Electromagnetic switch

a technology of electromagnetic switch and spring constant, which is applied in the direction of magnets, contact mechanisms, magnets, etc., can solve the problems of large impact noise or a large crashing sound, impact noise becomes an obstacle, etc., and achieves small spring constant, reduce spring constant, and increase damping (or attenuation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0039]A description will be given of the electromagnetic switch according to the first embodiment of the present invention with reference to FIG. 1 to FIG. 4.

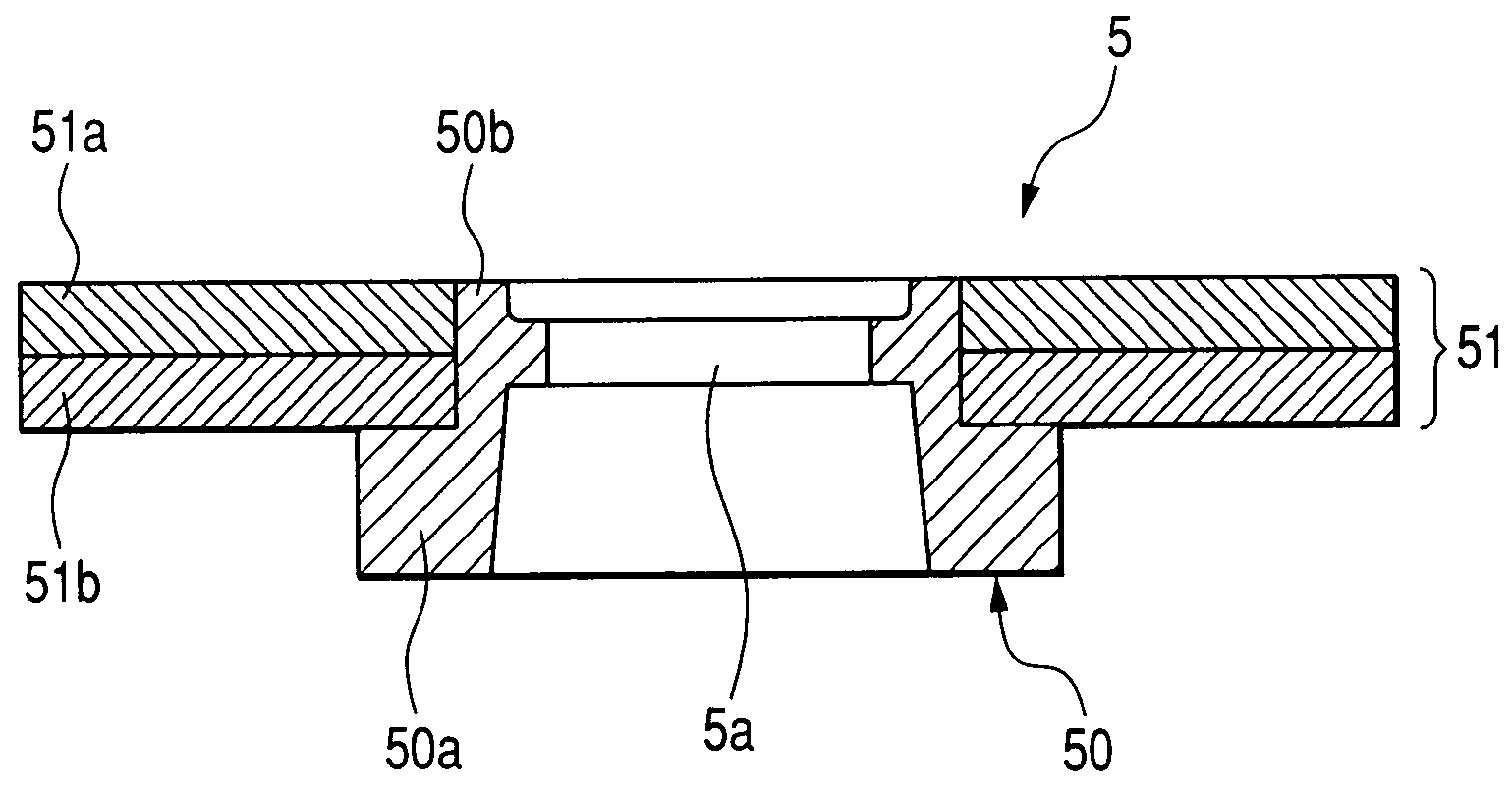

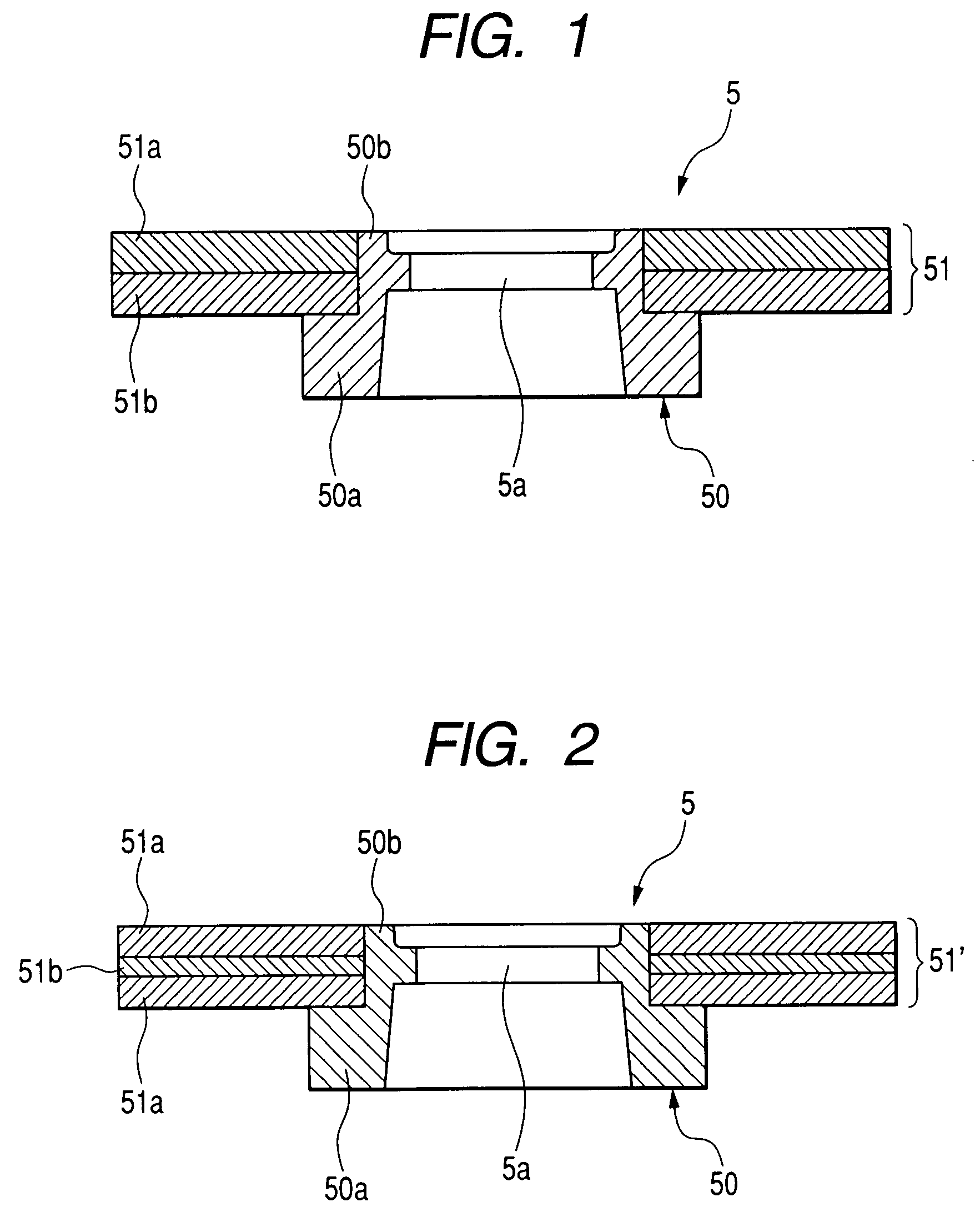

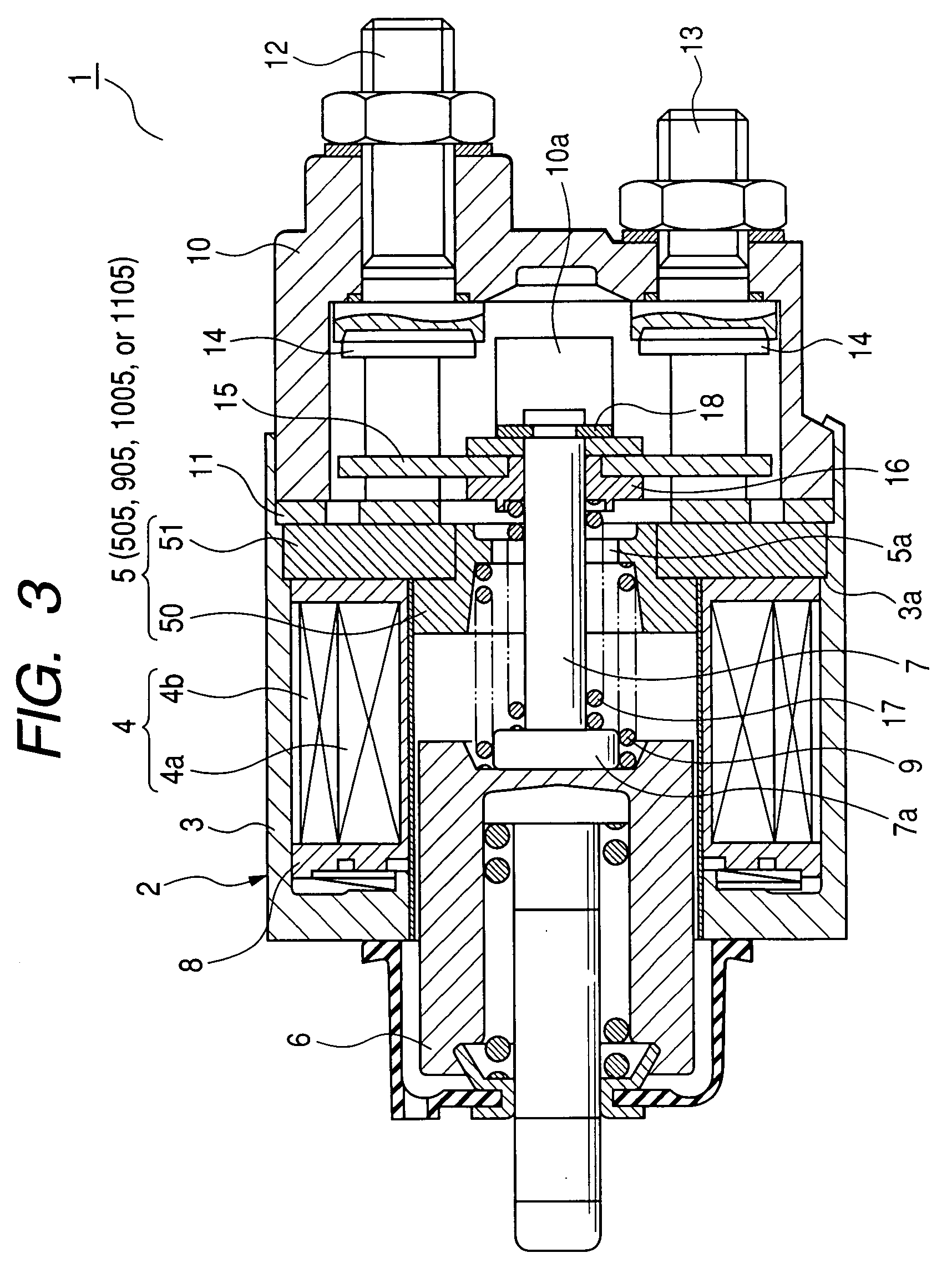

[0040]FIG. 1 is a sectional view showing a configuration of a stationary iron core 5 of the electromagnetic switch 1 according to the first embodiment of the present invention. FIG. 2 is a sectional view showing another configuration of the stationary iron core 5 of the electromagnetic switch 1 according to the first embodiment. FIG. 3 is a sectional view showing an entire configuration of the electromagnetic switch 1 according to the first embodiment.

