Purification method of long-carbon-chain dicarboxylic acid

A long carbon chain dibasic acid and dibasic carboxylic acid technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of difficult to obtain polymers with a high degree of polymerization, affecting the mechanical properties of products, edible alcohol, etc. Problems such as high price, to achieve the effect of reducing coexistence time, low cost, and reducing the probability of side reactions of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] A C of the present invention 12 Purification method of dicarboxylic acid

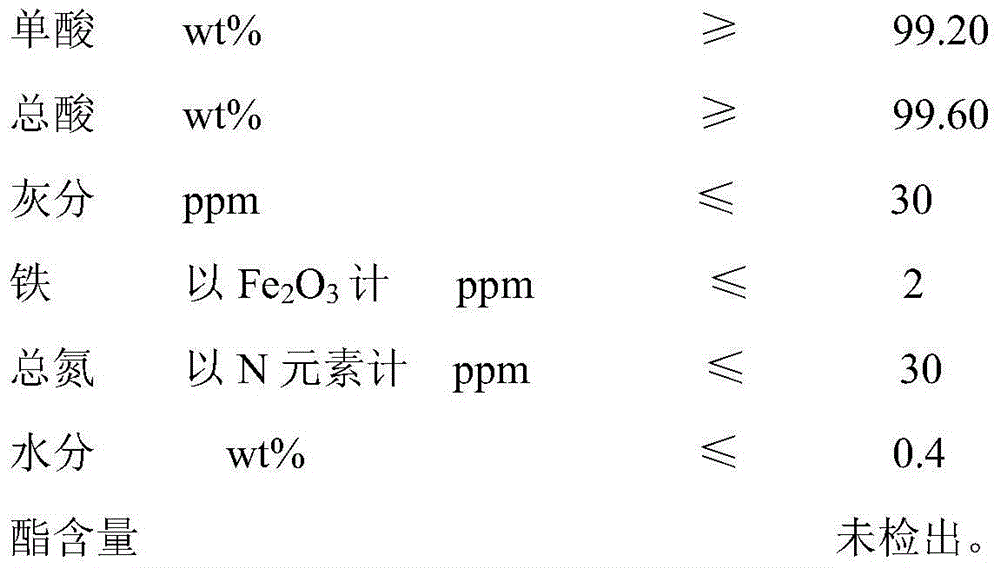

[0111] 600kgC 12 Dibasic carboxylic acid and 6kg of activated carbon are added to 2000L of methanol solution with a purity of 98%. After stirring evenly, the temperature of the plate heat exchanger is raised and it enters the decolorization kettle. The dibasic acid solution enters the crystallization kettle, quickly and uniformly cools down to 47°C in the crystallization kettle, controls the cooling time for 20 minutes, turns off the cooling water, and naturally cools down for 1 hour. ℃, control the cooling time for 3 hours. Centrifugal separation of the crystallization liquid, rinse the material in the centrifuge with 300L methanol solution with a purity of 98%, centrifuge for 15 minutes after the rinse, and obtain a material with a solid content of 84%, and dry it in a double-cone vacuum dryer to obtain a refined dibasic acid , the total acid content measured by neutralization titration is 9...

