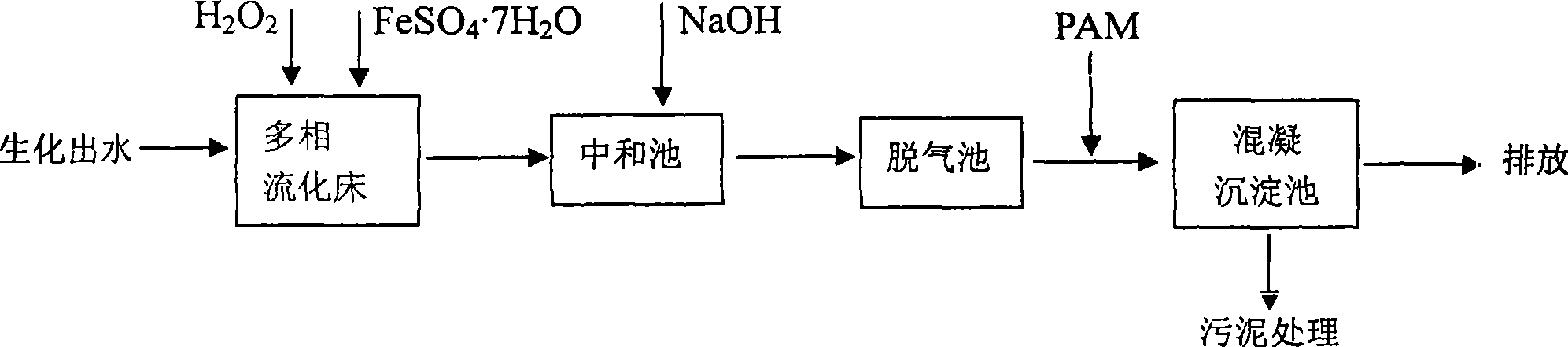

Process for treating bio-refractory waste water by up-flow multi-phase oxidation column

An oxidation tower, biochemically difficult technology, applied in the direction of oxidation water/sewage treatment, multi-stage water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of large amount of medicine, large amount of chemical sludge, high treatment cost, etc. Achieve the effect of cheap cost, simple operation and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

