Forming method for glass and glass-ceramic

A glass-ceramic and quartz glass-ceramic technology, which is applied in the field of mold preparation and lens matrix preparation, can solve the problems of inability to produce, small size, and high production cost of quartz molds, and achieves simplified production methods, easy polishing, high temperature resistance, etc. receptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

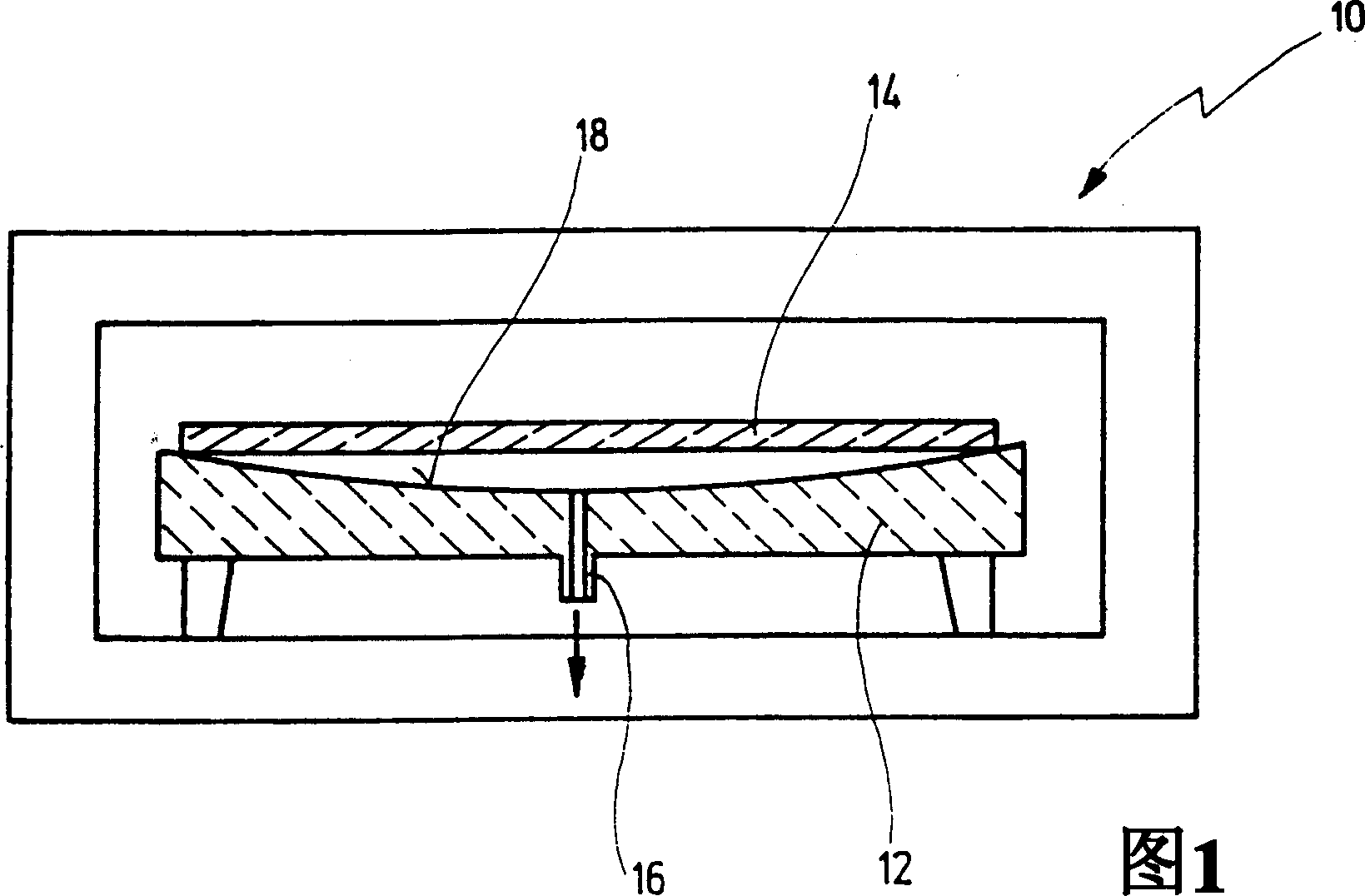

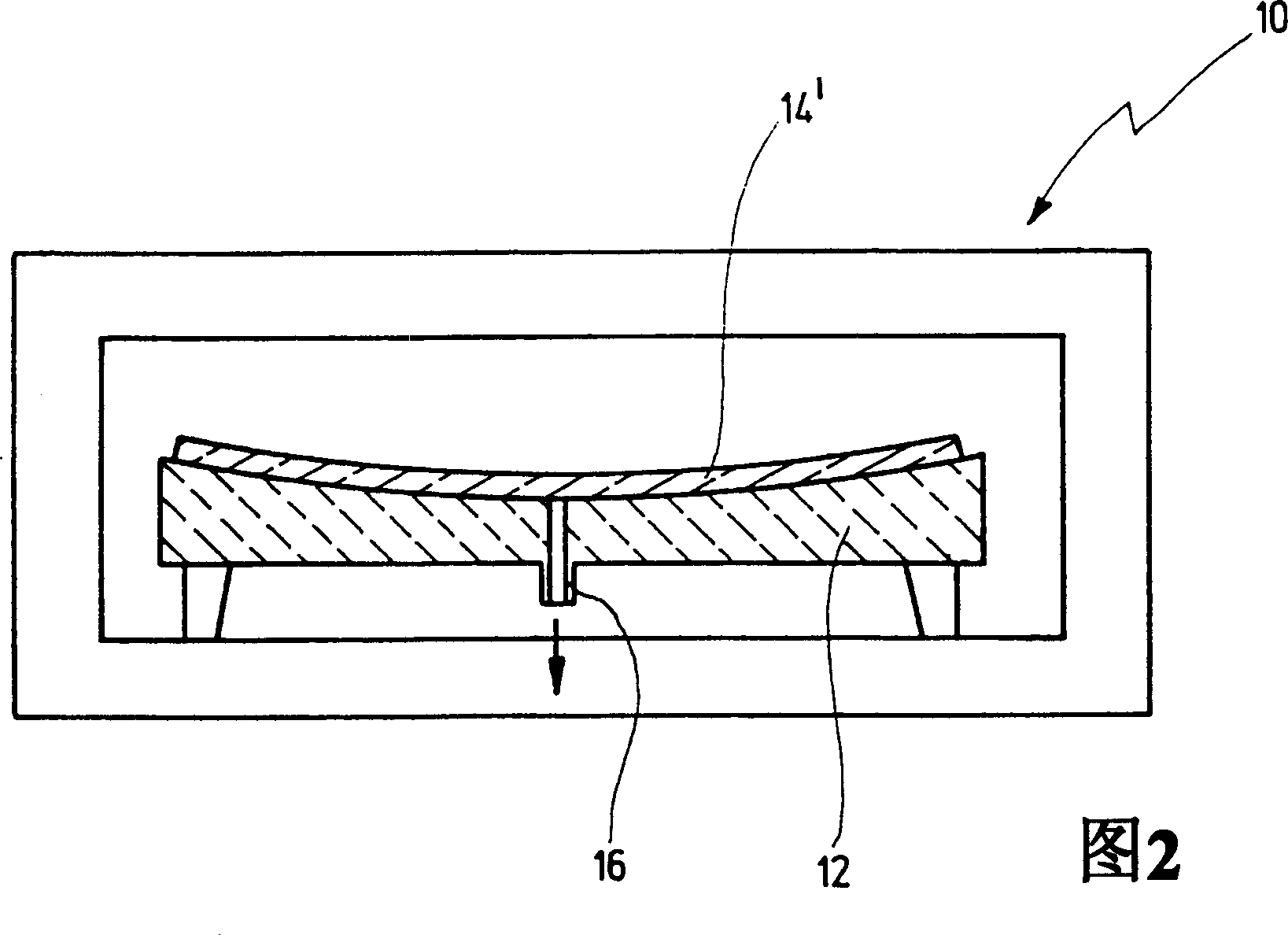

Image

Examples

Embodiment

[0122]The fused base glass contains the following ingredients (% by weight):

[0123] SiO 2 55.50

[0124] Al 2 o 3 25.30

[0125] P 2 o 5 7.90

[0126] Li 2 O 3.70

[0127] Na 2 O 0.50

[0128] MgO 1.00

[0129] ZnO 1.40

[0130] TiO 2 2.30

[0131] ZrO 2 1.90

[0132] As 2 o 3 0.50

[0133] The base glass may be comparable in composition to the applicant's commercially available glass-ceramic Zerodur(R). The base glass produced in this way is refined and cast into gobs of blank glass, which are subsequently vitrified using a controlled crystallization process through a temperature program. For this reason, start heating to 730°C at a heating rate of 0.1K / min, and keep it warm for 24 hours, then heat it to 850°C at a heating rate of 0.1K / min, and then keep it for 48 hours, and then slowly at a speed of 0.1K / min Cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com