Saccharomyces cerevisiae with high acid yield and low yield fusel oil as well as composition and application of saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and Saccharomyces cerevisiae, which is applied in the field of brewing, can solve problems such as low production of higher alcohol, and achieve the effects of reducing the content of higher alcohol, reducing the dosage, and increasing the content of total acid and total ester.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

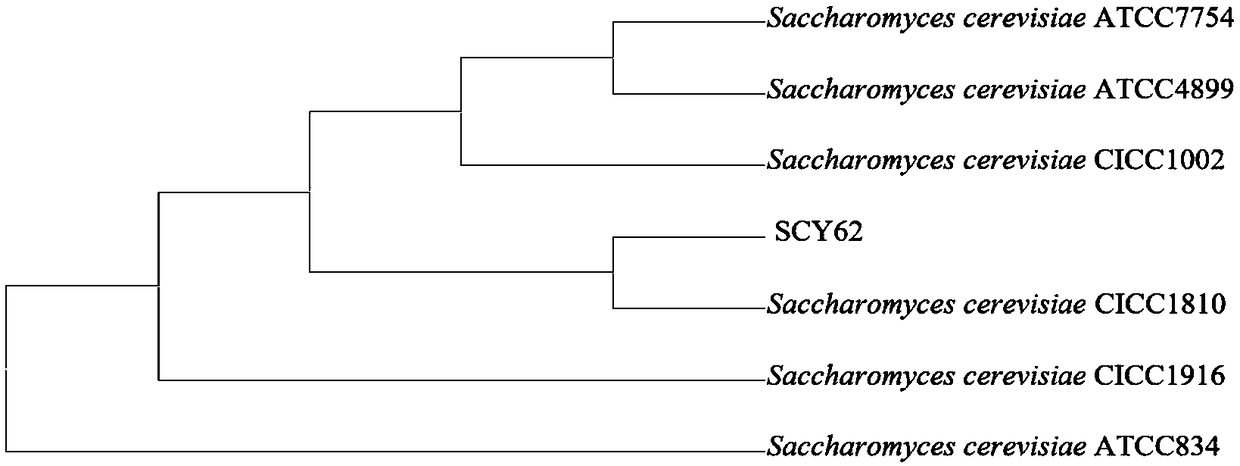

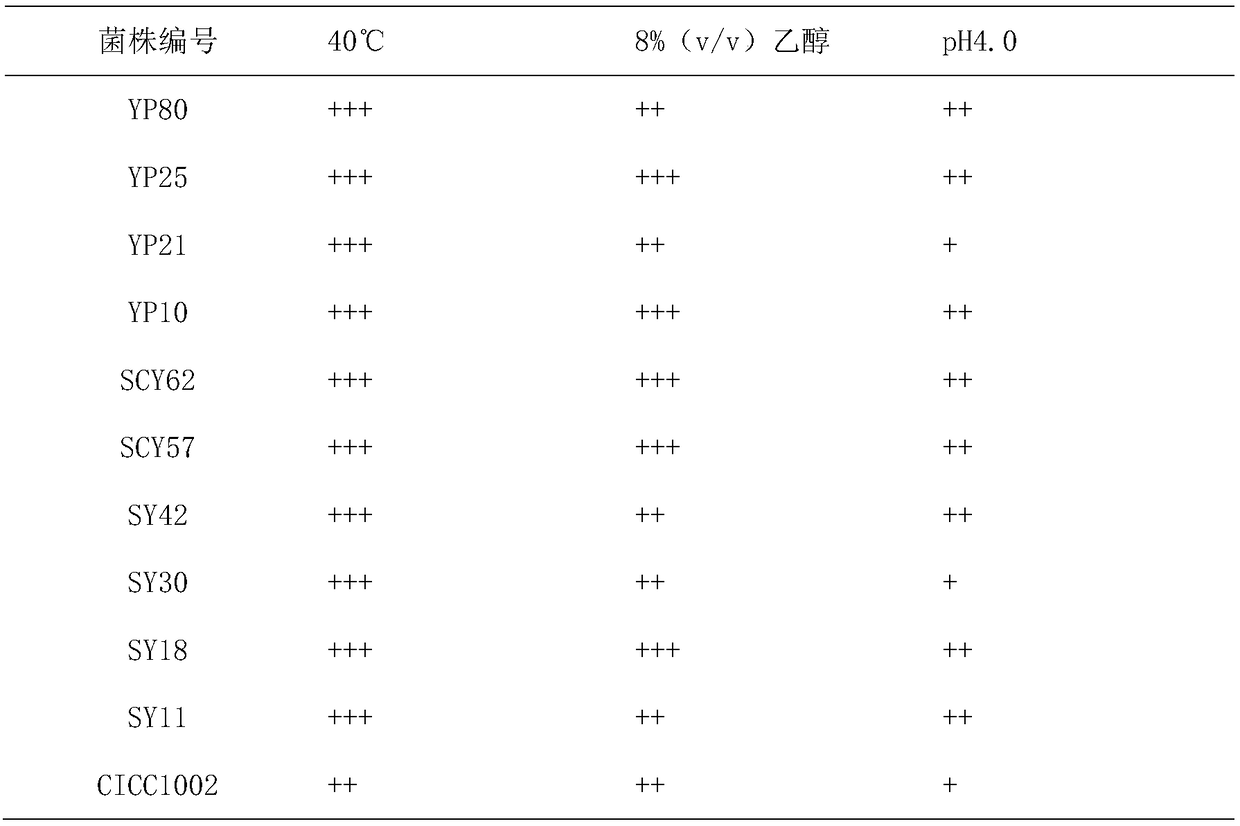

[0055] Example 1 Screening and Identification of Saccharomyces cerevisiae SCY62 Strain with High Tolerance and High Acid Production Rate