Embodiment 2

[0113] A C of the present invention 12 Purification method of dicarboxylic acid

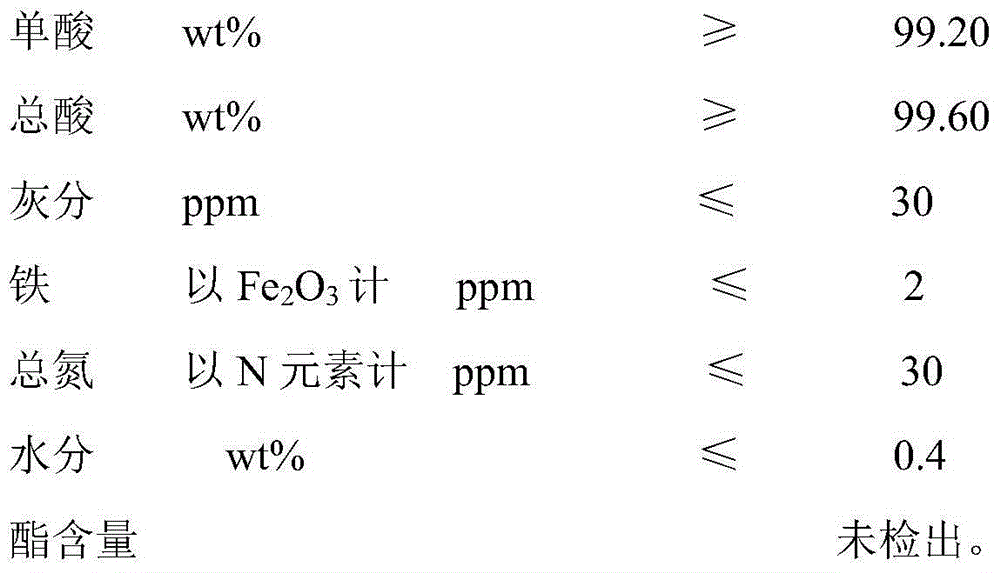

[0114] 400kgC 12Dibasic carboxylic acid and 6 kg of activated carbon are added to 2000 L of centrifuged mother liquor (including washing liquid) obtained in Example 1. After stirring evenly, the temperature of the plate heat exchanger enters the decolorization kettle, and the material outlet temperature of the plate heat exchanger is controlled at 60-64 ° C. The dibasic acid solution filtered by the filtration system enters the crystallization kettle, and quickly and uniformly cools down to 47°C in the crystallization kettle, controls the cooling time for 20 minutes, turns off the cooling water, and naturally cools down for 1 hour. Cool down to 25°C evenly, and control the cooling time for 3 hours. The crystallization liquid is centrifuged, and the centrifuged material is mixed with 2000L methanol solution with a purity of 98% at 20°C in 3m 3 Stir in the enamel kettle for 20 minutes, and centr...

Embodiment 3

[0116] A C of the present invention 12 Purification method of dicarboxylic acid

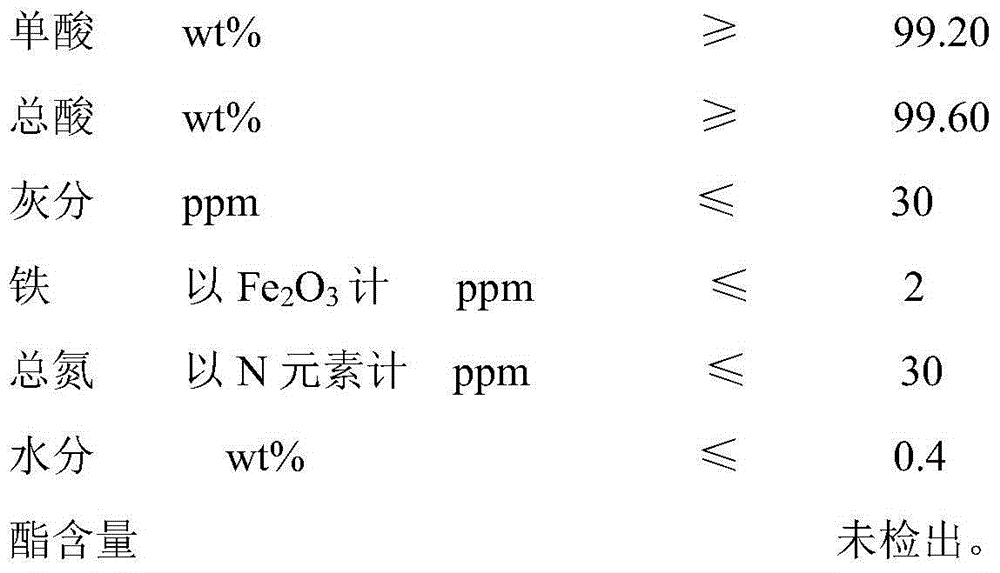

[0117] 400kgC 12 Dibasic carboxylic acid and 4 kg of activated carbon were added to 2000 L of the washing liquid obtained in Example 2, stirred evenly, and then heated up through the plate heat exchanger and entered into the decolorization kettle. The dibasic acid solution enters the crystallization tank, quickly and uniformly cools down to 47°C in the crystallization tank, controls the cooling time for 20 minutes, turns off the cooling water, and naturally cools down for 1 hour, the temperature in the crystallization tank reaches 43.2°C, turns on the cooling water and evenly cools down to 25°C , control the cooling time for 3 hours. Centrifugal separation of the crystallization liquid, rinse the material in the centrifuge with 300L methanol solution with a purity of 98%, centrifuge for 15 minutes after the rinse, and obtain a material with a solid content of 83%, and dry it in a double-cone va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com