Heavy oil hydrogenating treatment catalyst and preparation method thereof

A heavy oil hydrogenation and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor catalyst stability and high carrier acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

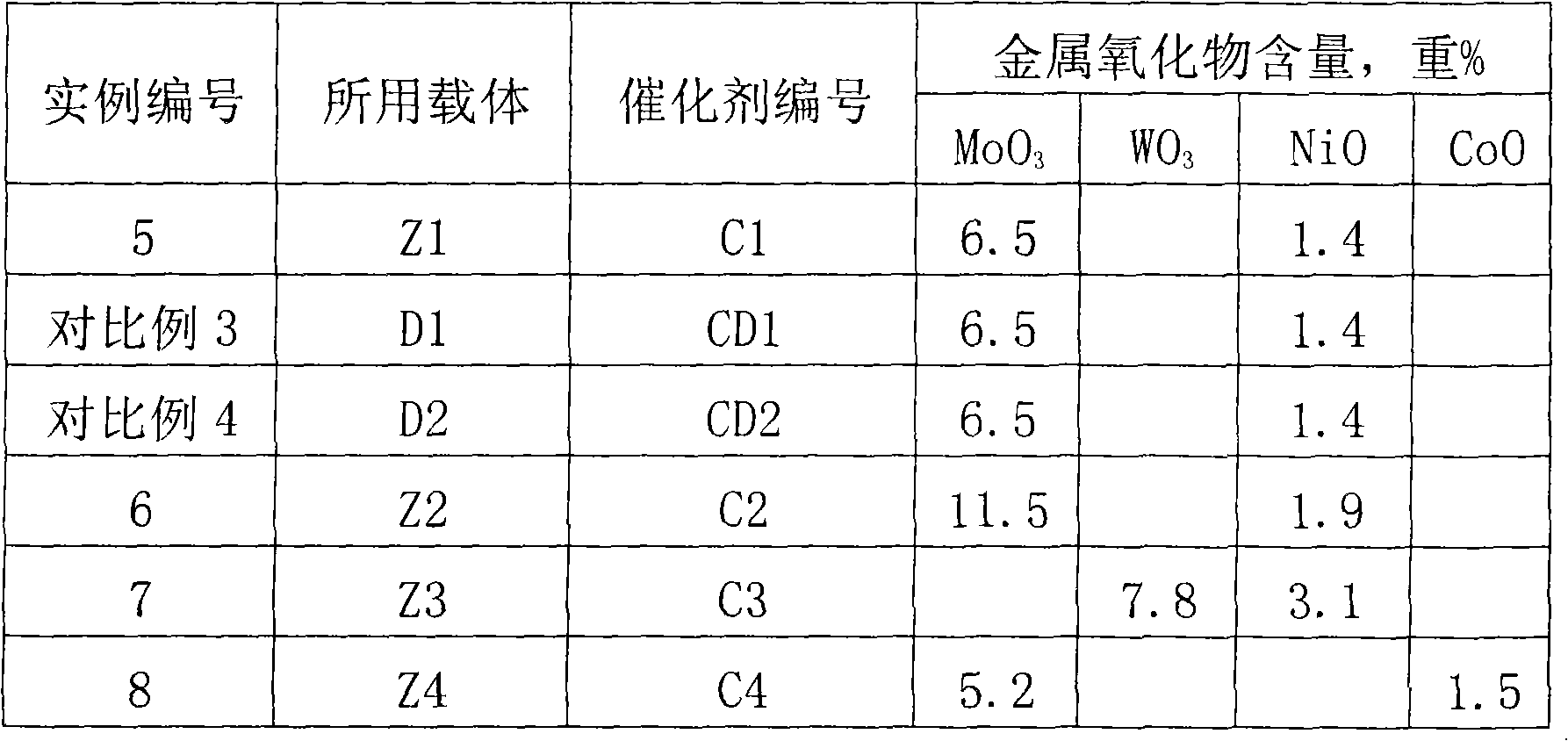

Examples

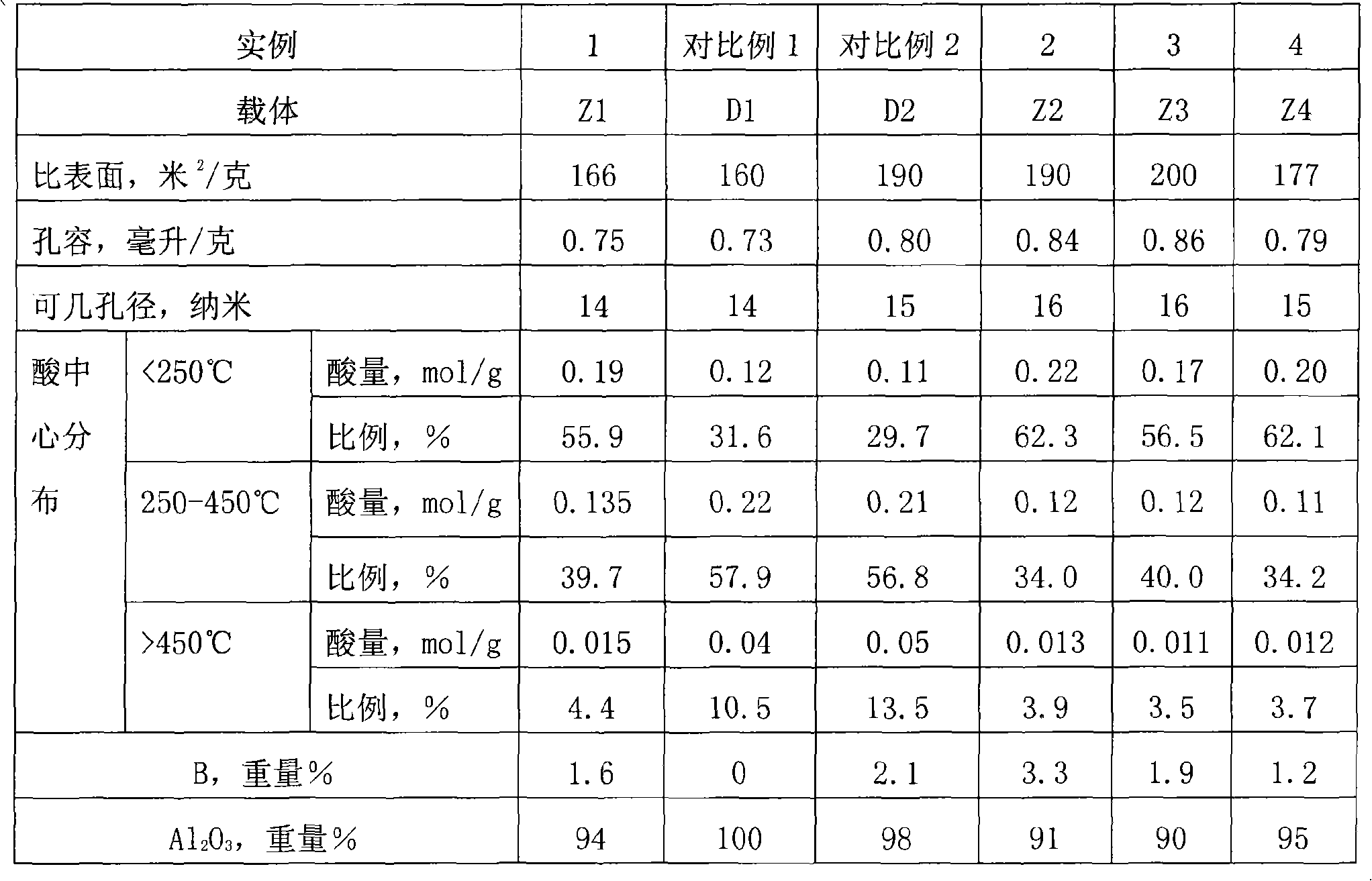

example 1

[0031] Take by weighing 300 grams of dry rubber powder produced by Changling Catalyst Factory, mix evenly with 10 gram of turnip powder and 30 gram of borax, then at room temperature this mixture is mixed with 4% ammonia solution 360 milliliters, in twin-screw extruder After continuing kneading on the strip machine to form a plastic body, extrude into a trefoil-shaped strip with a diameter of 1.5 mm. The wet strip was dried at 120°C for 4 hours and then calcined at 900°C for 4 hours to obtain the carrier Z1. The acid content, alumina content, boron content, specific surface area, probable pore diameter, and pore volume of Z1 were measured, and the results are shown in Table 1.

[0032] The boron content is determined by the ICP method, and the specific surface area, programmable pore size and pore volume are determined by the BET low-temperature nitrogen adsorption method (the same below).

example 2

