Fenton-assisted three-phase flowing pressure cavitation polishing SiC optimal curved surface method and device

A three-phase flow, Fenton technology, used in optical surface grinders, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as damage, improve polishing efficiency, improve recycling efficiency, and improve polishing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

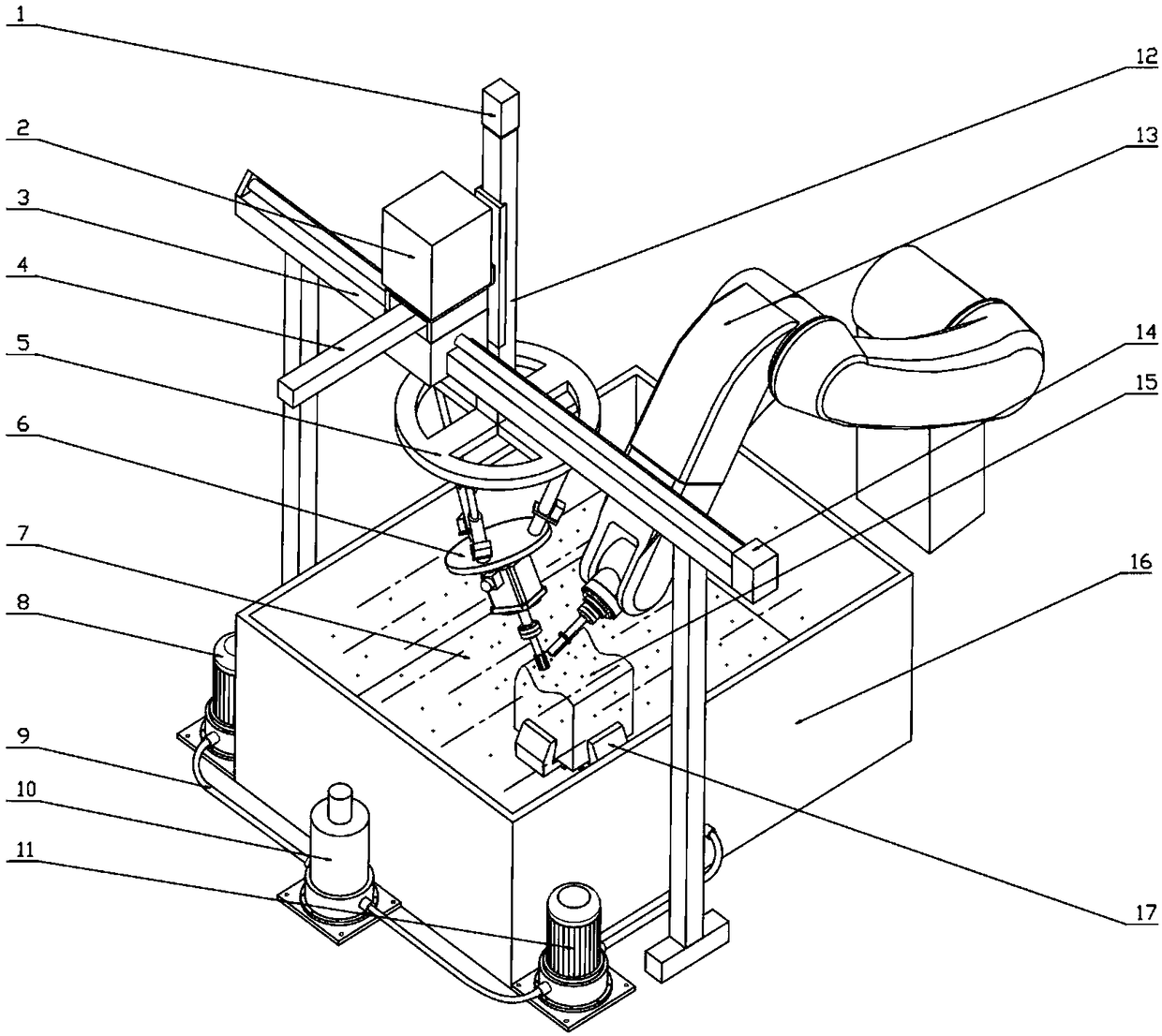

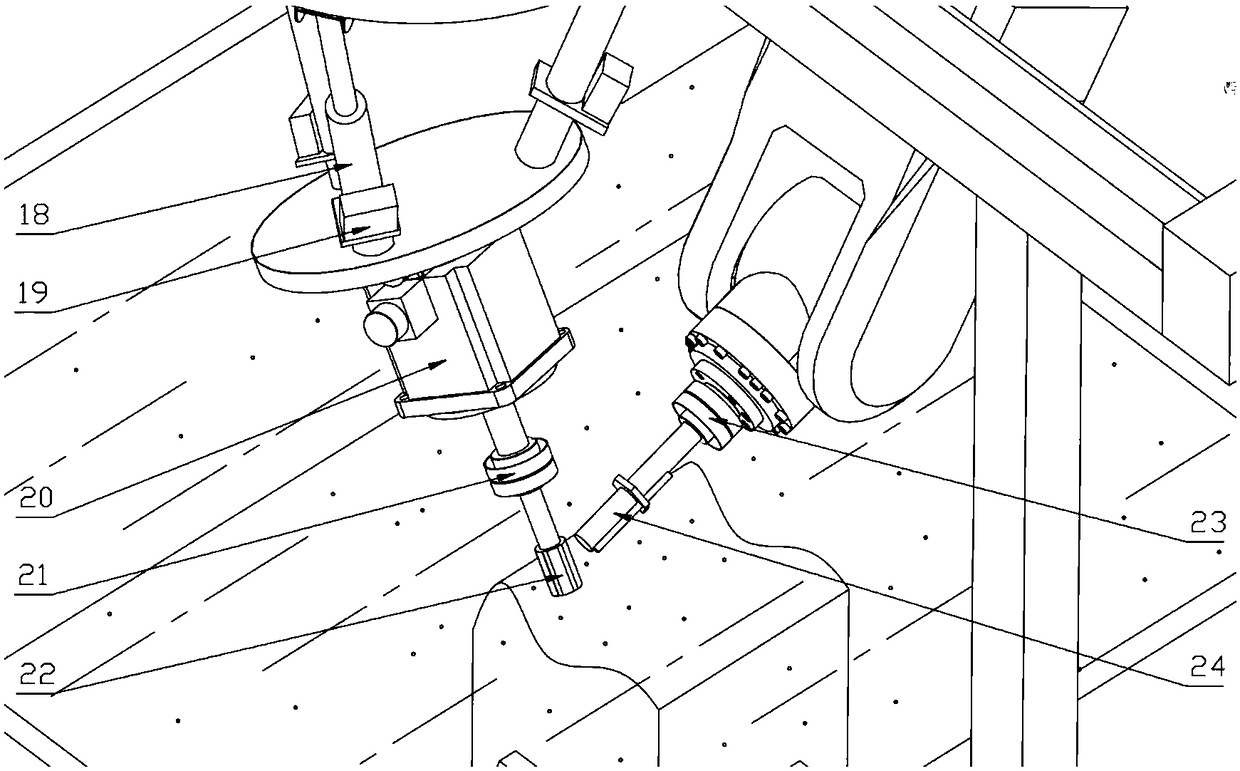

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] refer to figure 1 with figure 2 , a Fenton-assisted three-phase flow pressure cavitation polishing method for SiC optical curved surfaces, first wrapping the part of the SiC workpiece that does not need to be processed with an insulating material, and then immersing the SiC workpiece in a reaction pool filled with Fenton reagent. The strong oxidizing hydroxyl radicals generated in the Fenton reaction oxidize the surface of the SiC workpiece into SiO with softer hardness and lower binding force. 2 . After reacting for a period of time, the workpiece is taken out and fixed in the polishing liquid container with a clamp. The series-parallel polishing platform controls the posture of the cylindrical polishing tool relative to the workpiece, so that the polishing tool and the workpiece surface always maintain a small processing gap, and the tool and the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com