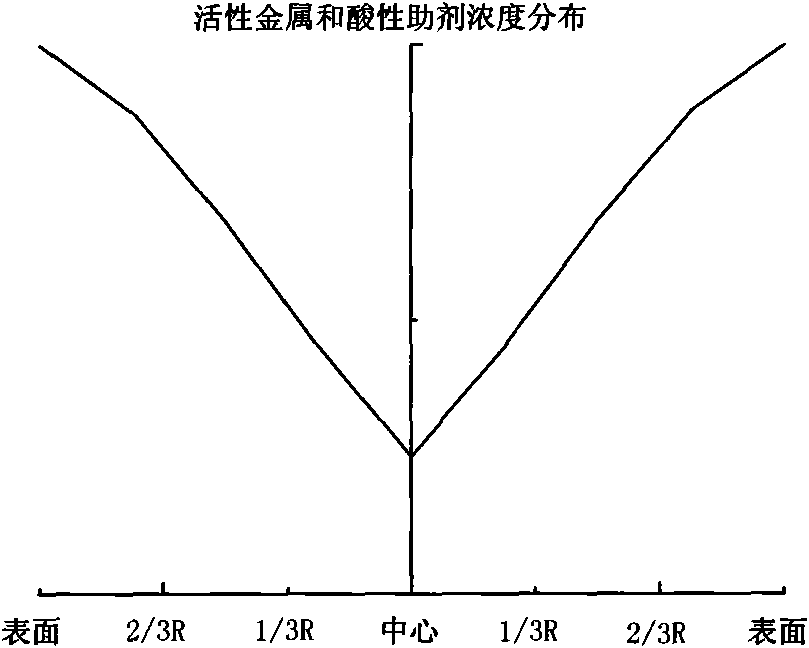

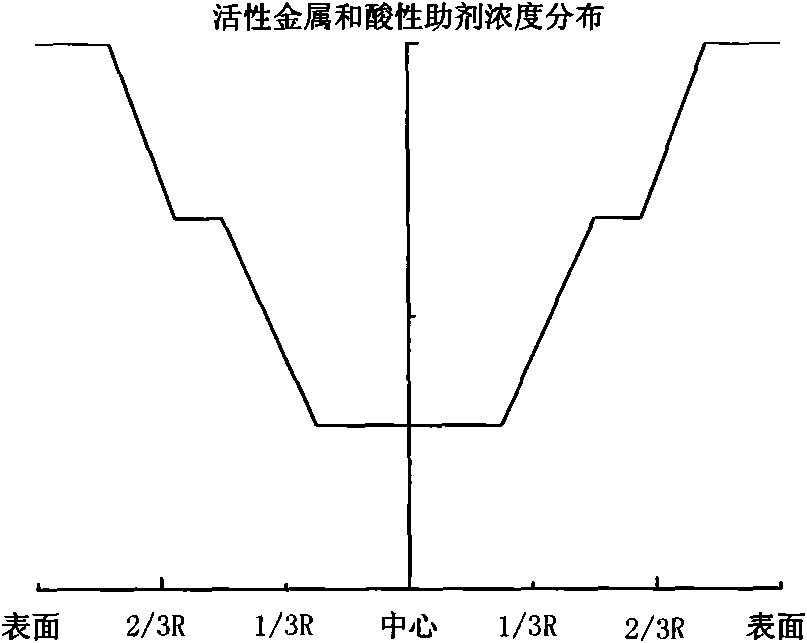

Hydrogenation catalyst showing gradient increase and distribution of concentration of active metal and acid additive and preparation method thereof

A technology of hydrogenation catalyst and acid promoter, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the problems of difficult control and poor gradient of active metal distribution. , to achieve the effect of low manufacturing cost, simple preparation process and high desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

