaluation results are shown in Table 1.

Embodiment 3

[0032] The difference from Example 1 is that the chemically treated diatomaceous earth is not subjected to roasting heat treatment after drying, and other conditions are the same as in Example 1. Catalyst evaluation conditions are shown in Example 1, and reaction evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com