Catalytic treatment device and catalytic treatment method for tail gas of fuel cell

A catalytic treatment and fuel cell technology, applied in fuel cells, fuel cell additives, electrical components, etc., can solve problems such as increasing uncertainty, difficulty in ensuring intrinsic safety, and inability to achieve hydrogen-containing exhaust gas treatment, to prevent sudden The effect of the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

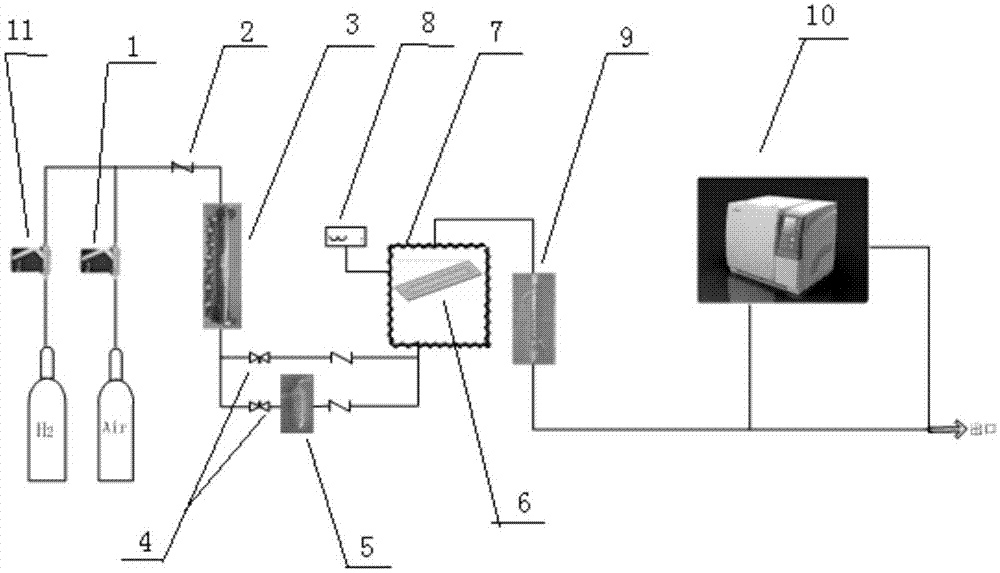

[0052] Embodiment 1: A method for catalytic treatment of fuel cell tail gas:

[0053] The hydrogen gas at the anode end of the fuel cell and the air at the cathode end of the fuel cell pass through the amount of hydrogen gas and air controlled by the gas mass flow meter respectively. After the two gases are mixed, they enter the gas mixer and then enter the micro-plate reactor. Pt-Al 2 o 3 Under the action of the catalyst, after the catalytic treatment, the gas analyzer will test the hydrogen concentration of the exhaust gas, and then it will be discharged into the atmosphere according to the standard.

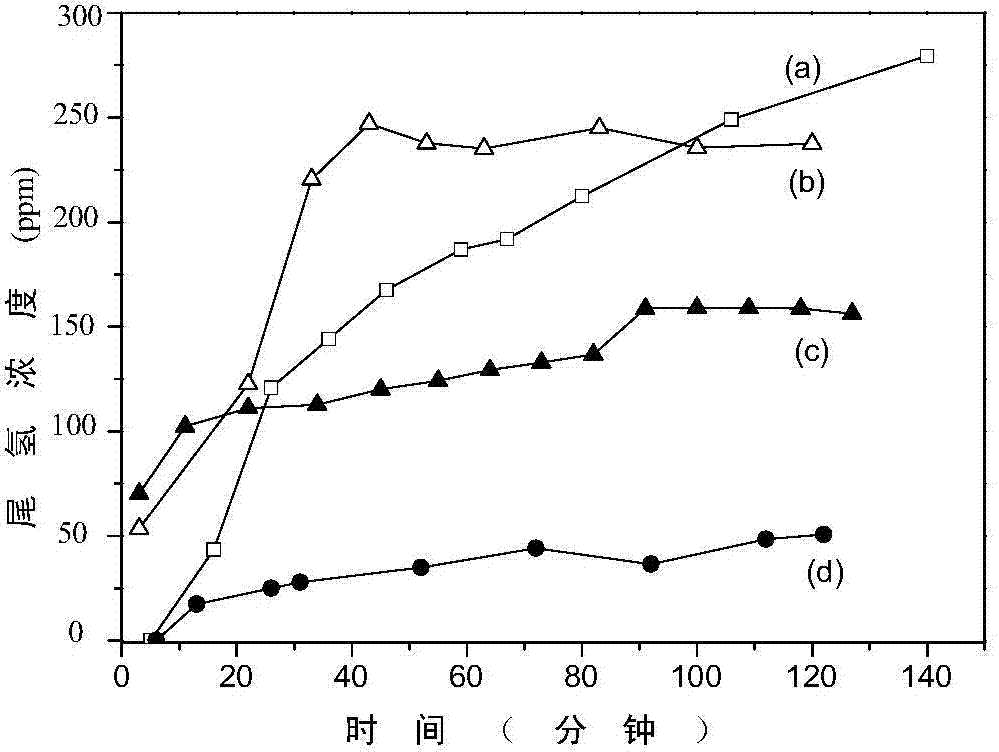

[0054] In this embodiment, a comparative treatment experiment was carried out on wet and dry premixed gas with 15 ml / min of hydrogen-oxygen mixed gas (4% hydrogen, 96% air) under the condition of using traditional catalyst and hydrophobically modified catalyst. The results of the change of hydrogen concentration with time by two different methods are shown in image 3 , 4 ...