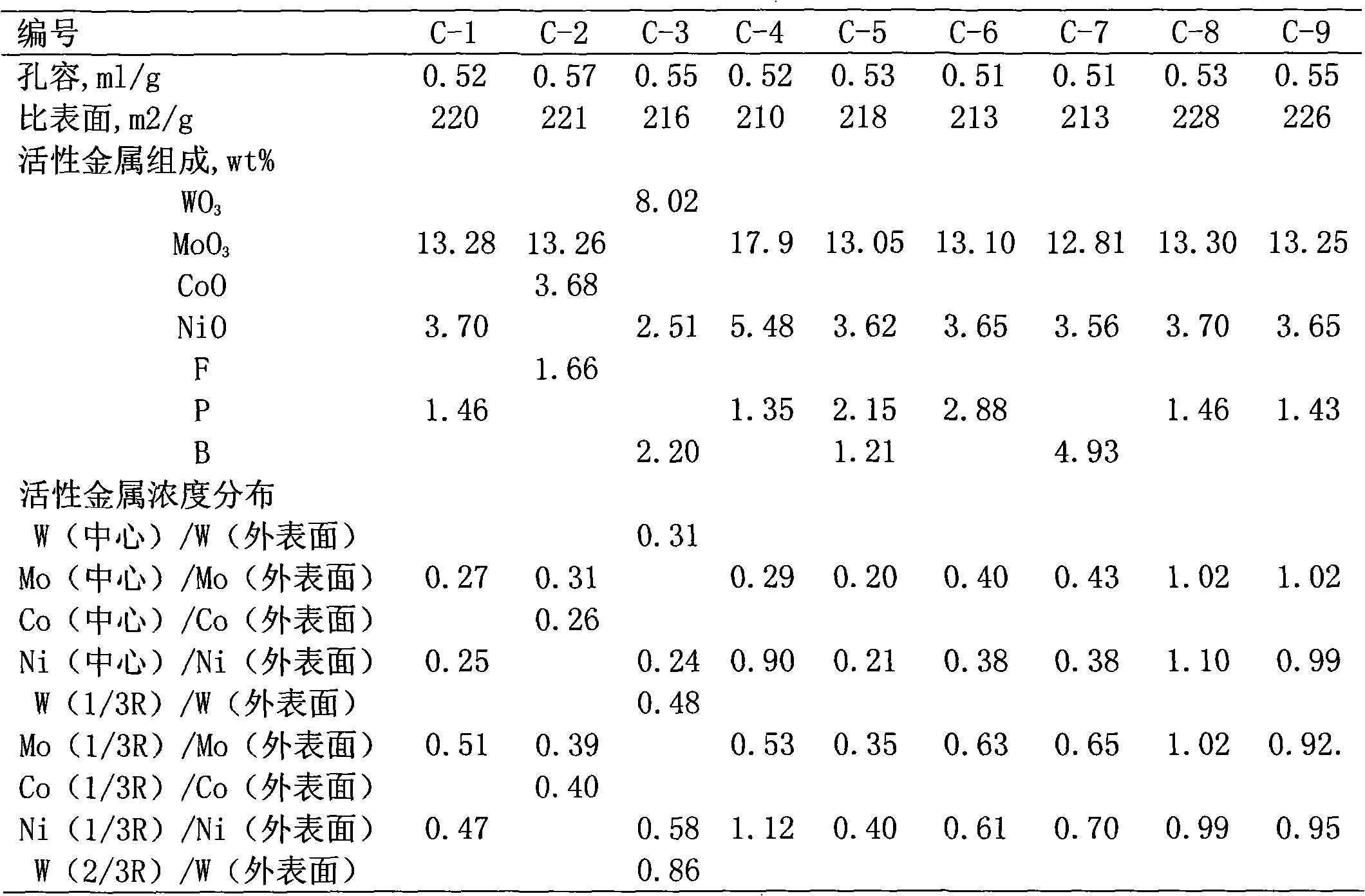

Embodiment 1

[0025] In this example, Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g, and the catalyst whose active metal components are Mo and Ni is prepared by saturated spray immersion method.

[0026] Weigh 150g carrier, spray immerse 65ml containing 5.8g ammonium molybdate (containing MoO 3 82m%, Beijing Chemical Reagent Company, the same below), 2.0g nickel nitrate (containing NiO 25.2m%, Beijing Chemical Reagent Company, the same below) and 1.0g 85% phosphoric acid (Beijing Chemical Reagent Company, the same below); spray After immersion, then spray 50ml containing 8.0g ammonium molybdate (containing MoO 3 82m%), 6.0g nickel nitrate (containing NiO 25.2m%) and 3.0g 85% phosphoric acid aqueous solution; 3 82m%), 19.0g nickel nitrate (containing NiO 25.2m%) and 6.0g 85% phosphoric acid aqueous solution, spray immersion in 15 minutes. After homogenizing for 10 minutes in the spray-dipping equipment, dry at 60°C for 2 hours, take it out and dry at 120°C for 3 hours, ...

Embodiment 2

[0028] This example uses 1.5m% SiO 2 Al 2 o 3 As a carrier, the catalyst with active metal components of Mo and Co was prepared by saturated spray-dipping method.

[0029] Weigh 150g, water absorption rate 1.10mL / g containing 1.5m% SiO 2 Al 2 o 3 Carrier, spray 100ml containing 5.0g ammonium molybdate (containing MoO 3 82m%) and 6.0g of cobalt nitrate (containing CoO 25.2m%, Beijing Chemical Reagent Company, the same below), 1.0g of 50% ammonium fluoride aqueous solution, drop into 65ml containing 24.8g ammonium molybdate (containing MoO 3 82m%), 21.0g cobalt nitrate (containing CoO25.2m%) and 5g 50% ammonium fluoride (Beijing Chemical Reagent Company, the same below) aqueous solution in the impregnating solution and stir evenly, drop while spray dipping, 5 minutes Dipping is done. After being homogenized for 10 minutes in the spray-dipping equipment, it was dried at 120°C for 3 hours, and then calcined in air at 500°C for 3 hours to prepare the catalyst. Numbered C...

Embodiment 3

[0031] In this example, 1.0m% SiO 2 and 1.5m%TiO 2 Al 2 o 3 As a carrier, the water absorption rate is 1.10mL / g, and the catalyst whose active metal components are W and Ni is prepared by saturated spray immersion method.

[0032] Weigh 150g carrier, spray 100ml containing 7g ammonium metatungstate (containing WO 3 82m%, Beijing Chemical Reagent Company, the same below), 5.0g nickel nitrate (containing NiO 25.2m%) and 5.0g 85% boric acid (Beijing Chemical Reagent Company, the same below) aqueous solution, drip into 65ml at a constant speed during the spray immersion process Contains 11.8g ammonium metatungstate (contains WO 3 82m%), 12.0g nickel nitrate (containing NiO 25.2m%) and 16.0g 85% boric acid aqueous solution in the impregnating solution and stirred evenly, while spraying while dripping, the impregnation was completed in 5 minutes. After homogenizing for 10 minutes in the spray-dipping equipment, dry at 60°C for 2 hours, take it out and dry at 120°C for 6 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com