Method for treating wastewater from preparation of glycine by chloroacetic acid ammonolysis process

A technology of glycine and chloroacetic acid, applied in natural water treatment, chemical instruments and methods, heating water/sewage treatment and other directions, can solve the problems of high evaporation condensate, strong corrosion of equipment, secondary pollution, etc., and achieves simple process, The effect of low investment and operating costs and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

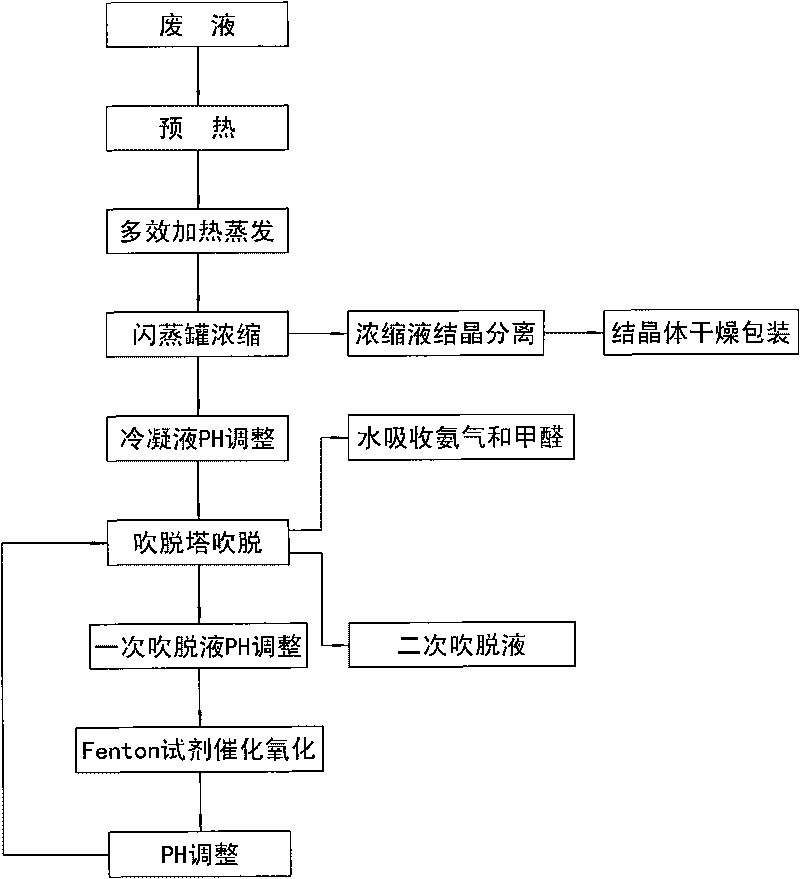

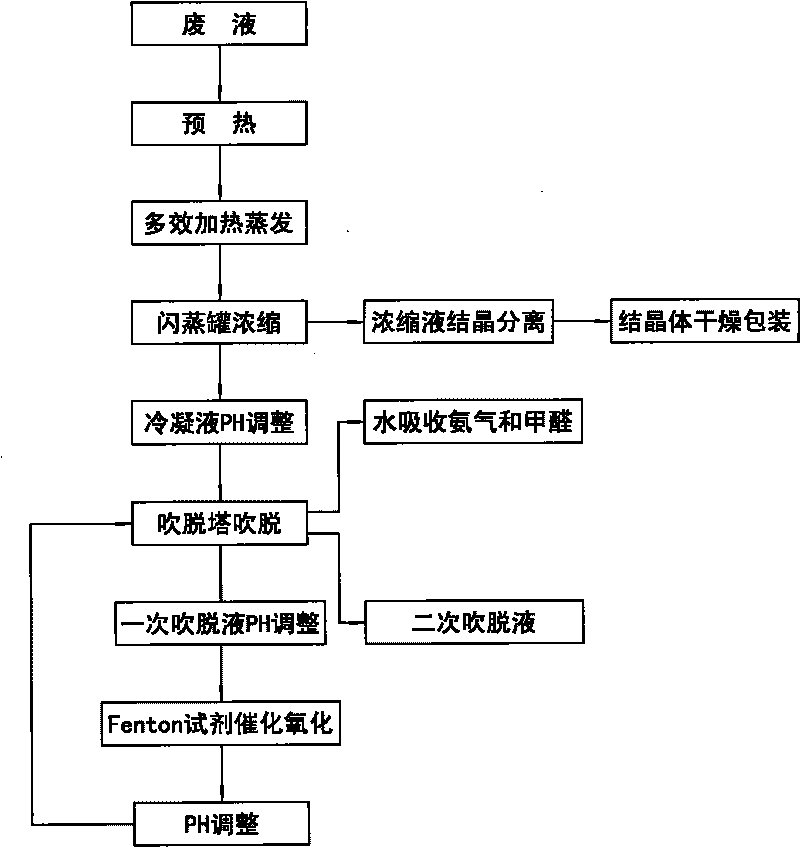

[0016] The technological process of the embodiment of the present invention is as figure 1 As shown, proceed as follows:

[0017] a. Put the waste liquid produced by the ammonolysis of chloroacetic acid into the exhaust steam preheater in the multi-effect falling film vacuum evaporation system for preheating, and then pass through the three-effect, two-effect and one-effect falling film evaporators respectively Heating and evaporating, and then entering the flash tank to concentrate until the concentration of ammonium chloride is 35% to 45%;

[0018] B. carrying out normal temperature crystallization by crystallizer of gained concentrated solution, and crystallization is dried, packaged, both obtains the ammonium chloride that can be used for compound fertilizer;

[0019] c. Because the condensate produced by multi-effect falling film vacuum evaporation contains 17000mg / L of ammonia nitrogen and about 30000mg / L of COD, it cannot be discharged directly, so NaOH is used to adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com