[0056] 1.1 Isolation of highly tolerant yeast strains

[0057] It was isolated from a high-temperature accumulation material of a liquor factory in Hubei. Get multiple parts of 10g of high-temperature accumulation materials in different time periods and different parts, and add them respectively to the enrichment culture medium (adjusted to pH4. ), enriched at 37°C for 2-3 days. Take 100 μl of the enriched culture solution after a certain gradient dilution, spread it on the solid plate of Martin Bengal red medium, place it at 37 ° C for 48 hours, pick a single colony of typical yeast form, and then spread it on the same medium Streak purification was repeated on the solid plate, and after cultured at 40°C for 48 hours, a total of 50 yeast strains with good single colony growth at the culture temperature of 40°C were obtained. The isolate...

Embodiment 2

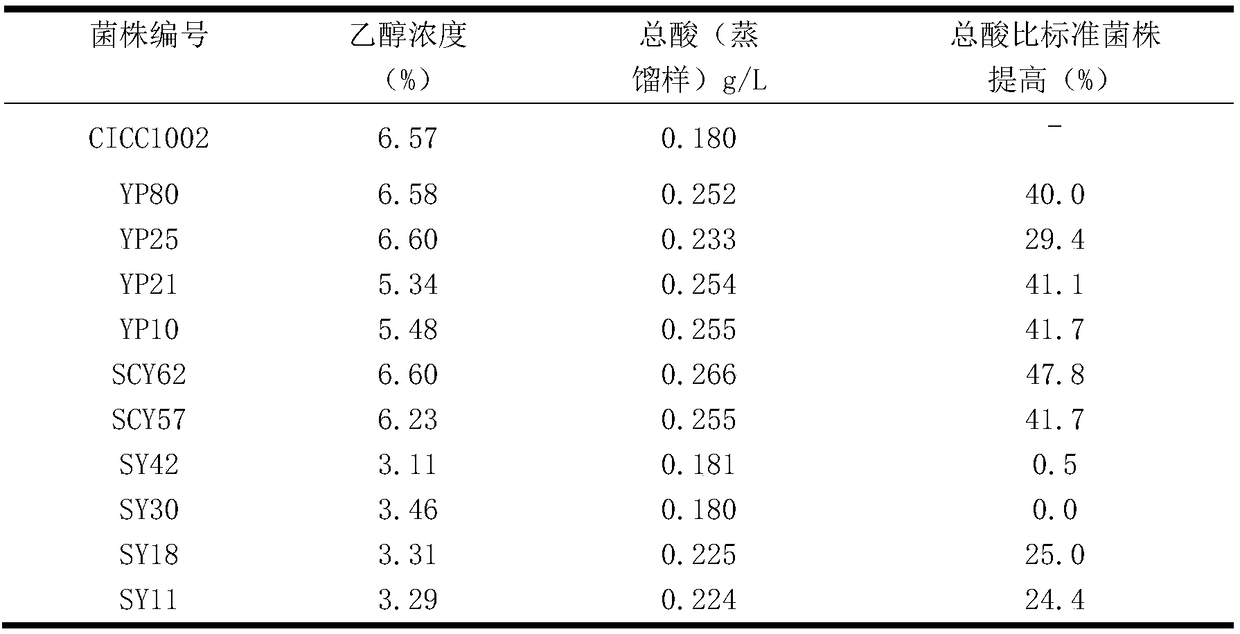

[0092] Example 2. Comparison of Saccharomyces cerevisiae SCY62 strain in fermenting sorghum saccharified liquid to produce ethanol, acid and higher alcohols Saccharomyces cerevisiae SCY62 strain has higher ethanol production capacity. The results of liquid state fermentation of liquor are shown in Table 7, and the fermentation ethanol yield of Saccharomyces cerevisiae SCY62 is high. Under the condition of liquor liquid fermentation at 28°C, the ethanol yield of SCY62 reached 6.81% (v / v), which was slightly higher than that of the standard strain CICC1002. However, the total acid produced by Saccharomyces cerevisiae SCY62 fermented sorghum saccharification liquor after distillation was 32.7% higher than that of the standard strain CICC1002. Among them, the content of acetic acid and hexanoic acid, which are closely related to the flavor of liquor, increased by 117.8% and 40.0% respectively compared with the standard strain; while the contents of the main higher alcohols in liqu...

Embodiment 3

[0099] Example 3 The preparation method of SCY62 brewing bacteria agent and its composition

[0100] 5.1 Strain activation: inoculate a ring of Saccharomyces cerevisiae SCY62 slant strains into sterilized YPD liquid Erlenmeyer flask culture medium, and culture on a shaker at 30°C for 18-24 hours;

[0101] 5.2 Solid state culture: 100% bran, add water according to the ratio of material to water 1:1, put into plastic box or plastic bag, sterilize at 121°C for 30min, cool to room temperature, inoculate 10% of activated Saccharomyces cerevisiae SCY62 In the sterilized bran medium, mix evenly, keep the room temperature at about 28°C, and the product temperature at about 35°C, after 2 days of cultivation, stir and mix once every 24 hours;

[0102] 5.3 Drying: Dry the fermented yeast solid sample at 35-42°C, stop drying when the moisture content of the sample is between 10% and 25%, and grind the dried culture with a pulverizer to prepare Solid powder brewing agent. The number of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com