Coupling agent-reacted mercury removal media

a technology of reacted mercury and coupling agent, which is applied in the direction of filtration separation, separation process, waste water treatment from quaries, etc., can solve the problems that the technology available for mercury and arsenic removal, such as precipitation, coagulation/co-precipitation, activated carbon adsorption, etc., is not sufficiently effective for mercury and arsenic (arsenite and arsenate compounds), and achieves the effect of increasing the d-

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

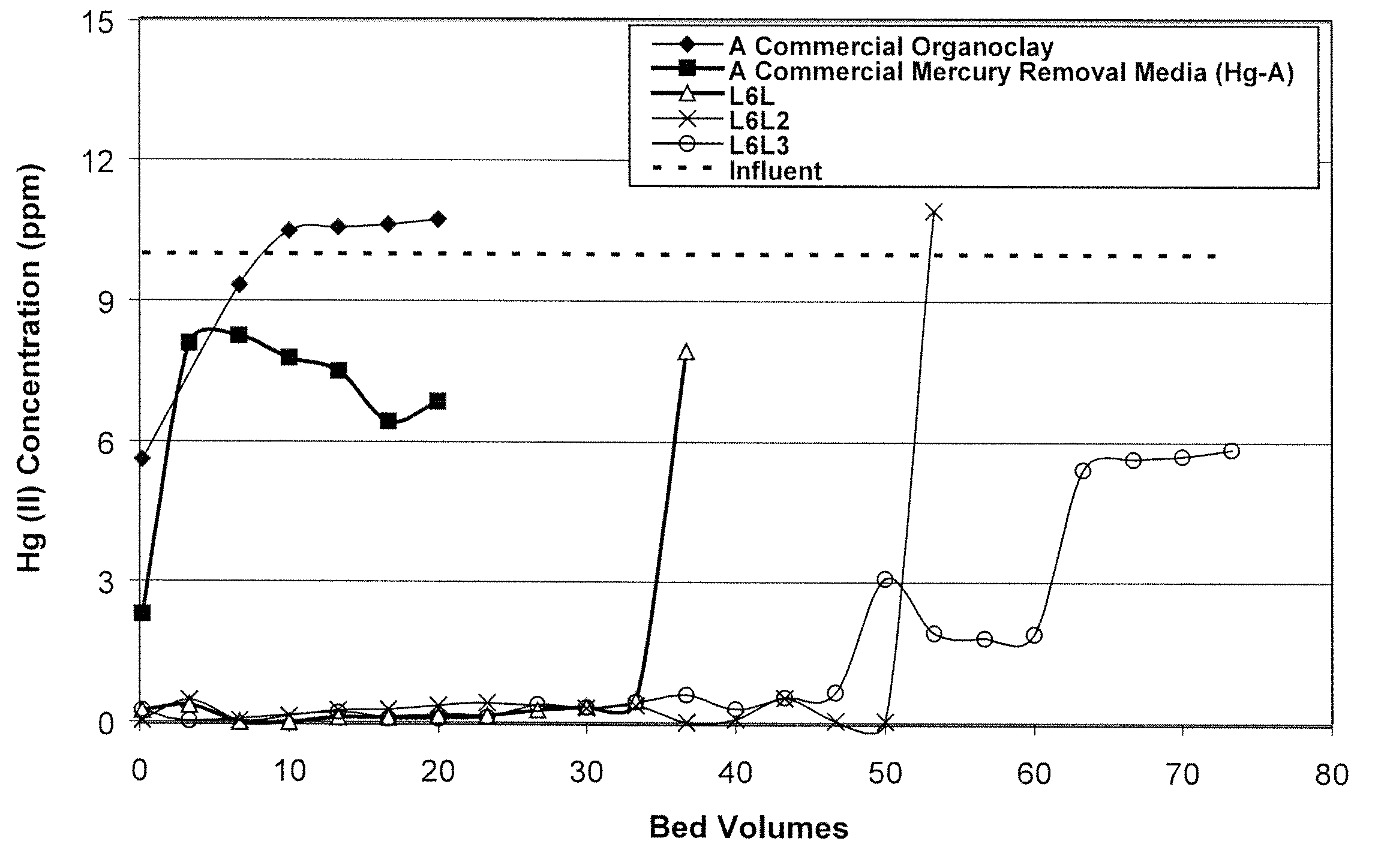

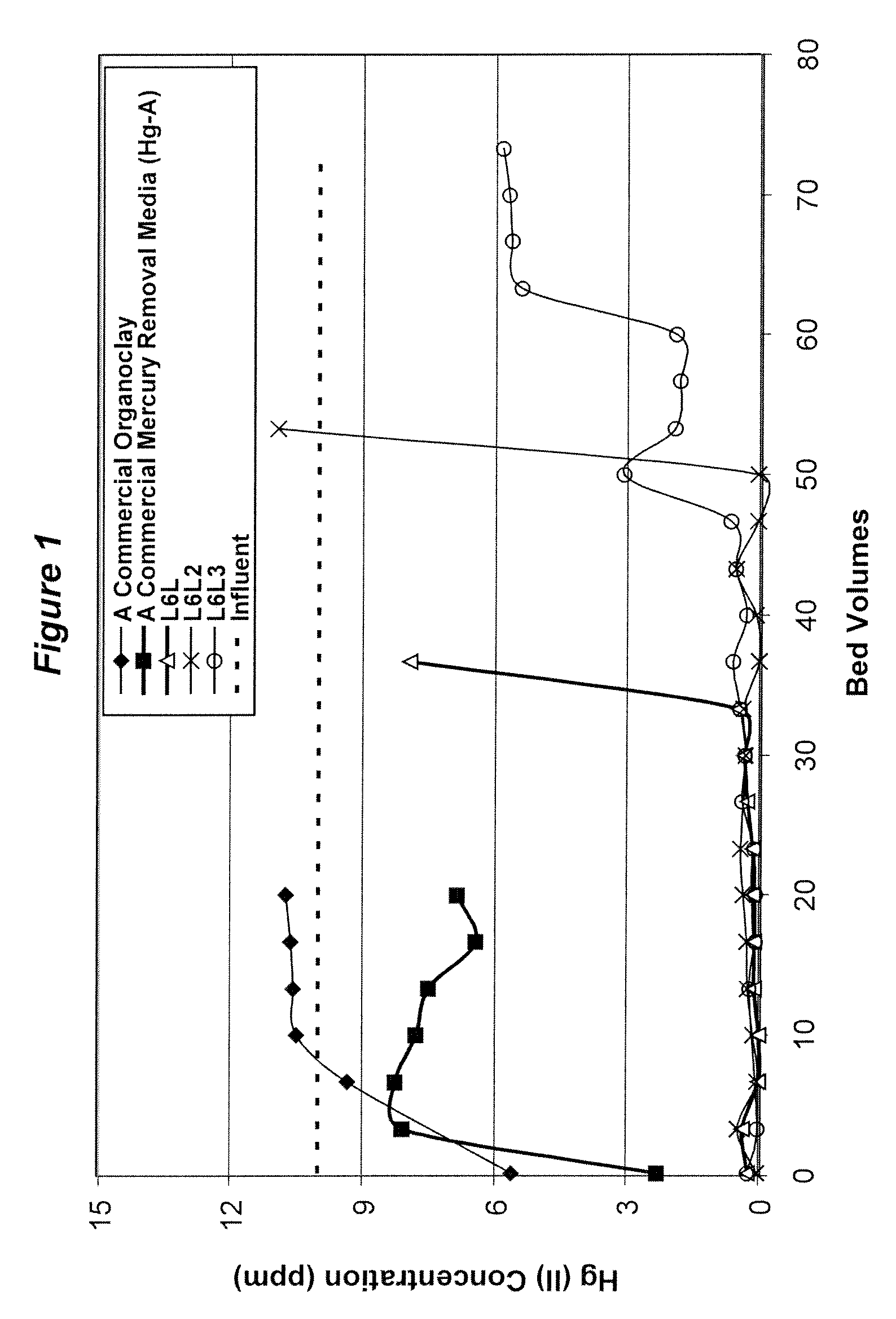

example 1

Sample L6L

[0058]800.0 g of bentonite clay (particle size <75 μm preferred, and ˜8% moisture content) was mixed with 160.0 g of deionized water using the Kitchen Aid mixer until a homogenous mixture was obtained. 380.0 g of melt quat (ARQUAD® 2HT from Akzo Nobel, bis(hydrogenated tallow alkyl)dimethyl ammonium chloride, ˜83% active) was added to this bentonite-water mixture under shearing using the same mixer, and mixed for 5 minutes. 40.0 g of the silane agent (Silquest® A-189 from GE Silicones, gamma-Mercaptopropyltrimethoxysilane) was pre-mixed with 20.0 g of ethanol and 2.0 g of water. This fresh prepared solution was added to the above clay-water-quat mixture, and mixed for 5 minutes. This mixture was extruded three times using a laboratory-scale extruder with a die-plate, and the final extrudates were oven-dried at 85° C. to a moisture content of less than 5% by weight. The dried extrudates were ground and resulting particles between 18 and 40 mesh (US standard sieves) were col...

