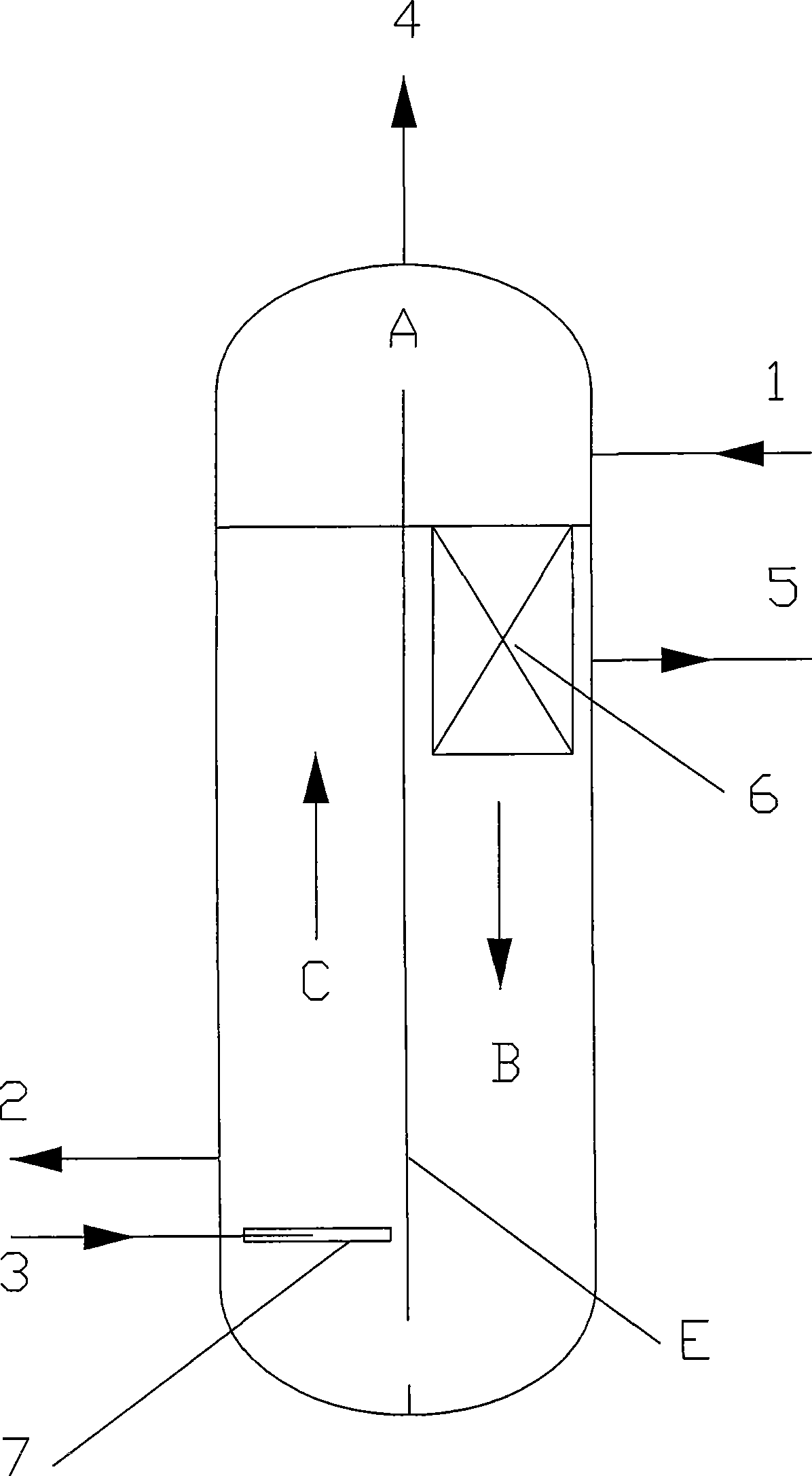

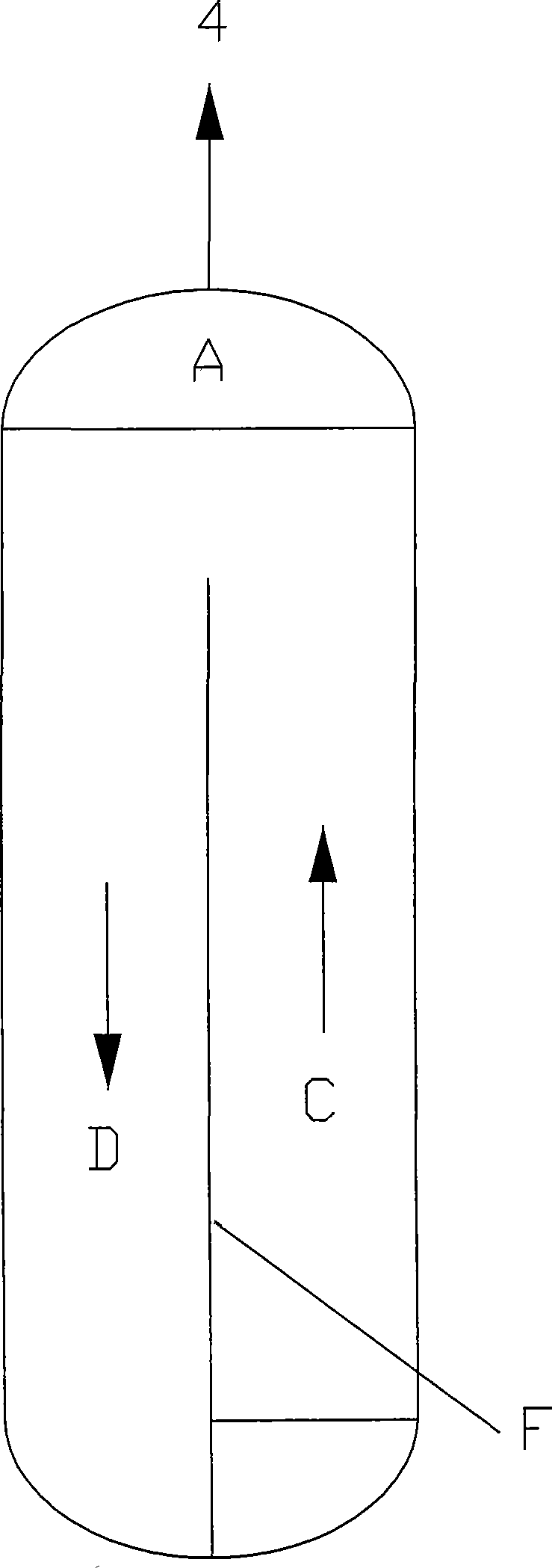

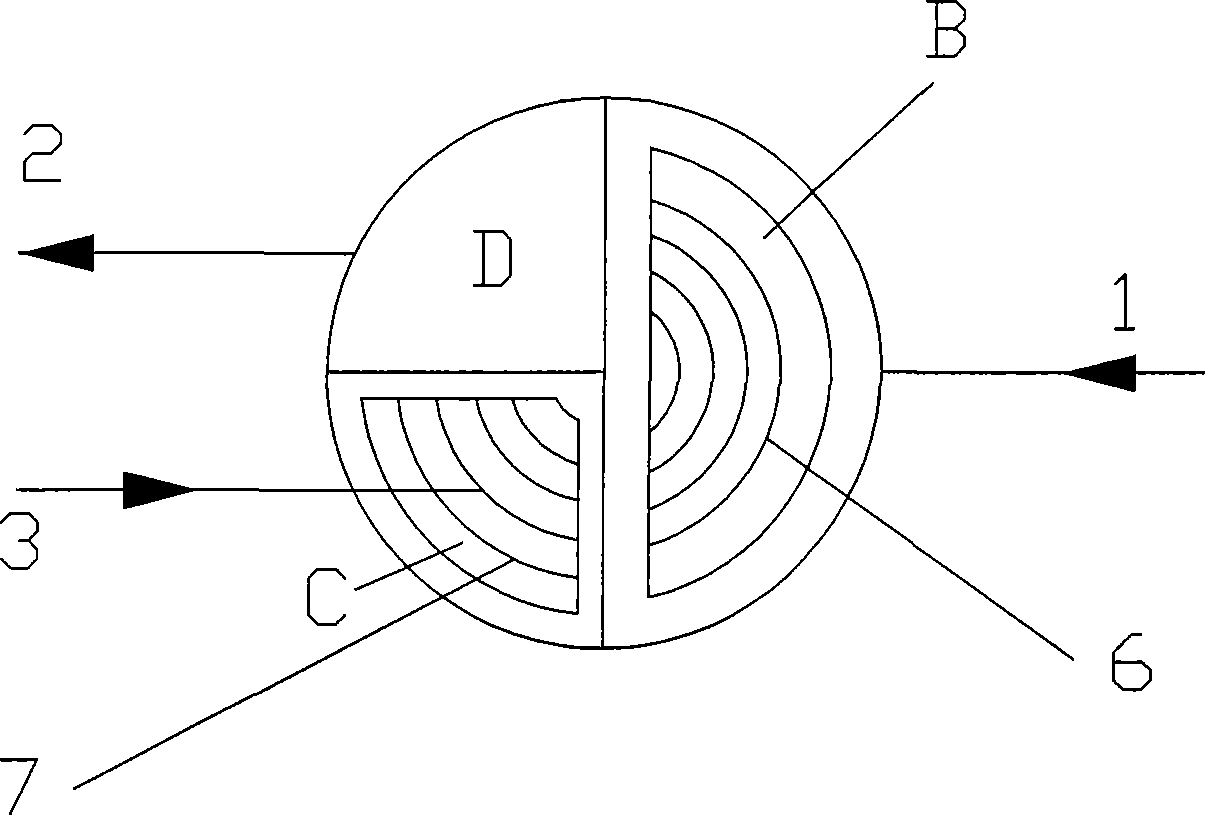

Oil-containing alkali liquor separation apparatus and method

A separation device and separation method technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of many by-products, complex processes, heavy environmental pollution, etc., and achieve low disulfide content, reasonable and practical process. , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] The area volume ratio of the separation device is tail gas separation zone: oil-alkali separation zone: gas lift separation zone: lye stabilization zone = 15:40:25:20. The lye entering the device is the lye after traditional air oxidation, the effective alkali concentration is 11.7%wt, the disulfide content is 9744ppm, the lye flow rate is 100L / h, and the air stripping gas flow rate is 35L / h. The disulfide content of the lye from the device is 1926ppm.

example 2

[0056] The area volume ratio of the separation device is tail gas separation zone: oil-alkali separation zone: gas lift separation zone: lye stabilization zone = 15:40:25:20. The lye fed into the device is the lye after traditional air oxidation, the effective alkali concentration is 11.7%wt, the disulfide content is 9744ppm, the lye flow rate is 100L / h, and the air stripping gas flow rate is 60L / h. The disulfide content of the lye from the device is 1542ppm.

example 3

[0058] The area volume ratio of the separation device is tail gas separation zone: oil-alkali separation zone: gas lift separation zone: lye stabilization zone = 15:40:25:20. The lye into the device is lye after oxygen-enriched room temperature oxidation, the effective alkali concentration is 23.9%wt, the disulfide content is 18978ppm, the lye flow rate is 100L / h, and the gas stripping gas flow rate is 35L / h. The disulfide content of the lye from the device is 1594ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com