Tin bisulfide single-crystal nanosheets selectively absorbing organic dyes, and preparation method thereof

A technology of tin disulfide and organic dyes, which is applied in the fields of nanotechnology, chemical instruments and methods, and inorganic chemistry for materials and surface science. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

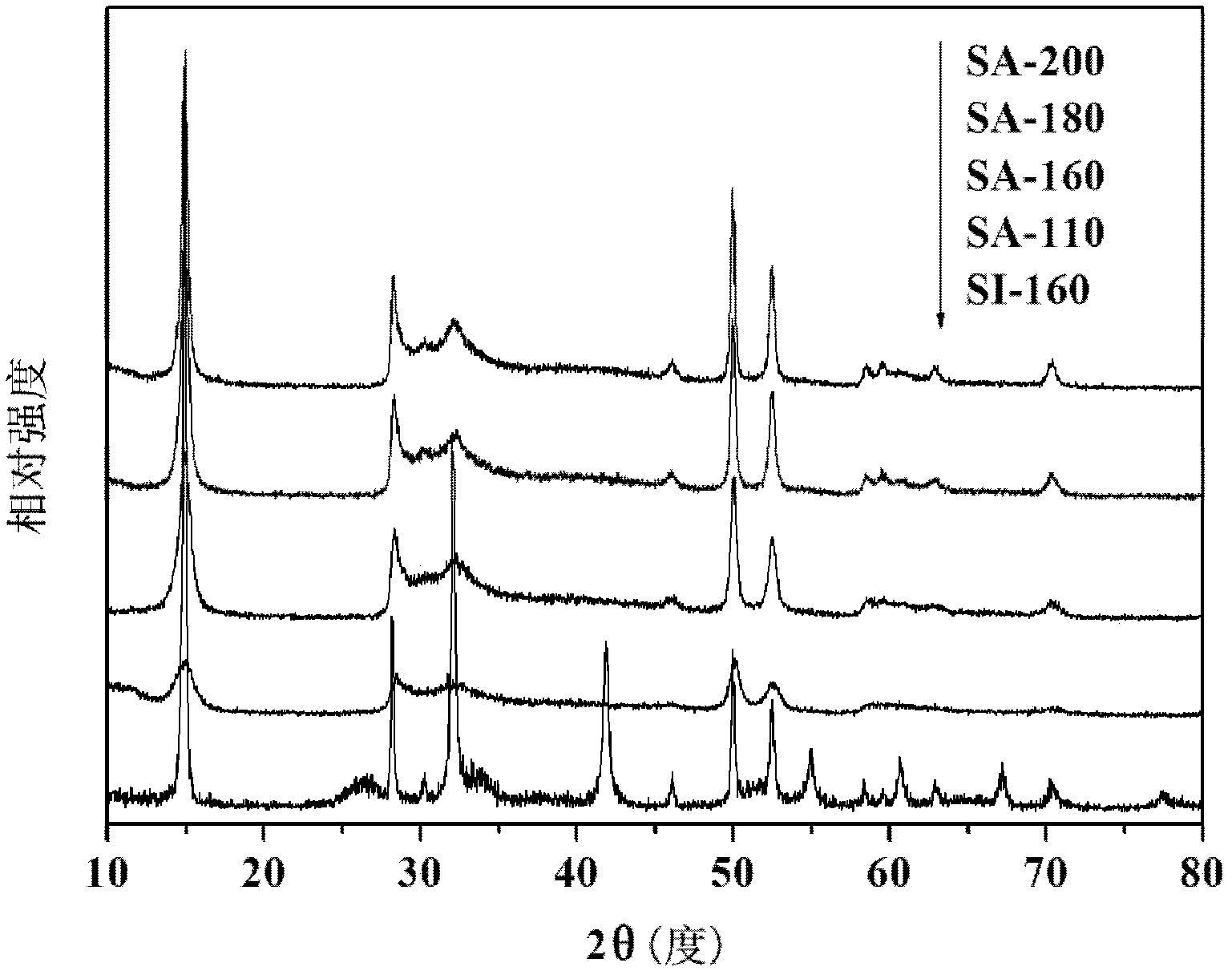

[0026] At room temperature, add 0.87g (2.5mmol) tin tetrachloride pentahydrate and 0.76g (10mmol) thioacetamide into 40mL deionized water, stir until the solution is colorless and clear, then transfer the solution to a 50mL hydrothermal kettle, Seal, place in an oven at a constant temperature of 110°C for 24 hours, cool naturally to room temperature, centrifuge, filter to obtain a brown powder, wash the obtained powder with deionized water and absolute ethanol three times, and dry at 80°C to obtain tin disulfide Sample (SA-110). Its X-ray powder diffraction pattern is as figure 1 As shown, the results show that the sample of Example 1 belongs to the hexagonal phase tin disulfide; its field emission scanning electron microscope picture is as figure 2 As shown, it is shown that it is a nanoparticle of fine size, the size is less than 30nm.

Embodiment 2

[0028] At room temperature, add 0.87g (2.5mmol) tin tetrachloride pentahydrate and 0.76g (10mmol) thioacetamide into 40mL deionized water, stir until the solution is colorless and clear, then transfer the solution to a 50mL hydrothermal kettle, Seal it, place it in an oven at a constant temperature of 160°C for 24 hours, cool naturally to room temperature, centrifuge, filter to obtain a brown powder, wash the obtained powder with deionized water and absolute ethanol three times, and dry at 80°C to obtain tin disulfide Sample (SA-160). Its X-ray powder diffraction spectrum is as figure 1 As shown, the result shows that the sample of embodiment 2 belongs to the hexagonal phase tin disulfide; its field emission scanning electron microscope figure is as image 3 As shown, the particles have formed a hexagonal shape with a size of about 30 nm.

Embodiment 3

[0030] At room temperature, add 0.87g (2.5mmol) tin tetrachloride pentahydrate and 0.76g (10mmol) thioacetamide into 40mL deionized water, stir until the solution is colorless and clear, then transfer the solution to a 50mL hydrothermal kettle, Seal, place in an oven at a constant temperature of 180°C for 24 hours, cool naturally to room temperature, centrifuge, filter to obtain a brown powder, wash the obtained powder with deionized water and absolute ethanol three times, and dry at 80°C to obtain tin disulfide Sample (SA-180). Its X-ray powder diffraction spectrum is as figure 1 As shown, the result shows that the sample of embodiment 3 belongs to hexagonal tin disulfide; its field emission scanning electron microscope picture is as Figure 4 As shown, the particles are hexagonal and about 40 nm in size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com