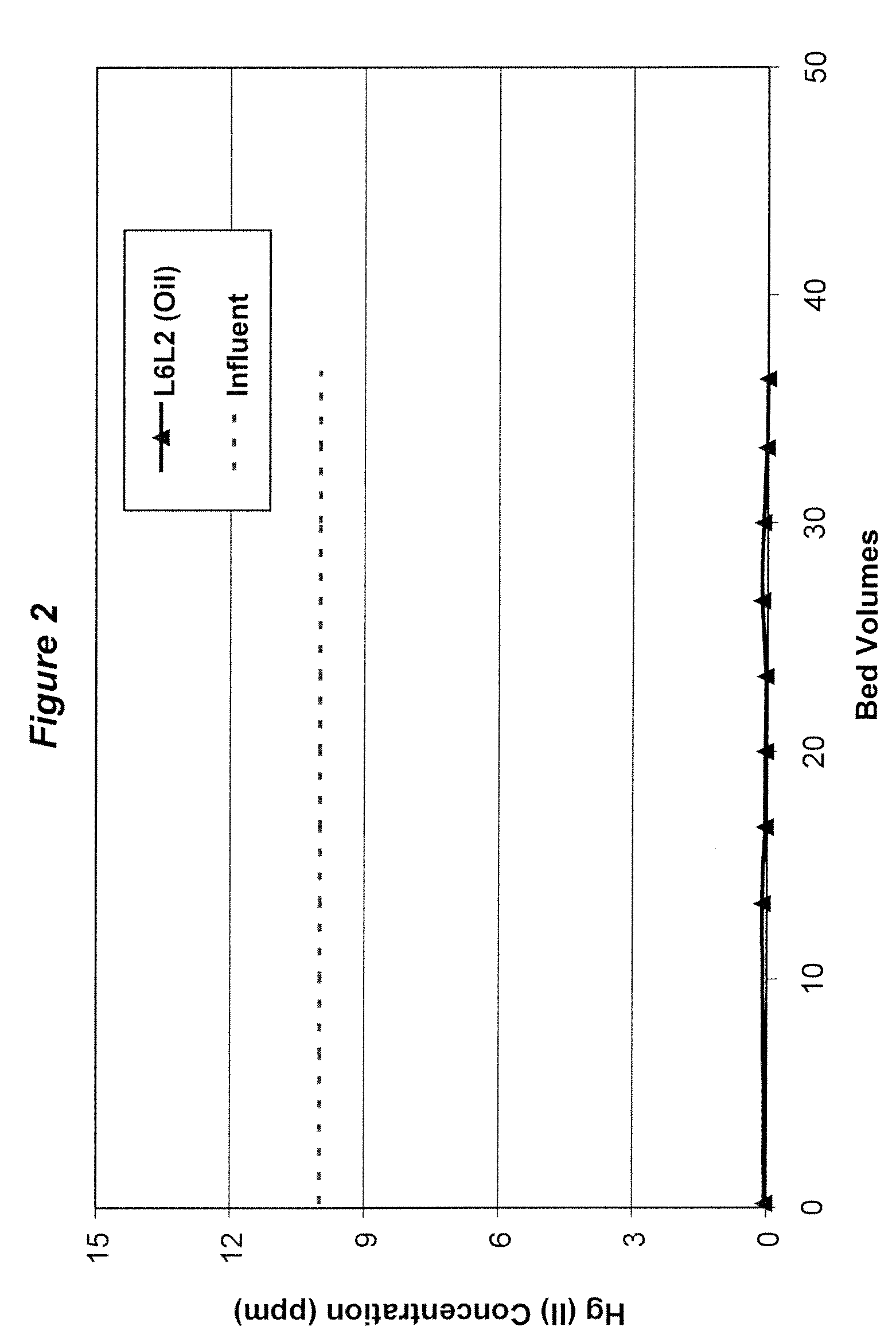

example 2

Sample L6L2

[0059]Very similar preparation procedure was conducted except 80.0 g of the silane agent was pre-mixed with 80.0 g of ethanol and 8.0 g of water, and was subsequently added to clay-water-quat mixture.

example 3

Sample L6L3

[0060]800.0 g of bentonite clay (particle size <75 μm preferred, and ˜8% moisture content) was mixed with 160.0 g of deionized water using the kitchen Aid mixer until a homogenous mixture was obtained. 60.0 g of the silane agent (Silquest® A-189 from GE Silicones, gamma-Mercaptopropyltrimethoxysilane) was mixed with 380.0 g of melt quat (ARQUAD® 2HT from Akzo Nobel, bis(hydrogenated tallow alkyl)dimethyl ammonium chloride, ˜83% active), and this mixture was added to the bentonite-water mixture under shearing using the same mixer, and mixed for 5 minutes. This mixture was extruded three times using a laboratory-scale extruder with a die-plate, and the final extrudates were oven-dried at 85° C. to a moisture content of less than 5% by weight. The dried extrudates were ground and resulting particles between 18 and 40 mesh (US standard sieves) were collected and tested for their performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com