Pure sorghum distilled fen-flavor liquor and manufacturing method thereof

The technology of a fragrant-flavor liquor and a production method, which is applied in the field of Xiaoqu liquor brewing, can solve the problems of uneven saccharification in the brewing process, low liquor yield of raw materials, bad taste and flavor, etc., achieve good taste and quality, improve liquor yield, good aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

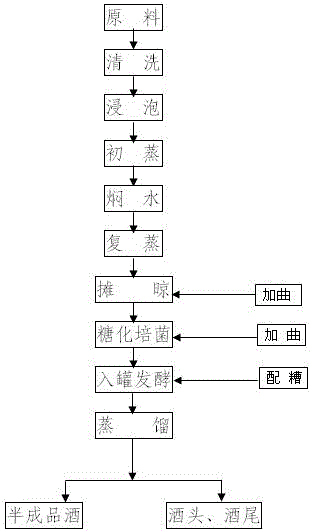

Image

Examples

Embodiment 1

[0025] A pure sorghum Xiaoqu Fen-flavor liquor is produced from japonica sorghum and waxy sorghum through soaking, cooking, saccharification, fermentation and distillation. The production method includes the following steps:

[0026] (1) Soaking: Put 980kg of japonica sorghum and 20kg of glutinous sorghum into the soaking grain pond, add water to wash 3 times, remove the suspended solids on the surface each time, and pass the sand settled at the bottom of the pond through Remove the filter screen set at the bottom of the soaking tank, and then soak in hot water at 30°C for 24 hours. The liquid level is 20cm higher than the material. 96%;

[0027] (2) Initial steaming: After the water in the steamer bottom pot is boiled, put the soaked materials into the steamer for initial steaming. Use a wooden knife to draw a small groove with a width of 2 cm and a depth of 2 cm from the inner wall of the retort, and scrape the surface of the material to make the whole retort steam evenly, ...

Embodiment 2

[0037] A kind of pure sorghum Xiaoqu baijiu is made from japonica sorghum and waxy sorghum through soaking, cooking, saccharifying, fermenting and distilling. The making method comprises the following steps:

[0038] (1) Soaking: put 970kg of japonica sorghum and 30kg of glutinous sorghum into the soaking grain tank, add hot water at 40°C for 18 hours, and the rest are the same as in Example 1;

[0039] (2) initial steaming: with embodiment 1;

[0040] (3) stewed water: with embodiment 1;

[0041] (4) Re-steaming: Cover with a pointed cover, stuffed with sackcloth, wait until the retort is fully steamed, count the time, re-steam for 55 minutes, then open the pointed cover and steam for another 30 minutes to prepare cooked sorghum.

[0042] (5) Spreading air: the amount of added koji is 0.6% of the amount of material, i.e. 6kg, and the rest are the same as in Example 1;

[0043] (6) Saccharification culture: same as Example 1;

[0044] (7) Fermentation in tanks: the starch c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com