Method for increasing speed of oxidative degradation of organic pollutant in soil

A technology for organic pollutants, oxidative degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

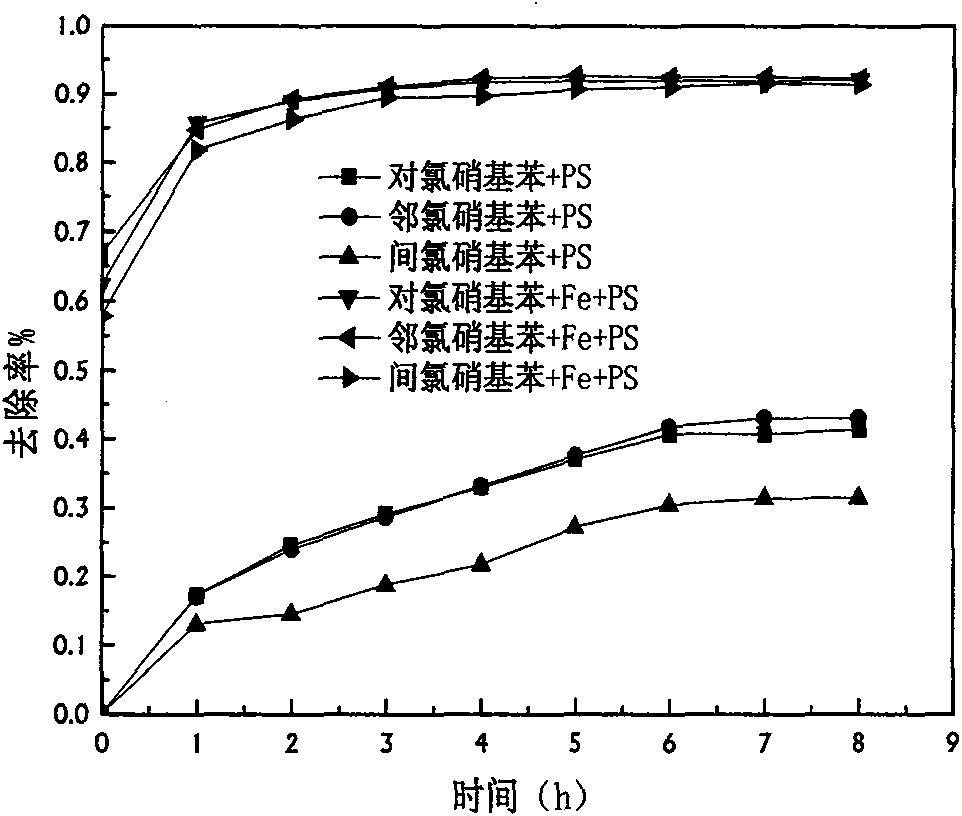

[0041] Sampling of nitrochlorobenzene-contaminated soil left over from the relocation of a chemical factory in Nanjing (the same below, coexistence of ortho, para and meta), air-dried and ground through a 2mm sieve, weighed 5g of soil into a 50ml centrifuge tube, added 5ml For ultrapure water, stir well with a glass rod, then adjust the pH of the soil solution to 6.8 with 0.01M HCl or NaOH, then add 0.05g iron powder, shake in a constant temperature shaker at 25°C, react for 1 hour, and then add 2mL0.5mol ·L -1 Potassium persulfate, continue to shake at constant temperature, take samples every 1h, and measure the concentration of remaining nitrochlorobenzene in the soil.

[0042] Weigh 5g of soil into a 50ml centrifuge tube, add a certain volume of ultrapure water, stir well with a glass rod, adjust the pH of the soil solution to 6.8 with 0.01M HCl or NaOH, and then add 2mL of 0.5mol L -1 Potassium persulfate was shaken in a constant temperature shaker at 25°C, and samples we...