[0038] Take by weighing 300 grams of dry rubber powder (same as example 1), mix evenly with 10 grams of scallop powder and 12 grams of boron oxide, then add 350 milliliters of aqueous solution containing 18 grams of sodium borate at 35 ° C, and continue kneading on a twin-screw extruder. After being plasticized, it was extruded into butterfly-shaped strips with a diameter of 1.1 mm, and the wet strips were dried at 120° C. for 2 hours and then calcined at 950° C. for 3 hours to obtain carrier Z2. The acid content, alumina content, boron content, specific surface area, probable pore diameter and pore volume of Z2 were measured, and the results are shown in Table 1.

example 3

[0040] Take by weighing 300 grams of aluminum hydroxide powder produced by Shanxi Aluminum Works, 10 grams of fenugreek powder, 20 grams of borax, and 20 grams of potassium borate and mix evenly, then add 380 milliliters of aqueous solution containing 40 grams of ammonium bicarbonate at room temperature, and extrude After continuing kneading on the strip machine to form a plastic body, extrude into butterfly-shaped strips with a diameter of 1.5 mm. The wet strips were dried at 120°C for 3 hours and then kept at 800°C for 4 hours to obtain carrier Z3. The acid content, alumina content, boron content, specific surface area, probable pore diameter and pore volume of Z3 were measured, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com