Diatomite-based porous composite material for adsorbing volatile organic pollutants and preparation method thereof

A volatile organic and composite material technology, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., to achieve the effects of low reaction temperature, increased content, increased specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

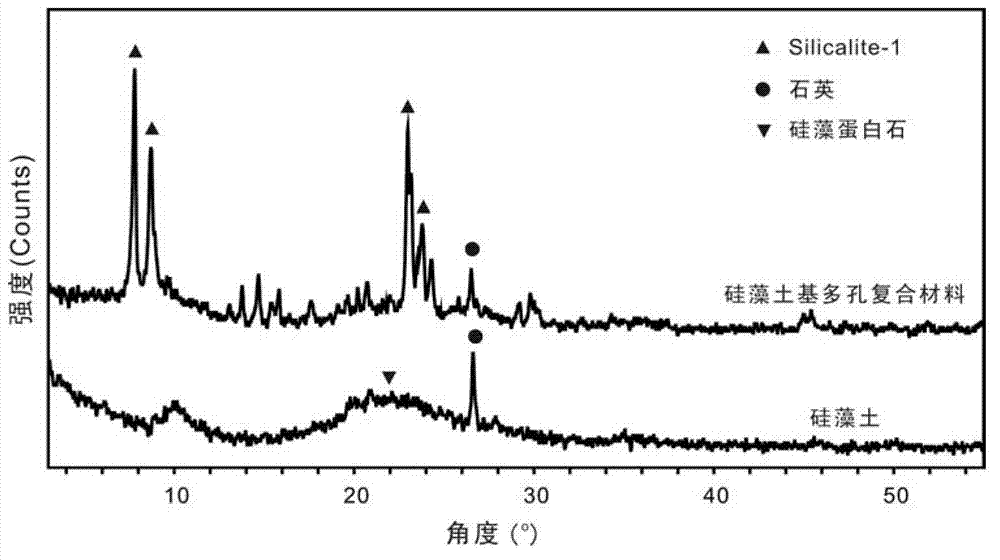

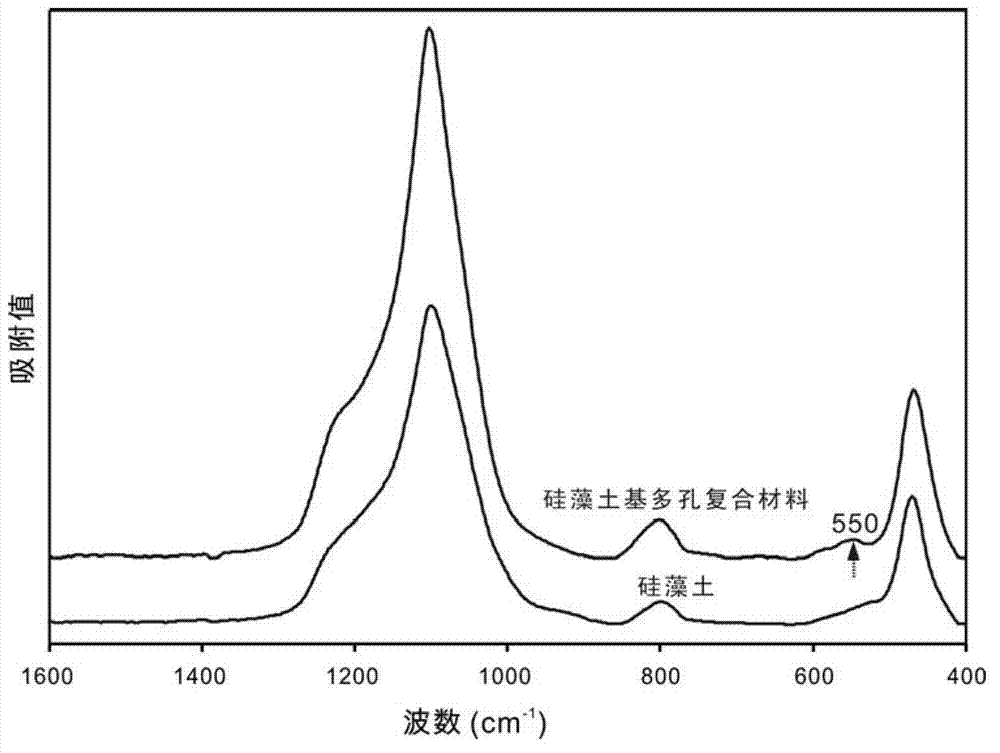

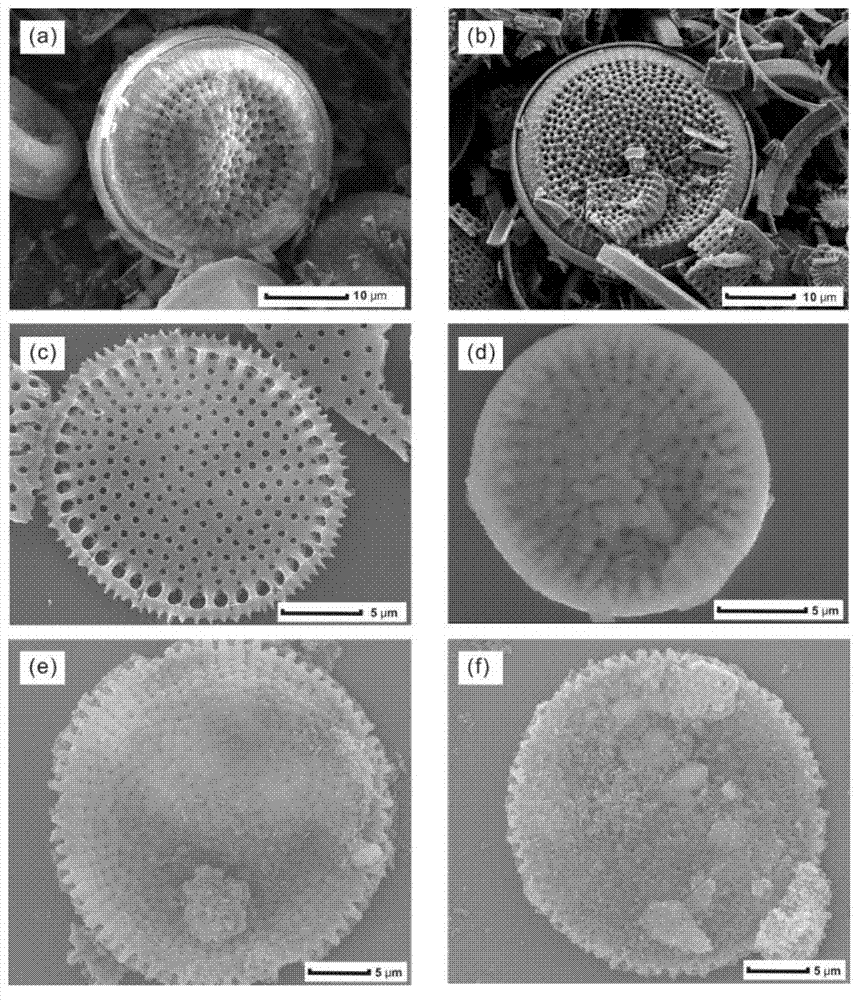

[0030] 1) 5 g of Jilin diatomite purified by sedimentation (the main diatom species is diatom of Cylindrocephalus, SiO 2 85.78% by mass) was added to 100 mL of NaOH solution with pH=10, fully stirred at 60 °C for 4 h, and the suspension was separated into solid-liquid by centrifugation. Dry to constant weight.

[0031] 2) Soak the solid dried to constant weight obtained in step 1) in 100 mL of a polydimethyldiallyl ammonium chloride solution with a mass fraction of 0.5 wt % for 20 minutes, and centrifuge the suspension. Solid-liquid separation was performed, and the solid portion was washed 4 times with water.

[0032] 3) The solid obtained after washing in step 2) is placed in 100 mL of Silicalite-1 zeolite sol with a concentration of 1.5 wt% and a pH of 9.5 (a hydrosol of Silicalite-1 nanocrystals with an average particle size of about 78 nm) to soak and deposit. After 20 minutes, the suspension was subjected to solid-liquid separation by centrifugation, and the obtained s...

Embodiment 2

[0038] 1) Add 5g of Jilin diatomite purified by sedimentation (same as the diatomite used in Example 1) into 100mL of NaOH solution with pH=13.5, fully stir at 25°C for 72h, and centrifuge the suspension. Solid-liquid separation was performed, and the separated solid was washed 4 times with water and then dried at 80° C. to constant weight.