[0041]The electromagnetic switch 1 according to the first embodiment is applied to a starter (not shown) mounted on a vehicle, for example. The starter is capable of starting an internal combustion engine mounted on the vehicle. As shown in FIG. 3, the electromagnetic switch 1 has a solenoid 2 forming an electromagnet by which a main contact, described later in detail, mounted on ...

second embodiment

[0061]A description will be given of the electromagnetic switch according to the second embodiment of the present invention with reference to FIG. 5 and FIGS. 6A and 6B.

[0062]FIG. 5 is a sectional view showing a configuration of the stationary iron core 505 in the electromagnetic switch according to the second embodiment of the present invention. FIG. 6A is a plan view showing a configuration of the metal plate 551a having slits 52, and FIG. 6B is a plan view showing a configuration of the metal plate 552a′ having holes 53.

[0063]As shown in FIG. 5, the disk part 551 forming the stationary iron core 505 in the electromagnetic switch according to the second embodiment is composed of a plurality of metal plates (for example, iron plates) that are laminated. In the configuration shown FIG. 5, the stationary iron core 505 has a pair of the metal plates 551a. Further, at least one metal plate 551a has slits 52, as shown in FIG. 6A, or at least one metal plate 551a′ has holes 53, as shown ...

third embodiment

[0068]A description will be given of the electromagnetic switch according to the third embodiment of the present invention with reference to FIG. 7 and FIG. 8.

[0069]FIG. 7 is a partial view showing a configuration of the electromagnetic switch according to the third embodiment of the present invention. FIG. 8 is a plan view showing a configuration of a disk part 751 forming the stationary iron core in the electromagnetic switch according to the third embodiment.

[0070]As shown in FIG. 7, each of the plural metal plates forming the disk part 751 of the stationary iron core has the slits 52 or the holes 53s, like the configuration of the second embodiment which has been explained with reference to FIGS. 6A and 6B. Further, a plurality of the plural metal plates 551a (see FIG. 6A) or 551a′ (see FIG. 6B) are laminated and the plural silts 52 (or the holes 53) form penetrating holes which penetrate through the entire of the plural metal plates 551a (see FIG. 6A) or 551a′ (see FIG. 6B). It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com