Embodiment 2

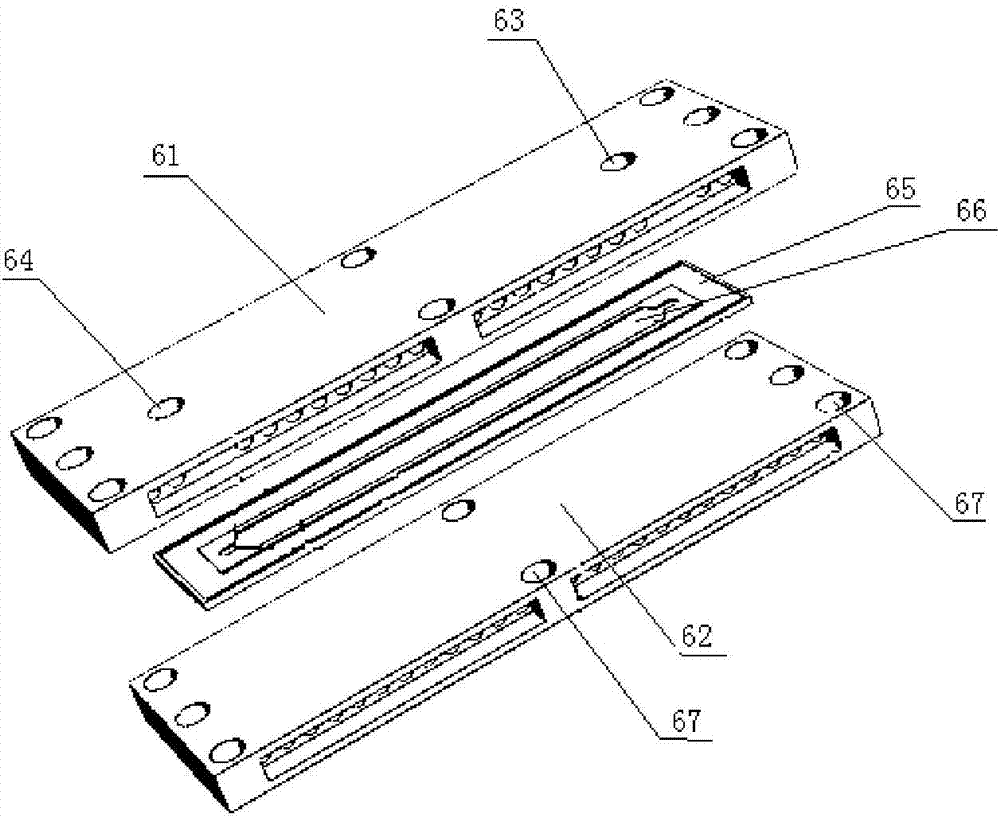

[0061] Embodiment 2: A kind has through hydrophobically modified Pt-Al 2 o 3 Coating method for catalyst-coated channel plates:

[0062] 1) Weigh the alumina nano powder, concentrated nitric acid solution, and deionized water (alumina powder: concentrated nitric acid: deionized water 1g: 0.8ml: 3.8ml), put them in a glass container, and stir at room temperature 2 hours until a uniform colloid is formed, and then aged for 3 hours; take the colloid and evenly coat it on an Fe-Cr-Al plate with micro-channels, age it at room temperature for 2 hours, and then place the Fe-Cr-Al plate in a drying oven to dry overnight , the temperature is 110 degrees; the cured catalyst coating is finally calcined in a muffle furnace for 2 hours at a temperature of 400 degrees, the furnace is cooled to room temperature, and stored in vacuum packaging;

[0063] 2) prepare ethanol solution of chloroplatinic acid, carry out precious metal platinum load by excessive impregnation method to iron-chromiu...

Embodiment 3

[0066] Embodiment 3: a kind of with hydrophobically modified Pt-Al 2 o 3 Coating method for catalyst-coated channel plates:

[0067] 1) Weigh the alumina nano powder, concentrated nitric acid solution, and deionized water (alumina powder: concentrated nitric acid: deionized water 1g: 1.2ml: 4.2ml), put them in a glass container, and stir at room temperature 2 hours until a uniform colloid is formed, and then aged for 3 hours; take the colloid and evenly coat it on an Fe-Cr-Al plate with micro-channels, age it at room temperature for 2 hours, and then place the Fe-Cr-Al plate in a drying oven to dry overnight , the temperature is 110 degrees; the cured catalyst coating is finally calcined in a muffle furnace for 2.2 hours at a temperature of 450 degrees, the furnace is cooled to room temperature, and stored in vacuum packaging;

[0068] 2) Prepare ethanol solution of chloroplatinic acid, and carry out precious metal platinum loading on iron-chromium-aluminum-alumina coating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com