Method and device for deep oxidation of sweetening alkali liquor and separation of disulfide

A disulfide and deep oxidation technology, which is applied in natural gas processing and petroleum fields, can solve the problems of high precision of gas distributor, high investment in equipment, high risk, etc., to improve oxidation conversion rate, increase contact area, and controllable devices good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through examples, and the following examples are explanations of the present invention and the present invention is not limited to the following examples.

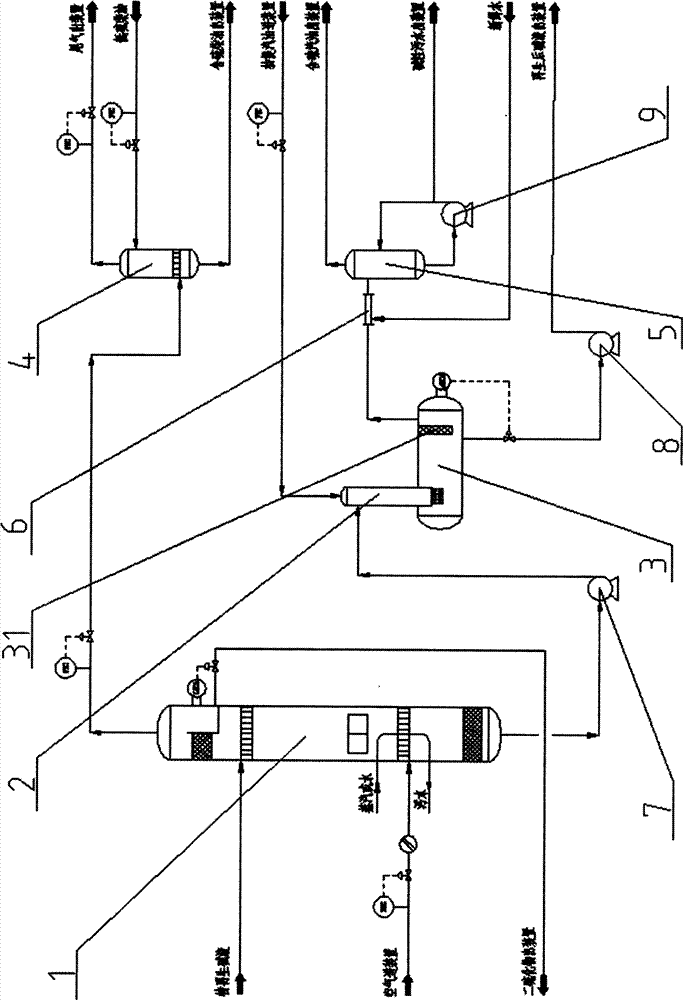

[0024] like Figure 1-2 Shown, a kind of sweetening lye deep oxidation and the method for separating disulfide, comprise the following steps:

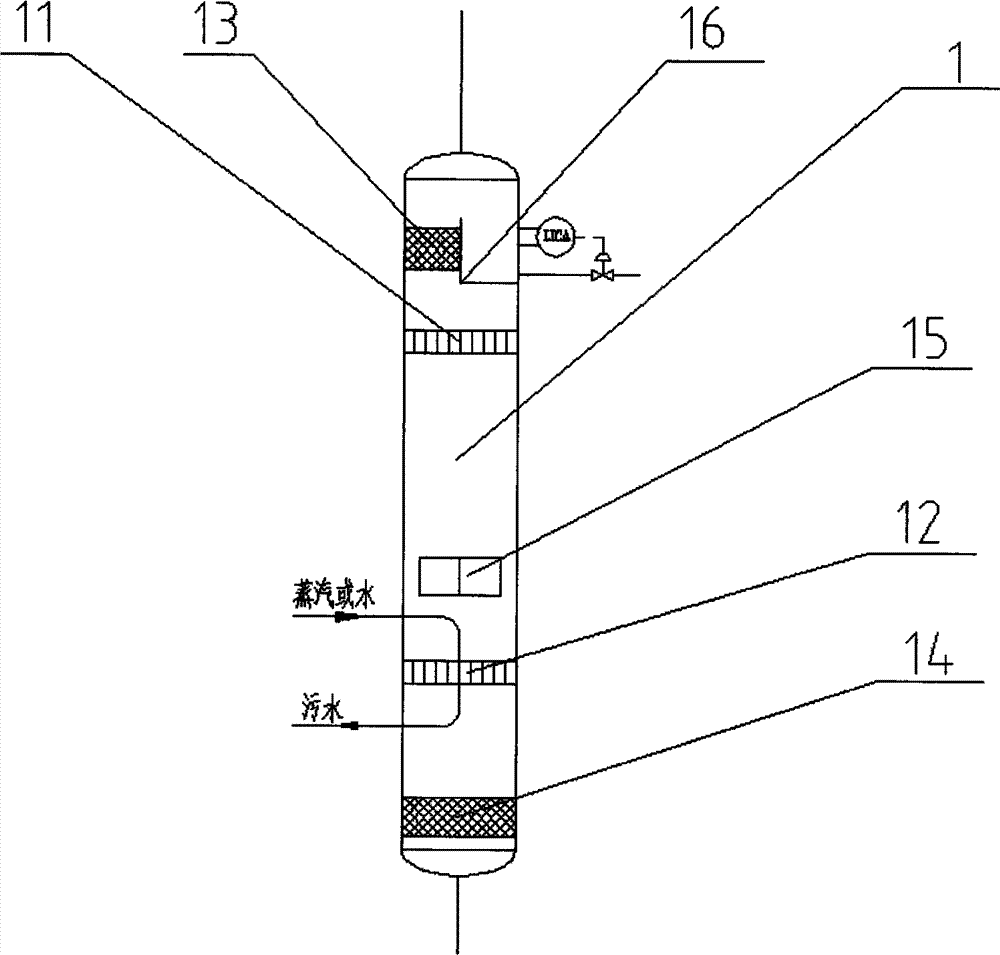

[0025] a, lye oxidation, the lye to be regenerated is injected from the middle and upper part of the lye oxidation tower 1, and through the liquid distributor 11, the lye to be regenerated is evenly distributed in the tower, and the air passes through the air filter from the lye oxidation tower 1 Entering from the lower part, the air passes through the air distributor 12 to generate bubbles with a diameter of 1-20 mm and evenly distributes them in the lye, so that the sodium mercaptide in the lye fully contacts with oxygen under the action of the titanium blue cobalt catalyst, and reacts to form sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com