Plastic filling master batch and preparation method thereof

A technology of filling masterbatch and plastic, which is applied in the field of plastic filling masterbatch and its preparation, which can solve the problems of poor physical and mechanical properties of plastic products, lower product quality, poor surface gloss, etc., and achieve good surface gloss and delay aging speed , good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

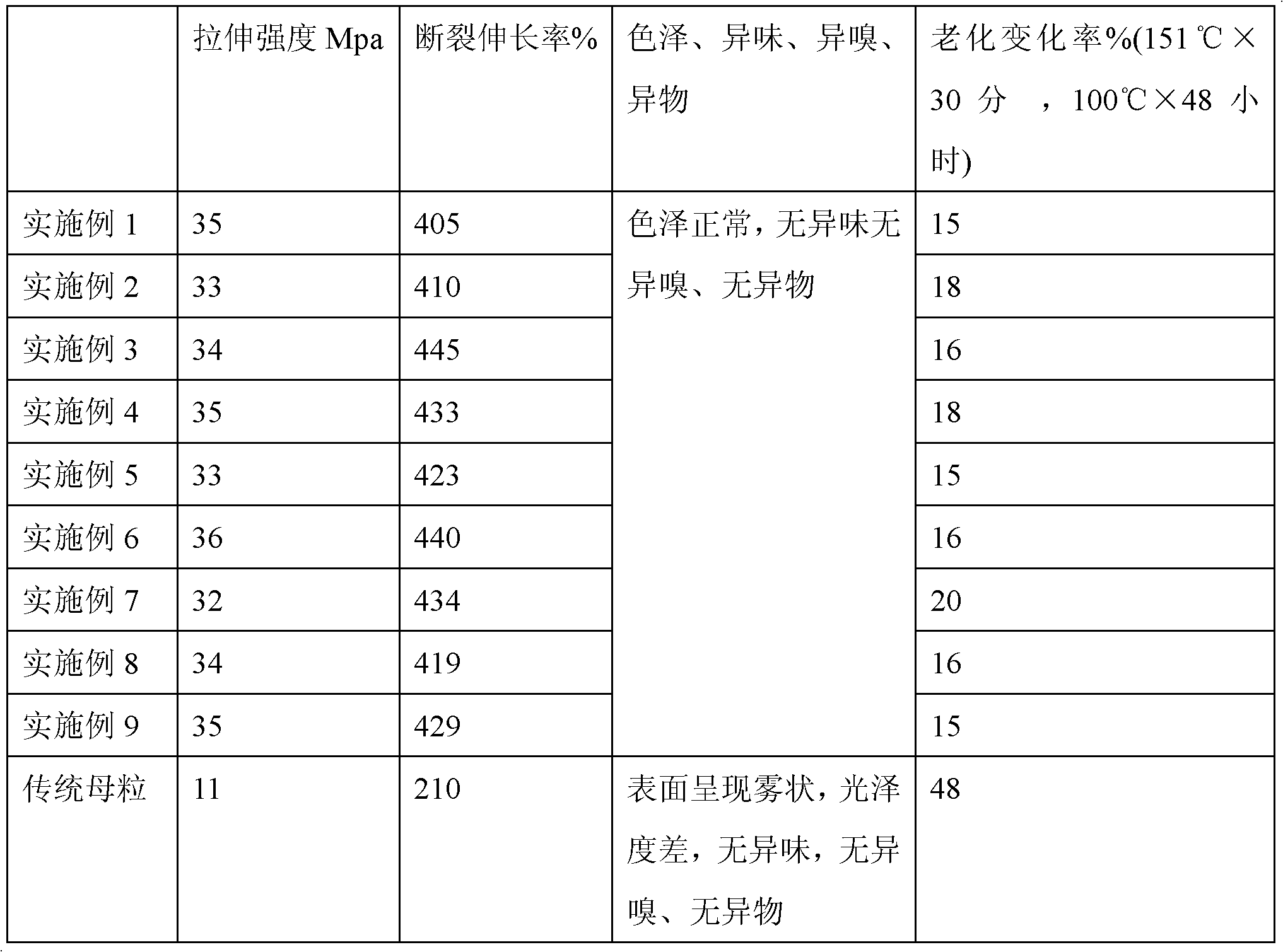

Examples

Embodiment 1

[0017] Embodiment 1: 70 parts of calcium terephthalate and 5 parts of paraffin are stirred at 1000 rev / min for 3 min in a stirred tank, then jump to high-speed stirring at 5000 rev / min for 4 min, change to 2000 rev / min Slowly add 5 parts of silane coupling agent Si69, stir for 5 min, then add 25 parts of carrier resin EVA, stir and mix at 150° C. for 15 min. Finally, the processed material is extruded at 100° C., hot-cut and air-cooled to obtain the masterbatch product obtained by the present invention.

Embodiment 2

[0018] Embodiment 2: 30 parts of magnesium terephthalate and 10 parts of white oil were stirred at 500 rev / min for 5min in a stirring tank, then jumped to high-speed stirring for 8min at 4000 rev / min, and changed under 1500 rev / min Slowly add 10 parts of silane coupling agent Si75 at a medium speed, stir for 5 minutes, then add 60 parts of carrier resin PE, and stir at 100° C. for hot melt mixing and stirring for 5 minutes. Finally, the processed material is extruded at 90°C, hot-cut, and air-cooled to obtain the master batch product of the present invention.

Embodiment 3

[0019] Embodiment 3: 85 parts of zinc terephthalate and 5 parts of stearic acid are stirred at 800 rev / min for 4min in the stirring tank, then jump to high-speed stirring 6min at 4500 rev / min, change 1200 rev / min Slowly add 5 parts of silane coupling agent Si230 at a medium speed, stir for 4 minutes, then add 5 parts of carrier resin PP, and stir at 70° C. for hot melt mixing and stirring for 10 minutes. Finally, the processed material is extruded at 100° C., hot-cut and air-cooled to obtain the masterbatch product obtained by the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com