Embodiment 2

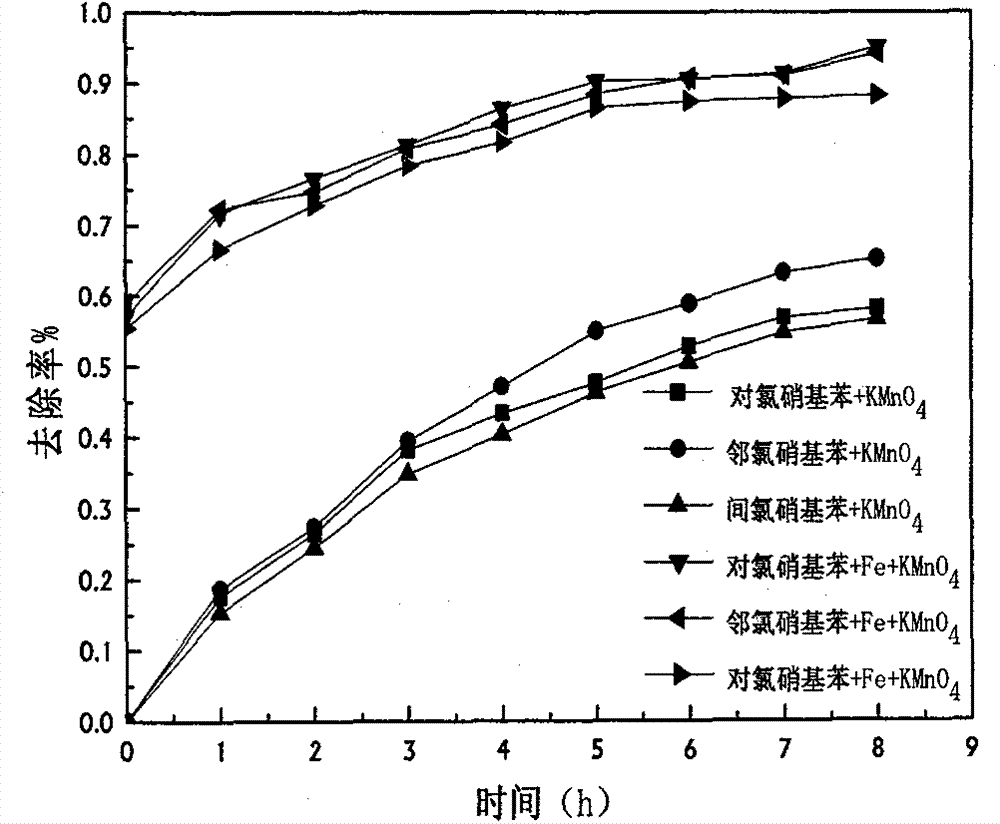

[0045] Sampling of nitrochlorobenzene-contaminated soil left over from the relocation of a chemical factory in Nanjing, air-dried and ground through a 2mm sieve, weighed 5g of soil into a 50ml centrifuge tube, added 5ml of ultrapure water, stirred with a glass rod, and then used 0.01M HCl or NaOH to adjust the pH of the soil solution to 6.8, after adding 0.05g of iron powder, add 2mL of 0.5mol L -1 Sodium permanganate was shaken at a constant temperature, and samples were taken every 1 hour to determine the concentration of remaining nitrochlorobenzene in the soil.

[0046] Weigh 5g of soil into a 50ml centrifuge tube, add a certain volume of ultrapure water, stir well with a glass rod, adjust the pH of the soil solution to 6.8 with 0.01M HCl or NaOH, and then add 2mL of 0.5mol L -1 Sodium permanganate was shaken in a constant temperature shaker at 25°C, and samples were taken every 1 hour to determine the concentration of residual organic matter in the soil.

[0047] Such as...

Embodiment 3

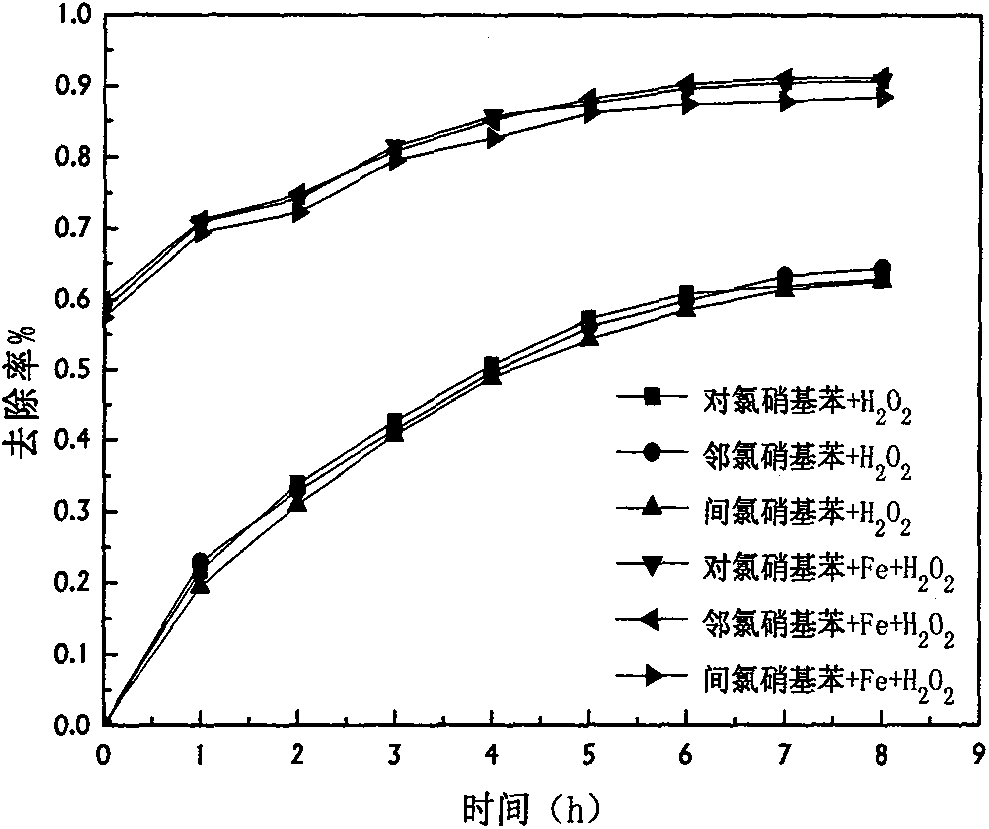

[0049] Sampling of nitrochlorobenzene-contaminated soil left over from the relocation of a chemical factory in Nanjing, air-dried and ground through a 2mm sieve, weighed 5g of soil into a 50ml centrifuge tube, added 5ml of ultrapure water, stirred with a glass rod, and then used 0.01M HCl or NaOH to adjust the pH of the soil solution to 6.8, after adding 0.05g of iron powder, add 2mL of 0.5mol L -1 The hydrogen peroxide was shaken at a constant temperature, and samples were taken every 1 hour to measure the concentration of remaining nitrochlorobenzene in the soil.

[0050] Weigh 5g of soil into a 50ml centrifuge tube, add 5ml of ultrapure water, stir well with a glass rod, then adjust the pH of the soil solution to 6.8 with 0.01M HCl or NaOH, then add 2mL of 0.5mol L -1 Hydrogen peroxide was shaken in a constant temperature shaker at 25°C, and samples were taken every 1 hour to determine the concentration of residual organic matter in the soil.

[0051] Such as image 3 , C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com