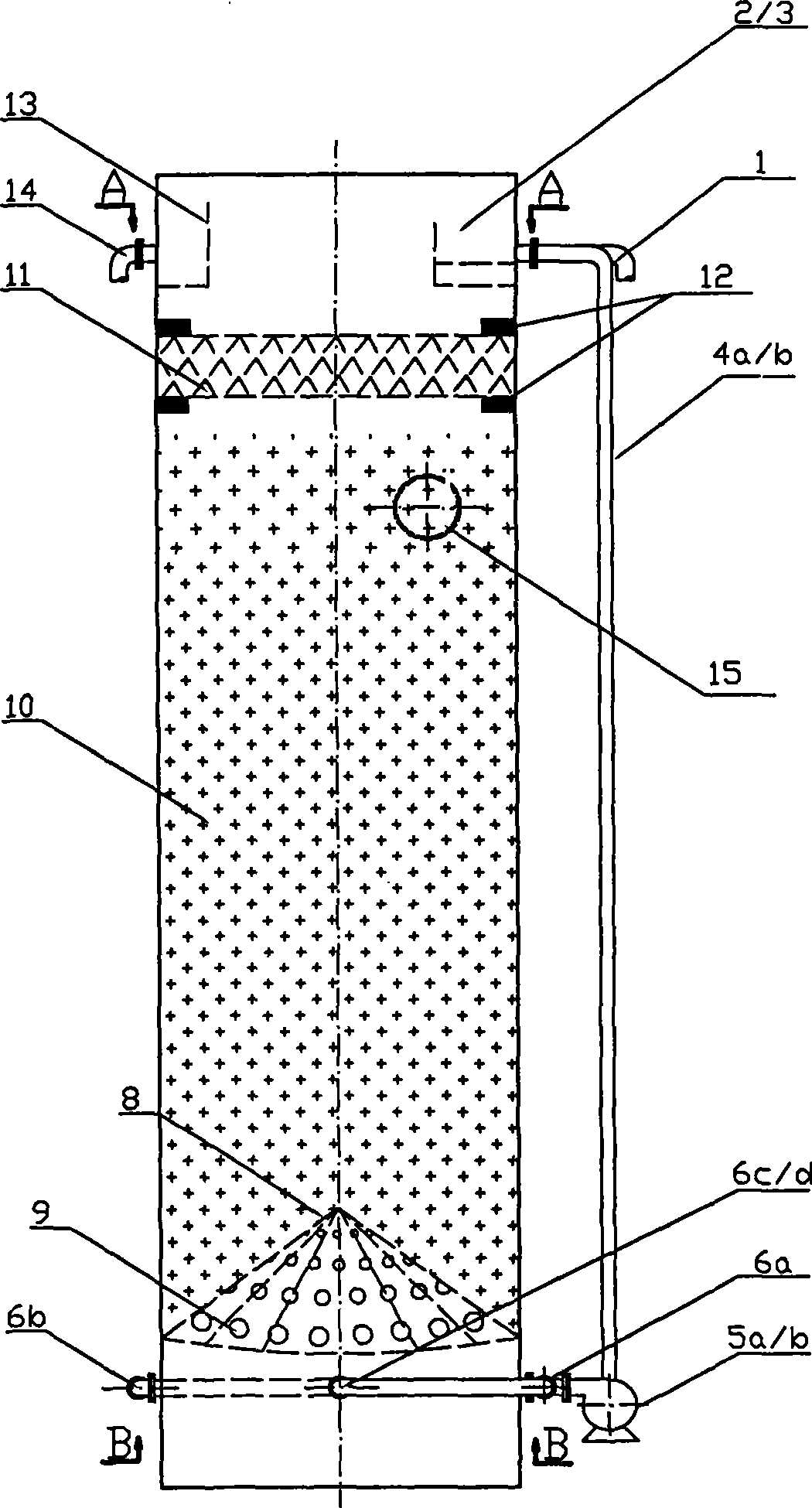

[0037] The biochemical effluent from the middle section of a paper mill in Guangxi was treated by using an upflow heterogeneous oxidation tower to treat refractory biochemically degradable wastewater. The wastewater treatment volume is 250t / h, the COD value of the wastewater is 265mg / L, and the chromaticity is 64 times. The waste water is pumped into the water inlet tank at the top of the oxidation tower, and the water inlet tank is distributed to two circulation tanks, and H is added to the circulation tanks respectively. 2 o 2 and FeSO 4 ·7H 2 O. The amount of the two drugs added is: the mass ratio of hydrogen peroxide to COD in the water to be treated is 2:1, that is, H 2 o 2 Dosage 530mg / L; H 2 o 2 with Fe 2+ The molar ratio of FeSO is 5:1, that is, FeSO 4 ·7H 2 O dosage 867mg / L.

[0038]The waste water is reacted in the oxidation tower, and the reaction time is 30 minutes. After being treated by the oxidation tower, the wastewater enters the neutralization tan...

Embodiment 2

[0040] The leachate wastewater from a landfill in Guangxi was treated by using an upflow heterogeneous oxidation tower to treat refractory biodegradable wastewater. The wastewater treatment volume is 4t / h, the COD value of the wastewater is 565mg / L, and the chromaticity is 112 times. The waste water is pumped into the water inlet tank at the top of the oxidation tower, and the water inlet tank is distributed to two circulation tanks, and H is added to the circulation tanks respectively. 2 o 2 and FeSO 4 ·7H 2 O. The amount of the two drugs added is: the mass ratio of hydrogen peroxide to COD in the water to be treated is 2.6:1, that is, H 2 o 2 Dosage 1469mg / L; H 2 o 2 with Fe 2+ The molar ratio of FeSO is 13:1, that is, FeSO 4 ·7H 2 O dosage 924mg / L.

[0041] The waste water is reacted in the oxidation tower, and the reaction time is 40 minutes. After being treated by the oxidation tower, the wastewater enters the neutralization tank, and sodium hydroxide is added...

Embodiment 3

[0043] The biochemical effluent of a molasses alcohol factory in Guangxi was treated by using an upflow heterogeneous oxidation tower to treat refractory biochemically degradable wastewater. The wastewater treatment volume is 1t / h, the COD value of the wastewater is 347mg / L, and the chromaticity is 80 times. The waste water is pumped into the water inlet tank at the top of the oxidation tower, and the water inlet tank is distributed to two circulation tanks, and H is added to the circulation tanks respectively. 2 o 2 and FeSO 4 ·7H 2 O. The amount of the two drugs added is: the mass ratio of hydrogen peroxide to COD in the water to be treated is 3:1, that is, H 2 o 2 Dosage 1041mg / L; H 2 o 2 with Fe 2+ The molar ratio of FeSO is 20:1, that is, FeSO 4 ·7H 2 O dosage 426mg / L.

[0044] The waste water is reacted in the oxidation tower, and the reaction time is 60 minutes. After being treated by the oxidation tower, the wastewater enters the neutralization tank, and so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com