[0039] 2) Soak the solid dried to constant weight obtained in step 1) in 100 mL of polydimethyldiallyl ammonium chloride solution with a mass fraction of 0.5 wt % for 20 minutes, and use the centrifugal method to solidify the suspension. The liquid was separated, and the solid portion was washed 4 times with water.

[0040] 3) The solid obtained after washing in step 2) is placed in 100 mL of Silicalite-1 zeolite sol with a concentration of 1.5 wt% and a pH of 9.5 (a hydrosol of Silicalite-1 nanocrystals with an average particle size of about 78 nm) to soak and deposit. After 20 minutes, the suspension was subjected to solid-liquid separ...

Embodiment 3

[0047] 1) Add 5g of Jilin diatomite purified by sedimentation (same as the diatomite used in Example 1) into 100mL of NaOH solution with pH=13.5, fully stir at 25°C for 72h, and centrifuge the suspension. Solid-liquid separation was performed, and the separated solid was washed 4 times with water and then dried at 80° C. to constant weight.

[0048] 2) Soak the solid dried to constant weight in step 1) in 100 mL of polydimethyldiallyl ammonium chloride solution with a mass fraction of 0.5 wt % for 20 minutes, and centrifuge the suspension for solid-liquid separation. Separated and the solid portion was washed 4 times with water.

[0049] 3) Soak the solid obtained after washing in step 2) in 100 mL of Silicalite-1 zeolite sol with a mass fraction of 1.5 wt% and a pH of 9.5 (a hydrosol of Silicalite-1 nanocrystals with an average particle size of about 78 nm). After sedimentation for 20 minutes, the suspension was subjected to solid-liquid separation by centrifugation, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com